mud pump motor commissioning brands

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Distributor of heavy duty submersible mud, sand, sludge & slurry pumps. Specifications of pumps include 5 hp to 30 hp motor, three phase, 208 V to 575 V, 6.8 A to 39 A, 3 in. to 6 in. NPT sizes, 38 ft. to 134 ft. head size & 475 gpm to 1,690 gpm flow rate. Features include impellers, wear plates & agitators made from abrasive resistant 28 percent chrome iron, process hardened ductile iron volutes casted with thick walls, class H motor insulation, double silicon carbide mechanical seals, heavy duty lip seal & stainless steel shaft & shaft sleeve. Sand, sludge & slurry pumps are used in mines, quarries, dredging, coal & ore slurries, sewage treatment plants & steel mills. UL listed. CSA approved. Meets OSHA standards.

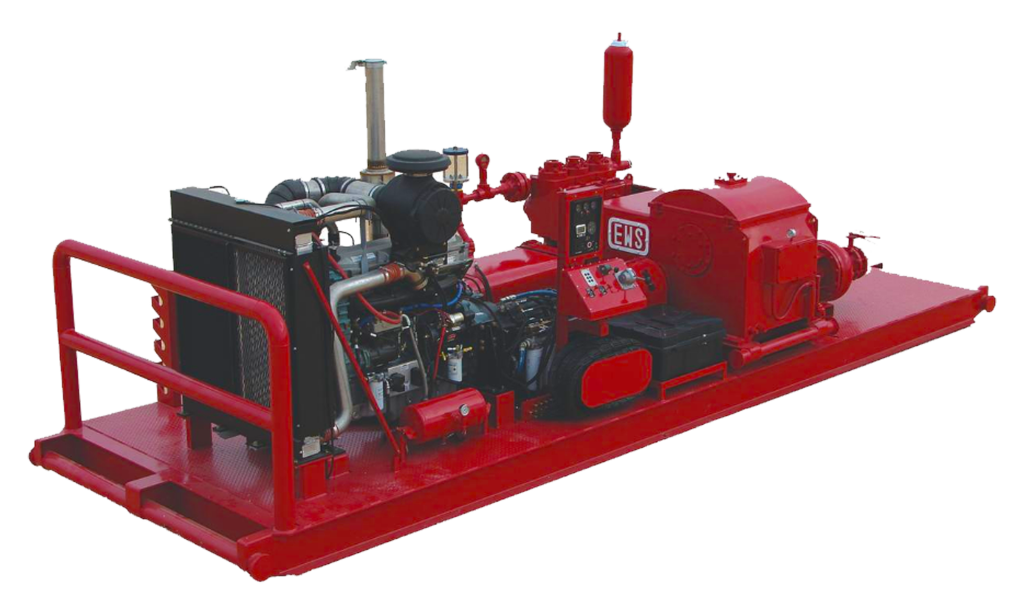

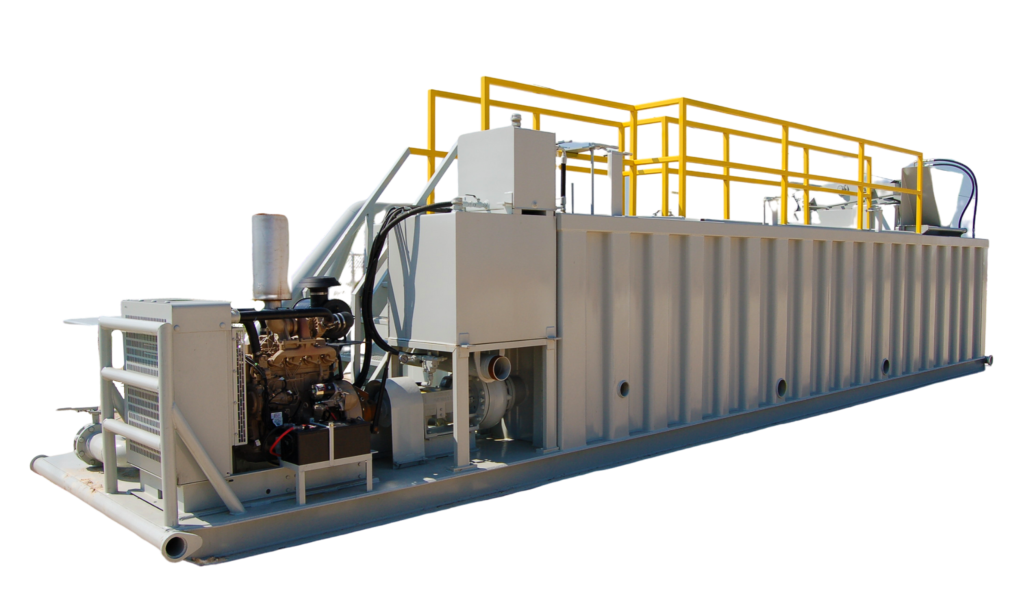

Having a quality mud pump is a critical part of keeping your oil well drilling system running as smoothly as possible. Dragon carries a wide range of mud pumps for systems of all kinds and jobs of all sizes. We also carry a 50 BPM mud mixing table to make drilling fluid mixing more efficient and accurate so you can always get the job done safely and correctly. View our full well service pump and mud pump selection to find the right system for your job site, or check out the rest of our drilling rigs for even more options.

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

Commissioning refers to the time when a machine or system is used for the first time by the operator, which is only permitted if compliance with the related requirements has been documented in accordance with relevant Manufacturer’s directives.

In the context of centrifugal pump technology, to ensure fault-free pump operation, it is not only the condition of the pump that needs to be taken into account from the time of delivery up until the time of commissioning, but also the condition of all the components that come into contact with it (e.g. foundation).

SEEPEX metering and dosing pumps are a range of precision pumps that have a metering accuracy of +/- 1%. The pumps are found in a variety of industrial and municipal applications and are especially suited for low pulsation delivery of low to viscous media as well as chemically aggressive media and media containing solids.

Optimizing production under dynamic well conditions requires flexible and adaptive electrical submersible pumping (ESP) solutions. ESP pumps from Baker Hughes incorporate innovative hydraulic designs to expand the application range of your ESP systems.

Our flexible pumps have the broadest operating range in the industry to deliver unsurpassed levels of efficiency, reliability, and speed to your production operations. You get customized pumping solutions to improve your operating economics, regardless of your field application.

Self-priming pumps are a specific type of liquid pump designed to have the required liquid inside the cavity or pump body necessary to start the pumping process.This offers the potential for increased operating efficiencies in process plants where pumps are used for a variety of repeated yet intermittent operations.

Some pumps are designed to always have the requisite start-up liquid in the pump’s chamber or body. These are called “self-priming” pumps. Other pumps require the start-up liquid be added to the pump before initiating operation. No one type of pump is intrinsically superior to another: it simply depends on what the pump is used for and how often.

Some types of pumps are engineered to be automatically self-priming.Pumps of this nature feature close tolerance working parts that trap fluids in the pump’s body, preventing them from returning from the discharge side of the pump to the suction side when the pump is not in operation.

In these types of pumps, the constant presence of fluid in the pump’s body allows the pump to better handle what are called “air pockets”. Air pockets are an accumulation of air bubbles in the pump’s working mechanism, which can impair proper pump operation.

For these types of low viscosity fluids, a V-type centrifugal pump design is often preferred, featuring a vacuum pump and positive seal that is located close to the discharge port. This allows a V-type centrifugal pump to readily pull a vacuum until it is full of fluid.

However, standard centrifugal pumps are not designed to be self-priming.Unlike the pump types already described, standard centrifugal pumps do not trap liquids when not in use — although engineered modifications to the pump’s housing may allow some of these types of pumps to be self-priming.

With centrifugal pumps, the pumping action occurs when an impeller is rotated in a liquid within a cavity or chamber of the pump, displacing the liquid and forcing it to flow into the discharge port of the pump via centrifugal force.

Fluids typically enter the pump at the center of the impeller and are discharged via a port on the outer perimeter of the pump’s body. The impeller is often directly coupled to the pump’s motor, in what is called a monoblock design.

Air is the primary enemy of this type of pump. When a standard centrifugal pump encounters air pockets, it can become “air bound”, and refuse to operate. Air intrusion into standard centrifugal pumps is typical, as these types of pumps don’t feature tightly coupled pumping mechanisms such as gears or screws and have no seals between the suction and discharge sides of the pump.

Self-priming centrifugal pumps overcome air binding by initially mixing any residual air in the pump’s working mechanism with fluid during the priming process.

This blending allows the resulting mix to move readily through the pump’s body on initial start-up, removing the air and aiding product flow on the suction side of the pump. The process liquids and any entrained air move toward the impeller, and normal pump operations commence.

In comparison to a standard centrifugal pump, what’s notable in the design of a self-priming centrifugal pump is that it features a liquid reservoir built into the body of the pump, typically either above or in front of the impeller.

This reservoir allows the pump to rid the pump’s body and suction line of air during the priming cycle, replacing it with liquid from the reservoir that is blended into the residual air. The “self-priming” capability of this type of centrifugal pump comes from the ability of the reservoir to retain liquid after its very first prime.

When compared to submersible-type pumps, self-priming centrifugal pumps will continue to pump liquids even after the pump is no longer submerged in a liquid tank or vessel

Due to the need for a liquid reservoir, this type of centrifugal pump can be larger than a standard model, which may cause issues in applications where space is limited

The LKH Prime pump from Alfa Laval is a centrifugal-type self-priming pump that is ideal forCIP operations. The LKH Prime also easily pumps products with entrained air. Once the liquid no longer contains entrained air, you are left with a highly efficient and quiet LKH Pump, one of the most capable centrifugal pumps produced.

For product applications, this pump features an air screw coupled with a highly efficient centrifugal impeller to effectively handle a variety of process media.

The SP Series is a liquid ring pump from Ampco that uses compression chambers to pump, and only uses centrifugal force to seal the chambers with a liquid. It is excellent for CIP return operations and pumping products with entrained air.

The SP Series pump is efficient at emptying tanks and drums, and can handle shear-sensitive products due to its tight manufacturing tolerances and unique impeller shape.

Bornemann’s SLH Twin Screw Pump is a self-priming positive displacement pump best for aseptic processes and applications involving high viscosities, high pressures, or sensitive materials. The variable speed feature of this pump is suited for varying operating conditions.

The C-Series is an eccentric disc pump featuring Mouvex technology. This positive displacement pump uses its strong suction power and ability to run dry to gently and effectively move both liquid and dry products.

The C-Series is available in stainless steel models that carry 3-A approval and are designed to meet EHEDG specifications. This pump can be flushed and cleaned using CIP methodswithout disassembly and can pump both high and low viscosity products with outputs not affected by variations in liquid viscosity.

This guide is intended for engineers, production managers, or anyone concerned with proper pump selection for pharmaceutical, biotechnology, and other ultra-clean applications.

For hygienic processing applications that require the frequent yet intermittent use of liquid pumps, choosing a self-priming pump may be the best solution for ensuring efficient pump operations.We"re here to help!

CSI offers a number of self-priming pumps based on centrifugal, twin screw, and eccentric disc technologies. Contact CSI at (417) 831-1411 to discuss your requirements.

Central States Industrial Equipment (CSI) is a leader in distribution of hygienic pipe, valves, fittings, pumps, heat exchangers, and MRO supplies for hygienic industrial processors, with four distribution facilities across the U.S. CSI also provides detail design and execution for hygienic process systems in the food, dairy, beverage, pharmaceutical, biotechnology, and personal care industries. Specializing in process piping, system start-ups, and cleaning systems, CSI leverages technology, intellectual property, and industry expertise to deliver solutions to processing problems. More information can be found at www.csidesigns.com.

features 2-stage, 44 to 1 gear reduction with a large diameter output gear and heavy duty ball bearing construction. Often referred to as Mud pumps or Sludge pumps, diaphragm pumps are designed to pump mud, slurry, sewage, and thick liquids that have the ability to flow. Koshin Diaphragm pump Honda GX120 OHV gasoline engines. Built-in molded polyurethane flapper/check valve assures self-priming to 20 feet after initial prime. Each unit includes a 3" NPT steel suction strainer, two 3" NPT nipples, and wheel kit with 10" semi-pneumatic transport wheels for portability. Pumps are designed for use with non-flammable liquids which are compatible with pump component materials. Suction and discharge port size cannot be reduced.

Suction and discharge port size cannot be reduced. Due to positive pumping action of diaphragm pumps, by all mfr"s, the discharge is recommended to only be 25FT long unless oversized. Discharge can not be restricted. There is no relief valve.

KBL recently developed a large Vertical Turbine pumpset. It is a single-stage Horizontal Axial Flow Pump developed for use in the Circulation of Fermentation Broth. The pump has a

8613371530291

8613371530291