mud pump rod made in china

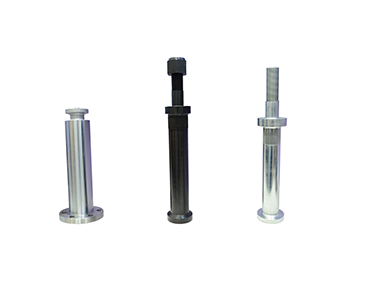

Baoshan`s piston rod, intermediate rod and clamp are made of high quality alloy steel which are exquisite and have strong abrasion resistance and corrosion resistance.

Emsco、Gardner-Denver, National oilwell, Ideco, Brewster, Drillmec, Wirth, Ellis, Williams, OPI, Mud King, LEWCO, Halliburton, SPM, Schlumberger, Weatherford

Dezhou Rundong Petroleum Machinery Co., Ltd is major in manufacturing oil drilling mud pump spare parts and drilling tools, in which liners, pistons and valves that developed new have got national patent certificate. Mud pump parts we manufactured can be totally exchangeable with spare parts from original manufacturer, and have excellent performance especially in drilling conditions of high temperature, high pressure, oil base mud, acid base mud and high sand content mud etc.

We have been committed to continuous optimization and upgrading of drilling mud pump products.We accumulate rich first-hand technical information through our service to drilling projects, for example different material products’ performance under different drilling conditions. Our aim is to make products manufactured can be more suitable for oilfield drilling needs, and our goal is where there is oil, there is Deshi Brand products.

Main advantages of the mud pump consumables that we manufacturedProducts are produced according to ISO9001 quality system,APISpec7K standard, and each process can be tracked, recorded and traceable

Years of production experience accumulation and continuous innovation, make parts manufacturing process more sophisticated, products service time more longer, cost performance more higher. Drilling cost can be effectively reduced by taking these products.

Import spare parts such as valve module, crankshaft, pinion shaft’s material are high quality alloy steel,The power end herringbone gear adopts the grinding process, the gear precision is high, the processing precision of the matching components is much more higher, which can make the whole mud pump can run more smoothly.

Production and quality inspection are separated, different process have different people to responsible, inspection methods are advanced, and have high-end inspection laboratories and detectors.

The products have excellent low temperature resistance and can be used normally in low temperature drilling conditions, minimum temperature can be - 45 °C.

F500、F800 、F1000、F1300、 F1600、F-1600HL 、F-2200HLHydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, crosshead assy, air capsule, crankshaft, pinion shaft, connecting rod, manifold etc

HHF-1300、HHF-1600 、HH3NB-1600H、HH3NB-2200HLHydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, crosshead assy, air capsule, crankshaft, pinion shaft, connecting rod, manifold etc

7P-50、8P-80、9P-100、10P-130、12P-160、14P-220Hydraulic end products and power end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, air capsule, manifold etc

PZ-7、 PZ-8、 PZ-9 、PZ-10、PZ-11Hydraulic end productsModule, Liner, Piston, Valve body, valve seat, piston rod, pony rod, flanges, air capsule, manifold etc

The Made-in-China F series mud pumps have same reliable quality and performance as other USA products. Now, F series mud pumps (from F-500 to F-2200) have been produced in batches and sold to many abroad oilfields. Your order for F series mud pumps is cordially welcome.

Huaxin"s export-orientated mud pump parts, including liners, pistons, piston inserts, valve inserts, oil seals, rod packing, fluid ends etc. All of them meet or exceed DIN and API standards and have been exported to U.K., Germany, USA, Canada, Pakistan, Middle East, and so on.

we are able to supply high-quality merchandise, competitive selling price and finest customer support. Our destination is “You come here with difficulty and we supply you with a smile to take away” for China OEM China Manufacturer /Mud Pump Connecting Rod, We imagine we’ll become a leader in building and producing high quality products in equally Chinese and international markets. We hope to cooperate with a lot more friends for mutual added benefits.

we are able to supply high-quality merchandise, competitive selling price and finest customer support. Our destination is “You come here with difficulty and we supply you with a smile to take away” for China Mud Pump, Connecting Rod, We have been committed to meet all your needs and solve any technical problems you may encounter with your industrial components. Our exceptional solutions and vast knowledge of technology makes us the preferred choice for our customers.

WX(R) & WXA(R) hard metal/rubber heavy duty slurry pumps are designed for the most difficult pumping applications for highly abrasive , high density or corrosive slurries. Extra thick sections at the critical wear points and superior Impeller structure ensures improved performance with extended wear and minimised maintenance, thus improving cost of ownership.

Rubber lined pumps expand applications to chemical products handling, several different rubber options are available to meet different application requirements.Best fitted in aggressive applications, like mill discharge and tailing transfer

WXA( R ) pumps are improved version of WX(R) pumps, in that it has an adjustable wear plate seated in at the Throatbush. This can be adjusted while the pump is running.

Usage of versatile wear-resistant and corrosion-resistant materials allows WX(R)/ WXA( R ) series slurry pumps to service in various industries, such as mining mill discharge, delivery of tailings, ash removal in power plant, FGD and coal washing in coal plant, etc.,resulting in low operating cost, as well as minimized maintenance and down time.

Dongying Zhaoxin Industry and Trade Co.,Ltd(Shandong Zhaoxin Oil Tools Co., Ltd.) is a modern enterprise specializing in the research manufacturing and distribution of petroleum equipment,such as tubing anchor,torque anchor,packer,centralizer,sucker rod guide,downhole gas separator,couplings,founded in 2009.The company had passed ISO9001 International Quality System Certification and obtained API 11D1 Certificate.

DC discharge rods are made of new insulating materials. It has the characteristics of lengthening and shrinking. The portable retractable new type discharge rods are easy to use in various outdoor high voltage tests, especially after the DC withstand voltage test. Discharge the charge accumulated on the sample to the ground to ensure personal safety. The use of a discharge rod to discharge is a necessary weapon to ensure the personal safety of each tester. The portable retractable discharge rod is easy to carry, convenient and flexible , With small size, light weight, safety and reliability, it is an indispensable safety tool for high-voltage workers.

2.Insert the prepared grounding wire plug into the socket at the head end of the discharge rod, and connect the other end of the grounding wire to the ground, and the grounding must be reliable.

4. When discharging, you should first use the metal tip of the front end of the discharge rod, and slowly move into the test product that has been disconnected from the test power supply. At this time, the discharge rod discharges the electric energy through the discharge resistance to discharge to the ground. Then use it again The hook on the discharge rod hooks the test sample for a second anti-electricity.

1. When discharging the large capacitor sample, after the test is completed, after disconnecting the test power supply, you should wait for a period of time, so that the charge on the sample is self-discharged to the ground through the pressure doubler and the sample itself. Observe that the voltage of the voltmeter on the control box is gradually dropping. When the voltmeter drops to a lower voltage, generally around 5Kv~15Kv, the discharge rod can be used to gradually move to the vicinity of the test product. First, discharge through the gap air, At this time, a hissing sound can be heard. When there is no sound, touch the test sample with the tip of the discharge rod, and finally discharge the test product directly to the ground.

3. After the test for high-voltage cables over a few kilometers, the discharge time is generally very long, and it needs to be repeatedly discharged. The resistance capacity is large, and a large-capacity discharge rod needs to be ordered.

5.It is strictly forbidden to step on or squeeze the discharge rod with heavy objects, and it is strictly prohibited to bend or break the discharge rod.

Zhuyi Import and Export Trading Co., Ltd. is located in Shanghai, China. It is a company engaged in import and export trade. The company members are a group of polite and ambitious young people. The company mainly deals in home gardening and pet supplies. The team is based on true and honest services. Inspirational attitude to promote Chinese products to the world stage, hoping to bring warmth to friends abroad during the epidemic, product quality is our aim, sincere service is our attitude, Zhuyi Trading Co., Ltd. hopes to be able to trade online In this way, more people can feel the power of China, make use of our traditional quality of hospitality, know more friends, and hope that our products and services can bring happiness to more families under the epidemic

Find W series mud pump from pressure grouting pump manufacturer - Saigao gruop in China. The W series mud pump can be widely used in all kinds of works in oil field, which is su...

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

Lake Petro provides high quality Mud Pump Parts including Mud Pump Liners, Mud Pump Fluid End Module, piston, Valve and Seat etc. With more than 10 years of experience in the oil and gas industry, we are dedicated to help and support our loyal clients with the most cost-effective and quality Liners and Pistons. We also provide mud pump price and mud pump for sale.

We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials for all common brands of the mud pump and triplex mud pump.

Bi-metal liners (double metal liners) are made of forged steel shell and wear-resistant sleeve of high chromium iron. In the production process, the size accuracy should be strictly controlled, which can ensure that they can be easily and stably installed. The inner sleeve with high finish and hardness is wear-resistant, corrosion-resistant and has a long service life. The bi-metal liners are suitable for a lot of bad working conditions. Its service life is more than 800 hours.

All Lake Petro liner products are interchangeable with O.E.M. products. Meanwhile, we provide customized Liners according to drawings. Our liners, also with our other mud pump spares, are supplied for use in Honghua, F-Series, Bomco, Emsco and National lines of triplex drilling pumps. Let Lake Petro be your one-stop shop for your whole fleet of pumps. Please refer to “Suitable Pump Models” Lable for more details.

8613371530291

8613371530291