mud pump suction line strainer factory

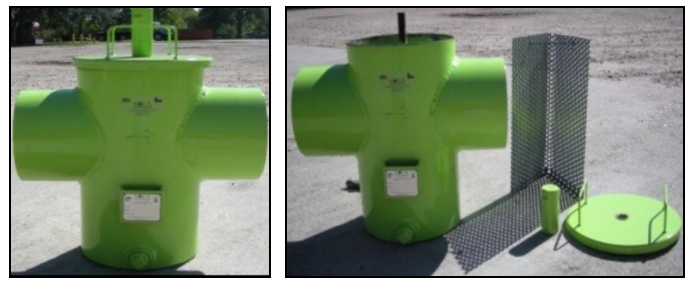

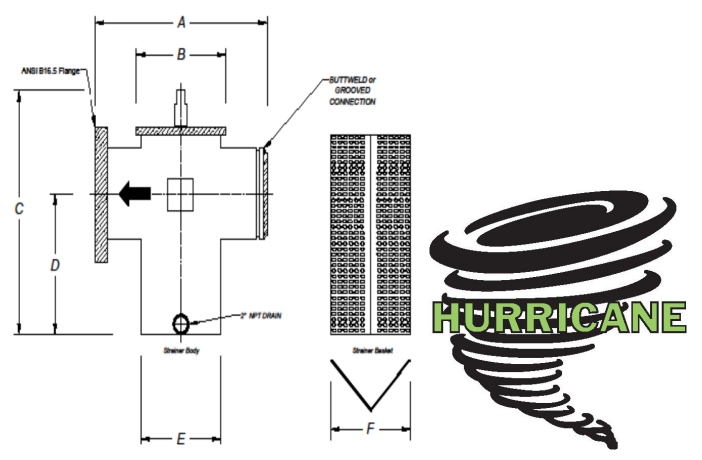

The HURRICANE suction line strainer protects mud pump fluid ends from unwanted debris entering the fluid stream. The strainer is easily cleaned and returned to service in minutes. A variety of end connections are available, including butt weld, flanged or threaded, to install in the suction line of any mud pump. HURRICANE strainers are built to withstand the rough service found on drilling rigs. Inlet / outlet diameters of 4”, 6”, 8”, 10” and 12” are standard. Provide the inlet / outlet size and height D as shown below with any price requests.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

One of the most important pieces of equipment in many different industries is the filtration system. Within each filtration system are a number of moving parts, which must all work together to ensure the system operates efficiently. Two parts that rely on each other the most are pumps and strainers. As the pump works, the strainer is in place to capture debris to ensure the pump can continue to function as designed.

Typically, when one refers to a hydraulic pump strainer, they are referring to a mesh strainer that is used as a filter at the pump inlet. The purpose of this strainer is to filter contaminants out of the hydraulic fluid as it approaches the suction side of the pump. These relatively coarse filters (about 140 microns) screw onto the pump intake, which is located inside the hydraulic reservoir.

Like we said above, the main purpose of a strainer is to filter out any solid contaminants from hydraulic fluid. If contaminants are left unfiltered, they can damage components of the pump. When the pump is damaged it can lead to lower system efficiency and a shortened lifespan.

That being said, picking the incorrect strainer for your system can also damage the pump. When selecting a strainer, it’s important to first consult the manufacturer recommendations. You also need to ensure you’ve selected the right sized filter, and one that meets your systems pressure and flow requirements. If your strainer fails to meet those requirements, you could potentially cause irreversible damage to your system.

The positioning of your strainer first and foremost depends on the type of strainer your system requires. The two most common types are pump suction strainers and inline filters. Pump suction strainers are a coarse mesh strainer that is used to collect large participles from entering the pump. They are installed at the suction inlet of the pump. Inline filters, sometimes called return line filters or spin-on filters, are installed in the fluid return line. This filter allows for a finer filtration of particles than the pump suction strainer and results in a highly efficient filtration system. Inline filters are not installed on the suction side of the pump because this can cause pump failure from high differential pressure.

Most pumps are designed to handle some number of solids, and the manufacturer can advise you on what size particles your pump can handle and may even have a suggestion on what filtration type is best for the system. Ultimately, the positioning of your strainer will depend on what type of system you have and how fine of a filtration you require.

While the strainer is an important part of a filtration system, there are instances where strainers are unnecessary. If the hydraulic fluid being placed into the system has already been filtered, it is unnecessary for it to be filtered again within the system. Additionally, some new hydraulic systems do not even require a strainer as the updated design minimizes the chance of debris. Though, if proper maintenance isn’t done on the system you could still experience pump damage.

There’s no other way to argue it: strainers are important to a pump system. It’s the choice of a strainer and the positioning of that strainer that can be up for debate sometimes. If you’re questioning where to place a strainer in your system, or what strainer to use, first consult the manufacturer for their recommendations. If you still have questions after that, consult a qualified suction strainer/filter designer.

Looking for reliable wholesale oil pump suction strainer? We have you covered with various oil pump suction strainer, and to ensure the success of all your vehicles" repair and maintenance requirements. Alibaba.com is the ideal online marketplace for some of your automotive needs. With over a thousand products offered online. Shop today and take advantage of our convenient and pocket-friendly wide variety of items. We have a great number of wholesalers who are just waiting for you to make a deal.

With numerous wholesale oil pump suction strainer, our tools, mostly bought in bulk can help you make great savings. Automobile tools are a broad category that includes several separate tools such as car scanner tools, dent puller for car, car code scanner, car tester, fixed car diagnostic, car tool kit, and so much more. But whatever it is that you are looking for, it is worth checking it out here, you might be surprised and come across some hard-to-find items.

A great tip would be to enter a word on the search bar to filter your search and get the desired outcome which will make your online shopping experience enjoyable and efficient! Besides, this platform was conceived to make your experience pleasurable as possible. Therefore, grab the opportunity and get oil pump suction strainer now on Alibaba.com.

The discharge line is the output end of pump, its end is provided with a discharge strainer assembly will mud pump generated pressure directly transported to underground; another end of the pipe with air out package assembly and safety valve and pressure gauge.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce Mud pump and its spare parts, DST tools and Solid control products.

Kingwell oilfield are able to supply the mud pump and other OEM interchangeable spare parts, kindly contact with us if there has some enquiries, we will quote you a competitive price and fine delivery soon.

Mud pumps consume more than 60% of all the horsepower used in rotary drilling. Mud pumps are used to circulate drilling fluid through the mud circulation system while drilling. A pump with two fluid cylinders, as shown in Figure 4-99, is called a duplex pump. A three-fluid-cylinder pump, as shown in Figure 4-100, is called a triplex pump. Duplex pumps are usually double action, and triplex pumps are usually single action.

Mud pumps consist of a power input end and a fluid output end. The power input end, shown in Figure 4-101, transfers power from the driving engine (usually diesel or electric) to the pump crankshaft. The fluid end does the actual work of pumping the fluid. A cross-section of the fluid end is shown in Figure 4-102.

The hydraulic horsepower produced by mud pumps depends mainly on the geometric and mechanical arrangement of the suction piping. If suction-charging centrifugal pumps (e.g., auxiliary pumps that help move the mud to the mud pump) are not used, the pump cylinders have to be filled by the hydrostatic head.

suction pipe. Minimizing the effect of inertia requires a reduction of the suction velocity and mud weight. It is generally practical to use a short suction pipe with a large diameter.

Mud temperatures of 150° can present critical suction problems. Under low pressure or vacuum existing in the cylinder on the suction stroke, the mud can boil, hence decreasing the suction effectiveness. Furthermore, hot mud accelerates the deterioration of rubber parts, particularly when oil is present. Large mud tanks with cooling surfaces usually solve the problem.

Entrained gas and air expands under the reduced pressure of the suction stroke, lowering the suction efficiency. Gas in water-base mud may also deteriorate the natural rubber parts used. Gases are usually separated with baffles or by changing mud composition.

The normally good lubricating qualities of mud can be lost if cuttings, particularly fine sand, are not effectively separated from the mud. Adequate settling pits and shale shakers usually eliminate this trouble. Desanders are used occasionally.

A poorly designed discharge manifold can cause shock waves and excessive pressure peaks. This manifold should be as short and direct as possible, avoiding any sharps turns. The conventional small atmospheric air chamber, often furnished with pumps, supplies only a moderate cushioning effect. For best results, this air chamber should be supplemented by a large atmospheric air chamber or by a precharged pulsation dampener.

A few strokes of the piston in a dry liner may ruin the liner. When the pump does not fill by gravity or when the cylinders have been emptied by standing too long or by replacement of the piston and liner, it is essential to prime the pump through the suction valve cap openings.

Suction lines are often partly filled by settled sand and by debris from the pits, causing the pump to hammer at abnormally low speeds. Frequent inspection and cleaning of the suction manifold is required. The suction strainer can also be a liability if it is not cleaned frequently.

The discharge strainer often becomes clogged with pieces of piston and valve rubber. This may increase the pump pressure that is not shown by the pressure gauge beyond the strainer. The strainer should be inspected and cleaned frequently to prevent a pressure buildup.

Usually special solids, such as nut shells, limestone, expanded perlite, etc., are added to the drilling muds to fill or clog rock fractures in the open hole of a well. Most of these lost circulation materials can shorten the life of pump parts. They are especially hard on valves and seats when they accumulate on the seats or between the valve body and the valve disc.

Pump parts for high-pressure service are made of precisely manufactured materials and should be treated accordingly. In storage at the rig, metal parts should be protected from rusting and physical damage, and rubber parts should be protected from distortion and from exposure to heat, light, and oil. In general, parts should remain in their original packages where they are usually protected with rust-inhibiting coatings and wrappings and are properly supported to avoid damage. Careless stacking of pistons may distort or cut the sealing lips and result in early failures. Hanging lip-type or O-ring packings on a hook or throwing them carelessly into a bin may ruin them. Metal parts temporarily removed from pumps should be thoroughly cleaned, greased, and stored like new parts.

The charts showing the performance of duplex pumps are shown in Table 4-38 [17]. The charts showing the performance of triplex pumps are shown in Table 4-39 [17]. A chart listing the pump output required for a given annular velocity is shown in Table 4-40 [18]. A chart listing the power input horsepower required for a given pump working pressure is shown in Table 4-41 [19].

Pump inlet strainers are common parts for all airless sprayers. Many inlet strainers are compatible with sprayers that are not listed above. Consult your parts manual to ensure the correct strainer is purchased

All categoriesActivated CarbonAdminAeration Kit PartsAir DiffuserAir TubingAlgae Removal ToolAlgae TreatmentAquarium AccessoryAquarium FiltrationAquarium SensorAuto Top offBarley ExtractBarley StrawBasinBead FilterBeneficial BacteriaBiological MediaBottom DrainCheck ValveCold Weather Fish FoodColor Fish FoodDecorativeElectrical AccessoryExternal FilterExternal PumpFilter FoamFilter KitFilter PadFish CareFish Feederfish medicineFloating Fountain SystemFoam TreatmentFountain & Pond AccessoriesFountain LightingFountain NozzleFountain PumpFountainsGift CardsGrowth Fish FoodHerbicideHose and PipeInstallation ToolsIonizerKoi fishKoi Fish FoodKoi Fish MedicineKoi Measuring BoardLake AerationLake DeicerLake FountainLighting AccessoryPest DeterrentspH ControlPhosphate TreatmentPlant CarePlant FertilizerPlumbing PartPond AerationPond Building SuppliesPond ConstructionPond DeicerPond DyePond FilterPond FiltrationPond HeaterPond KitPond KitsPond LightingPond LinerPond MaintenancePond NetsPond NettingPond PlantsPond PlumbingPond PumpPond PumpsPond SaltPond SkimmerPond UnderlaymentPond UVPond VacuumPondless Waterfall KitsPondless WaterfallsPremium Fish FoodPressure FilterPump ImpellerPump Pre-FilterPump ProtectionPump Replacement PartPump VaultReplacement PartsRock CleanerRock CoverRock LidRock LipSeasonalShippingShow Tanks and BowlsSkimmerSludge TreatmentSolids Handling PumpSpillwayStaple Fish FoodStrainer BasketSubmersible FilterSubmersible PumpTest KitThermometerTurtle FoodUltraviolet BulbUltraviolet ClarifierUnderlaymentUtility PumpVariable Speed PumpWater ClarifierWater ConditionerWater MatrixWater PlantsWater TestsWater Treatment KitWater TreatmentsWaterfall FilterWaterfall FoamWaterfall SpillwayWeir Lighting

How many times have you or your customers become frustrated over a debris clog when pumping waste oil? It happens all the time! So often it is rags, paper towels, sludge, and who knows what that gets clogged up in the suction line when emptying waste oil tanks. It is not just the clog that is so bad, it is the mess made from pulling out the suction line to remove the clogged item only to have oil pour all over the floor—what a mess.

This waste oil suction line strainer from SVI allows for the free flow of oil in one direction. Hold vertically or horizontally under slight back pressure to prevent backflow leaking. Get a clog, pull the suction line out, wipe the clog clear and go right back to pumping without all the mess and stress.

Made of a durable nylon material, this strainer assembly is a must-have for anyone who routinely engages in waste oil evacuation or fluid transfer systems. SVI is your Answer!

8613371530291

8613371530291