mud pump control system supplier

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Our control systems can be engineered as stand-alone systems or for integration with other control systems, such as the OnTrack integrated drilling controls system.

Control cabins are tailored to the installation area layout and incorporate integrated control system equipment for hands-off mixing, dosing, and transfer operations. They feature a noise- and vibration-insulated housing as well as windows, lights, and HVAC.

Field instrumentation incorporates a range of packages to enhance and support the control experience. Their level indicators, pressure transmitters, and density transmitters offer precise degree of measurement and indication.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

All equipment is rated for operating at ambient temperatures up to +120 Deg F at 1200 ft altitude. The unit is built on heavy duty oilfield skid with lift frame. The control system is mounted in a stainless steel box on the side of the unit. The digital display provides all important engine and transmission data. Unit is also equipped with emergency kill function.

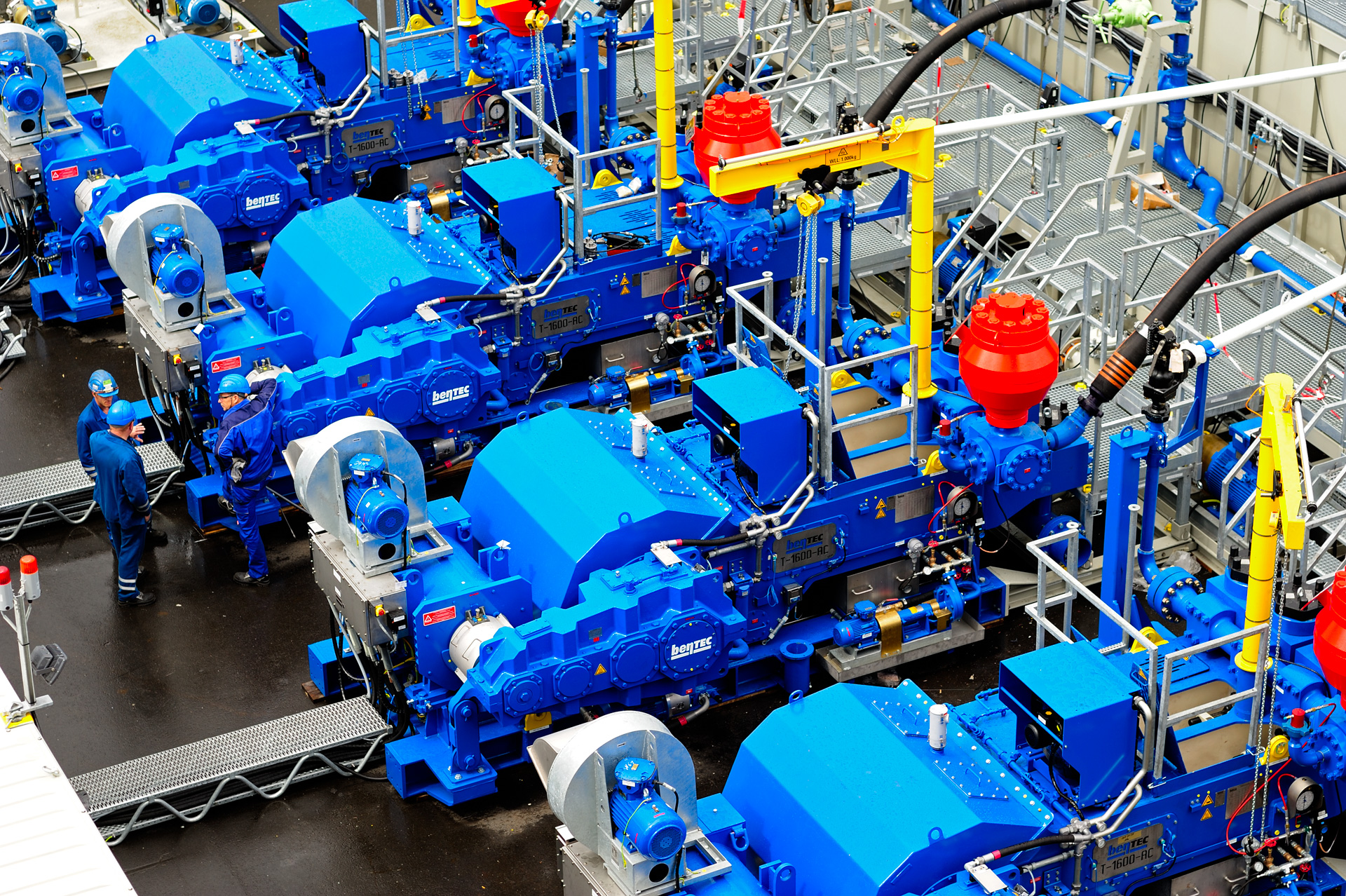

Bentec completely redeveloped the concept of Mud Pumps. Being equipped with a direct-driven gearbox, an own developed motor, and a state-of-the-art pump housing, there is no need for an internal gear coming with many disadvantages and no more belt tensioning.

Bentec Mud Pumps are light weight and have a small footprint. The AC-powered motor is top or rear mounted – suitable for any drilling rig arrangement. The pump is available with 5 000 or 7 500 psi fluid ends, and all its parts that are subject to wear and tear meet API standards and are available worldwide.

A handling crane makes it easy to handle the fluid end components. Furthermore, Bentec uses a patented liner and valve clamping technology to reduce the maintenance time significantly. A quick-change liner and piston system serves for easy maintenance. A special feature of the Bentec MUD PUMP is the side-mounted gear drive.

This design eliminates the need for chain or belt tensioning systems. The two-stage helical gear feeds directly into a forged/welded crankshaft, which is balanced and provides quiet and vibration-reduced operation.

Liner cooling and gear oiler systems are included; a supercharge pump and a noise reduction package can be installed upon request. The Bentec MUD PUMP is the right choice especially when it comes to noise-sensitive environments such offshore or densely populated environments.

Beyond the supply of Mud Pumps, Bentec acts as system supplier. The pumps can be delivered together with a Bentec Power Control System and a Bentec Soft Pump System.

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

triplex mud pumps and triplex mud pump parts meet the industry standards established by the American Petroleum Institute (API). As a global supplier of quality oilfield equipment to the oil and gas industry, we ship our products around the world.

Besides triplex mud pumps and triplex mud pump parts, we supply drilling rigs, workover rigs, top drives, drilling equipment, blowout preventers, BOP control systems, choke and kill manifolds, well service pumps for well cementing and hydraulic fracturing, wellhead equipment, casing heads, tubing heads, X-mas trees, FC type gate valves, etc. Please visit our company website

We supply unitized mud pump packages driven by DC or AC electric motors or diesel engines for electric and mechanical drilling rigs. The client can select DC or AC motors and diesel engine brands such as Caterpillar, Detroit, Cummins or others. Our unitized mud pump packages including everything on the skid and usually they are ready to work at delivery.

We strive to maintain our high reputation by producing drilling control systems and solutions to improve and maintain critical work environments in the Drilling industry. We provide a variety of products from variable frequency drives (VFD), programmable logic controllers (PLC), dynamic breaking systems, mud pumps, and other electrical components for your drilling applications.

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

Monitor Systems Engineering were asked to design and supply a new mud mixing control system for an operator"s Jack-up rig. The new system would monitor and control all 36 valves ranging in size from 6” to 12”. The new system design featured the replacement of the existing manual valves with pneumatically actuated units, eliminated the need for manual gearboxes, reach rods and stem extensions. Integral to the design was the installation of a new PLC & HMI based control system.

All components were mounted in a bespoke built processing enclosure and installed in the rig’s mud pump room. The process enclosure interfaces with the HMIs via a high speed Profinet network. A Siemens 19” touchscreen comfort panel HMI was mounted in the mud mixing office suspended from an adjustable bracket for operator efficiency and control. A Zone 1- 24” HMI was also installed in the rig’s mud pits room. All new valves were fitted with double acting pneumatic quarter turn actuators complete with dual coil 5/2 solenoid valves and feedback switch-box’s.

Brian Sinclair, Managing Director commented … “Changing the mud mixing manual system for a new automated system has increased efficiency for the operator, and provided a less labour intensive mud mixing procedure. The new system has also shown to reduce the time and manpower required during mud mixing operations.”

A well-placed suction stabilizer can also prevent pump chatter. Pump chatter occurs when energy is exchanged between the quick opening and closing of the reciprocating pump’s valves and the hammer effect from the centrifugal pump. Pump isolation with suction stabilizers is achieved when the charge pumps are isolated from reciprocating pumps and vice versa. The results are a smooth flow of pumped media devoid of agitating energies present in the pumped fluid.

Suction stabilizer units can mitigate most of the challenges related to pulsations or pressure surges, even in the most complex piping conditions. The resulting benefits prevent expensive unplanned downtime and decrease costs and inconvenience associated with system replacements and repairs.

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

GNSB Series Centrifugal pump is a very common device used at drilling mud solids control system. GNSB Series Centrifugal pump can be used for oil field drilling mud system, HDD and CBM drilling mud recycling system, piling and micro tunneling desanding plant. GN Solids Control is a professional manufacturer of centrifugal pump in China.

1. GNSB Series Centrifugal pump can be used as trip pump in the trip tank of the oil and gas drilling mud system. Trip tank is normally the first tank compartment inside drilling mud solids control system. The tank volume of trip tank is not big. It can be a separate smaller size tank other other tanks in the solids control system. It can also a compartment divided from shale shaker tank. Centrifugal pump size 3×2 or 4×3 are mostly used as trip tank trip pump.

2. GNSB Series Centrifugal pump can be used as feed pump for desander, desilter, mud cleaner. The pump transfer capacity should be matching the handling capacity of desander, desilter and mud cleaner. It can be a little big higher than the separation equipment, but it cannot be too much high. And the centrifugal pump transfer capacity cannot be lower than the separation equipment.

3. GNSB Series Centrifugal pump can be used as mixing pump of jet mud mixer and mixing unit. While add a T-pipe at the outlet of the mixing pump, the same pump can also be used as transfer pump.

4. GNSB Series Centrifugal pump can be used as transfer pump to transfer drilling mud or other slurries from one tank to another, or from one location to another.

All GN model centrifugal pump use tungsten carbide mechanical seal, with international famous brand Bearing. And spare parts interchangeable with most of the international Brand pump which helps customer to source spare parts easily. Open impeller design that lowers axial thrust loads, and make it easier for installation, repair and maintenance.

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec have delivered solid cost savings to our customers. This is due to our lower cost base, system with access to identical parts directly from manufacturer, and utilizing our experienced drilling equipment employees at very competitive rates.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

8613371530291

8613371530291