industrial replace mud pump motor factory

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

Distributor of heavy duty submersible mud, sand, sludge & slurry pumps. Specifications of pumps include 5 hp to 30 hp motor, three phase, 208 V to 575 V, 6.8 A to 39 A, 3 in. to 6 in. NPT sizes, 38 ft. to 134 ft. head size & 475 gpm to 1,690 gpm flow rate. Features include impellers, wear plates & agitators made from abrasive resistant 28 percent chrome iron, process hardened ductile iron volutes casted with thick walls, class H motor insulation, double silicon carbide mechanical seals, heavy duty lip seal & stainless steel shaft & shaft sleeve. Sand, sludge & slurry pumps are used in mines, quarries, dredging, coal & ore slurries, sewage treatment plants & steel mills. UL listed. CSA approved. Meets OSHA standards.

Periodically we"ll inspect for wear, cracks and damage to critical components such as bearings, bull gear and pinion, conrods and crossheads. We"ll check the condition of your seals and other rubber goods and look for oil contamination. We"ll inspect your frame and ensure your pump is set up as per the manufacturer"s recommended tolerances, providing feedback and detailed reporting.

Emsco parts including the fluid end, power end, stuffing boxes, plungers, seals, bearings, diesel engines, and natural gas engines. We also have blasting and painting facilities as well as a machine shop. We have many years of experience rebuilding mud pumps

Where Emsco overhaul is required we"ll take care of complete disassembly, cleaning and NDT. Repairs will be made to machined components as necessary. Bearings, seals and other components will be replaced in line with our inspections. Motors will be overhauled, lube systems serviced and pulsation dampeners recertified. We"ll also check your fluid ends are in spec and can repair or replace. Your pump is then fully reassembled and commissioned.

Periodically we"ll inspect for wear, cracks and damage to critical components such as bearings, bull gear and pinion, conrods and crossheads. We"ll check the condition of your seals and other rubber goods and look for oil contamination. We"ll inspect your frame and ensure your pump is set up as per the manufacturer"s recommended tolerances, providing feedback and detailed reporting.

TSC mud pumps and drilling mud pumps. We can rebuild all TSC parts including the fluid end, power end, stuffing boxes, plungers, seals, bearings, diesel engines, and natural gas engines. We also have blasting and painting facilities as well as a machine shop. We have many years of experience rebuilding mud pumps

Where TSC overhaul is required we"ll take care of complete disassembly, cleaning and NDT. Repairs will be made to machined components as necessary. Bearings, seals and other components will be replaced in line with our inspections. Motors will be overhauled, lube systems serviced and pulsation dampeners recertified. We"ll also check your fluid ends are in spec and can repair or replace. Your pump is then fully reassembled and commissioned.

General Pump balances technology, engineering, and stellar customer service. A world class distribution center, we bring you the exact pump products you need, backed up by industry knowledge and decades of expertise. We supply pump products for a wide variety of markets and applications, and are unfailingly committed to our customers’ satisfaction and success.

Merit Pump and Equipment is a factory authorized pump repair center for Kobe, Weatherford, Myers, and Aplex pumps. We also repair a wide range of other manufacturer pumps. See below for several of our primary repair service offerings:

Do you need general pump maintenance, pump refurbishment, or a complete pump overhaul? We specialize in several types, including reciprocating piston or plunger pumps, duplex, triplex, quintuplex, larger centrifugal pumps (including end suction), split case, frame-mounted, and many more.

Merit Pump and Equipment also specializes in the fabrication of pumping units (or complete pump skidded units) which include a pump, electric motor and steel base. These often include a gearbox and guards, belted units, or anything your application requires. We offer our services across the country and throughout Ohio.

Merit Pump provides comprehensive industrial pump repair. We have over 28 years of experience in the industrial pump repair business. A strict, quality pump maintenance schedule saves on costly future operations. That’s where we come in. We have a close working relationship with each pump company we represent. As a factory authorized repair center, we follow the highest standards in industrial pump repair.

We offer comprehensive repair solutions all over the country with a home-base in northeast Ohio. We provide industrial pump repair assistance in our immediate service area, including Cincinnati, Toledo, Columbus and all of northeast Ohio: Cleveland, Akron, Canton, Youngstown, and everywhere in-between.

We are also an agricultural pump repair center and represent several manufacturers and types of pumps. Whether you have a Berkeley irrigation pump, a truck mounted spray pump, or maybe a simple transfer pump, we can assist with your agricultural pump repair needs. Call us and we will discuss your options for service.

Oilfield applications require rugged equipment. We specialize in the repair of this worn equipment. Duplex, Triplex and Quintuplex pumps are common in this industry. For oilfield pump repair of these styles, look no further. Whether a Weatherford mud pump, oilfield injection pump, or a Kobe triplex platform pump, we will manage a wide range of oilfield pump repair needs. We are a proud member of the Ohio Oil and Gas Association and follow the highest repair and maintenance standards.

Reciprocating pump repair is our specialty. We represent several triplex pump repair lines, including Kobe, Myers, Aplex, Weatherford, Giant and many more. Merit Pump offers triplex pump repair, including duplex and quintuplex pump as well (both plunger and piston style). We also specialize in the fabrication of complete pumping units with electric motor, gearbox and base.

At Merit Pump and Equipment, our goal is to supply you with the very best in pump repair and pump & part sales. Contact us today to discuss your specific needs. We offer pump repair services across the country and throughout Ohio, including cities like Cleveland, Akron, Canton, Toledo, Cincinnati, Columbus, and Youngstown.

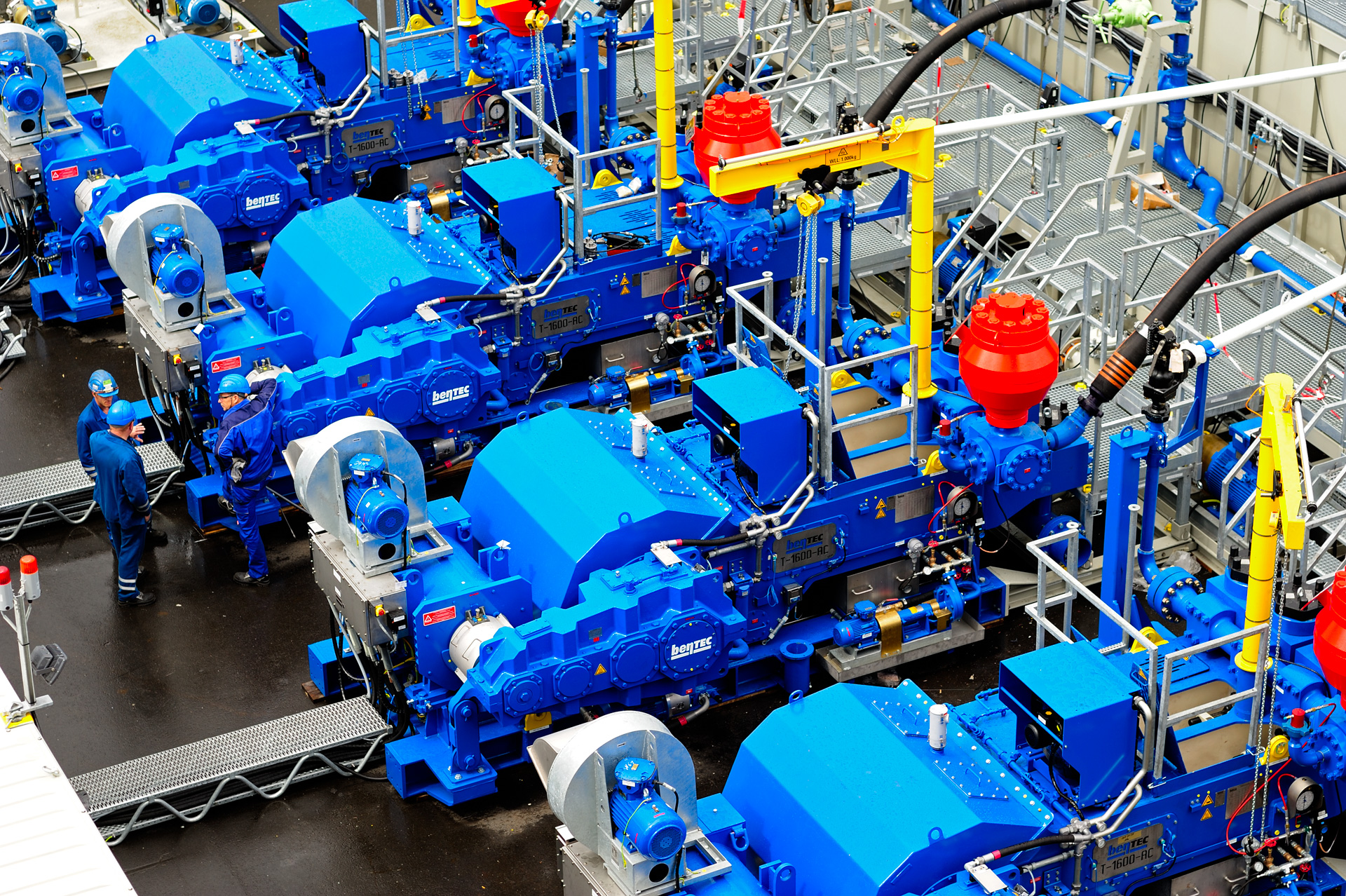

Exclusive distributor for TSC Workforce series pumps. From 450HP to 2200HP, these lightweight, high performance pumps are designed for todays drilling operations. Higher pressures, higher loads, these pumps deliver.

Full line offering of AC motors & VFD drives. Distributing and supporting WEG products ranging from 1/2HP to 2500HP, and variable frequency drives for control. From fan drives to pump drives, we provide both solutions and support for your needs.

Proudly carrying proven quality TSC fluid end consumables for all common model pumps, we also supply factory OEM power end and repair parts for many current brands/models including GD, HH, Bomco and others.

Serving a multitude of industrial engineering sectors, as well as the global horticulture, shipbuilding, water treatment and automotive markets, Johnson Pump has always put customer needs first. Supplying an expansive portfolio of pumps (based on positive displacement and centrifugal mechanisms), plus all the necessary accessories. Through close interaction with the global customer base, Johnson Pump is able to provide focused solutions that exactly match specific application requirements. This is facilitated by our modular approach to design - which allows greater interchangeability between component parts, thereby simplifying logistical aspects (thanks to the ordering and storing of fewer part numbers) and allowing a wider array of different pump variants to be covered using a smaller inventory. The Johnson Pump portfolio covers internal gear pumps, impeller pumps and circulation pumps. All of these items deliver strong performance and continued reliability. The Johnson Pump engineering team designs low noise operating equipment, and engineered coatings to protect against debris damage.

We are the original designers and manufacturers of the MudMaster MM420DT and MM435DT mud pumps. For over 35 years, we have built and supported the best pump packages in the industry. With over 1,000 units in service, you are assured of a quality product and after-sales support.

Standard build includes TEFC motor. “Explosion proof” motors are also available. This belt driven unit is easily adjusted and permanently aligned. The triplex piston type pump is simple, rugged and reliable. 50 Hz or 60 Hz motors are available at any common three-phase voltage input. A preset, adjustable pressure relief valve is standard equipment.

Rating is 25 US gpm (95 L) with disc type valves or 20 US gpm (76 L) with ball valves. Disc valves are intended for use with clean fluids and ball valves are suited to drilling mud solutions. The pumps are available with optional materials of construction to suit special applications.

Cameron AC electric motors improve the performance of your mud pumps, drawworks, and rotary tables. Custom configuration is available, and ATEX, ABS, and DNV certification can be provided for new motors. Our flexible design offers you a choice between a tapered shaft or BullShaft to meet specific application requirements.

Cameron AC traction motors are designed and manufactured to handle deep drilling applications. Available in 400-hp, 550/600-hp, 1,150-hp, and 1,500/1,600-hp models, these inverter motors are designed specifically for 460-V to 690-V duty and deliver maximum efficiency. To meet varying installation requirements, our AC motors are available in vertical or horizontal designs.

Unlike conventional traction motors, Cameron AC motors have a unique design that meets the requirements of oil and gas applications. A key characteristic of the motor is the ability to provide a high level of torque at speeds ranging from 0 to 800 rpm (select motors can achieve a maximum speed up to 3,000 rpm). The torque generated at a wide range of speeds can enhance the performance of a broad array of drilling equipment driven by these motors.

8613371530291

8613371530291