industrial replace mud pump motor supplier

Distributor of heavy duty submersible mud, sand, sludge & slurry pumps. Specifications of pumps include 5 hp to 30 hp motor, three phase, 208 V to 575 V, 6.8 A to 39 A, 3 in. to 6 in. NPT sizes, 38 ft. to 134 ft. head size & 475 gpm to 1,690 gpm flow rate. Features include impellers, wear plates & agitators made from abrasive resistant 28 percent chrome iron, process hardened ductile iron volutes casted with thick walls, class H motor insulation, double silicon carbide mechanical seals, heavy duty lip seal & stainless steel shaft & shaft sleeve. Sand, sludge & slurry pumps are used in mines, quarries, dredging, coal & ore slurries, sewage treatment plants & steel mills. UL listed. CSA approved. Meets OSHA standards.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Our motors meet the toughest industry specifications and standards and are built to the highest quality for our valued customers. We sell our motors individually, in combination with your pump as a bundle, or as a comprehensive package (including pump(s), motor(s), and control panel) to meet the needs of your specific application for the ultimate in cost-effectiveness no matter what your industrial automation needs entail. The future of the commodities markets lies in improving efficiency. Whether you are extracting, transporting, or refining energy, or operating a small to commercial-scale agricultural business, Replicate Pumps can assist you by dramatically improving your productivity level. Let us help you reach the heights that can place your business into the global market with a total industrial or agricultural automation system.

All of our motors and control panels are available completely assembled and ready to ship. In fact, we offer the fastest delivery in the industry. Our logistics team will work with you to ensure that you have the power you need, when and where you need it. We can also ship replacement parts. We sell most types of motors and pumps. If you don’t see what you need, contact us. We offer complete customization services for all industries throughout the world.

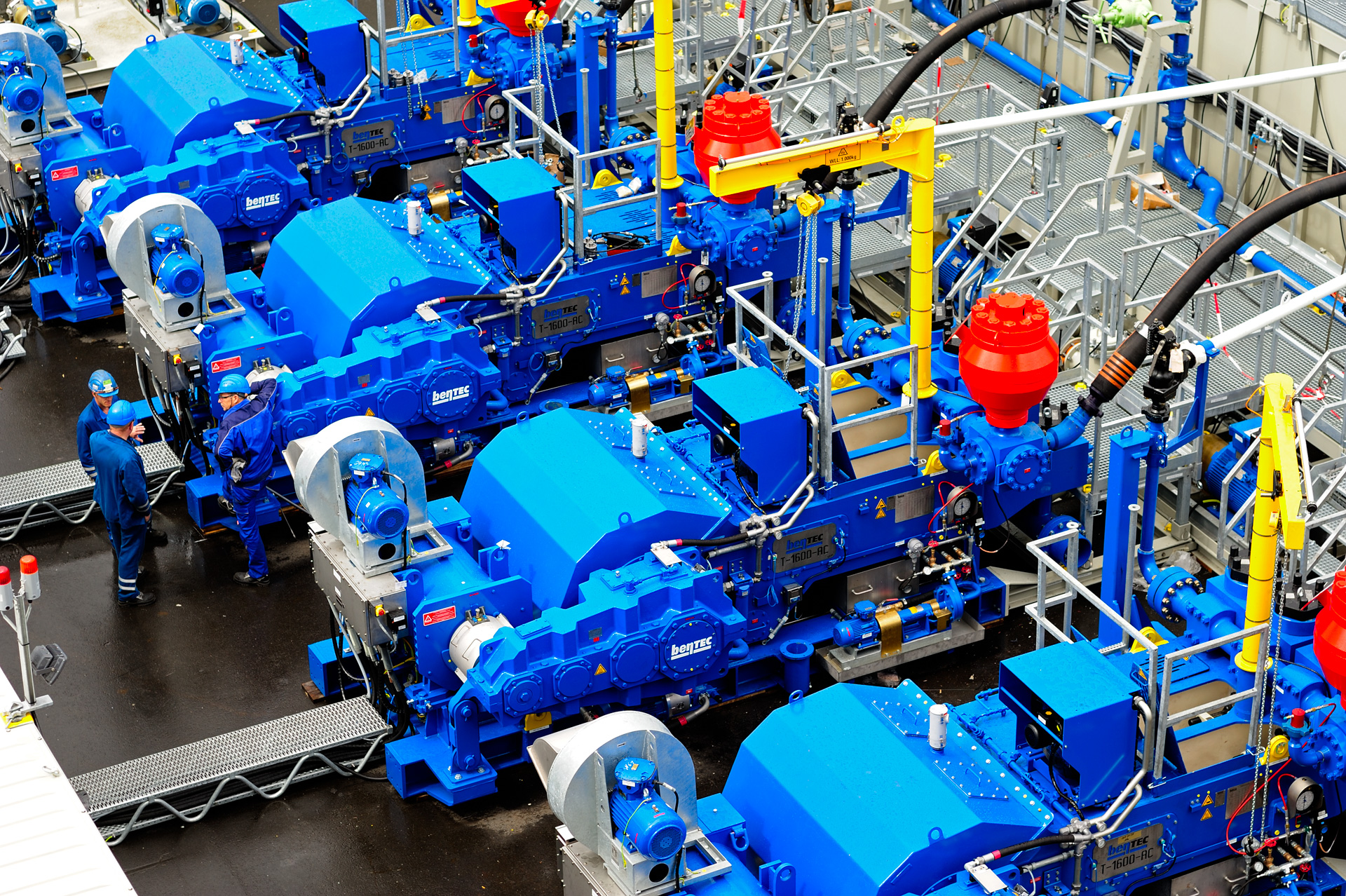

Replicate Pumps is a trusted pump and motor supplier for the oil and gas industry in Odessa, TX, across the nation, and around the world. We carry some of the most powerful and reliable pumps to provide clean water on oil platforms, as well as mix and transport all petrochemicals both on and off-shore. We offer a selection of stock pumps and motors or can custom-build exactly what your business needs to get the job completed safely and efficiently. A range of pumps and motors designed specifically to handle a wide range of needs specific to the oil and gas industry are available. Safety, extreme durability, corrosion resistance, and superior power are standard for all of our energy industry pumps and motors. Some of our most requested products include:

Prompt on-site support and comprehensive, personalized customer maintenance and logistics support is available before and after the sale. After-sales field support is provided, upon request. Our automation panels include a wide variety of designs to improve your commercial or industrial productivity level.

All motors, panels, and components are tested prior to shipment and very carefully packaged to virtually eliminate the possibility of damage during transport. Distribution centers are located throughout the United States for prompt nationwide and global shipping.

If you have already placed your order and require customer support, or are ready to order, contact Replicate Pumps directly. Our customers are our main priority and we are waiting to provide you with exceptional customer service. Call our friendly and knowledgeable staff at: (432) 258-3092. Expedited shipping is available for all in-stock parts.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

A part of National Oilwell Varco, the Mission line of centrifugal pumps are equipped with innovative features to match the demanding nature of routine, corrosive and abrasive applications. Because of the need for a low pressure mud system, Mission 1780 Type W centrifugal pumps were introduced in 1950s to replace duplex pumps. The aim was to apply a high quality centrifugal pump with concentric systems that allowed for abrasive fluids to be mixed and transferred thereby lowering the initial and maintenance costs of drilling. As a result, centrifugal pumps with low pressure mud systems such as Mission 1780 Type W became the industry standard.

As well depths increased, so was the need for heavier mud weights and centrifugal pumps that could withstand greater horsepower load. This led to the launch of Mission Magnum- a centrifugal pump.

The Magnum has an open impeller design that contains wide-tipped vanes and a more tangential circumference of the suction allowing the pump to create a smoother flow pattern when handling abrasive fluids. The Magnum is available in Magnachrome™, hard iron, stainless steel, and aluminum bronze fluid ends. The pumps can be unitized with electric motors, diesel engines, and hydraulic motors (horizontal, vertical, or close-coupled configuration).

Our pump engineering experts have the industry knowledge to gladly assist you with any questions, concerns, or inquiries you may have regarding the pumps & pump parts we distribute @ 800.560.7867.

Exclusive distributor for TSC Workforce series pumps. From 450HP to 2200HP, these lightweight, high performance pumps are designed for todays drilling operations. Higher pressures, higher loads, these pumps deliver.

Full line offering of AC motors & VFD drives. Distributing and supporting WEG products ranging from 1/2HP to 2500HP, and variable frequency drives for control. From fan drives to pump drives, we provide both solutions and support for your needs.

Proudly carrying proven quality TSC fluid end consumables for all common model pumps, we also supply factory OEM power end and repair parts for many current brands/models including GD, HH, Bomco and others.

Periodically we"ll inspect for wear, cracks and damage to critical components such as bearings, bull gear and pinion, conrods and crossheads. We"ll check the condition of your seals and other rubber goods and look for oil contamination. We"ll inspect your frame and ensure your pump is set up as per the manufacturer"s recommended tolerances, providing feedback and detailed reporting.

Emsco parts including the fluid end, power end, stuffing boxes, plungers, seals, bearings, diesel engines, and natural gas engines. We also have blasting and painting facilities as well as a machine shop. We have many years of experience rebuilding mud pumps

Where Emsco overhaul is required we"ll take care of complete disassembly, cleaning and NDT. Repairs will be made to machined components as necessary. Bearings, seals and other components will be replaced in line with our inspections. Motors will be overhauled, lube systems serviced and pulsation dampeners recertified. We"ll also check your fluid ends are in spec and can repair or replace. Your pump is then fully reassembled and commissioned.

Periodically we"ll inspect for wear, cracks and damage to critical components such as bearings, bull gear and pinion, conrods and crossheads. We"ll check the condition of your seals and other rubber goods and look for oil contamination. We"ll inspect your frame and ensure your pump is set up as per the manufacturer"s recommended tolerances, providing feedback and detailed reporting.

TSC mud pumps and drilling mud pumps. We can rebuild all TSC parts including the fluid end, power end, stuffing boxes, plungers, seals, bearings, diesel engines, and natural gas engines. We also have blasting and painting facilities as well as a machine shop. We have many years of experience rebuilding mud pumps

Where TSC overhaul is required we"ll take care of complete disassembly, cleaning and NDT. Repairs will be made to machined components as necessary. Bearings, seals and other components will be replaced in line with our inspections. Motors will be overhauled, lube systems serviced and pulsation dampeners recertified. We"ll also check your fluid ends are in spec and can repair or replace. Your pump is then fully reassembled and commissioned.

We are the original designers and manufacturers of the MudMaster MM420DT and MM435DT mud pumps. For over 35 years, we have built and supported the best pump packages in the industry. With over 1,000 units in service, you are assured of a quality product and after-sales support.

Standard build includes TEFC motor. “Explosion proof” motors are also available. This belt driven unit is easily adjusted and permanently aligned. The triplex piston type pump is simple, rugged and reliable. 50 Hz or 60 Hz motors are available at any common three-phase voltage input. A preset, adjustable pressure relief valve is standard equipment.

Rating is 25 US gpm (95 L) with disc type valves or 20 US gpm (76 L) with ball valves. Disc valves are intended for use with clean fluids and ball valves are suited to drilling mud solutions. The pumps are available with optional materials of construction to suit special applications.

The Mount Wilson Solar Observatory was first funded by the Carnegie Institution of Washington in 1904. The site is an astronomical observatory in Los Angeles, California and contains two historically important telescopes: the 60-inch Hale telescope built in 1908 and the 100-inch Hooker telescope. The facility is used for astronomical research and offers visitors guided tours. In 1911, A Deming Triplex pump with a 15 HP motor was installed to supply the pressure for the fire hydrant system. It operated continuously for an estimated 50 years until an entire system upgrade in the 1960’s obsoleted the pump. In 2008, there was a need for a backup firefighting unit while the new system was being serviced. The 1911 Deming Triplex pump was resurrected for the application. After routine servicing the pump operated without any issues. The Deming brand was the first pump line manufactured by Crane Pumps & Systems and offers a full line of highly regarded municipal and industrial pumps today.

The advanced motor design allows higher speed and torque in combination with a smaller motor design and lower losses. Even today the challenges of the future, for example efficency according IE5, ...

The advanced motor design allows higher speed and torque in combination with a smaller motor design and lower losses. Even today the challenges of the future, for example efficency according IE5, ...

The advanced motor design allows higher speed and torque in combination with a smaller motor design and lower losses. Even today the challenges of the future, for example efficency according IE5, ...

... these motors are perfectly suitable for the operation with our frequency inverters. The motor protection is factory-guranteed with three PTC"s. Our motors are designed for permanent operation ...

... the operation with our frequency inverters. The motor protection is factory-guranteed with three PTC"s. Our motors are designed for permanent operation S1 and belong to protection type IP55.

... heavy starting torque, our AC motors must be utilized with a built-in starting capacitor. These motors are particularly useful for conveyor belts, screw conveyors, stirring devices and ...

... series Compact Structure Three-phase Asynchronous Motors are high-efficiency,energy-save products which we developed in 21 centuries,which is an optimization series by using international popular design ...

YJC series(H355~560)squirrel cage three phase asynchronous motors are Jinchi motor’s products which learn the advantages of domestic and foreign similar motor’s and use new material and ...

... three phase motor designed for inverter or vector applications where up to a 2000:1 constant torque speed range is required. Typical uses include: Material handling, machine tools, conveyors, crane and hoist, metal processing, ...

Baldor-Reliance Jet pump motor are available in open drip proof or totally enclosed industrial steel band constructions. Motor construction can be tailored for specific applications and ...

Groschopp supplies AC-motors in both single- and three-phase-current. Single-phase-current motors are often found in domestic appliances, pumps, fans, conveyor belts and machine tools. ...

Rewindable submersible threephase asynchronous motors expressly designed for use with E Series pumps. Made both in 2 and 4 poles, water filled NEMA standards ...

The pump motor has two functions: pumping and powering. It is made from very special materials to withstand the stresses in the vehicle, since it is permanently ...

Menzel is one of the few manufacturers of large dual-speed low and medium voltage motors today. We recently delivered two 6000V pole-changing motors to a cement plant ...

... Printed Motor Works XR15Series is a compact yet very powerful brushless DC motor made for volume applications. The XR15range is an external rotor ...

... part of the trade fair SPS IPC Drives 2014, the ATB Group introduced its new transnorm motor range for the first time. The company will launch the surface-cooled motor already at the beginning of 2015.

This type of motor can be applied as mud pump motor, turntable motor or winch motor for DC electric-driven drilling machine. Installation dimension of ...

Our marine motors are specially designed for use in auxiliary machinery on ships below deck and for the offshore industry. Typical applications are winches, cranes, fans, pumps, ...

... 2004, Harbin electric group began to build the nuclear power equipment manufacturing capacity, and built the main equipment base, the nuclear main pump base, the main equipment base of the conventional ...

The NUERT Pump Motors has an engine that can be easily activated using the 48YZ engines. It is equipped with a direct connection that is especially designed for this particular type of ...

ML series motor which adopting the latest design and high quality material. And conform to the IEC standard. The efficiency of motor meets EFF2 standard in Europe, and EFF1 standard if request. The motor ...

8613371530291

8613371530291