high pressure suction mud pump manufacturer

Distributor of heavy duty submersible mud, sand, sludge & slurry pumps. Specifications of pumps include 5 hp to 30 hp motor, three phase, 208 V to 575 V, 6.8 A to 39 A, 3 in. to 6 in. NPT sizes, 38 ft. to 134 ft. head size & 475 gpm to 1,690 gpm flow rate. Features include impellers, wear plates & agitators made from abrasive resistant 28 percent chrome iron, process hardened ductile iron volutes casted with thick walls, class H motor insulation, double silicon carbide mechanical seals, heavy duty lip seal & stainless steel shaft & shaft sleeve. Sand, sludge & slurry pumps are used in mines, quarries, dredging, coal & ore slurries, sewage treatment plants & steel mills. UL listed. CSA approved. Meets OSHA standards.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

However, quality and service are always put in the priority of “fast growth”, by implementing the principle of quality control to every production process, we can ensure that every water well drilling rig and equipment we put out is a high quality one.

F 500 mud pump for oil drilling have features of solid and compact structure, small volume, good and reliable performance. It can meet the drilling requirements such as high pressure and big displacements whether in land drilling or off-shore drilling.

F 500 mud pumps have a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of mud pump fluid end parts greatly.

Gaodetec is a drilling rig high pressure mud pump equipment company located in central China. We have been in business for more than 6 years. Many of our employees have over 20 years of background and experience in the design and manufacture of piston mud pumps. We can create custom packaging and modify it, as well as provide specially designed reciprocating mud pumps. We provide our customers with pumps suitable for drilling projects.

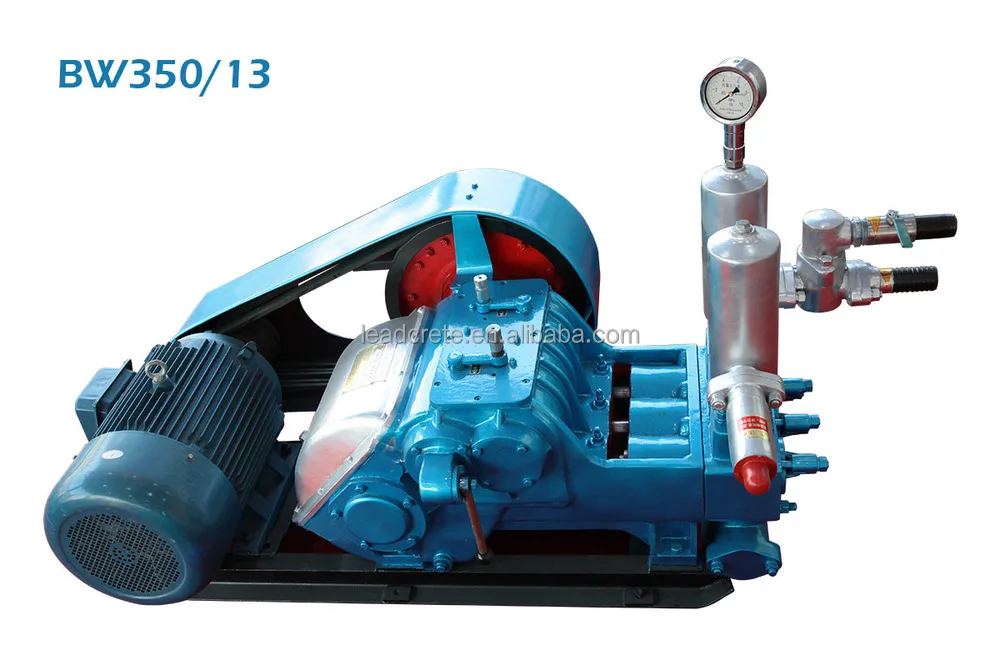

As a world-renowned manufacturer of high pressure mud pumps, we offer a wide range of high-pressure mud pumps to meet different construction needs. BW series of high-pressure mud pump is an energy saving, special structural equipment, widely used in mining, drilling, coal, railways, roads, water and hydropower, bridges, high-rise buildings, foundation reinforcement projects.

They are also the main equipment for geological surveys, and their primary role in the drilling of boreholes in the heart is to supply fluids (mud or water) that circulate during drilling and transport rock waste back to the ground to achieve and maintain bottom cleanliness and to lubricate drill bits and drills by cooling them.

1. Electric high-pressure piston double mud pump using advanced product design, reasonable structure, pressure, large flow, multi-shift variable, energy saving, small size, high efficiency, long service life, safe operation, convenient maintenance.

Gaode Equipment now has BW series three-cylinder mud pump inventory. Different flows and pressures are available. And meet the flow and pressure requirements of different projects. High-value, high-performance drilling mud pumps are ready for your project. For more information about diesel engine three-cylinder drilling mud pumps, feel free to email us at info@gaodetec.com

We manufacturer of mud pump, are presenting our range under “Vijay” Brand name. The offered mud pump is designed to circulate drilling fluid under high pressure and promote the variegated crude oil and mud slurry handling applications in oil & cement segments.

Handling of the mud during the drilling crude oil has become easy with the offered range of the mud pump, thanks to the ingenious configuration of thereof, wherein the inner curvatures of pump casing have been customized to reduce the load on the impeller, whereas raise the discharge volume. In order to prevent the corrosion and early aging, all the wet end parts of this mud pump are engineered using the considerably applauded PP (polypropylene) material attributing excellent corrosion resistance and hence is also perceived as the PP pump or polypropylene pump in the variegated industries.

The effectiveness of this mud pump ensures that drilling mud is circulated profoundly to the bottom of the home at sterling pressure and volume to bring drilling debris out of the well hole and thereby is immensely popular in the domestic as well as global market. Owing the fame of this mud pump (PP pump), we have made it available in the miscellaneous specifications as below.

LEC mud pumps use hydraulic power to convert hydraulic energy into the power that can convey high pressure mud. It’s self-suction plunger pump. The parts without rotation make piston linear motion.

•High reliability: no rotating parts, less moving parts, longer free maintenance time, high abrasive resistance and self-lubricating ability, which decrease the operating cost. When the hydraulic power less than max. rated power, the pump will decrease the output power automatically thus make the pump safe.

Explore a wide variety of high pressure mud sucking pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These high pressure mud sucking pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these high pressure mud sucking pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right high pressure mud sucking pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of high pressure mud sucking pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

Thermoid Mud Pump Suction hose is designed to be used as the flexible connection between mud pits and slush pumps. The CR cover and tube are resistant to abrasion, sunlight, weather and oil. This hose features a construction of multiple plies of synthetic cord fabric with a helical steel wire. This allows the hose to be flexible, helps prevent collapse and gives it a full vacuum rating.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

The first criterion for choosing a pump is the type of media concerned. The technical characteristics of the media must be taken into account because they will determine the choice of pump.

Then, in order to properly dimension the machine and calculate the operating point of the pump, it is necessary to know the parameters of the network such...

... 4,000 specially designed Warman® FGD pumps. Realising that modern flue gas absorber technology would require new and innovative pump designs, Weir Minerals developed the new high performance Warman® GSL ...

... for a wide range of applications. Warman® AHSM series pump offers the same features and benefits as the AH® pump, including identical hydraulics except the special impelelr and suction ...

The Warman® SLR pump is a proven horizontal end suction centrifugal pump that will reliably and economically handle abrasive and corrosive medium duty services. Several unique features ...

Gerotor pumps can be used in the low-pressure range and are used in cooling, filter or lubricant circuits. With the flange and shaft variants compliant with the standards, they can be affixed flexibly to Rexroth axial ...

W+ is a comprehensive range of premium sanitary end-suction centrifugal pumps designed with maximum operating benefits and minimal life cycle costs in mind.

W+ centrifugal pumps from SPX FLOW are designed to achieve total cost optimization with high efficiency and product dependability. They are installed in countless process facilities around the world helping producers ...

This pump offers strong performance and competitive price/value within the lower spectrum of heavy-duty, centrifugal pump applications. It can be installed in a series without fear of seal failure from ...

... heavy duty frac pump designed to operate at higher pressures for longer periods of time. Its compact design and 11” stroke results in less fatigue cycles and extended consumable life. With a legacy of ...

The ARO nonmetallic 3/8” PD03P-XXS-XXX compact pump is a favorite of OEMs everywhere around the world. It is designed to be fully corrosion resistant. ...

... 1” non-metallic diaphragm pumps are a versatile solution for numerous applications. Our EXP 1” models achieve flow rates of up to 53 GPM (200.6 LPM) and offer a wide array of material and porting configurations. These ...

GRI collaborates with OEM engineers who are unable to fulfill their unique pump specifications with an off-the-shelf solution and require a custom-engineered ...

Horizontal or vertical seal-less volute casing pump in back pull-out design with fully enclosed canned motor, low noise emission, with radial impeller, single-stage, single-entry, casing connecting dimensions to EN 733, ...

... agriculture, this electric pump with open impeller for diesel transfer is the perfect solution if you are looking for a high-performance product that is reliable over time.

... reliability. The basic equipment consists of a suction and delivery pipe, a manual nozzle, a bottom suction filter to ensure a liquid free from impurities, and an integrated switch.

The LSP pump is a single-phase portable self-priming residue drainage pump incorporating a submersible motor. The suction attachment, supplied as standard, makes the pump ...

... cast iron heavy-duty slurry pump driven by a 4-pole motor. It is equipped with a high-chromium cast iron agitator that assists smooth suction of the settled matters. The other wear parts such as the impeller ...

... explosion-proof slurry pump. It is equipped with a high-chromium cast iron agitator that assists the smooth suction of the settled material. Among other parts subject to wear, impellers and suction ...

The VC0301B is a diaphragm pump with attainable vacuum pressure -213 mbar and 25 l/min rated airflow. The rated voltage of the pump is 230 V and 120 V to produce maximum 0.2 bar pressure ...

... They are also capable of operating under suction lift conditions and operate equally well in either direction. The Universal Product Line has the broadest range of sealing options of all pumps built by ...

The compact ViscoTec Dispenser 4RD6-EC ensures smooth and reliable product supplying of abrasive, high-filled or shear sensitive material - with a repeatability of +/- 1 %!

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

8613371530291

8613371530291