mud pump slide lower pricelist

Pump body thick. The pump body is made of high quality pig iron, durable and equipped with a thickened base. Thickened impeller, wear-resistant and dry rotating.

(Place the vertical mud pump upright or tilted in the liquid. Make sure the pump case is completely submerged in water. In addition, the motor part can not be immersed in water.)

Sewage pump is mainly used for industrial sewage, sewage treatment, in environmental protection has played a great role. The sewage pump is also a sewage pump with a cutting wheel, so the sewage pump can cut up the dirt, and then the sewage is extracted clean. Mud pump without cutting impeller, mostly used for pumping mud. The two main performance parameters of mud pump are displacement and pressure, displacement to discharge a number of liters per minute calculation, and drilling diameter and the required flushing fluid from the bottom of the hole back speed, that is, the larger the aperture, the larger the required displacement. The upward return velocity of the flushing fluid is required to flush cuttings and rock powders removed from the bottom of the hole in time and carry them reliably to the surface. By drilling and pumping, the mud under the ground can be obtained.

5 hp vertical mud pump with pure copper motor and thick pump body. Motor with fan heat dissipation, dehydration use will not burn submersible mud pump.

Pump body thick. The pump body is made of high quality pig iron, durable and equipped with a thickened base. Thickened impeller, wear-resistant and dry rotating.

(Place the vertical mud pump upright or tilted in the liquid. Make sure the pump case is completely submerged in water. In addition, the motor part can not be immersed in water.)

The bottom of the pump should avoid large particles into the stuck impeller, such as found that the pump does not turn should immediately stop the inspection.

A well-placed suction stabilizer can also prevent pump chatter. Pump chatter occurs when energy is exchanged between the quick opening and closing of the reciprocating pump’s valves and the hammer effect from the centrifugal pump. Pump isolation with suction stabilizers is achieved when the charge pumps are isolated from reciprocating pumps and vice versa. The results are a smooth flow of pumped media devoid of agitating energies present in the pumped fluid.

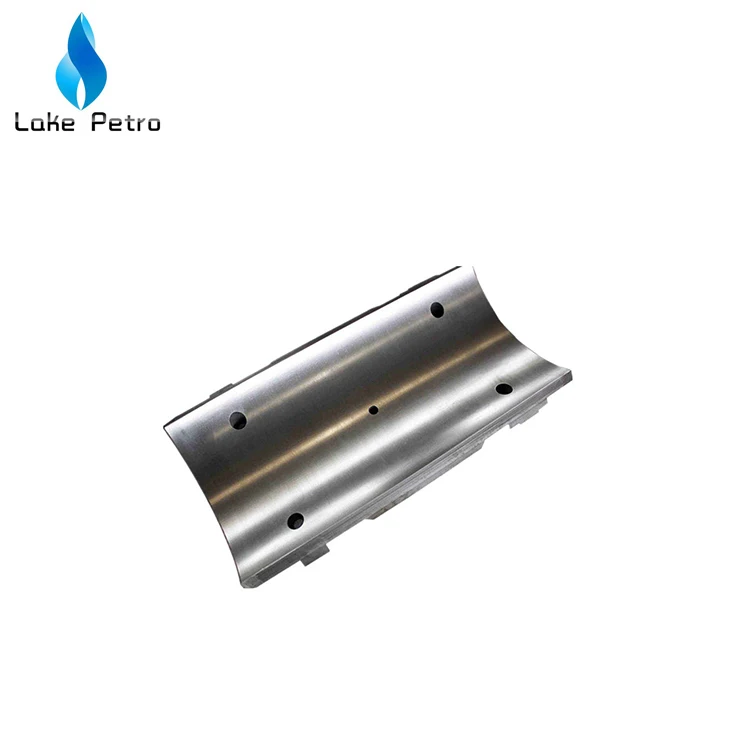

The Mud pump crosshead is the critical part on the power end of the mud pump. It slides in the upper and lower guide plates, motivating the intermediate draw bar to deliver driving force to the hydraulic end. One of its ends fixes the intermediate draw bar. The cavity connects the small end of the connecting rod through cross head pin.

The material of the mud pump crosshead is nodular cast iron with the strength of extension of more than 600MPa, which ensures high intensity and abrasive resistance.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

A mud pump is a reciprocating piston or plunger device designed to pump drilling fluid under high pressures and volumes down the drill string of a drilling rig. The main functions of drilling fluid are to provide hydrostatic pressure to prevent formation fluids from entering and to stabilize the bore, to keep the drill bit cool and clean, to carry drill cuttings back out to the surface, and to suspend the drill cuttings while drilling is paused or during the pullback process.

Mud pumps consist of two main sub-assemblies- the fluid end and the power end. The fluid end performs the pumping process with valves, pistons, and liners, or plungers and stuffing boxes- depending upon the type used. These components are considered expendables, and are designed to be easily replaced in the field. The power end contains the eccentric or crankshaft, along with the connecting rods, and cross heads/slides.

Tulsa Triplex is a Tulsa Rig Iron company. We manufacture pumps from 100 to 600 horsepower that are designed to be easily maintained and are capable of being completely rebuilt. Our pumps feature a smaller footprint and lighter weight than competing models, making them completely legal load size and weight in most instances. They are available as a bare pump, with chainbox, or a complete skidded package.

Central lubrication manifold system with Stainless Steel tubing for feeding all main, eccentric, and pinion bearings. Pressurized lubrication is also provided to the upper and lower crosshead slide for longer crosshead life

14 P-220 Mud Pumps 3 available completely overhauled. The pumps have been machine inspected and all data will be provided. These 2200 HP pumps complete with Southwest fluid end modules which have been reworked and pressure tested by Southwest and P-QUIP liner retention systems. The drives can be set up for AC or DC power. All Master Rig equipment meets or exceeds O.E.M. standards and a complete data pack is furnished with purchase. Please call if you have any questions.

READY TO SHIP - Three (3) completely refurbished 1600 HP Continental Emsco 7500 PSI Mud Pump Packages - liner spray system, suction manifold and dampener, discharge strainer cross, reset relief valve, 20 gallon pulsation dampener, 75 HP charge pump, two (2) GE 752 1000 HP rear mounted motors, 10 HP blower, mounted on a 3 runner skid with loading hitches and much more. Units come with complete data books and have been tested. MRI is a API facility and units comply with API standards.

Duplex mud pump package completely refurbished and never operated. Tri-Services Manufacturing TSM-500 pump, CAT engine. Data book provided with complete refurbishment details.

8613371530291

8613371530291