mud pump motor commissioning made in china

We can design and manufacture utilized mud pump packages at customers’ requirement. Our unitized mud pump packages include power, transmission and mud pump, and they are ready to work after installation and commissioning at site.

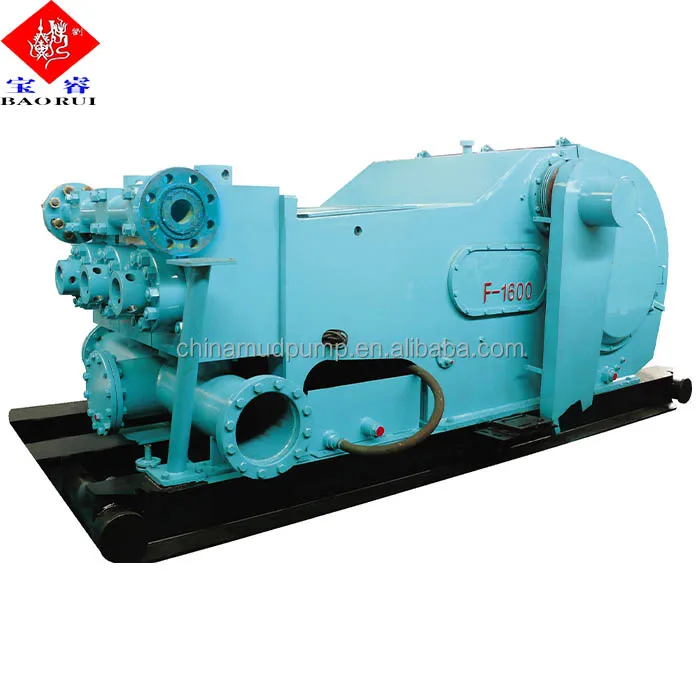

1). F series mud pump are applicable to the requirement of high pump pressure in oilfield and high displacement technology of well drilling with its solid and compact structure,small volume and out-standing operation performance.

2). F series mud pump has a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of expendable parts in the fluid end greatly. The suction pulsation dampener has an advanced structure which is reliable to use and can make the pump realize its best suction performance.

3). The power end of F series mud pump adapts combined lubricating system of forced lubrication and splash lubrication. Reliable to lubricate and increased the service life of power end.

1). The whole unit is in the form of “L”. The transmission way: the power from the diesel engine (KTA19-C700) is transferred throughNT-1041four-shift gear box and cardan shaftto drive the pump and makes it work. The charging pump will greatly strengthen the suction effect of the mud pump.

2). Thepower and transmission systemis assembled on the same skid, which brings great convenience to the transportation, assembling and commissioning.

Using advanced inspection and scanning equipment, we create 3-D models of existing components. Our design team verifies the critical features and properties of the parts to ensure the original design intent is maintained or improved. We can also offer upgraded designs or materials to improve the reliability of your existing pump and motor. Utilizing advanced 3-D models reduces the manufacturing time for replacement parts, allowing for quicker turnaround.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

▅ The max pressure for F500, F800, F1000 pump is 34.5MPa (5000PSI). These pumps are small, light and reliable. They are the best choices for shallow well and mid-deep well drilling rigs.

▅ The max pressure for F1300/1600, F22000 pump is 34.5MPa (5000PSI). These pumps are the best choices for mid-deep well and deep well drilling rigs due to its large displacement and high reliability.

▅ The max pump pressure for F1600HL and F22000HL pump is 34.5MPa (5000PSI), and the max displacement can reach 51.85L/S and 77.65L/S respectively. It is the best choice for deep well, super deep well, large displacements horizontal well, high pressure jetbit drilling, off-shore platform and other drilling rigs.

▅ The F1 series light weight pump is a new product. Under approximately equivalent power, displacement, pump pressure, and other basic conditions, the pump is 20% to 25% lighter than same model of F series. Meanwhile, all fluid end parts are forgings with outstanding quality. This pump is used when size and weight of drilling rigs are highly demanding, such as offshore platform drill rigs.

▅ QDP-3000 drilling mud pump is the largest power of quintuplex drilling mud pumps and pump package. The max pressure is 51.7MPa (7500PSI), and the largest displacement is 76.34L/S. The largest displacement under the max pump pressure reaches 55.08L/S, and the max pressure under the largest displacement is 27.0MPa, making it work better than similar products. Without pulsation dampener, the displacement and pressure fluctuation of this quintuplex pump is only about one third of triplex pump. The fluctuations are even less when pulsation dampener is installed. The pump package is inspired by ideas of modular and skid-mounted design, endowing it with reasonable layout, smooth operation, high transmission efficiency and reliability. This pump is particularly suitable for offshore platform purpose.

▅ Permanent magnet motor direct drive pump and pump package possess qualities of small volume, light weight, simple and reliable transmission, and high efficiency. It is a new energy-saving product, and also one of the developing trends for future drilling mud pump products.

Our pump manufacturing facility owns advanced paint coating production line, complete assembly production line and excellent mechanical processing equipment. There are 283 sets of various types of equipment altogether. Below are the high-lights:

The large-scale boring & milling machines group which includes XKA2840X160 CNC gantry moving milling machine, SKODA W250HD/W250G/W200G boring-milling machine, Speedram2000 CNC boring-milling machine, G60F CNC floor-type boring-milling machine and PAMA boring-milling machine. It is mainly responsible for boring and milling of drilling mud pump parts and large structural parts.

The drilling mud pump assembly line is equipped with advanced assembly tools, assembly facilities and skilled operators. There is a drilling mud pump test base. It is mainly responsible for the assembly, pressure test and factory test of the pumps.

To meet the needs of customers in a better way, our pump manufacturing facility take “customer satisfaction” as tenet and has been providing repair, test and on-site services of drilling mud pumps globally for a long time. Below are our commitments to the customers:

features 2-stage, 44 to 1 gear reduction with a large diameter output gear and heavy duty ball bearing construction. Often referred to as Mud pumps or Sludge pumps, diaphragm pumps are designed to pump mud, slurry, sewage, and thick liquids that have the ability to flow. Koshin Diaphragm pump Honda GX120 OHV gasoline engines. Built-in molded polyurethane flapper/check valve assures self-priming to 20 feet after initial prime. Each unit includes a 3" NPT steel suction strainer, two 3" NPT nipples, and wheel kit with 10" semi-pneumatic transport wheels for portability. Pumps are designed for use with non-flammable liquids which are compatible with pump component materials. Suction and discharge port size cannot be reduced.

Suction and discharge port size cannot be reduced. Due to positive pumping action of diaphragm pumps, by all mfr"s, the discharge is recommended to only be 25FT long unless oversized. Discharge can not be restricted. There is no relief valve.

On December 21nd, two F1600L Mud Pumps, designed and manufactured by ZPEC for CNOOC Ltd., successfully passed the third-party BV acceptance and were shipped from the ZPEC Shanghai Headquarters. This is the second time that ZPEC cooperated with CNOOC to supply offshore platforms, marking ZPEC’s solid steps on its way to entering the high-end oil service market.

The F1600L Mud Pump serves the CNOOC Oil Canxue Offshore Platform. The site is located in the East China Sea, 400 kilometers east of Zhoushan. The Equipment Group relies on strong technical research and development capabilities according to the offshore platform operating environment and safe lifting requirements. These tailored two mud pump sets include a modular design. The single piece does not exceed 13 tons and it meets the requirements of drilling platform hoisting operations. The appearance has a blue coating and is resistant to marine salt spray corrosion. The main components of the product, such as pump body, motor and lock, have passed CCS certification.

During the production and commissioning of the CNOOC F1600L Mud Pumps, the company was in the resolute battle phase of the Sino-Tharwa Project. The time was tight and the task was heavy. The leaders of Group attached great importance to it to ensure product quality and delivery time while closely cooperating. The project team prepared operational plans, clarified responsibilities, and tracked and implemented each link and step one by one. During the equipment joint debugging test stage, the machine ran continuously for 24 hours without stopping. In order to deliver the products as scheduled, the people of ZPEC carried forward “the spirit of iron-blooded journey" and worked continuously for 24 hours throughout the night, finally ensuring the project was completed on time.

The re-delivery of the CNOOC F1600L Mud Pumps mark a historic leap made by ZPEC in the field of offshore engineering equipment manufacturing and the ability of ZPEC to manufacture offshore engineering equipment is a major breakthrough.

The structural features and properties of F series mud pumps are more advanced. Wearing parts of fluid end can be universally used with those of API standards.

F series mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

This series of pumps is manufactured strictly in accordance with API Spec 7K Drilling and Workover Equipment Specifications and carried out delivery test in accordance with the standard.

equipment in China, is the earliest established, largest and most powerful oil drilling rig and production equipment developer and manufacturer under CNPC, the largest research and production base of land rigs and series mud pumps in the world, and also the largest and most powerful base for R&D and production of wire ropes for special purposes in China.

The company owns five subsidiaries totally in home and abroad, with 3600 employees. Company headquarter is located in Deyang City, Sichuan, a heavy-duty equipment base in China, which covers an area of about 1,000 mus, and with more than 2,200 employees, annual output of 150 drilling rigs and 600 mud pumps etc. Its production capacity is up to 8 billion RMB production scale.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electric rig, mechanical drilling rig, composite drive rig, trailer mounted rig and independent RT electric drive drilling rig, as well as their matched equipments, i.e. drilling pumps, traveling block system, solid control system, electric control system etc.

Our company Shandong Kerui Holding Group is located in Shengli Oilfield the second largest oilfield in China. Our company arranges a wide range of businesses covering the scientific research and manufacture of the petroleum drilling equipment and oilfield engineering technical service. The main products manufactured and supplied include drilling equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China.

The main products manufactured and supplied include oil drilling rig equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China

From inspection and maintenance to pumps and motors, complete rotor balancing, mechanical repairs, Sulzer Shanghai Service Center can provide a wide range of hydraulic, mechanical and metallurgical problems.

Our skilled field technicians are ready for on-site overhauls, installation and commissioning work plus machinery diagnostics and troubleshooting of pumps, motors and generators onshore and offshore.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

8613371530291

8613371530291