mud pump pop off valves quotation

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

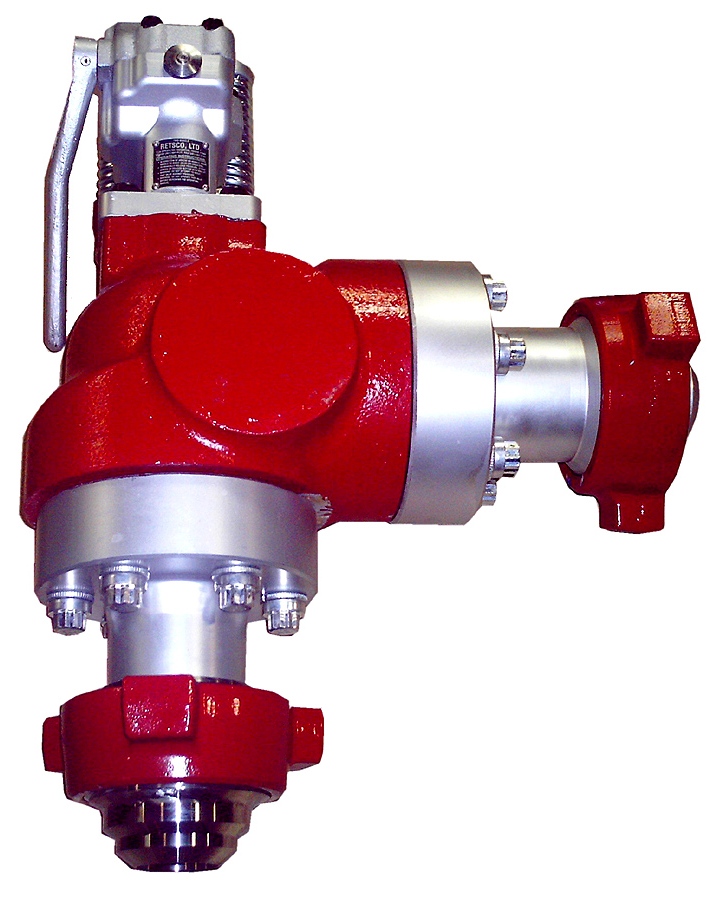

Over-pressurization is a looming factor that can cause significant damage to drills and machinery, making quality drilling pop-off valves a must. Drillmax, Inc. specializes in pop-off and relief valves, ensuring that your equipment is adequately protected during the course of your application.

In fact, since 1996, Drillmax, Inc. has specialized in a wide range of quality gate, float, relief and drilling mud valves. We have built strong ties working with a wide range of clients, including:

We our proud of the fact that our drilling pop-off valves are used all across the world in the industry, providing superior performance and longevity for the clients we service. As an aftermarket manufacturer of drilling mud valves and other components, we are able to offer superior service at a lower price point than OEM.

We offer drilling valve 2” aftermarket replacement parts, along with a wide range of other essentials that ensure your machinery and equipment runs efficiently and with minimal downtime. We offer:

Drillmax Shear Relief valves are known for their dependability and effectiveness and are usually installed on the discharge end of the mud pump. When pressure exceeds the preset limit, the pin is sheared allowing the excess pressure to escape and be re-directed, preventing costly repairs. Different pin diameters are used to set the desired shear pressure. Once the problem is corrected, a new pin can be inserted to reactivate the valve.

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,As well as from energy & mining, construction works , and machinery repair shops. And whether pressure relief valve for mud pump is 1.5 years, 3 months, or {3}.

Relief valve mud pump is also called the centrifugal pump, a compressor, and a compressor. It has a series of pistons, this is done in the form of a centrifugal pump, with a compressor. It is usually used by hydraulic maintenance. The rotating pumps have different cuffs and suction cuffs.@@@@@

Relief valve mud pumps are specially designed for the rotation of the vehicle. There are many types of relief valve mud pumps, suitable for a rotating purpose, such as electric relief valve mud pumps. In the case of the different, pumps are suitable for a rotating process. They are suitable for rotating, there are various sizes and varieties of the pumps depending on the rotation pattern, but with a lesser water flow. On the other hand, there are various types of relief valve mud pumps that are specially designed for use in rotating processes. If the pump is suitable for a rotary motion, these pumps are suitable for a rotary process, and can be used on both sides of the vehicle. On Alibaba.com, there are various types of relief valve mud pumps, such as electric relief valve mud.

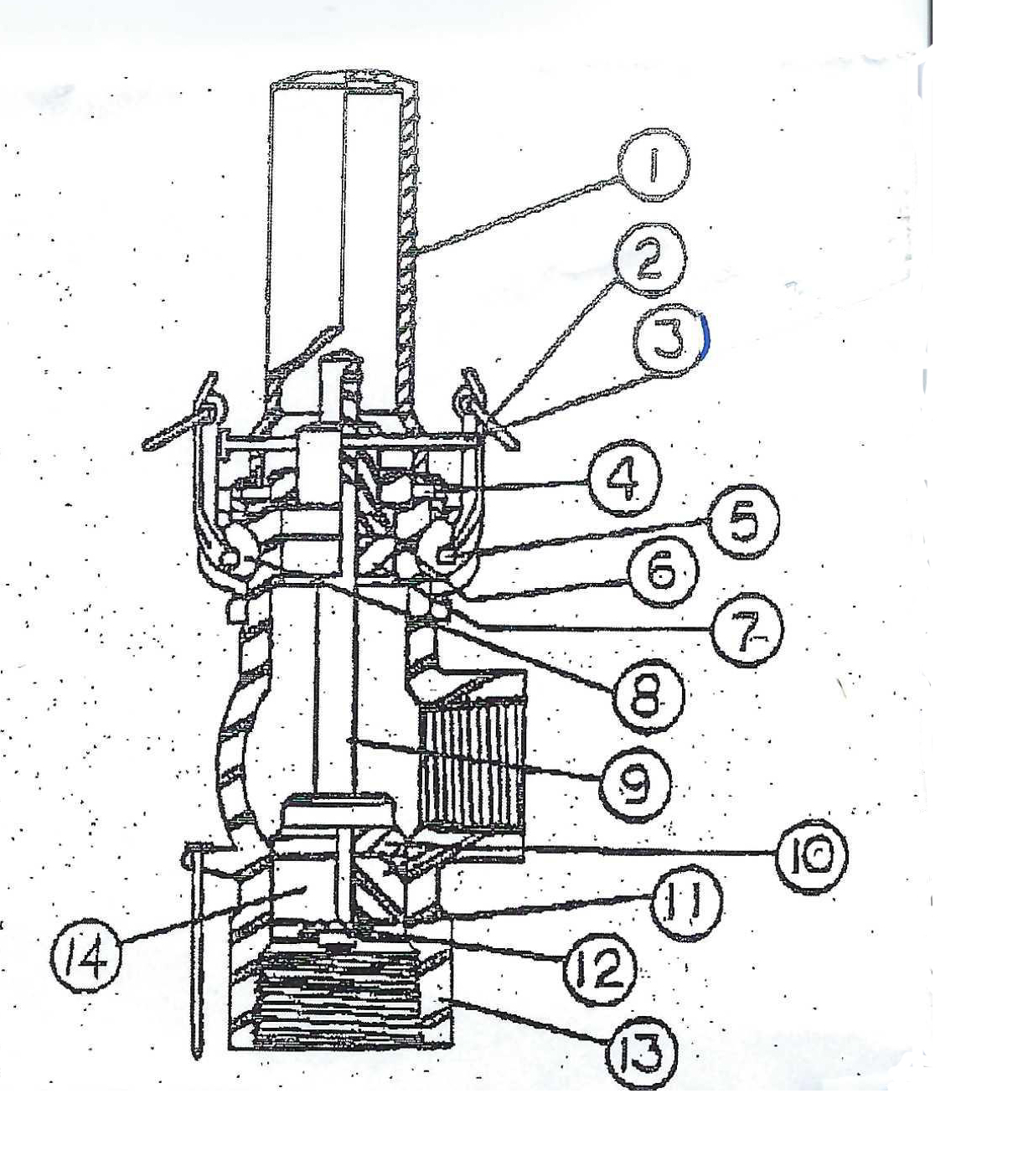

A relief valve is a Valve which is installed on a pump or pipework to relieve excessive pressure in a positive displacement pump which could cause damage to a pump or system. Relief valves (also known as bypass valve or safety valve) are known as an Internal Relief Valve if installed on the pump itself, and if installed on the system they are known as an External Relief Valve.

Such valves are used on positive displacement pumps as the pumps are designed to prevent recirculation of fluid back to the inlet, meaning the displacement is always forward. However if a valve is closed on the outlet of the pump, or a blockage occurs the pump will continue to build pressure in the outlet pipework and within itself. This can cause pressures to reach dangerously high levels, and the pressure will vent at the weakest part of the system, causing a leak, damage or pump failure.

Such valves work in different ways depending on where they are installed. If installed on a pump the fluid is recirculated within the pump head, preventing the buildup of pressure, however the fluid begins to heat up, and is something which should only be done temporarily as it can lead to pump failure. External relief valves should be used in conjunction with internal relief valves to relieve any excessive pressure in the pipework either back to a vented tank or to dump contents in an emergency to atmosphere.

Internal relief valve set pressure is usually set at 10% above the operating pressure of the pump, and external relief valves should be set at 10% higher than the relief valve on the pump to prevent nuisance tripping. Valves are typically calibrated during manufacture and can be set on site with the use of pressure gauges during commissioning. Valves are rated in ranges such as from 0-10 bar, or 10-15 bar so should a valve pressure rating require recalibrating, checks should be made to ensure the setting is inline with the rating of the valve. Equipment should be checked at regular intervals to ensure succesful operation during an emergency.

Relief valves are not always required if the pressure capability of the pump is low, but also if used in conjunction with a product which can solidify when cooled if it enters the relief valve such as Chocolate or Bitumen. If fluid sets within a relief valve this will prevent it from operating as normal as any material which hardens will form a plug and can also cause contamination as it can be very difficult to clean thoroughly.

On some pumps a pressure relief valve is used in conjunction with a pressure regulator which regulates the pump to deliver the required pressure for the system. An analogy often used to describe a pressure regulator is akin to brakes in a car, with and the relief valve being the seat belt. A relief valve should only be relied on for use in emergencies to prevent damage to the pump or system and not as frequent protection for the system.

Valves are to be mounted vertically only. Care should be taken to prevent damage to the seats when placing in form and pouring concrete. Cover and grate should be installed in the body, turned a quarter turn, and tested to be sure cover and grate cannot lift off body.Parts

This relief valve can be used as a primary pressure control device or secondary (safety) pressure relief device. Many systems also use two relief valves, one set as the primary pressure control and the other set as a secondary relief. When used as a secondary pressure relief device, it is typically set approximately 200 PSI above the system pressure and provides additional protection for the pump and high-pressure system.

“OCV and Jim Gibson are the #1 supplier of control valves in our circle of vendors. Their integrity is never compromised as they strive for Complete Customer Satisfaction. Their word is their bond and they live by it. Their intimate knowledge of their products and our industry is unsurpassed and we look forward to many years of a mutually successful relationship as we continue to grow together and discover new markets.”

“Since 1996DakotaPump & Control has partnered with OCV. DPC takes who we represent on our line card very seriously, and we couldn’t be happier with this partnership. OCV has a catalog that covers all our needs, as well as the support a service based company like ours demands. We look forward to whatever valve challenges are presented to us, because we have the right manufacturer that can support us every step of the way.”

“The Otoe-MissouriaTribe of Oklahoma has been doing business with OCV since 1993. We have utilized them for all types of valves, as well as parts. OCV always has the answers. Working with Robert and Jarrod has been a pleasure!”

“A lotof companies preach customer service, but their actions don’t reflect it. That’s not the case when it comes to OCV. I have met many associates at OCV, from Plant to Sales to Engineering – all are focused on taking care of their customers. OCV is expedient in quoting projects and has even been known to troubleshoot valves from other manufacturers and construct valves in an emergency to get a city out of a jam. OCV practices what they preach!”

“D&W has maintained a relationship with OCV as a Rep for 30+ years. Although this industry, and even products, have gone through major transformations over that time, OCV’s dedication to customer service has remained steadfast. From a friendly voice when you call their office, to the expert advice you receive when troubleshooting a problem – OCV sets the standard and no one else comes close.”

“As an inside salesman for a pump company located in Southern Illinois, I am always looking for various pumping related parts and materials. Jim Gibson and the fine folks at OCV Fluid Solutions were ready to meet my needs. The service is great and the price is even better!”

“OCV Control Valves delivered the products on time, made them perform as proposed and helped answer our questions. There was good teamwork all around.”

“Personally having 18 years of verifiable field experience, OCV is very easy to work with. They have knowledgeable tech support, their sales team is exceptional, and there have been no hiccups with lead times. Everyone I talk to at OCV knows the valves and know the equipment they are selling.”

“OCVwas very helpful. Not only did they always answer our questions and make sure the valves were exactly what we needed. but they were also able to provide us with two new pre-set valves in about three to four weeks.”

8613371530291

8613371530291