mud pump inspection checklist factory

Created specifically for drilling equipment inspectors and others in the oil and gas industry, the Oil Rig Mud Pump Inspection app allows you to easily document the status and safety of your oil rigs using just a mobile device. Quickly resolve any damage or needed maintenance with photos and GPS locations and sync to the cloud for easy access. The app is completely customizable to fit your inspection needs and works even without an internet signal.Try Template

Fulcrum helps us improve our processes and make our work environment safer by streamlining inspections, surfacing inspection-related insights, and managing follow-up actions. Once you close the loop from action to insight to further action, the possibilities are limitless.

Instead of using paper checklists when out in the field, drilling contractors and rig inspection services can generate a new inspection form from anywhere and the results are saved electronically.

Specifically designed for drilling companies and others in the oil and gas industry, the easy to use drilling rig inspections app makes it easy to log information about the drill rigs, including details about the drill rigs operators, miles logged and well numbers. The inspection form app covers everything from the mud pump areas and mud mixing area to the mud tanks and pits, making it easy to identify areas where preventative maintenance is needed. The drilling rig equipment checklist also covers health and safety issues, including the availability of PPE equipment, emergency response and preparedness processes, and other critical elements of the drilling process and drill press equipment.

03/05/2011 8:19 AMHello my friendsDo you know any standard for inspection a pump ? ( when it is on service) thatexplain what is important parameter of inspection a pumpCan you upload it ?Thank you

• #2 "Re: Question About Inspection A Pump" by Noudge79 on 03/05/2011 7:36 PM (score 1) • #5 "Re: Question About Inspection A Pump" by brich on 03/06/2011 7:34 AM (score 1)

Re: Question About Inspection A Pump 03/05/2011 10:19 AM Contact the pump manufacturer. What means, "on service"?

Re: Question About Inspection A Pump 03/05/2011 7:36 PM 1)Install a Differential Pressure gauge between suction and discharge line. Head delivered of the pump is the Pressure difference between those points. You monitor it. Normal pump would maintain a constant DP (Head). If DP is lowering that means somethings wrong with your pump. (Check the impeller, motor, bearings)

Re: Question About Inspection A PumpJoin Date: Jun 03/05/2011 11:10 PM2008 Need more details . General inspection includes physicalLocation: Oman inspection, abnormal sound, vibration, controls etc. Ensure that the preventive maintenance is carried out as per the manufactures recommendation.Posts: 347

Join Date: Oct 2. the OEM hand book for installation and servicing2009 3. check the RPM, intake & discharge pressure with the OEMLocation: UK pump curve

Posts: 314 and if the pump is still under the OEM warrantee, then ask them for the EXACT specifications you need & if you are havingGood Answers: problems then get them to honour their contact commitment to fix your problem (if you have one), if not covered by the24 OEM then still ask for the details, pump curves etc.. so you can compare you findings with that of the pump curve.

As for standards... that will depend on what type of pump you have, who made it and what standard they made the pump too! You can try API standards for pumps.. google it..

Pump manufacturer curves, flow meter and a current probe are your best bet. supposing that the pump is working normally.Join Date: Aug 2006 __________________Location: Santiago Never trade luck for skill.Chile.

praneethsuddapall #7Browser Re: Question About Inspection A Pump 03/07/2011 6:32 AMJoin Date: Nov 2010 simply you go to a mechanic give him his fare and sayPosts: 6 your problem thats it there ends the matter

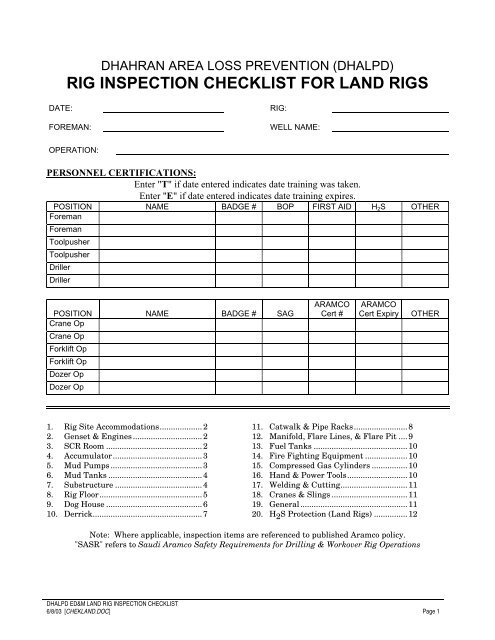

Drilling rigs are complex and expensive machinery used for oil drilling, exploration, and extraction. Therefore, proper management and oversight are essential to ensure the drilling rig functions correctly. To this end, drilling rigs undergo detailed inspections before commissioning to accept them for use. For that purpose, drilling rig inspection checklists are employed to outline the criteria and parameters for proving drilling rig efficiency.

This article will provide a full guide on drilling rig inspection checklists, including what they are, why they’re important, how to write one effectively, and some tips for successful implementation.

A drilling rig inspection is assessing the rig to determine if it is safe and suitable for drilling operations. This inspection includes examining the drilling rig’s structural and mechanical integrity, as well as its drilling components. It is also the primary method for ensuring drilling rigs meet safety regulations and industry standards before drilling operations begin.

A drilling rig inspection is critical for drilling operations, as it ensures that the drilling rig is safe and suitable for drilling operations. Many companies have lost much money from drilling rig failure due to poorly maintained drilling rigs. By conducting a drilling rig inspection, you can mitigate the risks and ensure your drilling operations are conducted safely and efficiently.

A drilling rig inspection checklist is a document that outlines the criteria and parameters for proving drilling rig efficiency. This checklist helps ensure drilling rigs can meet safety standards and drilling requirements. At the same time, drilling rig inspection checklists help identify potential problems with drilling or production operations.

Creating a drilling rig inspection checklist is an essential part of drilling operations. It helps to ensure that drilling rigs are inspected thoroughly and that any necessary repairs or modifications can be done in a timely manner. In addition, drilling rig inspection checklists can help to reduce the risk of unexpected downtime, equipment failure, and other issues that could result in costly losses.

Creating a practical drilling rig inspection checklist is essential to ensure personnel safety, production efficiency, and adherence to industry standards. When creating a drilling rig inspection checklist, follow the steps outlined below.

Start by obtaining a copy of the drilling rig’s original documentation, which includes all information about the drilling rig—specifications, maintenance, and operation information. This document will serve as a baseline for the drilling rig inspection checklist.

Develop a drilling rig inspection template based on the drilling rig’s documentation. This template should include areas such as drilling parameters, safety protocols and procedures, drilling parameters, mud systems, and other components.

Make sure to include an inspection checklist for drilling rig personnel. This should consist of qualifications and certifications, as well as drilling experience.

Once the drilling rig inspection checklist is completed, it should be reviewed by a qualified drilling engineer or drilling consultant to ensure accuracy.

During the drilling rig inspection, review and compare all drilling parameters to the drilling rig’s original documentation. Document discrepancies or potential issues during drilling operations and note them in the drilling log.

By following these steps, drilling operators can ensure the drilling rig is inspected promptly and accurately. An effective drilling rig inspection checklist will help identify potential issues before they become safety or production issues while also providing drilling personnel with the information they need to safely and efficiently operate the drilling rig safely and efficiently.

Paper-based drilling rig inspection checklists can be cumbersome and inconvenient. Instead, use a low-code platform to streamline drilling rig inspections. DATAMYTE is an excellent solution as it provides low-code features that will help you create and implement checklists. It’s a quality management platform with low-code capabilities.

The DataMyte Digital Clipboard, in particular, is a low-code workflow automation software that features a checklist builder. With this tool, drilling operators can easily create drilling rig inspection checklists. With low-code features such as a drag-and-drop interface, drilling operators can quickly and easily create drilling rig inspection checklists tailored to their specific drilling rigs.

With DATAMYTE, you have an all-in-one solution for creating and implementing drilling rig inspection checklists. Book a demo with us today to learn more about how DATAMYTE can help you create drilling rig inspection checklists.

There’s no denying that drilling rigs are complex units of machinery and technology. To ensure their safe operation and efficient commissioning, it is essential to create a drilling rig inspection checklist. By following the guidelines in this article, drilling contractors can create a comprehensive drilling rig inspection checklist to ensure that all aspects of the drilling process are properly inspected.

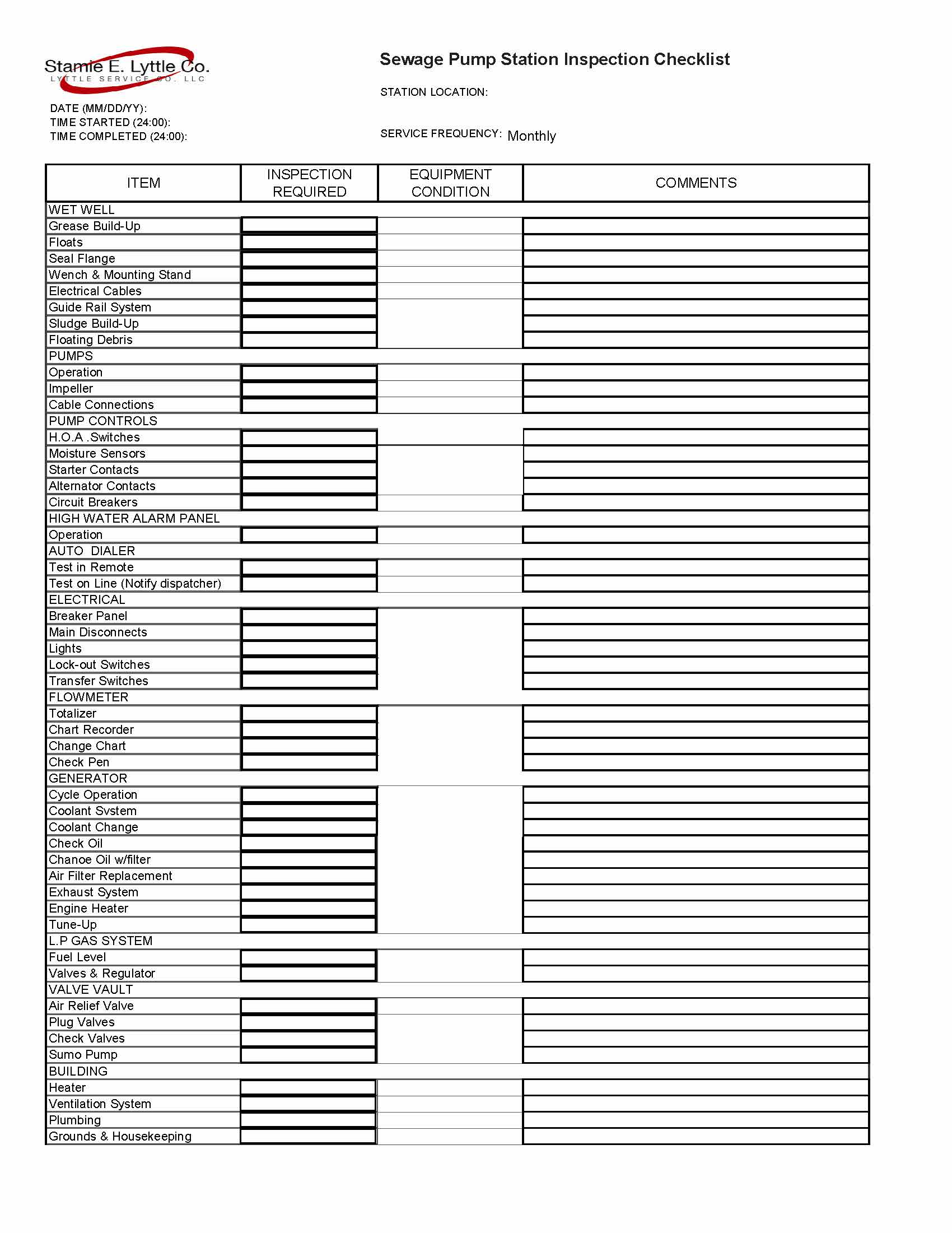

Pump maintenance is the process of keeping your pumps in good working condition. A thorough checklist that guides the maintenance engineer for pump maintenance can be very beneficial as pump maintenance is essential to keep your pumps running smoothly and prevent them from breaking down. This includes regularly checking and cleaning your pumps and replacing any parts that are worn out.

Modern pumps are essential equipment in the industrial and manufacturing sectors. These devices allow companies to move liquids and gases from one place to another, which can be crucial to operations. While modern pumps are reliable and rarely need maintenance, they require some attention over time.

The ideal way of classifying pump maintenance is through the method used for drawing out the maintenance plan. Based on this, the following are the four significant types of pump maintenance:

Corrective maintenance is the most reactive type of pump maintenance, and it involves repairing or replacing parts as needed to keep a pump functioning properly. While this approach may be necessary for some situations, it is often not ideal due to its high cost and disruption of operations.

Preventive maintenance is another common approach to pump maintenance that focuses on proactive measures such as regular inspections and adjustments. This can help avoid potential problems and keep pumps operating at peak efficiency. Using a reliable checklist for pump maintenance, engineers conduct a thorough checking and carry out the needful maintenance as and when needed. This approach is widely used in industries.

Predictive maintenance uses advanced sensors and equipment to monitor the condition of pumps and other components in real-time. This enables users to detect potential problems before they become serious issues that require extensive repairs or replacements. However, this type of maintenance is cost-intensive and unsuitable for small-scale pump systems.

This type of pump maintenance is a newer type of pump maintenance that uses data collected from sensors to assess the condition of pumps and other equipment. This information is then used to develop a customized maintenance plan tailored to the equipment’s specific needs. This approach can be more effective than traditional pump preventive maintenance plans and can help to reduce downtime and costs. But setting up a CBM system can prove to be a costly affair.

Whether you are using one of these approaches or a combination of them, it is essential to ensure that your pump maintenance program is adequately designed and implemented to optimize the performance and longevity of your pumps. Pump maintenance plans are also created based on the system they target, including mechanical, electrical, and hydraulic. Mechanical maintenance typically involves replacing parts that have worn out or broken down due to normal wear and tear. Electrical pump maintenance requires checking the wiring for any signs of damage and replacing fuses if necessary. And hydraulic pump maintenance may involve changing fluid levels or upgrading the oil viscosity depending on the level of use.

The strength and effectiveness of your pump preventive maintenance plan depending on how robust your checklist is. While you would want to include all possible checks in the plan, it is impractical and inadvisable for all routine checks. Therefore the checklist is divided based on the frequency of checks making it more sustainable and effective:

Please note that the pump preventive maintenance schedule for each pump would depend on its design and application, and hence you should always consult the pump manufacturer for the same. However, the above checklist is a general checklist that can guide the process of pump preventive maintenance. A well-maintained pump will last longer and perform better than one not correctly cared for.

Check the manufacturer’s recommendation for service interval schedules. Depending on the type of pump, different servicing may be required at different intervals.

Maintain the proper records for all pump maintenance activity. Good data collection will give you the correct information about the pump’s health and operational condition.

Based on the checklist, pump maintenance may seem a simple task that needs to be done regularly. However, this is not true. Understanding the pump behaviour and performing suitable maintenance activities requires years of experience. Therefore, it is always advisable to hire a qualified expert to carry out pump maintenance due to the following reasons:

Safety – Pump maintenance through a qualified expert, ensures that all safety hazards are identified and eliminated. This keeps you, your equipment, and your employees safe from harm.

Efficiency – Qualified experts know how to service and maintain pumps to operate at peak efficiency. This can save you money on your energy bills and help prolong the life of your pump.

Peace of Mind – Pump maintenance can be a complex task. By entrusting it to a qualified expert, you can rest assured that the job will be done correctly and on time.

Avoid Downtime – Downtime is costly, both in terms of lost productivity and repair costs. Pump maintenance through a qualified expert can help minimize the risk of unexpected downtime.

Compliance – Pump maintenance through a qualified expert can help ensure that your pump complies with all relevant safety and environmental regulations. This can save you from costly fines or penalties.

The majority of reliable pump manufacturers offer pump maintenance as a part of their service. Therefore, it is always a good practice to hire them to execute the pump maintenance of your site. They will also be able to create an effective schedule and an exhaustive checklist that your site engineers can follow for pump inspection. Ensuring that pump preventive maintenance is done at the right time in the right way will make your overall system more reliable and efficient.

The PZ 2400 features a Y-shaped module design, meaning less stress is placed on the pumps internal components and higher flow rates can be achieved with improved fatigue life.

8613371530291

8613371530291