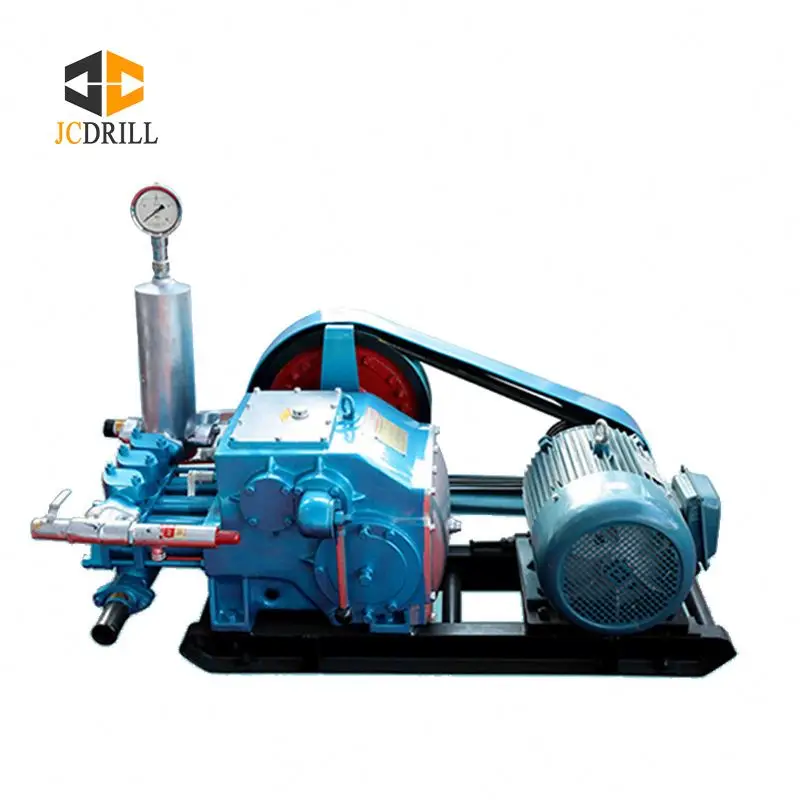

high pressure mud pump factory quotation

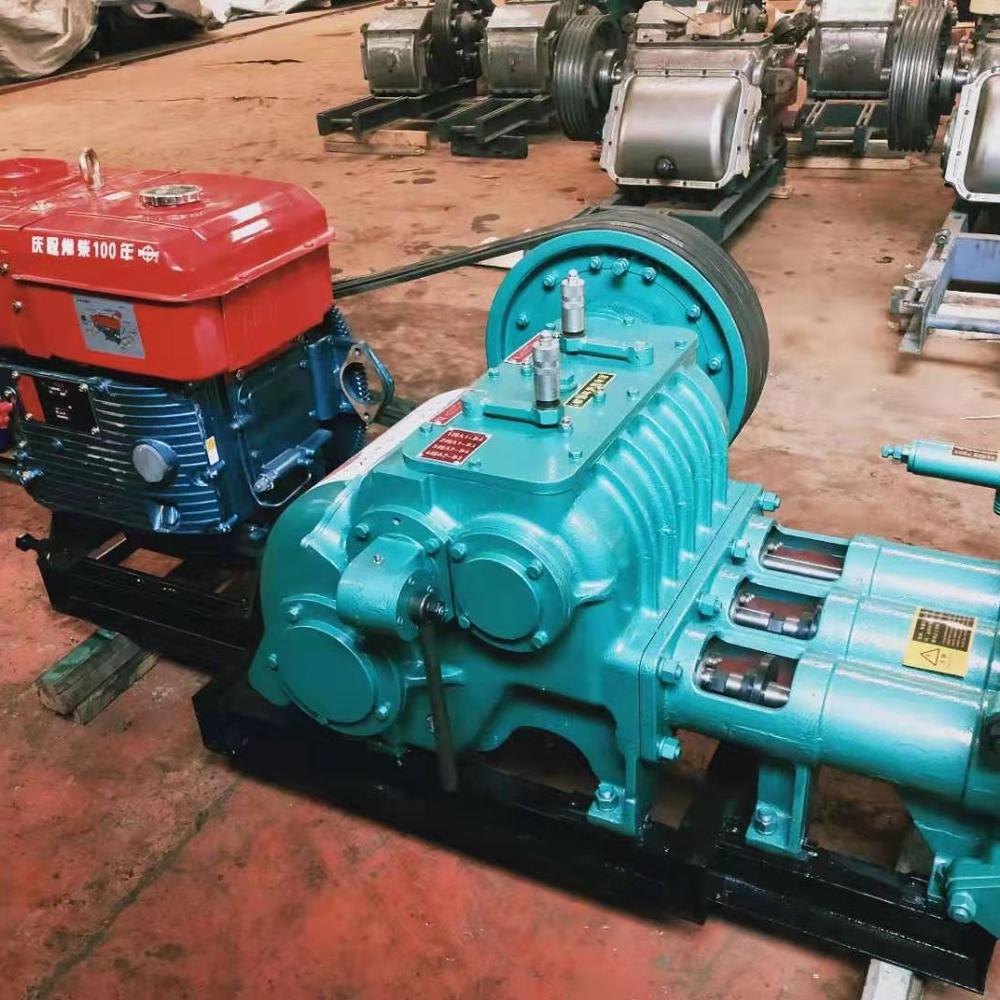

There are three types of mud pumps, depending on the type of client and the size they want. For general, mud pumps, there are three basic types of mud pumps, depending on the type of client and budget. The piston pump is another compressed mud pump, which is a pushed electric compressor mud pumps and by compressed air.@@@@@

Electric mud pumps are largely divided into three categories, among them the electric mud pumps and the semi-trash mud pumps. The piston inflated mud pumps are also classified in terms of the type of mud pumps, among them are electric mud pumps and semi-trash mud pumps. In addition, the piston inflates mud and mud pumps will be inflated by the piston, which is inflated mud pumps.

Distributor of heavy duty submersible mud, sand, sludge & slurry pumps. Specifications of pumps include 5 hp to 30 hp motor, three phase, 208 V to 575 V, 6.8 A to 39 A, 3 in. to 6 in. NPT sizes, 38 ft. to 134 ft. head size & 475 gpm to 1,690 gpm flow rate. Features include impellers, wear plates & agitators made from abrasive resistant 28 percent chrome iron, process hardened ductile iron volutes casted with thick walls, class H motor insulation, double silicon carbide mechanical seals, heavy duty lip seal & stainless steel shaft & shaft sleeve. Sand, sludge & slurry pumps are used in mines, quarries, dredging, coal & ore slurries, sewage treatment plants & steel mills. UL listed. CSA approved. Meets OSHA standards.

The report focuses on the High Pressure Mud Pump market size, segment size (mainly covering product type, application, and geography), competitor landscape, recent status, and development trends. Furthermore, the report provides strategies for companies to overcome threats posed by COVID-19.

Players, stakeholders, and other participants in the High Pressure Mud Pump market will be able to gain the upper hand as they use the report as a powerful resource. The segmental analysis focuses on revenue and forecast by region (country), by Type, and by Application.

List of Top Key Players in High Pressure Mud Pump Market Report: The survey describes the qualities of the entire company based on an industry-wide analysis: -

Geographically, this report is segmented into several key regions, with sales, revenue, market share, and High Pressure Mud Pump market growth rate in these regions covering ● North America (United States, Canada and Mexico)

● Indicates of the region and segment breakdown that is expected to witness the fastest growth rate and acts as market dominant. Analysis of geography highlighting, the region vice consumption of the product/service and an indication of the factors that are affecting the market within each region.

● The global High Pressure Mud Pump market research report studies the latest global market trends, up-to-date, and thorough competitive analysis, along with various other key features of the worldwide market.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

With the addition of a high pressure mud pump to the pipeline equipment lineup, Vermeer offers contractors a one-stop shop for major components of pipeline drilling operations. On a job with tight deadlines, contractors can work easier knowing they are supported by quality equipment and a knowledgeable dealer network.

Bimetal liners are made of wear-resistant cast iron, and the surface hardness is HRC60-65. Therefore, liners feature wear resistance, corrosion resistance and high surface finish.

Valve assembly is the critical component of mud pump fluid end , with high operation frequency and great impact subjected. The quality of valve assembly will have a direct effect on the life of hydraulic cylinder.

Piston assembly is the major part of the mud pump fluid end. The discharge pressure of mud pump is generated by the up-and-down motion of the piston in the cylinder. Small piston—high pressure and low flow rate; Big piston—low pressure and high flow rate. Metric pump and inch pump adopts metric piston and inch piston respectively.

8613371530291

8613371530291