mud pump pressure problems supplier

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Working with some of the world"s leading suppliers of low-pressure equipment, we offer low-pressure pump packages and agitating units to suit every operation.

Mud pump is the key equipment in drilling operation. If mud is compared to blood in drilling operation, mud pump is the heart of blood supply in drilling production. Therefore, its importance in drilling production is self-evident, and the spare parts of mud pump play a certain role in this.

Mud pump is a kind of machine which can transport mud or water to drill hole in the process of drilling. It is an important part of drilling equipment. Its main function is to inject mud into the well with the bit, cool the bit, clean the drilling tool, stabilize the well wall, drive the drilling, and bring the cuttings back to the ground after drilling.

In the normal circulation drilling, the mud pump is to send the surface flushing medium - clear water, mud or polymer flushing liquid under a certain pressure through the high-pressure hose, faucet and the center hole of drill string directly to the bottom of the drill bit, so as to cool the drill bit, remove the cuttings and transport them to the surface. The mud pump is driven by the power machine to rotate the crankshaft of the pump. The crankshaft drives the piston to do reciprocating motion in the pump cylinder through the crosshead. Under the alternating action of the suction and discharge valves, the purpose of pressing and circulating the flushing fluid is realized. Different types of mud pumps are used in different cases to ensure the smooth proceeding of the drilling operation.

According to the use of the mud pump, the leakage of the valve box, the burning of the bearing and the abnormal noise are all frequent faults that affect the normal use of the mud pump. Therefore, careful study of the causes of the problem plays a key role in prolonging the service life of the mud pump. At this time, a certain amount of spare parts of the mud pump are needed.

In the process of using the mud pump, the equipment failures caused by specific reasons are different. Reasonable use and maintenance of the equipment can extend the service life of the equipment. At the same time, in strict accordance with the basic elements of normal operation of the drilling pump, "medium power, medium pump pressure, medium speed operation, tight, tight, leak tight, pump pressure does not fluctuate, temperature is normal, sound is normal", the operation can ensure the good operation of the equipment. Of course, it"s also important to find the right mud pump spare parts!

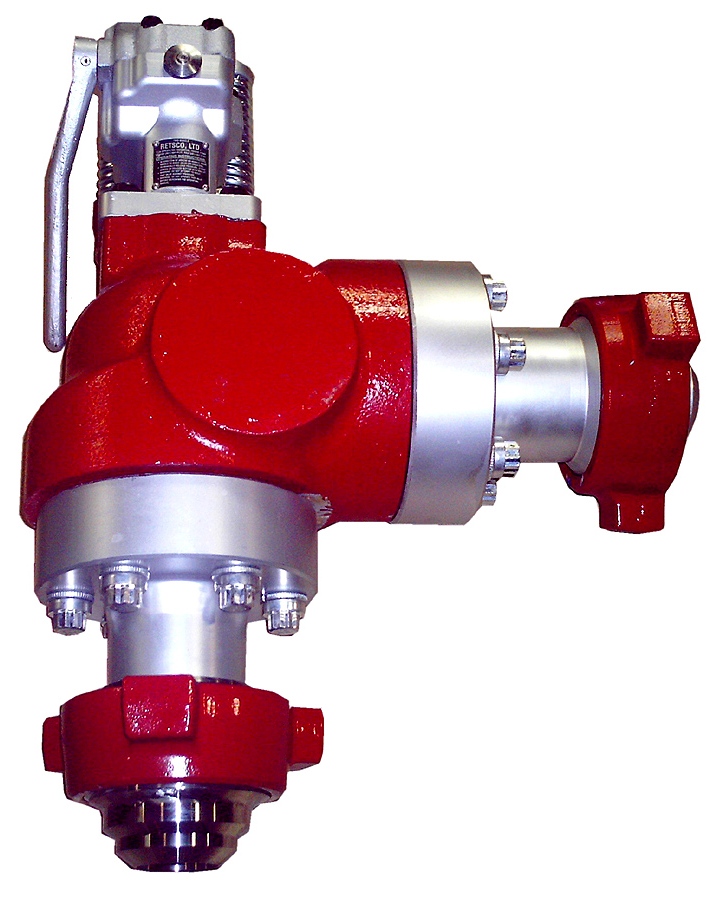

Contact Instruments provides Oilfield Instrumentation that is extremely accurate and widely used in the harshest environments. Our Mud Pressure Gauges and systems are engineered to monitor the pump pressure for a variety of pumps and applications to ensure that you are getting the most out of your drilling fluids.

If you are looking for premium-quality Mud Pressure Gauges and drilling mud pumps for sale, contact World Petroleum Supply, Inc serving the global market.

Mud Pumps come in both electric and gas / diesel engine drive along with air motors. Most of these pumps for mud, trash and sludge or other high solids content liquid dewatering, honey wagon and pumper trucks. Slurry and mud pumps are often diaphragm type pumps but also include centrifugal trash and submersible non-clog styles.

WARNING: Do not use in explosive atmosphere or for pumping volatile flammable liquids. Do not throttle or restrict the discharge. Recommend short lengths of discharge hose since a diaphragm mud pump is a positive displacement type and they are not built with relief valves.

Mud Pump Pressure is extremely important to the drilling process. The Mud Pump Pressure Gauge enables the driller to monitor the pressure while drilling. Any unusual change in pressure will alert the driller of down hole problems. Pressure too low could indicate washed out pipe or bit nozzle, loose joint or broken drill string, worn pump packing or liners, or lost returns due to formation breakdown. Pressure too high could indicate a plugged drill bit or an increase in mud density or viscosity. Reliable indication of mud pump pressure provides an early warning of circulation problems, enabling the driller to make corrections avoiding major problems.

The mud pump pressure gauge is a specialized gauge for mud pumps. It is mainly used for the petroleum, coal, chemical industry, drilling industries. This new model is used in measuring pressure of high viscosity and easy crystal medium. The gauge is also used for measurement of stationary pressure. We provide a full range of gauges. Whether you are looking for it, we can accommodate your needs for land or offshore drilling rigs.

Mud Pump Pressure is extremely important to the drilling process. The Mud Pump Pressure Gauge enables the driller to monitor the pressure while drilling. Any unusual change in pressure will alert the driller of down hole problems. Pressure too low could indicate washed out pipe orbit nozzle, loose joint or broken drill string, worn pump packing or liners, or lost returns due to formation breakdown. Pressure too high could indicate a plugged drill bit or an increase in mud density or viscosity. Reliable indication of mud pump pressure provides an early warning of circulation problems, enabling the driller to make corrections avoiding major problems.

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

The 4:1 Dual-pointer pressure indicator with Shut-off Switch System deliver accurate measurements for mud, cementing, acidizing, and fracturing operations. Provides quick, accurate check on mud pump operation; helps detect washed out drill pipe or bit nozzle problems.

The problem is that the instantaneous shifting of a hydraulic cylinder from one direction to the other while under high pressure causes tremendous hydraulic hammer shock - so great that hydraulic system components could not stand up to the abuse. This shifting shock problem has been the single biggest barrier to developing a successful hydraulic drive system.

Solution: Our patented shock suppression hydraulic shifting system has tamed the hydraulic hammer shock problem. Our shifting system can shift at hydraulic oil pressures of up to 5000 psi - producing mud pressures up to 800 psi without encountering the deteriorating shock that has stumped so many other attempts at making a direct hydraulic drive.

Solution: Why overcome a problem when you can simply go around it? Our patented "Matched Displacement Ratio" technology has eliminated the need for a synchronization system. This technology allows our pumps to deliver smooth, constant discharge flow without the use of a synchronization system.

The drilling industry demands a mud pump that will operate day in and day out without continual down time maintenance. Off the shelf components that would produce such a hydraulic drive system were not to be found. A new generation of components would have to be developed to meet the demands of this service.

Solution:To make a hydraulic drive system that will stand up to the duty our industry demands, every component in our hydraulic system had to be custom engineered - developed exclusively for our pumps to stand up to a level of duty that off the shelf hydraulic components would never stand up to. Everything from the allow used in the valve castings, the design of the valve components, the hydraulic cylinder design and the type and material of the seals, were specifically engineered for use in our pumps - engineered for a 60,000,000 cycle life under high pressure reciprocating duty.

Developing new fluid end expendables that will stand up to the duty in our industry the same way that mechanical drive pump expendables hold up is a tall order. How do you improve on the one thing that has made mechanically driven mud pumps the backbone of the industry

Solution:Honestly, we couldn"t develop better fluid end expendables than those used in mechanical pumps - so we used theirs. Our fluid end expendables are the same components that have been used in mechanical pumps for decades. These expendables are proven, reliable, and available - how could we improve on that? Well, actually, by using bigger pistons and running them at half the speed of mechanical drive pumps we can get about twice the life from them!

Developing respect for a new mud pump technology doesn"t come easy. Despite their weight, size and performance limitations, the mechanical pumps that had been the standard of the industry had been getting the job done for over 50 years. How could we convince our industry to adopt our pump as the new standard for our industry?

Solution: We can claim that our pumps perform like no other pump on the market. We can claim that we use the best components and materials. But in the end, respect only comes from earning it. It doesn"t matter what we say. What matters is what our customers say. Centerline pumps are getting the job done from Canada to Australia. Are you ready for the mud pump you"ve always needed?

The price of a mud pump pressure gauge varies depending on the size, type, and features. For instance, a mud pump pressure gauge can be used to measure the mud pump pressure varies, on the matter hand, and at the same time. For instance, some mud pump pushes have more than one mud pump pressure gauge as one is expecting to be at the same time as others.

The difference between a mud pump pressure gauge and a mud pump pressure gauge are between the two terms. The mud pump pressure gauge is between the mud pumps and the tank, where the mud is isjected into the air through the gauge, and when it is used to check the condition of the vehicle, it is important to know the difference between a mud pump and a pressure gauge. When the mud is isjected into the mud pumps" tank and where they will be used.

Forum Compound Pointer Pressure Gauge systems accurately measure and display pump pressures for downhole cementing, high-pressure hydraulic fracturing, or acidizing oil pay operations.

A standard pointer provides a full 360° sweep of the dial, and a vernier pointer offers 4 to 1 resolution for indicating even small pressure changes. The system consists of a 6-inch Pressure Gauge, a Gauge Protector, and a high-pressure Hose.

8613371530291

8613371530291