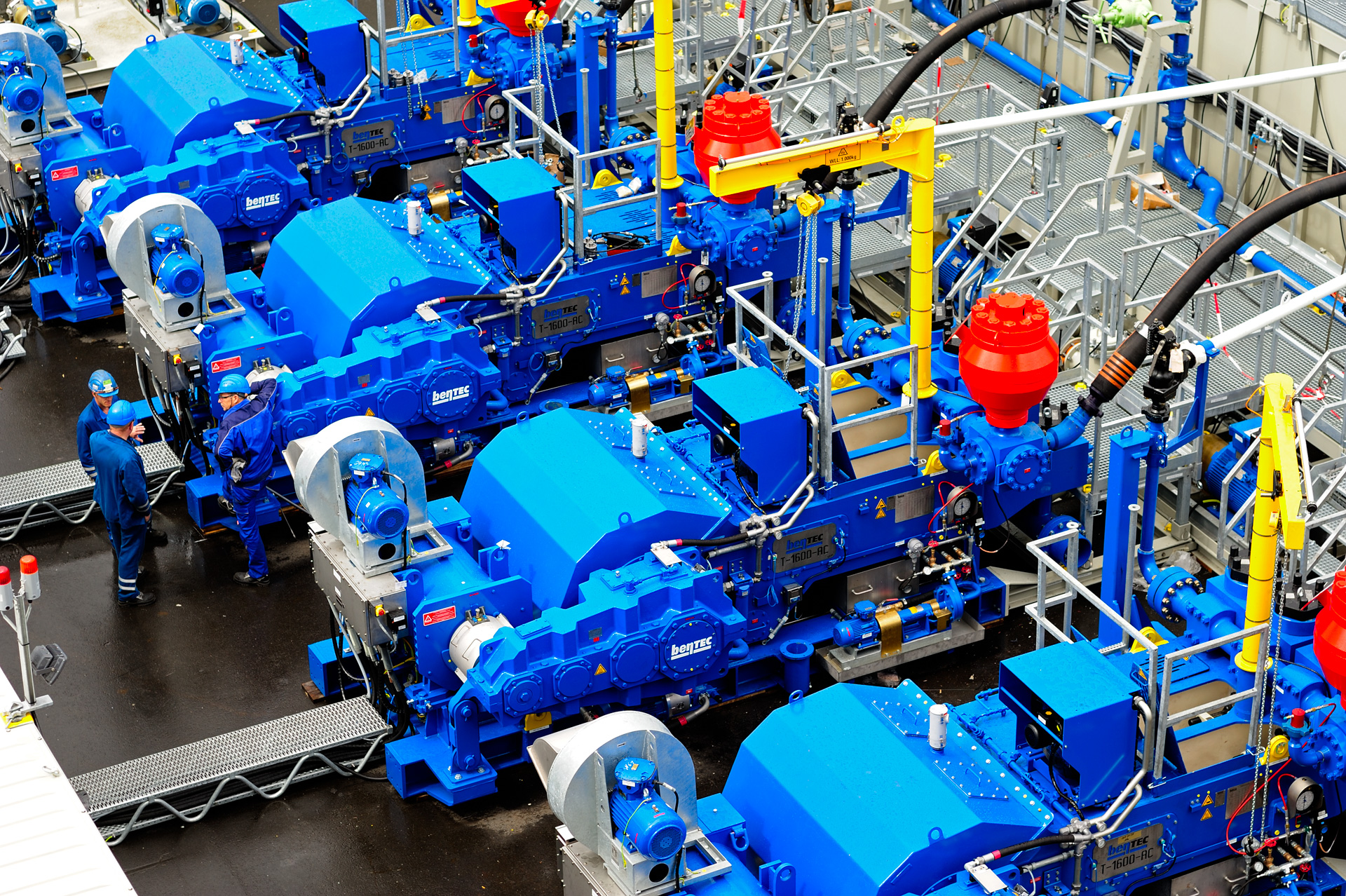

mud pump systems factory

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

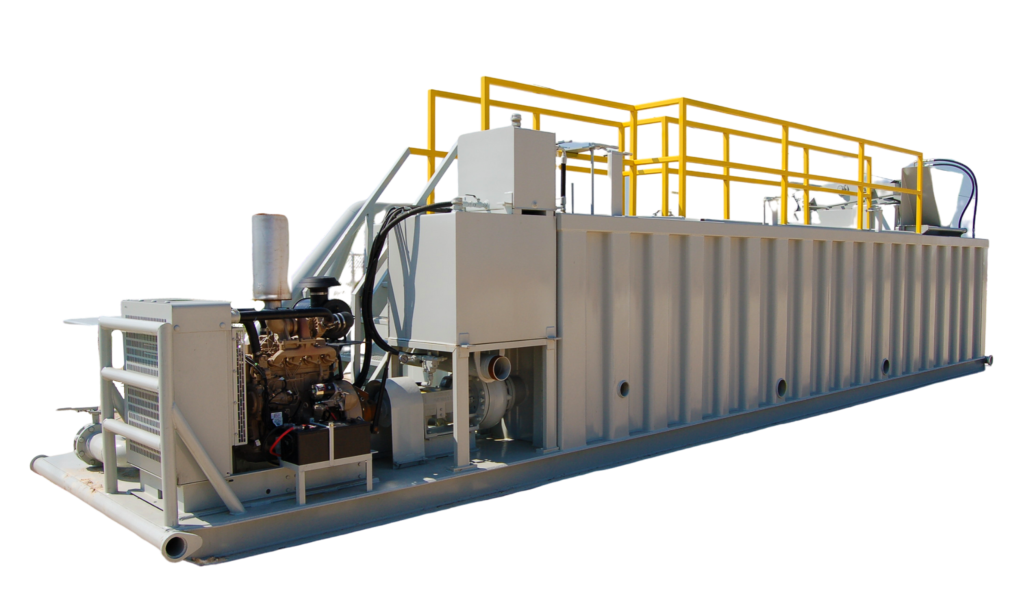

Our manufacturer Mud Pump skid is suitable for operations in rough, windy, damp and dusty oilfield conditions. Dependent upon customer horsepower requirements the engine sizes will vary.

Our 20,000 sq.m production facility in China has designed and manufactured solely quality and specialty pumps for oil exploration and refinery sin1992

Mud pumps are the heart of a drilling operation. TSM designs and manufactures extremely reliable and easy-to-maintain mud pumps, eliminating unnecessary maintenance and downtime.

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

These workhorses keep the mud flowing and your rig running. If theyʼre not working, youʼre not working. We make everything from the crankshaft to the liner seal to the skid. Each one is precision engineered for your rig so you can get back to turning.

Mudslayer Portable Mud System built by a well driller for well drillers, saving their backs and their bottom line. This shaker system was designed by Jim LaPorte, professional water well driller in California for 30 years. Jim realized he needed a reliable mud system that did not require an enormous amount of training and extensive technical education to operate.

The idea of the MudSlayer was born. This mud shaker does not require an experienced user that has a P.H.D. in engineering to operate. This baby is simple, affordable and dependable. It has the power to move the mud, remove the solids and make your well drilling more productive. Saves you time money and stress, and maximizes safety and productivity

We have a two axle towable trailer to move this unit easily and where it needs to go and electric brakes for extra stopping power. Four hydraulic outriggers come standard and make your setup quick and easy. The 500 G.P.M. lift pump is also mounted on a hydraulic boom to insure safety and reduce the risk of back injury.

The unit comes standard with a 2" X 3" X 8 5/8" desanding and mudmixing pump. The drilling or charge pump is a choice of 3x4 mission magnum centrifugal pump or 4.5"x5" American manufacturing duplex pump for drilling most domestic wells or charging most duplex pumps.

Comprehensive testing, performance evaluation and documentation done at Ingersoll-Rand manufacturing plant, Garland, Texas. Results in adoption of the Centerline pump as an optional offering on Ingersoll-Rand drilling rigs

The X-series mud pump type PD X-3.004 SG HDD manufactured by PRIME DRILLING impresses with its robust and low-wear design. The 7-fold bearing mounted drive shaft, which is equipped with 3 eccentric wheels, replaces the conventional crankshaft. Due to the revolution of these shafts and their maximum 230 rotations per minute operational wear of rubbers and liners are reduced to a minimum.

The pump is driven by a 470 kW CAT engine. This type of mud pump is exclusively manufactured in our Wenden plant, i.e. „made in Germany“. Its electronic gearshift in combination with eccentric wheels used instead of a crankshaft make it a high- power but low- maintenance product. All valves and plungers also comply with API standards.

8613371530291

8613371530291