mud pump suction stabilizer supplier

Performance Pulsation Control is meeting the suction stabilizer needs of clients across the country. We can tailor a suction stabilizer and suction pulsation dampener to fit the specific output requirements of any commercial industry that relies on consistent and precise pump solutions. Some of the customization possibilities you’ll find for your business applications include:

Buy high-capacity pump suction stabilizer that are guaranteed to keep your appliances up and running in perfect condition from Alibaba.com. These pump suction stabilizer are offered from the best and most energy-efficient brands and provides users with an elevated experience. These pump suction stabilizer are designed to ensure safety and stability and are available in a number of variants.

pump suction stabilizer offered on Alibaba.com have many necessary and interesting features such as fail-safe circuit protection and cut-off points. These pump suction stabilizer have a high range and are likely to fit most home and commercial purposes. These pump suction stabilizer have finely crafted exteriors to ensure that there is no risk of shock or accidents. Some of these items even have LED displays for a smoother experience and greater transparency.

pump suction stabilizer are suitable for all sorts of large appliances and do not malfunction easily. They require very limited maintenance and not much has to be spent on their upkeep. pump suction stabilizer ensure that your expensive appliances and machines do not get damaged due to fluctuations and are inevitable for any home or commercial enterprise that engages multiple electronic items. pump suction stabilizer on the site offer optimal performance at economical prices.

Choose the pump suction stabilizer that best suit your needs, whether for home, office or industry. pump suction stabilizer suppliers are sure to want to snap up this attractive chance to buy quality items at discounted prices. Grab these amazing deals today.

The reciprocating pump’s cylinders pull its fluids from the suction manifold. When the suction manifold has trouble refilling with fluid, the cylinders will take in vapor and create a void in the cylinder. This is called cavitation, and it produces a very adverse reaction that is transferred into the fluids.

When you install a suction stabilizer off the suction manifold port, this gives the manifold extra capacity to pull fluid from and eliminates the manifold’s opportunity to lack fluids, thus eliminating cavitation.

The second benefit the suction stabilizer offers is eliminating negative forces in the fluids produced by the pump’s valves opening and closing rapidly, creating a water hammer effect. The suction stabilizer’s compressible element is designed to absorb these energies and smooth out the fluid flow. This causes pump isolation or, in other words, the reciprocating pump is now isolated from the charge pump, and vice versa. The negative energies produced by the reciprocating pump never make it back to the charge pump, which extends the life of the pump expendables.

Pulsation dampeners, also known as pulsation stabilizers, accumulators, arrestors and surge suppressors, are used to control and minimize the pulsations that result from a pressurized system’s pump stroking action. They increase system efficiency, performance, and pump life; decrease maintenance costs and down time; and protect pipes, meters, valves and instrumentation from pulsation, vibration, and hydraulic shock.

Most pulsation dampeners use a bladder, or bellows, to separate the process fluid from a compressible gas. During the pump’s discharge stroke, fluid pressure displaces the bladder or bellows and compresses the trapped gas. During the following cycle, the momentary interruption of fluid flow causes the compressed gas to expand, forcing the bladder or bellows to push the accumulated fluid back into the discharge line.

Generally, the majority of pump pulsation problems can be traced to and remedied on the suction side of a pump, even though some symptoms may show up on the discharge side In feeding the pump. It is extremely important to maintain a steady flow of fluid through the suction valves. Also, the fluid column must attach thoroughly to the face of the plunger to achieve complete cylinder fill on the suction stroke.

Determine the amount of fluid a pump will be moving, at what speed, and at what pressure. Indicators: Number of plungers, Bore, Stroke Length, RPM Suction & Discharge Pressure

The pulsation stabilizer opening should be the same size as the opening on the side of the pump on which it will operate. This will guard against unwanted acceleration or deceleration of fluid as it passes between the pump and stabilizer. Always defer to the next larger size should an exact match not be available.

Before installing any pulsation stabilizer or discharge dampener, be sure to consider the makeup of the overall system. Be aware of system characteristics that could effect a stabilizer decision, such as other pumps running in line, upstream/downstream pressure considerations, fluid composition and temperature, such as crude oil, salt water or drilling mud, or multiple pumps on a common header.

NOTE: The stabilizer opening should be the same size as the pump opening or larger. flanged and threaded Sizes are available from 1" to 8" - depending on the Series.

Pulsation problems often start on the suction side. Pulsation or cavitation is caused by the variation of fluid movement within a contained system. Since fluid is non-compressible, the energy produced by this pulsation or cavitation must be compensated for. With the introduction of pulsation equipment into a system this energy now has a place to expend itself. Without the pulsation equipment involved in your pumping system, the pulsation or cavitation that is present can lead to the following:

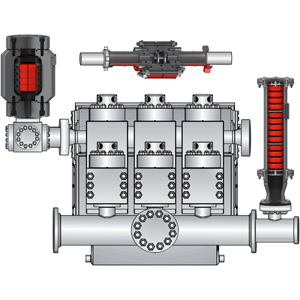

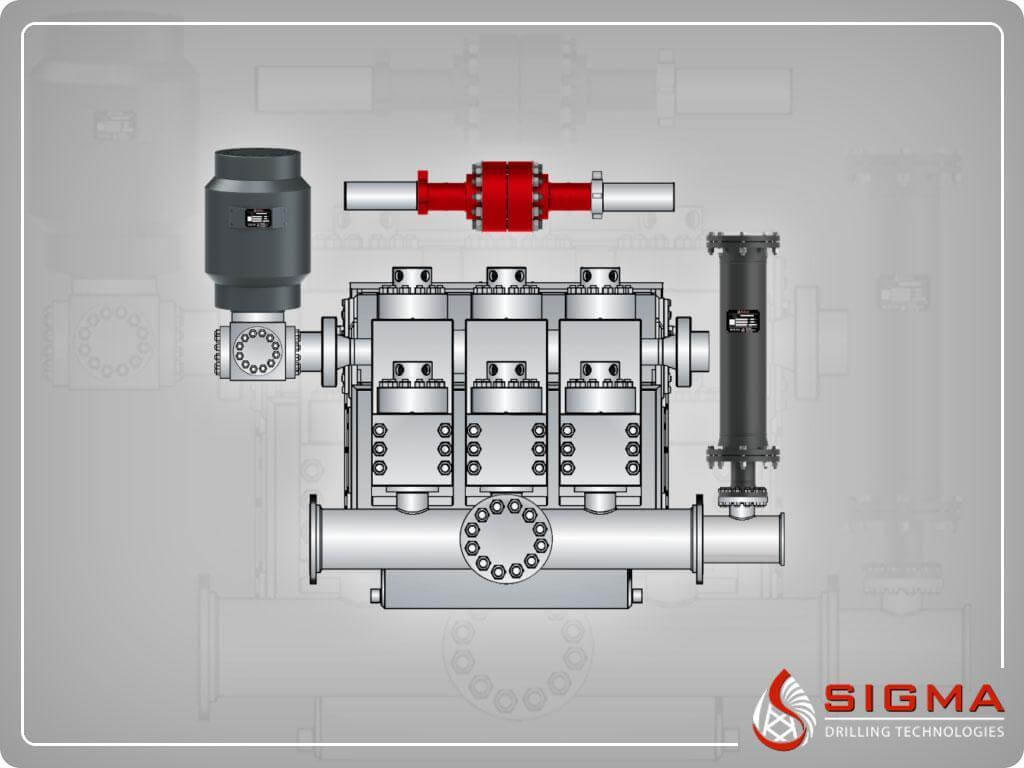

F2000 triplex piston mud pumps are firm and compact in structure and small in size, with good functional performances, which can adapt to drilling technological requirements such as oilfield high pump pressure and large displacement etc. The F series mud pumps can be maintained at lower stroke rate for their long stroke, which effectively improves the feeding water performance of mud pumps and prolongs the service life of the fluid end. The suction stabilizer, with advanced structure and reliable service, can achieve the best buffering effect. Power ends of the F series mud pumps adopt the reliable combination of forced lubrication and splash lubrication to increase the service life of power ends.

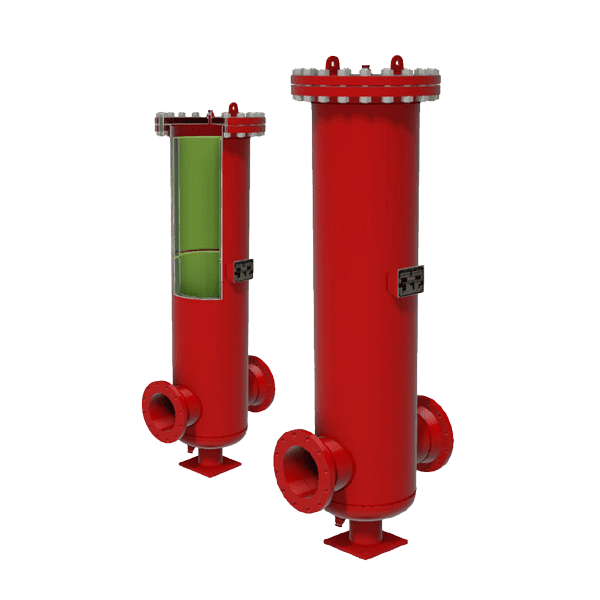

Southwest Oilfield Products is proud to offer a full line of Pulsation Dampener Solutions. Our PD series dampeners are available in 5, 10 & 20-gallon models and are rated for 5000 or 7500psi. Installed on the mud pump strainers cross, these gas-charged drilling dampeners provide optimum performance and dampening of flow variation pulsations generated by the mud pump. Key features include:

Positive displacement (PD) pumps contain an inlet valve that alternatively opens and closes, creating an acceleration and deceleration of fluid into the pump.

The patented “J” Model Inlet Stabilizer works to minimize these pressure fluctuations and acceleration head losses by preventing fluid column separation at the pump’s inlet. This improved flow to the pump’s inlet effectively extends the service life of all inlet system components.

In today"s growing industrialized market, the need for reciprocating pumps is increasing daily. As technology drives modernization, the demand placed on the pumping systems is continually rising.

Early piping systems were typically designed for less stringent circumstances, which have often created surges within the newer operating conditions. These surges, known as water hammer or pulsation amplification, are phenomena generated within the design of the system or the operation of the pump.

Blockage and leakage is normal within most operating systems and usually results from a safety valve opening or closing or a reciprocating pump fluid end valve"s normal operation.

The regeneration of these amplification sources has justified the need for better fluid controls. Primarily, piping fatigue, metering malfunctions or system vibrations are the early signs that pulsation amplification exists within the system. Ultimately, the amplification can be diminished within the design, but due to the cyclical nature of reciprocating pumps, it cannot be eliminated. Suction stabilizers and discharge dampeners can be inserted within the system at strategic points to help mitigate pressure spikes.

Discharge dampeners were developed to dampen the effects of the amplification of a pumping mechanism. In the late 1950s, discharge dampeners were developed to attenuate pressure spikes on single acting production pumping oil wells. These wells were creating excessive spikes that could break piping flow lines and manifold collection points. The need to control these pressure spikes was rising at an alarming rate. Different methods considered at the time actually decreased overall well production, which pushed the need for more control and facilitated the development of new-age pulsation dampeners.

Suction stabilization is a means of stabilizing the fluid and its erratic motion before the fluid can be amplified within the reciprocating pump. This attenuation of the fluid is known in the industry as stabilizing, so the term suction stabilizer became common. Suction instability is normally generated through the blockage and leakage of the pump valves. As the suction valves close, a blockage is created within the system, which causes the fluid to stop, reverse its motion and generate a shock wave. The pump valves open and leakage is generated, forcing the fluid to start in motion again. To return this fluid in motion requires a certain amount of inertia, called acceleration head calculated (HAc).

The use of both suction stabilizers and discharge dampeners within the same operating system will allow for the least turbulent action to be generated. The control on the suction side of the pump absorbs the acceleration head, prompting the fluid to stay in constant motion. This attenuation is generated through the use of a nitrogen-filled cartridge or bladder. The nitrogen charged bladder is compressed by the pressure surge and decompressed upon demand generated by the suction line pressure decrease. The fluid will enter the suction cavity and be available to move through the suction valves with the least amount of turbulence. The less turbulence entering through the suction valves results in a minimum pressure spike that can be amplified within the pressure cavity of the pump.

Once the fluid reaches the pump valving, monitor the fluid"s velocity. Neglect in maintaining proper fluid velocity through pump valves in relation to the speed of plunger travel (crank rotation) will result in a mid-stroke implosion. As the fluid flows through the valves, it must fill the pressure cavity of the pump while keeping a solid mass of fluid on the face of the plunger. If the fluid separates from the face of the plunger, a pressure drop occurs. In the event this pressure drop falls below the vapor pressure of the fluid, then tiny air bubbles will form on the plunger service. If the pressure does not rise above the fluid vapor pressure before the forward stroke of the pump, the bubbles will be atomized into thousands more bubbles. These bubbles are known as cavitation and under pressure can cause a severe, damaging fatigue to a pump"s valves and downstream instrumentation.

Not all reciprocating pumps need pulsation equipment but almost all pumps generate some pulsation due to the cyclical nature of their design. As the crankshaft makes a full rotation of each plunger and starts its next rotation, the plunger stops for a fraction of a second. This stationary moment in the rotation allows the fluid to completely flood the pressure cavity. In the case where complete flooding of the fluid end is not achieved, voids are formed.

If piping systems are designed to eliminate an excessive amount of acceleration head effect, some HAc remains due to blockage and leakage (suction valves opening and closing) within the system. Suction stabilization will absorb the motion of the fluid within the compressible charged bladder as the suction valve closes. When the suction valve opens, the compressed gas will react to the pressure difference, decompressing the fluid simultaneously with the suction valve opening. This action within the stabilizer will keep the fluid in motion-attenuating the unsteady flow.

If the suction valves have a sufficient amount of fluid under them they will seat softer, disallowing the seats to be driven deeper into the fluid-end decks. The decreased amount of turbulence within the pressure chamber will decrease the amount of vibration, which is transmitted through the plunger into the power end of the pump. This decrease of vibration will increase life of crankshaft bearings, other power end and fluid end components, rewarding the user with a reduction in general maintenance operations.

In general, watching the flow characteristics of the fluid before it enters the pump can increase pump performance and decrease major unscheduled maintenance.

F 500 mud pump for oil drilling have features of solid and compact structure, small volume, good and reliable performance. It can meet the drilling requirements such as high pressure and big displacements whether in land drilling or off-shore drilling.

F 500 mud pumps have a longer stroke and can be operated at a lower stroke, thus improved the water supplying performance effectively and extended the lifetime of mud pump fluid end parts greatly.

Manufacturing utilizes the latest technologies to produce accurate and uniform parts. All products offered are either OEM or completely interchangeable. All fluid end accessories are available for most triplex and duplex mud pumps.

8613371530291

8613371530291