godwin mud pump factory

Manufactured since 1982, Goodwin pumps have been continually developed to create the world’s most dependable submersible pumps. Goodwin pumps can have electric or hydraulic motors to suit a multitude of tasks. The range of heavy duty slurry pumps us complemented by specialist acid resisting and high head dirty water submersible pumps.

Download our latest case study and read about how the teams engineered a solution using Flygt submersible pumps and Godwin equipment that operated continuously for nine months while crews made the repairs in a high-traffic area near critical infrastructure.

When a storm event shut down both Southern Iowa Rural Water Association pump stations, it caused authorities to scramble to move water to their customers.

Greenwich, Connecticut is a scenic New England town that is home to approximately 60,000 people. Its ongoing initiatives include repairs and upgrades to the town’s wastewater treatment plant and 28 pumping stations.

The first sign of trouble in “America’s Hometown” came on December 19, 2015. Plymouth, Massachusetts is the celebrated site where the Pilgrims landed in 1620, but on this day the prominent municipality was facing a major problem: the 4.5mile force main from the Water Street Pump Station to the Plymouth Wastewater Treatment Plant (WWTP) had given way.

When the West Side sewage pump station in Onondaga County, New York, prepared to undergo its first major upgrade in over 30 years, the project required a bypass system to move a peak flow of 30 million gallons per day (MGD). The bypass contractor for the project worked with Xylem to design and install a temporary system to convey the full amount of flow.

Godwin’s Dri-Prime 16-in. pump ran a sewer bypass system continuously for a month without issues while the city of Raleigh, North Carolina, replaced a major outfall line feeding its wastewater treatment plant.

Sanitation District No. 1 of Northern Kentucky (SD1) needed to perform wet well concrete rehabilitation to two pump stations in Covington, Kentucky, located just across the Ohio River from Cincinnati.

Xylem Inc., a leading global water technology company dedicated to solving the world’s most challenging water issues, has launched a new website to provide customers – for the first time – with the option of purchasing Factory Certified Pre-Owned Godwin pumps. The website features specifications and pricing for more than 100 premium Godwin pumps from Xylem’s U.S. rental fleet, including powerful dewatering pumps from its popular Godwin Dri-Prime CD and HL series, all of which are immediately available for customers in North America to purchase.

To receive Xylem’s Factory Certification, each Godwin Dri-Prime pump has to pass a rigorous 50-point inspection process. Additionally, over the life of the pump, it is serviced every 250-hours by Godwin-trained technicians and only genuine Godwin parts are used to maintain factory-level standards of performance.

“Customers can now choose from the speed and 24/7 flexibility of renting our pumps, buying them brand new, or the convenience of sourcing pre-owned options online,” said Jackie Helfrich, Vice President, Global Strategy and Marketing for Xylem’s dewatering business. “Every pump featured on the site has been part of our own rental fleet and maintained to our exacting factory standards. As we refresh our fleet, customers can easily access the industry-leading reliability and performance that our Godwin brand stands for – at a lower cost of ownership.”

In addition to featuring commercial and industrial water and wastewater pumps for the mining, construction and agriculture markets, the site also offers Godwin generators and light towers. Products are sold in “as is” condition and customers have the option of purchasing a six month, 500-hour extended warranty.

Fixed Competitive Price Godwin Trash Pump - BD series Double Suction Split Casing pumps – Beken, The product will supply to all over the world, such as: , , ,

The Goodwin Submersible Slurry Pump was developed for the UK mining industry and has since grown into a range of products that deliver proven performance in the most demanding environments.

Product development is performed in the UK, however all pump production manufacturing is done at our high quality, low cost manufacturing operation Goodwin India Pvt Ltd, located in Chennai, India, which was started in 2005.

Within the purpose built 70,000 sq feet factory area, submersible pumps are machined and assembled at our Indian facility, utilising the latest equipment to ensure we manufacture extremely reliable, high quality pumps.

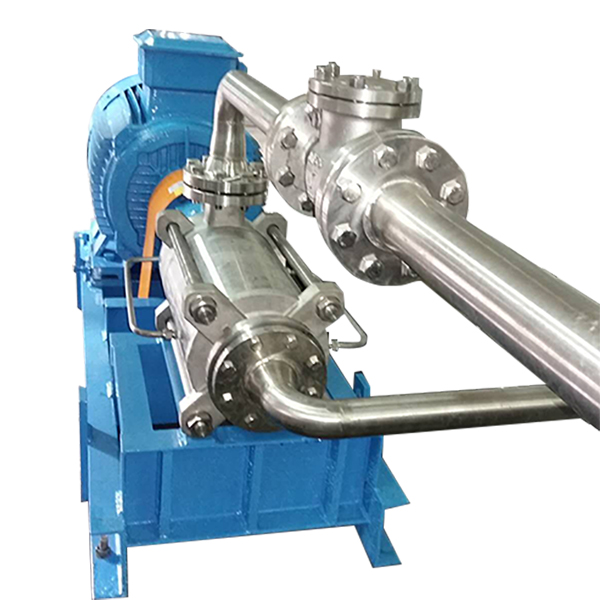

From the initial start-up in India in 2005, there were three variants of a 30Kw 100mm pump designed and manufactured. Now that the range has been properly developed, there are five variants of 100mm, 150mm and 200mm submersible slurry pumps, two variants of ultra-reliable multistage submersible dirty water high head pumps for mine dewatering, as well as acid resistant super duplex stainless steel pumps for chemical ponds and acid leaching applications.

Goodwin submersible pumps are electrically-driven, abrasion resistant submersible pumps that are capable of pumping dense slurries containing abrasive solids within a wide range of industries.

Due to the arduous duties our submersible pumps are subject to in all locations that we service, we ensure that there is exemplary back up and support to make sure our customers’ sites remain operational; this is because it is necessary to maintain, repair and replace wear parts on pumps when pumping abrasive slurries.

As well as pumps, our companies can deliver tailored pumping solutions with custom made pontoons and slurry handling systems specifically aimed at tailings reclamation applications.

8613371530291

8613371530291