mud pump suction line strainer supplier

1-1/2 inch FNPT Suction Strainer with 1/2 inch round holes. 1.5" Irrigation or sprinkler pump strainer. Also comes in the 1/8" size holes SRHS-200-SM Zinc plated steel. Good for use with sprinkler pumps, irrigation pumps and other centrifugal and semi-trash pumps which can accept limited debris.

These zinc plated round hole strainers can be used with all popular makes of centrifugal pumps for use with hoses and pipes. Drop in to liquid to be suctioned. An "open" area of 50% allows filtering out large damaging debris, yet permits sufficient water passage to keep pumps functioning at full capacity.

For Top Hole skimmer strainers see SSKS-TH or SSKS-BH for Bottom Hole series or SRHS for barrel suction strainers. Image tab belows shows some of the various strainers available from PumpBiz. Please let us know if you do not see what you are looking for or for complete hose kits.

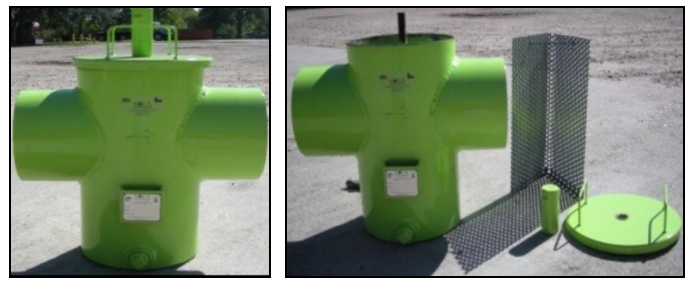

The HURRICANE suction line strainer protects mud pump fluid ends from unwanted debris entering the fluid stream. The strainer is easily cleaned and returned to service in minutes. A variety of end connections are available, including butt weld, flanged or threaded, to install in the suction line of any mud pump. HURRICANE strainers are built to withstand the rough service found on drilling rigs. Inlet / outlet diameters of 4”, 6”, 8”, 10” and 12” are standard. Provide the inlet / outlet size and height D as shown below with any price requests.

We offer pump strainers that are great at preventing large particles of sediment, sewage, mud, or solids from entering the suction port of drainage pumps. These strainers are great for use in swimming pools, pit blinds, or any other situation where you are pumping out water that is not clean. we offer 2 inch, 3 inch, and 4 inch strainers to fit all of the different size pumps. These strainers go great with our Koshin pumps. If you have any questions regarding strainers feel free to call us at 800-488-9146 or email us at orders@frankwall.com.

A wide variety of pump strainer mud pump options are available to you, such as 1 year, not available and 3 years.You can also choose from new, pump strainer mud pump,As well as from energy & mining, construction works , and manufacturing plant. And whether pump strainer mud pump is 1.5 years, unavailable, or {3}.

Looking for reliable wholesale oil pump suction strainer? We have you covered with various oil pump suction strainer, and to ensure the success of all your vehicles" repair and maintenance requirements. Alibaba.com is the ideal online marketplace for some of your automotive needs. With over a thousand products offered online. Shop today and take advantage of our convenient and pocket-friendly wide variety of items. We have a great number of wholesalers who are just waiting for you to make a deal.

With numerous wholesale oil pump suction strainer, our tools, mostly bought in bulk can help you make great savings. Automobile tools are a broad category that includes several separate tools such as car scanner tools, dent puller for car, car code scanner, car tester, fixed car diagnostic, car tool kit, and so much more. But whatever it is that you are looking for, it is worth checking it out here, you might be surprised and come across some hard-to-find items.

A great tip would be to enter a word on the search bar to filter your search and get the desired outcome which will make your online shopping experience enjoyable and efficient! Besides, this platform was conceived to make your experience pleasurable as possible. Therefore, grab the opportunity and get oil pump suction strainer now on Alibaba.com.

The discharge line is the output end of pump, its end is provided with a discharge strainer assembly will mud pump generated pressure directly transported to underground; another end of the pipe with air out package assembly and safety valve and pressure gauge.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce Mud pump and its spare parts, DST tools and Solid control products.

Kingwell oilfield are able to supply the mud pump and other OEM interchangeable spare parts, kindly contact with us if there has some enquiries, we will quote you a competitive price and fine delivery soon.

One of the most important pieces of equipment in many different industries is the filtration system. Within each filtration system are a number of moving parts, which must all work together to ensure the system operates efficiently. Two parts that rely on each other the most are pumps and strainers. As the pump works, the strainer is in place to capture debris to ensure the pump can continue to function as designed.

Typically, when one refers to a hydraulic pump strainer, they are referring to a mesh strainer that is used as a filter at the pump inlet. The purpose of this strainer is to filter contaminants out of the hydraulic fluid as it approaches the suction side of the pump. These relatively coarse filters (about 140 microns) screw onto the pump intake, which is located inside the hydraulic reservoir.

Like we said above, the main purpose of a strainer is to filter out any solid contaminants from hydraulic fluid. If contaminants are left unfiltered, they can damage components of the pump. When the pump is damaged it can lead to lower system efficiency and a shortened lifespan.

That being said, picking the incorrect strainer for your system can also damage the pump. When selecting a strainer, it’s important to first consult the manufacturer recommendations. You also need to ensure you’ve selected the right sized filter, and one that meets your systems pressure and flow requirements. If your strainer fails to meet those requirements, you could potentially cause irreversible damage to your system.

The positioning of your strainer first and foremost depends on the type of strainer your system requires. The two most common types are pump suction strainers and inline filters. Pump suction strainers are a coarse mesh strainer that is used to collect large participles from entering the pump. They are installed at the suction inlet of the pump. Inline filters, sometimes called return line filters or spin-on filters, are installed in the fluid return line. This filter allows for a finer filtration of particles than the pump suction strainer and results in a highly efficient filtration system. Inline filters are not installed on the suction side of the pump because this can cause pump failure from high differential pressure.

Most pumps are designed to handle some number of solids, and the manufacturer can advise you on what size particles your pump can handle and may even have a suggestion on what filtration type is best for the system. Ultimately, the positioning of your strainer will depend on what type of system you have and how fine of a filtration you require.

While the strainer is an important part of a filtration system, there are instances where strainers are unnecessary. If the hydraulic fluid being placed into the system has already been filtered, it is unnecessary for it to be filtered again within the system. Additionally, some new hydraulic systems do not even require a strainer as the updated design minimizes the chance of debris. Though, if proper maintenance isn’t done on the system you could still experience pump damage.

There’s no other way to argue it: strainers are important to a pump system. It’s the choice of a strainer and the positioning of that strainer that can be up for debate sometimes. If you’re questioning where to place a strainer in your system, or what strainer to use, first consult the manufacturer for their recommendations. If you still have questions after that, consult a qualified suction strainer/filter designer.

8613371530291

8613371530291