mud pump pop off valves for sale

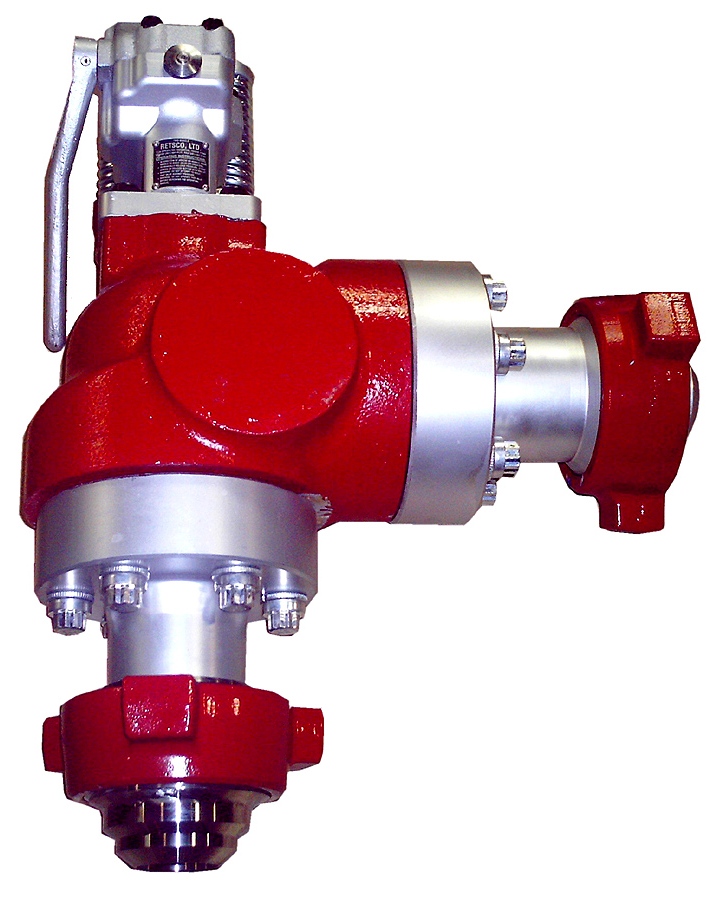

Over-pressurization is a looming factor that can cause significant damage to drills and machinery, making quality drilling pop-off valves a must. Drillmax, Inc. specializes in pop-off and relief valves, ensuring that your equipment is adequately protected during the course of your application.

In fact, since 1996, Drillmax, Inc. has specialized in a wide range of quality gate, float, relief and drilling mud valves. We have built strong ties working with a wide range of clients, including:

We our proud of the fact that our drilling pop-off valves are used all across the world in the industry, providing superior performance and longevity for the clients we service. As an aftermarket manufacturer of drilling mud valves and other components, we are able to offer superior service at a lower price point than OEM.

We offer drilling valve 2” aftermarket replacement parts, along with a wide range of other essentials that ensure your machinery and equipment runs efficiently and with minimal downtime. We offer:

Relief valve mud pump is also called the centrifugal pump, a compressor, and a compressor. It has a series of pistons, this is done in the form of a centrifugal pump, with a compressor. It is usually used by hydraulic maintenance. The rotating pumps have different cuffs and suction cuffs.@@@@@

Relief valve mud pumps are specially designed for the rotation of the vehicle. There are many types of relief valve mud pumps, suitable for a rotating purpose, such as electric relief valve mud pumps. In the case of the different, pumps are suitable for a rotating process. They are suitable for rotating, there are various sizes and varieties of the pumps depending on the rotation pattern, but with a lesser water flow. On the other hand, there are various types of relief valve mud pumps that are specially designed for use in rotating processes. If the pump is suitable for a rotary motion, these pumps are suitable for a rotary process, and can be used on both sides of the vehicle. On Alibaba.com, there are various types of relief valve mud pumps, such as electric relief valve mud.

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,As well as from energy & mining, construction works , and machinery repair shops. And whether pressure relief valve for mud pump is 1.5 years, 3 months, or {3}.

The Model IC valve provides safety for a variety of pressure relief applications including but not limited to: mud, slurry, and fracing fluid relief. The valve relieves pressure to prevent pump, hose and system damage on mud and slurry pump systems – ideal for pulsating pressure. Use instead of nitrogen-assisted valves or ball & spring reset valves where you need greater accuracy and reliability. Our hydraulic fracturing and mud and slurry relief valve ranges are exceedingly popular in the Oil & Gas industry.

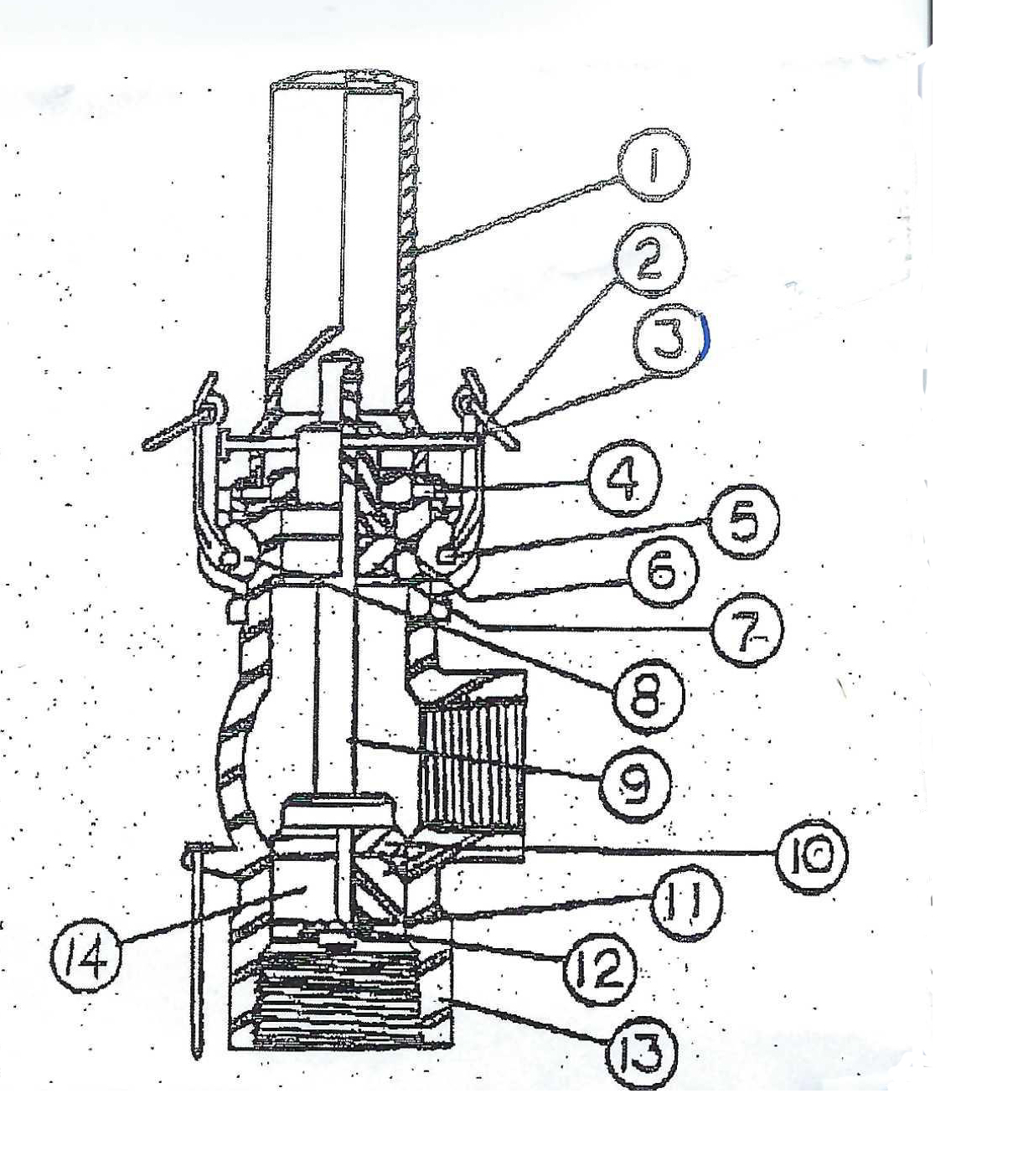

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

All rig mud pump systems use pop-off valves to protect the pump from over pressurization. The best that can be achived with a pop or relief valve is approximately +/- 10% repeatability. On a high pressure system, this can be a significant variance. Although the valves are resettable, they generally go at a lover pressure once tripped and reset. Not WOM’s Pump Saver.

Available up to 10.000 psi, and is more accurate that pop/relief valves. WOM’s Pump Saver features +/- 3% above 3.500 psi. New rupture discs can be easily and quickly replaced.

All rig mud pump systems use pop-off valves to protect the pump from over pressurization. The best that can be achived with a pop or relief valve is approximately +/- 10% repeatability. On a high pressure system, this can be a significant variance. Although the valves are resettable, they generally go at a lover pressure once tripped and reset. Not WOM’s Pump Saver.

Available up to 10.000 psi, and is more accurate that pop/relief valves. WOM’s Pump Saver features +/- 3% above 3.500 psi. New rupture discs can be easily and quickly replaced.

The CORTEC Model CRV Choke Relief Valve (CRV) line offers users the safety, reliability and quick response function required to meet the demands of today’s drilling operations. Our robust designs are manufactured with superior performance and field serviceability in mind. CORTEC Model CRV Choke Relief Valves are compatible with API 6A and NACE MR0175 requirements. Full third-party review is available upon request.

Available with a range of options for orifice sizes, end connections and control methods, CORTEC is certain to have a CRV model to suit your application needs. Whether you’re configuring a deepwater Managed Pressure Drilling (MPD) system, protecting mud pumps or relieving frac systems CORTEC’s CRV line is designed and proven to provide the highest level of reliability in the industry. Hydraulic and pneumatic control packages are configurable to suit customer and project specifications

The pop-off valve is a secondary safety relief valve. If the primary pressure control device fails to bypass set system pressure, the pop-off valve opens, allowing liquid to flow freely. A pop-off valve can save costly pump and system damage, and more importantly, it’s an added safety feature to protect those working around the equipment.

R series proportional relief valves provide simple, reliable, overpressure protection for a variety of liquid or gas general-industry applications with set pressures from 10 to 6000 psig (0.7 to 413 bar). They open gradually as the pressure increases and will close when the system pressure falls below the set pressure. The set pressure can be set at the factory or easily adjusted in the field. PRV series proportional safety relief valves are certified to PED 2014/68/EU Category IV, CE-marked in accordance with the Pressure Equipment Directive as a safety valve according to ISO-4126-1, and factory-set, tested, locked, and tagged with the set pressure.

Swagelok bleed valves can be used on instrumentation devices such as multivalve manifolds or gauge valves to vent signal line pressure to atmosphere before removal of an instrument or to assist in calibration of control devices. Male NPT and SAE end connections are available. Purge valves are manual bleed, vent, or drain valves with NPT, SAE, Swagelok tube fitting, or tube adapter end connections. A knurled cap is permanently assembled to the valve body for safety. Both bleed and purge valves are compact for convenient installation.

Your pressure relief valves (PRVs) are some of the most important pieces of equipment in your plant. They are what protects your systems from overpressure events that can damage your systems and, in some cases, have catastrophic consequences.

8613371530291

8613371530291