mud pump module inspection pricelist

Explore a wide variety of mud pump price list on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mud pump price list are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mud pump price list is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mud pump price list for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mud pump price list to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

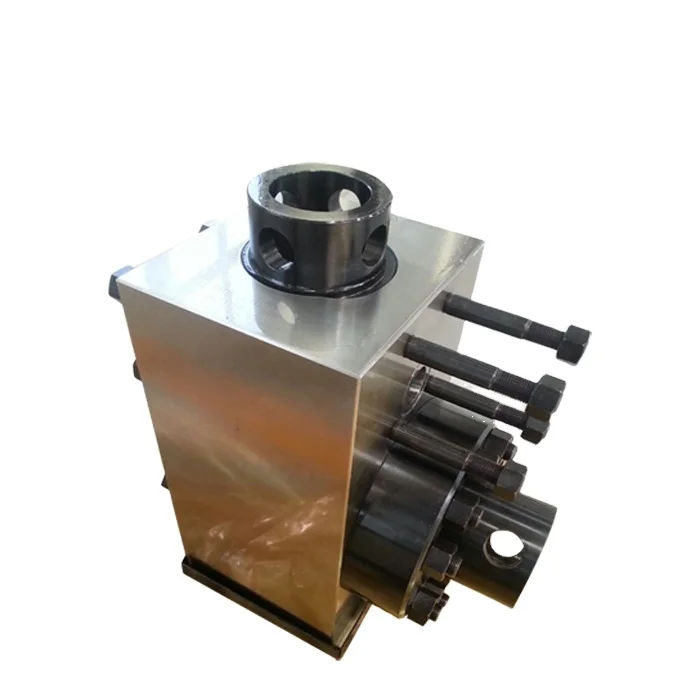

Explore a wide variety of mud pump modules on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These mud pump modules are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these mud pump modules is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right mud pump modules for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of mud pump modules to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

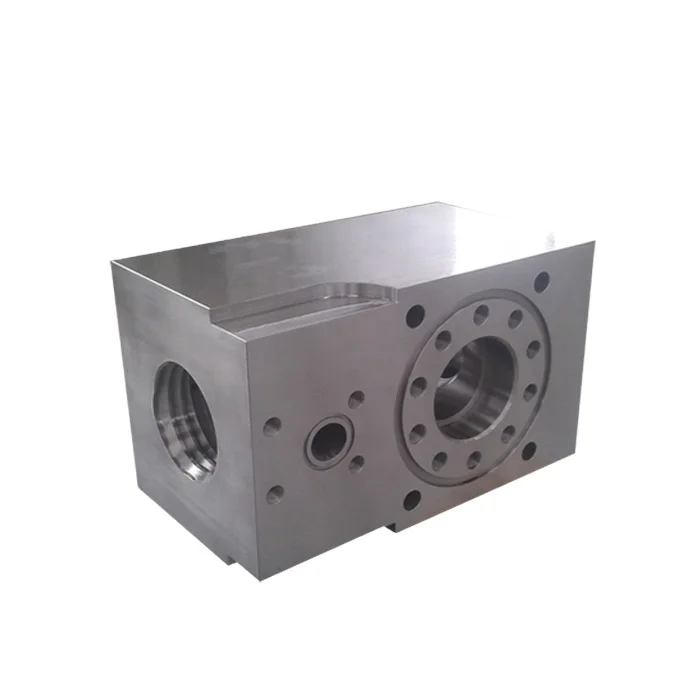

During the production cycle, these Fluid Ends have strictnon-destructive testing, as ultrasound inspectionsandpenetrant tests to ensure the ultimate suitability.

14 P-220 Mud Pumps 3 available completely overhauled. The pumps have been machine inspected and all data will be provided. These 2200 HP pumps complete with Southwest fluid end modules which have been reworked and pressure tested by Southwest and P-QUIP liner retention systems. The drives can be set up for AC or DC power. All Master Rig equipment meets or exceeds O.E.M. standards and a complete data pack is furnished with purchase. Please call if you have any questions.

READY TO SHIP - Three (3) completely refurbished 1600 HP Continental Emsco 7500 PSI Mud Pump Packages - liner spray system, suction manifold and dampener, discharge strainer cross, reset relief valve, 20 gallon pulsation dampener, 75 HP charge pump, two (2) GE 752 1000 HP rear mounted motors, 10 HP blower, mounted on a 3 runner skid with loading hitches and much more. Units come with complete data books and have been tested. MRI is a API facility and units comply with API standards.

Duplex mud pump package completely refurbished and never operated. Tri-Services Manufacturing TSM-500 pump, CAT engine. Data book provided with complete refurbishment details.

You are viewing three (3) fully reconditioned National Oilwell 12P160 Triplex Mud Pumps for sale by Pickett Oilfield, LLC. These National 12-P-160 Mud Pumps are Rebuilt and Ready to go to work.

Some refurbishments include: Fully reconditioned mud pump assembly. Pinion shaft assembly complete with new SKF bearings and new seals. Pump internals painted with Oil Resistant 2 Part epoxy Jotun Tank guard. MPI inspection of all critical areas of pump frame. MPI of all load path components of Crankshaft and Pinion shaft assemblies, and all new Southwest Premium “L” Shape 6,000 psi Fluid End Modules. A full Data Pack with all dimensional control & MPI reports will be furnished.

Warranty on National 12-P-160 Triplex Mud Pumps: All new parts fitted come with a 12 month warranty or such as offered by the part manufacturer; The refurbished GE-752 traction motors come with an 18 month warranty.

Pickett Oilfield, LLC offers prospective buyers an extensive selection of quality new, used, and refurbished Oilfield Drilling Equipment at competitive prices, including Triplex Mud pumps.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

We know that cost savings on identical spare parts is important for offshore rig Companies today. Therefore we provide our services and spare parts at considerable cost reductions compared to sourcing from the major OEMs. Tratec can guarantee identical parts with all required part certificates. We maintaing the highest quality, using state-of-the art service facilities and experienced, specialist mud pump engineers for service work.

Tratec has supplied more than 20 mud pump spare part, overhaul and recertification projects the last 5 years. References include rig companies Odfjell Drilling, Maersk Drilling, Archer, Saipem, KCA Deutag, and others.

Tratec can supply overhaul and parts compatible with the following Mud Pump makers and trademarks: National Oilwell Varco (NOV), MHWirth, Continental Emsco, Gardner Denver, Lewco, Drillmec, and others. Tratec is an independent supplier of drilling equipment parts. Tratec is neither a licensee, nor is affiliated with any of the named original equipment manufacturers (OEM). The manufacturer’s names, equipment names, or trademarks used herein are solely for identification purposes, and are not intended by Tratec to cause confusion as to the source, sponsorship, or quality of the parts supplied by Tratec. The original equipment manufacturers named above and throughout this website do not sponsor, promote, warranty or endorse Tratec’s supply of parts.

Mud Pump Fluid End Module is forged by high-quality alloy steel 35CrMo or 40CrMnMo. It has no defects such as interlayer, crack, impurity, looseness and over-burning. Welding is not allowed. The Mud Pump Fluid End Module is in full compliance with API7K standard and is inspected according to the third-grade forging and internal hardening treatment, high durability. Above process is strictly checked and strict non-destructive testing.

Black gold is truly the best description to sum up the value of oil. One of the most important contributors to change and industrialization, it drives the wheels of progress. ShalePumps is headquartered in Houston, the global oil capital. Headed by experts, it has a vision to support the industry with superior completion equipment. Frac operators, drilling contractors and well service companies source rely on ShalePumps for superior quality.

The key personnel of ShalePumps have a combined experience of more than a hundred years. This experience is reflected in the quality of our equipment. The fracking pumps, components and all services are much sought after for reliability and long life. This is because of the processes we follow. The design, materials, precision engineering and expertise contribute to an advanced assembly line.

After many years of thought and conscientious engineering, the team at ShalePumps is proud to add the Q5K™ 5000 HP Frac Pump to their list of many product offerings. Perfectly capable and suited for the next generation of hydraulic fracking market demands and technology. The Q5K is the only frac pump that has been designed and developed from the ground up to be capable of accepting true 5000 HP in a continuous duty frac application.

ShalePumps has consistently delivered high quality completion equipment to all stakeholders. The mission is to develop faster, rugged and efficient equipment to help the Oil and Exploration Industry. The vision is to continue leading the race with the best quality in completion equipment.

NOV 12-P-160 Mud Pump is rated at 1600 input horsepower (1193 kw) at 120 strokes per minute, with a 12-inch (304.8 mm) stroke. Multiple liner sizes allow pressures and volumes to handle circulation requirements in deep drilling applications.

Flexibility: Compact engineering provides higher efficiency in less space. The NOV 12-P-160 Triplex Mud Pump light weight and flexible design make it easily adaptable to a variety of rig configurations. This provides flexibility as drilling requirements and conditions change.

Fluid End Modules: NOV offers a choice of fluid end modules and valve covers for every P Series pump model to select the fluid end module that exactly matches drilling requirements. All pump models can be equipped with either the standard or premium forged, two-piece interchangeable fluid modules

The mud pump piston is a key part for providing mud circulation, but its sealing performance often fails under complex working conditions, which shorten its service life. Inspired by the ring segment structure of earthworms, the bionic striped structure on surfaces of the mud pump piston (BW-160) was designed and machined, and the sealing performances of the bionic striped piston and the standard piston were tested on a sealing performance testing bench. It was found the bionic striped structure efficiently enhanced the sealing performance of the mud pump piston, while the stripe depth and the angle between the stripes and lateral of the piston both significantly affected the sealing performance. The structure with a stripe depth of 2 mm and angle of 90° showed the best sealing performance, which was 90.79% higher than the standard piston. The sealing mechanism showed the striped structure increased the breadth and area of contact sealing between the piston and the cylinder liner. Meanwhile, the striped structure significantly intercepted the early leaked liquid and led to the refluxing rotation of the leaked liquid at the striped structure, reducing the leakage rate.

Mud pumps are key facilities to compress low-pressure mud into high-pressure mud and are widely used in industrial manufacture, geological exploration, and energy power owing to their generality [1–4]. Mud pumps are the most important power machinery of the hydraulic pond-digging set during reclamation [5] and are major facilities to transport dense mud during river dredging [6]. During oil drilling, mud pumps are the core of the drilling liquid circulation system and the drilling facilities, as they transport the drilling wash fluids (e.g., mud and water) downhole to wash the drills and discharge the drilling liquids [7–9]. The key part of a mud pump that ensures mud circulation is the piston [10, 11]. However, the sealing of the piston will fail very easily under complex and harsh working conditions, and consequently, the abrasive mud easily enters the kinematic pair of the cylinder liner, abrading the piston surfaces and reducing its service life and drilling efficiency. Thus, it is necessary to improve the contact sealing performance of the mud pump piston.

As reported, nonsmooth surface structures can improve the mechanical sealing performance, while structures with radial labyrinth-like or honeycomb-like surfaces can effectively enhance the performance of gap sealing [12–14]. The use of nonsmooth structures into the cylinder liner friction pair of the engine piston can effectively prolong the service life and improve work efficiency of the cylinder liner [15–17]. The application of nonsmooth grooved structures into the plunger can improve the performance of the sealing parts [18, 19]. The nonsmooth structures and sizes considerably affect the sealing performance [20]. Machining a groove-shaped multilevel structure on the magnetic pole would intercept the magnetic fluid step-by-step and slow down the passing velocity, thus generating the sealing effect [21–23]. Sealed structures with two levels or above have also been confirmed to protect the sealing parts from hard damage [24]. The sealing performance of the high-pressure centrifugal pump can be improved by adding groove structures onto the joint mouth circumference [25]. The convex, pitted, and grooved structures of dung beetles, lizards, and shells are responsible for the high wear-resistance, resistance reduction, and sealing performance [26–28]. Earthworms are endowed by wavy nonsmooth surface structures with high resistance reduction and wear-resistance ability [29]. The movement of earthworms in the living environment is very similar to the working mode of the mud pump piston. The groove-shaped bionic piston was designed, and the effects of groove breadth and groove spacing on the endurance and wear-resistance of the piston were investigated [30]. Thus, in this study, based on the nonsmooth surface of earthworms, we designed and processed a nonsmooth striped structure on the surface of the mud pump piston and tested the sealing performance and mechanism. This study offers a novel method for prolonging the service life of the mud pump piston from the perspective of piston sealing performance.

The BW-160 mud pump with long-range flow and pressure, small volume, low weight, and long-service life was used here. The dimensions and parameters of its piston are shown in Figure 1.

A mud pump piston sealing performance test bench was designed and built (Figure 3). This bench mainly consisted of a compaction part and a dynamic detection part. The compaction part was mainly functioned to exert pressure, which was recorded by a pressure gauge, to the piston sealed cavity. This part was designed based on a vertical compaction method: after the tested piston and the sealing liquid were installed, the compaction piston was pushed to the cavity by revolving the handle. Moreover, the dynamic detection part monitored the real-time sealing situation and was designed based on the pressure difference method for quantifying the sealing performance. This part was compacted in advance to the initial pressure P0 (0.1 MPa). After compaction, the driving motor was opened, and the tested piston was pushed to drive the testing mud to reciprocate slowly. After 1 hour of running, the pressure P on the gauge was read, and the pressure difference was calculated as , which was used to measure the sealing performance of the piston.

To more actually simulate the working conditions of the mud pump, we prepared a mud mixture of water, bentonite (in accordance with API Spec 13A: viscometer dial reading at 600 r/min ≥ 30, yield point/plastic viscosity radio ≤ 3, filtrate volume ≤ 15.0 ml, and residue of diameter greater than 75 μm (mass fraction) ≤ 4.0%), and quartz sand (diameter 0.3–0.5 mm) under complete stirring, and its density was 1.306 g/cm³ and contained 2.13% sand.

Figure 4 shows the effects of stripe depth and angle on the sealing performance of mud pump pistons. Clearly, the stripe depth should be never too shallow or deep, while a larger angle would increase the sealing performance more (Figure 4).

The standard piston and the bionic piston were numerically simulated using the academic version of ANSYS® Workbench V17.0. Hexahedral mesh generation method was used to divide the grid, and the size of grids was set as 2.5 mm. The piston grid division is shown in Figure 8, and the grid nodes and elements are shown in Table 3. The piston cup was made of rubber, which was a hyperelastic material. A two-parameter Mooney–Rivlin model was selected, with C10 = 2.5 MPa, C01 = 0.625 MPa, D1 = 0.3 MPa−1, and density = 1120 kg/m3 [32, 33]. The loads and contact conditions related to the piston of the mud pump were set. The surface pressure of the piston cup was set as 1.5 MPa, and the displacement of the piston along the axial direction was set as 30 mm. The two end faces of the cylinder liner were set as “fixed support,” and the piston and cylinder liner were under the frictional interfacial contact, with the friction coefficient of 0.2.

The piston surface flow field was numerically simulated using the CFX module of the software ANSYS® Workbench V17.0. The side of the lips was set as fluid inlet, and the other side as fluid outlet, as shown in Figure 11. The inlet and outlet were set as opening models, and the external pressure difference between them was 0 Pa. The moving direction of the piston was opposite to the fluid flow direction. The fluid region was divided into grids of 0.2 mm, while the striped structures were refined to grade 2.

To better validate the sealing mechanism of the bionic striped pistons, a piston’s performance testing platform was independently built and the sealed contact of the pistons was observed. A transparent toughened glass cylinder liner was designed and machined. The inner diameter and the assembly dimensions of the cylinder liner were set according to the standard BW-160 mud pump cylinder liners. The sealing contact surfaces of the pistons were observed and recorded using a video recorder camera.

(1)The bionic striped structure significantly enhanced the sealing performance of the mud pump pistons. The stripe depth and the angle between the stripes and the piston were two important factors affecting the sealing performance of the BW-160 mud pump pistons. The sealing performance was enhanced the most when the stripe depth was 2 mm and the angle was 90°.(2)The bionic striped structure can effectively enhance the contact pressure at the piston lips, enlarge the mutual extrusion between the piston and the cylinder liner, reduce the damage to the piston and cylinder liner caused by the repeated movement of sands, and alleviate the abrasion of abrasive grains between the piston and the cylinder liner, thereby largely improving the sealing performance.(3)The bionic striped structure significantly intercepted the leaked liquid, reduced the leakage rate of pistons, and effectively stored the leaked liquid, thereby reducing leakage and improving the sealing performance.(4)The bionic striped structure led to deformation of the piston, enlarged the width and area of the sealed contact, the stored lubricating oils, and formed uniform oil films after repeated movement, which improved the lubrication conditions and the sealing performance.

The bionic striped structure can improve the sealing performance and prolong the service life of pistons. We would study the pump resistance in order to investigate whether the bionic striped structure could decrease the wear of the piston surface.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

Yes. We use third-party companies to provide best quotations for your shipment and inspection of manufactured goods. We make sure that you get quality products from the manufacturer at the best price.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Fluid-End Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mud-Pump Gear Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8613371530291

8613371530291