mud pump suction line strainer manufacturer

1-1/2 inch FNPT Suction Strainer with 1/2 inch round holes. 1.5" Irrigation or sprinkler pump strainer. Also comes in the 1/8" size holes SRHS-200-SM Zinc plated steel. Good for use with sprinkler pumps, irrigation pumps and other centrifugal and semi-trash pumps which can accept limited debris.

These zinc plated round hole strainers can be used with all popular makes of centrifugal pumps for use with hoses and pipes. Drop in to liquid to be suctioned. An "open" area of 50% allows filtering out large damaging debris, yet permits sufficient water passage to keep pumps functioning at full capacity.

For Top Hole skimmer strainers see SSKS-TH or SSKS-BH for Bottom Hole series or SRHS for barrel suction strainers. Image tab belows shows some of the various strainers available from PumpBiz. Please let us know if you do not see what you are looking for or for complete hose kits.

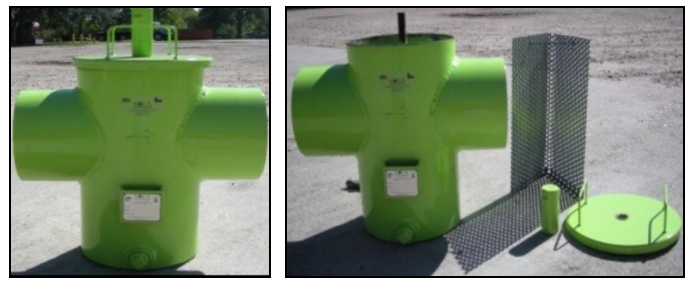

The HURRICANE suction line strainer protects mud pump fluid ends from unwanted debris entering the fluid stream. The strainer is easily cleaned and returned to service in minutes. A variety of end connections are available, including butt weld, flanged or threaded, to install in the suction line of any mud pump. HURRICANE strainers are built to withstand the rough service found on drilling rigs. Inlet / outlet diameters of 4”, 6”, 8”, 10” and 12” are standard. Provide the inlet / outlet size and height D as shown below with any price requests.

Our hydraulic strainers are designed and engineered for versatility and durability, fitting in almost any hydraulic system and meeting some of the most demanding operating and environmental conditions. They are suitable for use in a wide range of industries, including, but not limited to, the following:

Round root and crest pleat designs. Our strainers feature a rounded root and crest pleat design that allows for 100% utilization of the straining area. The design also facilitates the cleaning of the strainer when needed, allowing industry professionals to reuse the strainer several times over.

Suction strainers are employed in hydraulic systems to remove large contaminants from process fluids that can damage system components. They capture and collect the particulates as the process fluid flows through them.

Within hydraulic systems, strainers are generally incorporated within the suction lines to the pump. Compared to other contaminant filtration methods, they are much less flow restrictive, reducing the risk of the suction pressure increasing and causing cavitation within the pump. However, it is essential to regularly remove contaminant buildup from the strainer to avoid clogging up the straining surface area, which can lead to the above problems.

Although the terms “strainer” and “filter” are sometimes used interchangeably—largely due to the similarities in their function—they are distinct components with distinct use cases.

Both strainers and filters are employed to remove contaminants from process fluids in hydraulic systems. However, they differ in regard to the size of the particles they allow to pass through them. Strainers are generally used for contaminants that are 50 microns or greater, while suction filters are utilized with wire mesh, perforated material, and wire screen, for contaminants that are smaller than 50 microns (typically 40 microns or smaller).

At DOMS Incorporated, we provide hydraulic filters and strainers for any application or industry. In addition to our standard product lines, we also manufacture custom strainer solutions for any unique specification. Whether it’s a metric or SAE connection, full flow or bypass valve requisite, or a standard or non-standard mesh, we will handle your customized requirements. We can also incorporate any type of client-specified hardware into the strainer design.

Almost all our units can be furnished with metal components constructed from high-strength 300 series stainless steel for maximum durability and reliability. We also provide thorough inspection, testing, and evaluation services for new and existing strainer units.

At DOMS, we accept any production challenge. We handle large blanket orders with regularly scheduled shipments for up to 12 months—saving your organization time and considerable cost per unit. To find out more details about our strainer solutions, contact our technical team today.

A wide variety of pump strainer mud pump options are available to you, such as 1 year, not available and 3 years.You can also choose from new, pump strainer mud pump,As well as from energy & mining, construction works , and manufacturing plant. And whether pump strainer mud pump is 1.5 years, unavailable, or {3}.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

One of the most important pieces of equipment in many different industries is the filtration system. Within each filtration system are a number of moving parts, which must all work together to ensure the system operates efficiently. Two parts that rely on each other the most are pumps and strainers. As the pump works, the strainer is in place to capture debris to ensure the pump can continue to function as designed.

Typically, when one refers to a hydraulic pump strainer, they are referring to a mesh strainer that is used as a filter at the pump inlet. The purpose of this strainer is to filter contaminants out of the hydraulic fluid as it approaches the suction side of the pump. These relatively coarse filters (about 140 microns) screw onto the pump intake, which is located inside the hydraulic reservoir.

Like we said above, the main purpose of a strainer is to filter out any solid contaminants from hydraulic fluid. If contaminants are left unfiltered, they can damage components of the pump. When the pump is damaged it can lead to lower system efficiency and a shortened lifespan.

That being said, picking the incorrect strainer for your system can also damage the pump. When selecting a strainer, it’s important to first consult the manufacturer recommendations. You also need to ensure you’ve selected the right sized filter, and one that meets your systems pressure and flow requirements. If your strainer fails to meet those requirements, you could potentially cause irreversible damage to your system.

The positioning of your strainer first and foremost depends on the type of strainer your system requires. The two most common types are pump suction strainers and inline filters. Pump suction strainers are a coarse mesh strainer that is used to collect large participles from entering the pump. They are installed at the suction inlet of the pump. Inline filters, sometimes called return line filters or spin-on filters, are installed in the fluid return line. This filter allows for a finer filtration of particles than the pump suction strainer and results in a highly efficient filtration system. Inline filters are not installed on the suction side of the pump because this can cause pump failure from high differential pressure.

Most pumps are designed to handle some number of solids, and the manufacturer can advise you on what size particles your pump can handle and may even have a suggestion on what filtration type is best for the system. Ultimately, the positioning of your strainer will depend on what type of system you have and how fine of a filtration you require.

While the strainer is an important part of a filtration system, there are instances where strainers are unnecessary. If the hydraulic fluid being placed into the system has already been filtered, it is unnecessary for it to be filtered again within the system. Additionally, some new hydraulic systems do not even require a strainer as the updated design minimizes the chance of debris. Though, if proper maintenance isn’t done on the system you could still experience pump damage.

There’s no other way to argue it: strainers are important to a pump system. It’s the choice of a strainer and the positioning of that strainer that can be up for debate sometimes. If you’re questioning where to place a strainer in your system, or what strainer to use, first consult the manufacturer for their recommendations. If you still have questions after that, consult a qualified suction strainer/filter designer.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Drilling consumables such as mud pump systems and their components can drastically increase your uptime while reducing costs and health/safety/environmental (HSE) risks. To support your drilling needs, Forum’s patented P-Quip® mud pump system offers a single-source solution that integrates high-quality fluid end components for maximum longevity and performance.

With more than 20 years of successful operation in severe environments, P-Quip offers a proven track record for the lowest cost of ownership in the industry. As part of our commitment to quality, our mud pump parts use patented Banded Bore™ technology that significantly reduces stress concentrations and leads to longer module life.

One of Forum’s most committed core values is that “no one gets hurt,” and the P-Quip system is designed to support that principle. Streamlined and easy to use, it reduces or eliminates the need for manual force during maintenance, shrinking the time needed to replace high-use components and minimizing safety risks.

The discharge line is the output end of pump, its end is provided with a discharge strainer assembly will mud pump generated pressure directly transported to underground; another end of the pipe with air out package assembly and safety valve and pressure gauge.

With over 10 years developing, we were developed from the beginning drilling service to manufacture factory who produce Mud pump and its spare parts, DST tools and Solid control products.

Kingwell oilfield are able to supply the mud pump and other OEM interchangeable spare parts, kindly contact with us if there has some enquiries, we will quote you a competitive price and fine delivery soon.

Pump inlet strainers are common parts for all airless sprayers. Many inlet strainers are compatible with sprayers that are not listed above. Consult your parts manual to ensure the correct strainer is purchased.

8613371530291

8613371530291