mud pump rod pricelist

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

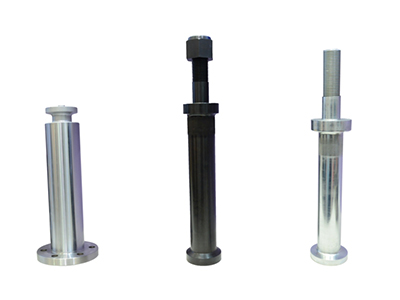

The construction of all the details of the Rod Systems begins with the acquisition of raw materials, from which are then derived all finished components by means of tooling machines. These components are then assembled at our assembly department to get theRod System finished.

The construction of all the parts that make up the Rod System begins with the acquisition of raw materials, from which are then derived all finished components by means of tooling machines. These components are then assembled at our assembly department to get the Rod System finished.

A mud pump is a reciprocating piston or plunger device designed to pump drilling fluid under high pressures and volumes down the drill string of a drilling rig. The main functions of drilling fluid are to provide hydrostatic pressure to prevent formation fluids from entering and to stabilize the bore, to keep the drill bit cool and clean, to carry drill cuttings back out to the surface, and to suspend the drill cuttings while drilling is paused or during the pullback process.

Mud pumps consist of two main sub-assemblies- the fluid end and the power end. The fluid end performs the pumping process with valves, pistons, and liners, or plungers and stuffing boxes- depending upon the type used. These components are considered expendables, and are designed to be easily replaced in the field. The power end contains the eccentric or crankshaft, along with the connecting rods, and cross heads/slides.

Tulsa Triplex is a Tulsa Rig Iron company. We manufacture pumps from 100 to 600 horsepower that are designed to be easily maintained and are capable of being completely rebuilt. Our pumps feature a smaller footprint and lighter weight than competing models, making them completely legal load size and weight in most instances. They are available as a bare pump, with chainbox, or a complete skidded package.

Titan Oil Tools offers high quality mud pump expendables and mud pump replacement parts for the wide variety of mud pumps, centrifugal pumps found on the world market today. These quality pump parts offer great performance and our pricing will save you money.

We are your oilfield supplier of choice for mud pump spares and mud pump parts: mud pump piston liners and pistons. All mud pump parts can be sourced for fast delivery; Come to us for mud pump liners, pistons, piston rods and parts, pony rods, threaded rings and caps,and more. Try us for duplex and triples pump spares and duplex and triplex mud pump parts, and also valve parts like valve seats. gland nut, and mud pump gaskets.

Mud pump liners may come in chrome, alumina ceramic and zirconia ceramic. Chrome liners and alumina ceramic liners are less costly, their cost of replacement over one year as the chart below shows, is much more than zirconia ceramic liners.

The table below shows a Mud Pump Liner Cost of Ownership which shows a reasonable cost comparison for a rig in continuous service for 36 months. This of course does not include the high cost of maintenance downtime and the cost of labor.

The prices below are based on cost/cylinder. Savings increase when you add up the number of pump cylinders on your rigs and extend the savings to understand the big difference it can make for your budget.

14 P-220 Mud Pumps 3 available completely overhauled. The pumps have been machine inspected and all data will be provided. These 2200 HP pumps complete with Southwest fluid end modules which have been reworked and pressure tested by Southwest and P-QUIP liner retention systems. The drives can be set up for AC or DC power. All Master Rig equipment meets or exceeds O.E.M. standards and a complete data pack is furnished with purchase. Please call if you have any questions.

READY TO SHIP - Three (3) completely refurbished 1600 HP Continental Emsco 7500 PSI Mud Pump Packages - liner spray system, suction manifold and dampener, discharge strainer cross, reset relief valve, 20 gallon pulsation dampener, 75 HP charge pump, two (2) GE 752 1000 HP rear mounted motors, 10 HP blower, mounted on a 3 runner skid with loading hitches and much more. Units come with complete data books and have been tested. MRI is a API facility and units comply with API standards.

Duplex mud pump package completely refurbished and never operated. Tri-Services Manufacturing TSM-500 pump, CAT engine. Data book provided with complete refurbishment details.

We are a leading Manufacturer of Mud Pump Spare, Duplex Mud Pump Parts, Mud Pump Valve Guide And Spring, SS Gland Flange, Mud Pump Spanner And Puller and Pinion Gear from Mehsana, India.

With great zeal and enthusiasm, our quality certified entity is successfully committed in manufacturing, exporting and supplying optimum quality range of Mud Pump Valve Guide And Spring.Our highly experienced team of professionals manufacture these products with the use of premium grade raw materials. Especially used in mud pumps for controlling the flow of liquids, the offered products are made available in different sizes and finishes. Also, checked by quality experts on various aspects, the provided Mud Pump Valve Guide AndMud Pump ValveSpringat reasonable prices from us.

We are a quality conscious enterprise, successfully engaged in manufacturing, exporting and supplying the best grade of Mud Pump Spanner And Puller.The offered puller is manufactured at our premises with the use of supreme grade raw materials as per international quality standards. The provided spanner with puller is widely used for installation in mud pumps in order to ensure its smooth operations. Additionally, we provide this Mud Pump Spanner AndMud PumpPullerat marginal prices to our clients.

We are a well known firm in this domain, betrothed in manufacturing, exporting and supplying top quality Piston Rod. Finding usefulness in automobile applications, this rod is used to connect the crankshaft to the pistons. Available in various technical specifications, the offered rod can be bought at industry leading prices from us. With the aid of cutting edge techniques, the provided Piston Rod is manufactured using high grade raw material under the stern direction of experts.

This mud pump will deliver the consistent flow of drilling fluid that is vital to HDD pipeline drilling projects. Suction inlet valve suspends charged flow during drill rod makeup and breakout process, keeping excess drilling fluid from escaping as drill pipes separate. The lubrication pump is driven off the auxiliary pad on the engine. It provides 55 psi (3.8 bar) of continuous crankshaft lubrication. The internal hydraulic reservoir has a capacity of 49 gal (185.5 L). Clutch with continuous duty throw-out bearing allows for longer pump disengagement during drill rod makeup/breakout....

A triplex piston pump produces up to 435.3 gpm (1647.8 L/min), providing a continuous flow of drilling fluid during drill operations. An electric centrifugal pump provides constant flow, keeping the pump running cool and leading to a longer life for both pistons and liners. Remote pendant control allows operator to mount controls where it makes sense for them. The remote pendant control monitors mud rate and eliminates the need for stroke counter. The integrated liner wash tank eliminates the need for additional water containers or electricity when running the pump. An engine-mounted air...

Mud pump, refers to the drilling process to the drilling mud or water and other washing liquid machinery. The main components are volute, impeller, pump seat, pump case, support cylinder, motor seat, motor and other components. Impeller nut is cast iron, so corrosion resistance is good, and convenient processing technology. Pump seat is equipped with four skeleton oil seal and shaft sleeve, prevent shaft wear, prolong the service life of the shaft.

ATO offers high quality vertical mud pumps with thick, solid shaft and copper motor. Various models are available, such as 2 inch mud pump, 3 inch mud pump, 4 inch mud pump and 6 inch mud pump.

Vertical mud pump is used as suction and pouring of river mud, suitable for oil refining, construction, printing and dyeing, chemical industry and other industries.

8613371530291

8613371530291