mud pump for dug well supplier

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Manufacturer of vertical turbine deep well pumps, including close coupled, single or multi-stage, low-lift & submersible styles. Semi-open or enclosed impellers. Product lubricated, water flush or oil lubricated shafting. Low vibration designs. Capacities to 35,000 gpm / 7,950 m3/hour with low lift models reaching 150,000 gpm. Pressures to 3,000 psi & settings to 2,000 feet available with motors as large as 3,000 HP. Temperatures of pumped fluids range from -150 degrees F to +500 degrees F. API610 Compliant. Low NPSHR impellers to meet NPSHR standards. Applications including, industrial, municipal, water supply, water treatment & control, commercial, power, mining, dewatering, reefing, agriculture, electric power, petroleum, oil & gas production, geothermal, snow making, cooling tower, condensate/boiler feed, HVAC, aircraft fueling, pulp & paper, barge stripper/tank unloading, chemical processes, pipelines & transfer & many other applications.

Preferred Pump offers the best rewards program in the water well equipment industry. Check out our social media pictures to see what you"ve been missing!

Shallow well pumps: These pumps are not submersible and are used on wells under 25" deep. The Star Water Systems SJ05S Shallow Well Jet Pump, for example, is used above ground and provides ½ HP of pumping power.

Deep well pumps: Also known as submersible pumps, these are placed into the water and can reach a variety of depths. For extra-deep wells, take a look at the Red Lion Submersible Pump, which can go as deep as 270’.

Convertible well pumps: These are used for both deep- and shallow-well purposes. A product like the Wayne Cast Iron Convertible Well Jet Pump will reach depths from zero to 90’ deep.

As the mechanism that manages your pump, a control box keeps the water at the optimal level. There are many reliable products available to today"s homeowner, including Franklin’s ¾ HP Control Box for 4” Submersible Pumps and their ½ HP 230V Deep Well Pump Control Box option.

There are many things that indicate it’s time to replace your well pump. This includes poor water pressure in your faucets and showers, the sound of clicking coming from your well, and noticeably high electric bills.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

When choosing a size and type of mud pump for your drilling project, there are several factors to consider. These would include not only cost and size of pump that best fits your drilling rig, but also the diameter, depth and hole conditions you are drilling through. I know that this sounds like a lot to consider, but if you are set up the right way before the job starts, you will thank me later.

Recommended practice is to maintain a minimum of 100 to 150 feet per minute of uphole velocity for drill cuttings. Larger diameter wells for irrigation, agriculture or municipalities may violate this rule, because it may not be economically feasible to pump this much mud for the job. Uphole velocity is determined by the flow rate of the mud system, diameter of the borehole and the diameter of the drill pipe. There are many tools, including handbooks, rule of thumb, slide rule calculators and now apps on your handheld device, to calculate velocity. It is always good to remember the time it takes to get the cuttings off the bottom of the well. If you are drilling at 200 feet, then a 100-foot-per-minute velocity means that it would take two minutes to get the cuttings out of the hole. This is always a good reminder of what you are drilling through and how long ago it was that you drilled it. Ground conditions and rock formations are ever changing as you go deeper. Wouldn’t it be nice if they all remained the same?

Centrifugal-style mud pumps are very popular in our industry due to their size and weight, as well as flow rate capacity for an affordable price. There are many models and brands out there, and most of them are very good value. How does a centrifugal mud pump work? The rotation of the impeller accelerates the fluid into the volute or diffuser chamber. The added energy from the acceleration increases the velocity and pressure of the fluid. These pumps are known to be very inefficient. This means that it takes more energy to increase the flow and pressure of the fluid when compared to a piston-style pump. However, you have a significant advantage in flow rates from a centrifugal pump versus a piston pump. If you are drilling deeper wells with heavier cuttings, you will be forced at some point to use a piston-style mud pump. They have much higher efficiencies in transferring the input energy into flow and pressure, therefore resulting in much higher pressure capabilities.

Piston-style mud pumps utilize a piston or plunger that travels back and forth in a chamber known as a cylinder. These pumps are also called “positive displacement” pumps because they literally push the fluid forward. This fluid builds up pressure and forces a spring-loaded valve to open and allow the fluid to escape into the discharge piping of the pump and then down the borehole. Since the expansion process is much smaller (almost insignificant) compared to a centrifugal pump, there is much lower energy loss. Plunger-style pumps can develop upwards of 15,000 psi for well treatments and hydraulic fracturing. Centrifugal pumps, in comparison, usually operate below 300 psi. If you are comparing most drilling pumps, centrifugal pumps operate from 60 to 125 psi and piston pumps operate around 150 to 300 psi. There are many exceptions and special applications for drilling, but these numbers should cover 80 percent of all equipment operating out there.

The restriction of putting a piston-style mud pump onto drilling rigs has always been the physical size and weight to provide adequate flow and pressure to your drilling fluid. Because of this, the industry needed a new solution to this age-old issue.

Enter Cory Miller of Centerline Manufacturing, who I recently recommended for recognition by the National Ground Water Association (NGWA) for significant contributions to the industry.

As the senior design engineer for Ingersoll-Rand’s Deephole Drilling Business Unit, I had the distinct pleasure of working with him and incorporating his Centerline Mud Pump into our drilling rig platforms.

In the late ’90s — and perhaps even earlier — Ingersoll-Rand had tried several times to develop a hydraulic-driven mud pump that would last an acceptable life- and duty-cycle for a well drilling contractor. With all of our resources and design wisdom, we were unable to solve this problem. Not only did Miller provide a solution, thus saving the size and weight of a typical gear-driven mud pump, he also provided a new offering — a mono-cylinder mud pump. This double-acting piston pump provided as much mud flow and pressure as a standard 5 X 6 duplex pump with incredible size and weight savings.

The true innovation was providing the well driller a solution for their mud pump requirements that was the right size and weight to integrate into both existing and new drilling rigs. Regardless of drill rig manufacturer and hydraulic system design, Centerline has provided a mud pump integration on hundreds of customer’s drilling rigs. Both mono-cylinder and duplex-cylinder pumps can fit nicely on the deck, across the frame or even be configured for under-deck mounting. This would not be possible with conventional mud pump designs.

The second generation design for the Centerline Mud Pump is expected later this year, and I believe it will be a true game changer for this industry. It also will open up the application to many other industries that require a heavier-duty cycle for a piston pump application.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

It’s best to think of a water well as a complete system. There are numerous working parts beginning at ground level down to the groundwater aquifer and up to the delivery infrastructure servicing your residential or commercial property.

Your water well will not work properly if it’s not constructed properly and with quality assurance. In the worst case, the well will deliver poor quality water that may be unhealthy for consumption. So it’s best to have an experienced water well drilling and pump installation professional tackle each part of the process.

After the well is drilled in the right location and down to the proper depth, a well casing is inserted into the hole. This casing is a carbon-steel pipe — or a series of interconnected pipes — sometimes extending several hundred feet into an underground aquifer. The casing maintains the well opening. Once installed, it’s cemented or filled with grout around the circumference to further seal any empty spaces between the casing and hole. This ensures no outside dirt, geological elements or other contaminants can make their way into your water supply. The well casing also restricts the groundwater to its location for future delivery.

The cap seals the well from any contaminants above ground. It must be installed and sealed correctly to the portion of the well casing that extends above the ground. It ensures disease-causing microbes, debris, insects and even small animals can’t enter the well. The best way for a secure seal is to bolt the cap down snugly so it can’t be easily or accidentally removed. It should be removed only by a professional for routine and ongoing maintenance.

The pump draws the water from the well. Thank amazing advances in technology for the fact that you no longer have to pull water up with a bucket. It’s important to select the pump that will supply your average daily needs in both water head pressure and volume per minute. Anything short will leave you and your property thirsting for water — literally and figuratively — especially during peak usage times. In the household market, there are two types: submersible and jet pumps. Submersible pumps are typically best for deeper wells. Jet pumps are often the right choice for shallow wells no more than 25 feet deep. Work with your experienced water well professional to determine which pump will provide the most consistent and reliable water volume and pressure. Here at Adams Well Drilling, we proudly use only American-made pumps by Goulds Water Technology – a Xylem brand, the leading technology in water wells.

The pitless adapter begins the water-delivery infrastructure to the point of consumption. It forms a sanitary seal between the well casing and water service line, or water main. Here in Western New York, where winter seems to last half the year, we take special care to install these below the frost line. If this critical seal is broken, you may experience water quality and contamination issues. An experienced contractor will install the pitless adapter securely for a seal that lasts many years.

The pressure tank is a critical component of your delivery infrastructure. It stores well water under pressure to relieve unnecessary strain on the pump. Without a pressure tank, the pump would be forced to kick on and supply sufficient water every time a tap is turned. Considering the sometimes lengthy distances and optional treatment and heating processes your water must travel through, relying on the pump alone would be unrealistic or downright impossible. An average residential water tank serving a family of two to four people will hold between 20 and 80 gallons of pressurized water at a time.

A quality water well and pump system is a big piece of infrastructure. The interconnected equipment, installed correctly, should serve your property with safe, clean water for years with minimal ongoing maintenance. Trust the experienced professionals at Adams Well Drilling to do it right for you. Call (585) 968-3923 for a free consultation.

A well is an excavation or structure created in the ground by digging, driving, or drilling to access liquid resources, usually water. The oldest and most common kind of well is a water well, to access groundwater in underground aquifers. The well water is drawn up by a pump, or using containers, such as buckets or large water bags that are raised mechanically or by hand. Water can also be injected back into the aquifer through the well. Wells were first constructed at least eight thousand years ago and historically vary in construction from a simple scoop in the sediment of a dry watercourse to the qanats of Iran, and the stepwells and sakiehs of India. Placing a lining in the well shaft helps create stability, and linings of wood or wickerwork date back at least as far as the Iron Age.

Wells have traditionally been sunk by hand digging, as is still the case in rural areas of the developing world. These wells are inexpensive and low-tech as they use mostly manual labour, and the structure can be lined with brick or stone as the excavation proceeds. A more modern method called caissoning uses pre-cast reinforced concrete well rings that are lowered into the hole. Driven wells can be created in unconsolidated material with a well hole structure, which consists of a hardened drive point and a screen of perforated pipe, after which a pump is installed to collect the water. Deeper wells can be excavated by hand drilling methods or machine drilling, using a bit in a borehole. Drilled wells are usually cased with a factory-made pipe composed of steel or plastic. Drilled wells can access water at much greater depths than dug wells.

Two broad classes of well are shallow or unconfined wells completed within the uppermost saturated aquifer at that location, and deep or confined wells, sunk through an impermeable stratum into an aquifer beneath. A collector well can be constructed adjacent to a freshwater lake or stream with water percolating through the intervening material. The site of a well can be selected by a hydrogeologist, or groundwater surveyor. Water may be pumped or hand drawn. Impurities from the surface can easily reach shallow sources and contamination of the supply by pathogens or chemical contaminants needs to be avoided. Well water typically contains more minerals in solution than surface water and may require treatment before being potable. Soil salination can occur as the water table falls and the surrounding soil begins to dry out. Another environmental problem is the potential for methane to seep into the water.

Very early neolithic wells are known from the Eastern Mediterranean:pre-pottery neolithic (PPN) site of Kissonerga-Mylouthkia on Cyprus. At around 8400 BC a shaft (well 116) of circular diameter was driven through limestone to reach an aquifer at a depth of 8 metres (26 ft). Well 2070 from Kissonerga-Mylouthkia, dating to the late PPN, reaches a depth of 13 metres (43 ft). Other slightly younger wells are known from this site and from neighbouring Parekklisha-Shillourokambos. A first stone lined‘Atlit-Yam off the coast near modern Haifa in Israel.

Wood-lined wells are known from the early Neolithic Linear Pottery culture, for example in Ostrov, Czech Republic, dated 5265 BC,Erkelenz), dated 5090 BC, and Eythra in Schletz (an outlying centre of Asparn an der Zaya) in Austria, dated 5200 BC.

Some of the earliest evidence of water wells is located in China. The neolithic Chinese discovered and made extensive use of deep drilled groundwater for drinking.Hemedu excavation site was believed to have been built during the neolithic era.

Wells for other purposes came along much later, historically. The first recorded salt well was dug in the Sichuan province of China around 2,250 years ago. This was the first time that ancient water well technology was applied successfully for the exploitation of salt, and marked the beginning of Sichuan"s salt drilling industry.oil wells were also drilled in China, in 347 CE. These wells had depths of up to about 240 metres (790 ft) and were drilled using bits attached to bamboo poles.brine and produce salt. By the 10th century, extensive bamboo pipelines connected oil wells with salt springs. The ancient records of China and Japan are said to contain many allusions to the use of natural gas for lighting and heating. Petroleum was known as Burning water in Japan in the 7th century.

Until recent centuries, all artificial wells were pumpless hand-dug wells of varying degrees of sophistication, and they remain a very important source of potable water in some rural developing areas, where they are routinely dug and used today. Their indispensability has produced a number of literary references, literal and figurative, including the reference to the incident of Jesus meeting a woman at Jacob"s well (John 4:6) in the Bible and the "Ding Dong Bell" nursery rhyme about a cat in a well.

Hand-dug wells are excavations with diameters large enough to accommodate one or more people with shovels digging down to below the water table. The excavation is braced horizontally to avoid landslide or erosion endangering the people digging. They can be lined with stone or brick; extending this lining upwards above the ground surface to form a wall around the well serves to reduce both contamination and accidental falls into the well.

A more modern method called caissoning uses reinforced concrete or plain concrete pre-cast well rings that are lowered into the hole. A well-digging team digs under a cutting ring and the well column slowly sinks into the aquifer, whilst protecting the team from collapse of the well bore.

Hand-dug wells are inexpensive and low tech (compared to drilling) and they use mostly manual labour to access groundwater in rural locations of developing countries. They may be built with a high degree of community participation, or by local entrepreneurs who specialize in hand-dug wells. They have been successfully excavated to 60 metres (200 ft). They have low operational and maintenance costs, in part because water can be extracted by hand, without a pump. The water often comes from an aquifer or groundwater, and can be easily deepened, which may be necessary if the ground water level drops, by telescoping the lining further down into the aquifer. The yield of existing hand dug wells may be improved by deepening or introducing vertical tunnels or perforated pipes.

Drawbacks to hand-dug wells are numerous. It can be impractical to hand dig wells in areas where hard rock is present, and they can be time-consuming to dig and line even in favourable areas. Because they exploit shallow aquifers, the well may be susceptible to yield fluctuations and possible contamination from surface water, including sewage. Hand dug well construction generally requires the use of a well trained construction team, and the capital investment for equipment such as concrete ring moulds, heavy lifting equipment, well shaft formwork, motorized de-watering pumps, and fuel can be large for people in developing countries. Construction of hand dug wells can be dangerous due to collapse of the well bore, falling objects and asphyxiation, including from dewatering pump exhaust fumes.

The Woodingdean Water Well, hand-dug between 1858 and 1862, is the deepest hand-dug well at 392 metres (1,285 ft).Big Well in Greensburg, Kansas is billed as the world"s largest hand-dug well, at 109 feet (33 m) deep and 32 feet (9.8 m) in diameter. However, the Well of Joseph in the Cairo Citadel at 280 feet (85 m) deep and the Pozzo di San Patrizio (St. Patrick"s Well) built in 1527 in Orvieto, Italy, at 61 metres (200 ft) deep by 13 metres (43 ft) wide

Driven wells may be very simply created in unconsolidated material with a well hole structure, which consists of a hardened drive point and a screen (perforated pipe). The point is simply hammered into the ground, usually with a tripod and driver, with pipe sections added as needed. A driver is a weighted pipe that slides over the pipe being driven and is repeatedly dropped on it. When groundwater is encountered, the well is washed of sediment and a pump installed.

Drilled wells are constructed using various types of drilling machines, such as top-head rotary, table rotary, or cable tool, which all use drilling stems that rotate to cut into the formation, thus the term "drilling."

Drilled wells can be excavated by simple hand drilling methods (augering, sludging, jetting, driving, hand percussion) or machine drilling (rotary, percussion, down the hole hammer). Deeprock rotary drilling method is most common. Rotary can be used in 90% of formation types.

Drilled wells with electric pumps are used throughout the world, typically in rural or sparsely populated areas, though many urban areas are supplied partly by municipal wells. Most shallow well drilling machines are mounted on large trucks, trailers, or tracked vehicle carriages. Water wells typically range from 3 to 18 metres (10–60 ft) deep, but in some areas can go deeper than 900 metres (3,000 ft).

Rotary drilling machines use a segmented steel drilling string, typically made up of 6 m (20 ft) sections of galvanized steel tubing that are threaded together, with a bit or other drilling device at the bottom end. Some rotary drilling machines are designed to install (by driving or drilling) a steel casing into the well in conjunction with the drilling of the actual bore hole. Air and/or water is used as a circulation fluid to displace cuttings and cool bits during the drilling. Another form of rotary-style drilling, termed mud rotary, makes use of a specially made mud, or drilling fluid, which is constantly being altered during the drill so that it can consistently create enough hydraulic pressure to hold the side walls of the bore hole open, regardless of the presence of a casing in the well. Typically, boreholes drilled into solid rock are not cased until after the drilling process is completed, regardless of the machinery used.

The oldest form of drilling machinery is the cable tool, still used today. Specifically designed to raise and lower a bit into the bore hole, the spudding of the drill causes the bit to be raised and dropped onto the bottom of the hole, and the design of the cable causes the bit to twist at approximately 1⁄4 revolution per drop, thereby creating a drilling action. Unlike rotary drilling, cable tool drilling requires the drilling action to be stopped so that the bore hole can be bailed or emptied of drilled cuttings.

Drilled wells are usually cased with a factory-made pipe, typically steel (in air rotary or cable tool drilling) or plastic/PVC (in mud rotary wells, also present in wells drilled into solid rock). The casing is constructed by welding, either chemically or thermally, segments of casing together. If the casing is installed during the drilling, most drills will drive the casing into the ground as the bore hole advances, while some newer machines will actually allow for the casing to be rotated and drilled into the formation in a similar manner as the bit advancing just below. PVC or plastic is typically welded and then lowered into the drilled well, vertically stacked with their ends nested and either glued or splined together. The sections of casing are usually 6 metres (20 ft) or more in length, and 6 to 12 in (15 to 30 cm) in diameter, depending on the intended use of the well and local groundwater conditions.

Surface contamination of wells in the United States is typically controlled by the use of a surface seal. A large hole is drilled to a predetermined depth or to a confining formation (clay or bedrock, for example), and then a smaller hole for the well is completed from that point forward. The well is typically cased from the surface down into the smaller hole with a casing that is the same diameter as that hole. The annular space between the large bore hole and the smaller casing is filled with bentonite clay, concrete, or other sealant material. This creates an impermeable seal from the surface to the next confining layer that keeps contaminants from traveling down the outer sidewalls of the casing or borehole and into the aquifer. In addition, wells are typically capped with either an engineered well cap or seal that vents air through a screen into the well, but keeps insects, small animals, and unauthorized persons from accessing the well.

At the bottom of wells, based on formation, a screening device, filter pack, slotted casing, or open bore hole is left to allow the flow of water into the well. Constructed screens are typically used in unconsolidated formations (sands, gravels, etc.), allowing water and a percentage of the formation to pass through the screen. Allowing some material to pass through creates a large area filter out of the rest of the formation, as the amount of material present to pass into the well slowly decreases and is removed from the well. Rock wells are typically cased with a PVC liner/casing and screen or slotted casing at the bottom, this is mostly present just to keep rocks from entering the pump assembly. Some wells utilize a filter pack method, where an undersized screen or slotted casing is placed inside the well and a filter medium is packed around the screen, between the screen and the borehole or casing. This allows the water to be filtered of unwanted materials before entering the well and pumping zone.

Deep or confined wells are sunk through an impermeable stratum into an aquifer that is sandwiched between two impermeable strata (aquitards or aquicludes). The majority of deep aquifers are classified as artesian because the hydraulic head in a confined well is higher than the level of the top of the aquifer. If the hydraulic head in a confined well is higher than the land surface it is a "flowing" artesian well (named after Artois in France).

A special type of water well may be constructed adjacent to freshwater lakes or streams. Commonly called a collector well but sometimes referred to by the trade name Ranney well or Ranney collector, this type of well involves sinking a caisson vertically below the top of the aquifer and then advancing lateral collectors out of the caisson and beneath the surface water body. Pumping from within the caisson induces infiltration of water from the surface water body into the aquifer, where it is collected by the collector well laterals and conveyed into the caisson where it can be pumped to the ground surface.

production or pumping wells, are large diameter (greater than 15 cm in diameter) cased (metal, plastic, or concrete) water wells, constructed for extracting water from the aquifer by a pump (if the well is not artesian).

A well constructed for pumping groundwater can be used passively as a monitoring well and a small diameter well can be pumped, but this distinction by use is common.

Before excavation, information about the geology, water table depth, seasonal fluctuations, recharge area and rate must be found. This work is typically done by a hydrogeologist, or a groundwater surveyor using a variety of tools including electro-seismic surveying,geophysical imaging.

Shallow pumping wells can often supply drinking water at a very low cost. However, impurities from the surface easily reach shallow sources, which leads to a greater risk of contamination for these wells compared to deeper wells. Contaminated wells can lead to the spread of various waterborne diseases. Dug and driven wells are relatively easy to contaminate; for instance, most dug wells are unreliable in the majority of the United States.

Most of the bacteria, viruses, parasites, and fungi that contaminate well water comes from fecal material from humans and other animals, for example from on-site sanitation systems (such as pit latrines and septic tanks). Common bacterial contaminants include enteroviruses, and hepatitis A and E. Parasites include microsporidia.

Chemical contamination is a common problem with groundwater.Nitrates from sewage, sewage sludge or fertilizer are a particular problem for babies and young children. Pollutant chemicals include pesticides and volatile organic compounds from gasoline, dry-cleaning, the fuel additive methyl tert-butyl ether (MTBE), and perchlorate from rocket fuel, airbag inflators, and other artificial and natural sources.

Some chemicals are commonly present in water wells at levels that are not toxic, but can cause other problems. Calcium and magnesium cause what is known as hard water, which can precipitate and clog pipes or burn out water heaters. Iron and manganese can appear as dark flecks that stain clothing and plumbing, and can promote the growth of iron and manganese bacteria that can form slimy black colonies that clog pipes.

The quality of the well water can be significantly increased by lining the well, sealing the well head, fitting a self-priming hand pump, constructing an apron, ensuring the area is kept clean and free from stagnant water and animals, moving sources of contamination (pit latrines, garbage pits, on-site sewer systems) and carrying out hygiene education. The well should be cleaned with 1% chlorine solution after construction and periodically every 6 months.

Well holes should be covered to prevent loose debris, animals, animal excrement, and wind-blown foreign matter from falling into the hole and decomposing. The cover should be able to be in place at all times, including when drawing water from the well. A suspended roof over an open hole helps to some degree, but ideally the cover should be tight fitting and fully enclosing, with only a screened air vent.

Minimum distances and soil percolation requirements between sewage disposal sites and water wells need to be observed. Rules regarding the design and installation of private and municipal septic systems take all these factors into account so that nearby drinking water sources are protected.

Cleanup of contaminated groundwater tends to be very costly. Effective remediation of groundwater is generally very difficult. Contamination of groundwater from surface and subsurface sources can usually be dramatically reduced by correctly centering the casing during construction and filling the casing annulus with an appropriate sealing material. The sealing material (grout) should be placed from immediately above the production zone back to surface, because, in the absence of a correctly constructed casing seal, contaminated fluid can travel into the well through the casing annulus. Centering devices are important (usually one per length of casing or at maximum intervals of 9 m) to ensure that the grouted annular space is of even thickness.

Upon the construction of a new test well, it is considered best practice to invest in a complete battery of chemical and biological tests on the well water in question. Point-of-use treatment is available for individual properties and treatment plants are often constructed for municipal water supplies that suffer from contamination. Most of these treatment methods involve the filtration of the contaminants of concern, and additional protection may be garnered by installing well-casing screens only at depths where contamination is not present.

Wellwater for personal use is often filtered with reverse osmosis water processors; this process can remove very small particles. A simple, effective way of killing microorganisms is to bring the water to a full boil for one to three minutes, depending on location. A household well contaminated by microorganisms can initially be treated by shock chlorination using bleach, generating concentrations hundreds of times greater than found in community water systems; however, this will not fix any structural problems that led to the contamination and generally requires some expertise and testing for effective application.

A risk with the placement of water wells is soil salination which occurs when the water table of the soil begins to drop and salt begins to accumulate as the soil begins to dry out.

The potential for soil salination is a large risk when choosing the placement of water wells. Soil salination is caused when the water table of the soil drops over time and salt begins to accumulate. In turn, the increased amount of salt begins to dry the soil out. The increased level of salt in the soil can result in the degradation of soil and can be very harmful to vegetation.

Methane, an asphyxiant, is a chemical compound that is the main component of natural gas. When methane is introduced into a confined space, it displaces oxygen, reducing oxygen concentration to a level low enough to pose a threat to humans and other aerobic organisms but still high enough for a risk of spontaneous or externally caused explosion. This potential for explosion is what poses such a danger in regards to the drilling and placement of water wells.

Low levels of methane in drinking water are not considered toxic. When methane seeps into a water supply, it is commonly referred to as "methane migration". This can be caused by old natural gas wells near water well systems becoming abandoned and no longer monitored.

Lately,handpumps or treadle pumps. Another alternative is the use of self-dug wells, electrical deep-well pumps (for higher depths). Appropriate technology organizations as Practical Action are nowDIY) handpumps and treadle pumps in practice.

A study concluded that of ~39 million groundwater wells 6-20% are at high risk of running dry if local groundwater levels decline by less than five meters, or – as with many areas and possibly more than half of major aquifers

Springs and wells have had cultural significance since prehistoric times, leading to the foundation of towns such as Wells and Bath in Somerset. Interest in health benefits led to the growth of spa towns including many with wells in their name, examples being Llandrindod Wells and Royal Tunbridge Wells.

Eratosthenes is sometimes claimed to have used a well in his calculation of the Earth"s circumference; however, this is just a simplification used in a shorter explanation of Cleomedes, since Eratosthenes had used a more elaborate and precise method.

Many incidents in the Bible take place around wells, such as the finding of a wife for Isaac in Genesis and Jesus"s talk with the Samaritan woman in the Gospels.

For a well with impermeable walls, the water in the well is resupplied from the bottom of the well. The rate at which water flows into the well will depend on the pressure difference between the ground water at the well bottom and the well water at the well bottom. The pressure of a column of water of height z will be equal to the weight of the water in the column divided by the cross-sectional area of the column, so the pressure of the ground water a distance zT below the top of the water table will be:

where ρ is the mass density of the water and g is the acceleration due to gravity. When the water in the well is below the water table level, the pressure at the bottom of the well due to the water in the well will be less than Pg and water will be forced into the well. Referring to the diagram, if z is the distance from the bottom of the well to the well water level and zT is the distance from the bottom of the well to the top of the water table, the pressure difference will be:

where R is the resistance to the flow, which depends on the well cross section, the pressure gradient at the bottom of the well, and the characteristics of the substrate at the well bottom. (e.g., porosity). The volume flow rate into the well can be written as a function of the rate of change of the well water level:

The above model does not take into account the depletion of the aquifer due to the pumping which lowered the well water level (See aquifer test and groundwater flow equation). Also, practical wells may have impermeable walls only up to, but not including the bedrock, which will give a larger surface area for water to enter the well.

Peltenburg, Edgar (2012). "East Mediterranean water wells of the 9th–7th millennium BC". In: Florian Klimscha (ed.), Wasserwirtschaftliche Innovationen im archäologischen Kontext. Von den prähistorischen Anfängen bis zu den Metropolen der Antike. Rahden/Westfalia: Leidorf: 69–82. Cite journal requires |journal= (help)

Galili, Ehud; Nir, Yaacov (1993). "The submerged Pre-Pottery Neolithic water well of Atlit-Yam, northern Israel, and its palaeoenvironmental implications". The Holocene. 3 (3): 265–270. Bibcode:1993Holoc...3..265G. doi:10.1177/095968369300300309. S2CID 130032420.

Chang, Mingteh (2012). Forest Hydrology: An Introduction to Water and Forests (3rd ed.). CRC Press (published November 1, 2012). p. 31. ISBN 978-1439879948.

A pump is an excellent tool in multiple settings, from the small ones in fridges to large ones used in irrigation schemes. You can find these solutions in cars, and others in water dispenser. There are countless applications of a pump. However, you could run out of stock or be in need for one to make repairs to your system. When you do, you can find the hand pump for drilled well you want from Alibaba.com. From a wholesale hand pump for drilled well operating on solar energy to the ones hand-operated, any product you want, you can find it in the catalog.

A hand pump for drilled well comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the hand pump for drilled well of choice from the collection at Alibaba.com.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes hand pump for drilled well wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

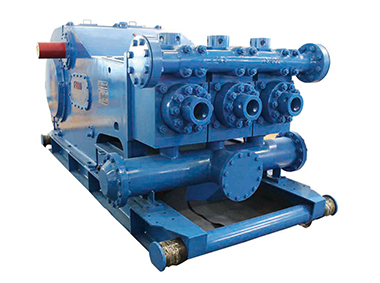

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

Your well pump is an essential component to ensuring your home has a steady source of fresh, clean water. With proper well maintenance, your well pump can last, on average of 8 to 15 years, though many homeowners report their pumps lasting far longer, often between 20 and 30 years!

However, owning a home with a well means that you"ll likely have to replace your well pump at some point, but how will you know when it"s time? To help you, we"re sharing the 5 signs you need a new well pump, and what those signs could mean instead!

If there is no water at all when you turn on a faucet or flush a toilet, that is a definite sign there is something wrong. Troubleshoot the issues below, and if those aren"t the problem, you may need to have your well pump repaired or replaced.

When you turn on your water, if there is a noticeable decrease in your typical water pressure, that is a sign that your pump is not able to draw as much water up because it"s beginning to fail. It could also mean your well pump is too small, perhaps caused by adding a new bathroom, installing a dishwasher, or adding a larger water heater.

If you turn on the faucet and it seems like there are air bubbles coming through the pipes and the water is not consistently flowing, the pump may be unable to pull water up and is pulling in air. Like a decrease in water pressure, this is a sign that the pump is not functioning efficiently and may be about to fail altogether.

A metallic smell or taste, or an egg smell coming from your water is generally a sign of harmless minerals in your well. However, if the water is actually coming out with dirt, sand, or sediment, it"s absolutely essential to get it fixed immediately. Most likely, this is an issue directly related to the pump itself.

The pump may be too large for your well, and it"s pulling silt and dirt up from the bottom, and it needs to be replaced. A repair may be necessary instead, if it"s placed too far down in the well and needs to be relocated, or the pump"s filter screen has gotten torn or damaged somehow. This is a fixable problem by a well pump repair specialist.

No matter what the issue might be, from harmless minerals to a broken well pump, don"t drink cloudy, muddy, or dirty water until the problem is solved and you have well water testing performed.

If you have high mineral content in your well, mineral deposits can break down and lead to sediment in your water. Having a well water filtration system will help keep your water fresh and clean.

If your well pump is running continuously, it is probably a sign that it needs to be replaced or, at the very least, repaired. If you have an above-ground jet pump system, the intake pipe needs to be primed, usually caused by a leak in the suction line. This means it needs to have water in the jet system in order to generate the suction needed to pull water up and into the water line. Otherwise, the pressure control switch is faulty, the pipe has a leak, or the pump may be wearing out and is unable to generate enough water pressure to trigger the cut-off.

Having a reliable source of clean water is an absolute necessity for your Raleigh home. If you are experiencing issues, from a sudden decrease in water quality to no water at all, reach out A & T Well and Pump immediately. We offer comprehensive well pump repair services, including replacement, testing, and maintenance and will work with you to get your water well up and running fast! Call us today at (919)-291-4063 or fill out our contact form to get started!

8613371530291

8613371530291