mud pump technology brands

For the successful execution of your projects, it is important to find an appropriate company with a good track record. We help you in connecting with the top mud pump manufacturers and companies and get the best quotation.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

Yes. We help you find the best mud pumps irrespective of your location. We simplify your search by connecting you with top mud pump manufacturers and mud pump companies in your location, according to your budget and business requirement.

The most widely used mud pumps across the industry are Triplex Reciprocating Pumps. Their application has gained immense popularity with time because they are 30% lighter than duplex reciprocating pumps with relatively less operational cost. Moreover, through these pumps the discharge of mud is smooth and they are capable of moving large volume of mud at higher pressure.

The different parts of a mud pump are Housing itself, Liner with packing, Cover plus packing, Piston and piston rod, Suction valve and discharge valve with their seats, Stuffing box (only in double-acting pumps), Gland (only in double-acting pumps), and Pulsation dampener. A mud pump also includes mud pump liner, mud pump piston, modules, hydraulic seat pullers along with other parts.

The wearing parts of a mud pump should be checked frequently for repairing needs or replacement. The wearing parts include pump casing, bearings, impeller, piston, liner, etc. Advanced anti-wear measures should be taken up to enhance the service life of the wearing parts. This can effectively bring down the project costs and improve production efficiency.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Mud King Products offers a full line of Triplex Mud Pumps from 165HP to 1600HP. All of our P Series as well as F Series are fully interchangeable with the OEM. All MKP pumps are manufactured under API License. Our pumps are thoroughly inspected at the plant and a second quality inspection is performed in the USA.

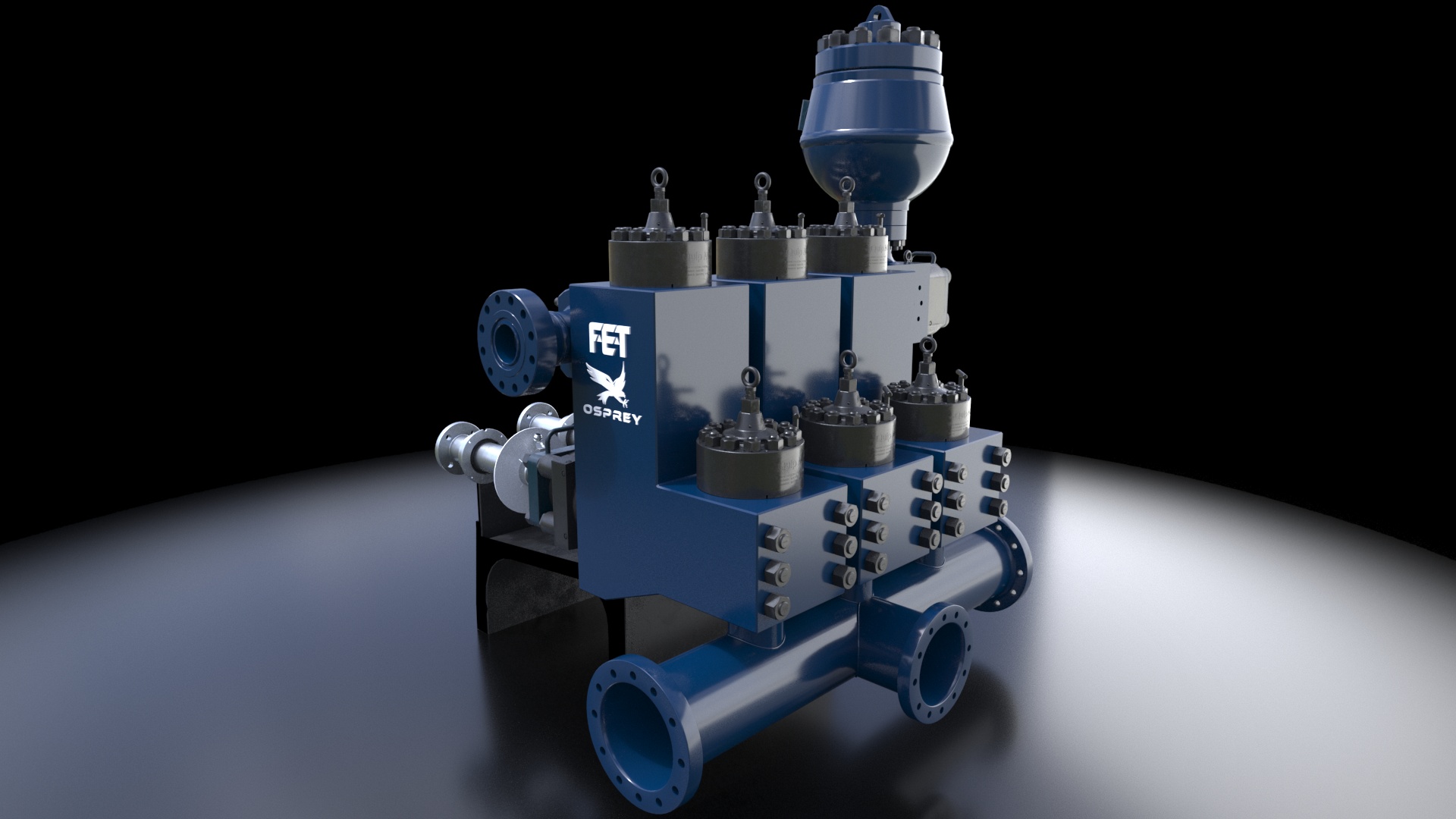

Mud systems are essential to every oil and gas rig. To successfully transfer fluid throughout your circulating system at pressures up to 7,500 pounds per square inch you need proven and reliable products. FET’s products have 30 years of innovation and field experience in providing industry-leading technology for your mud system operations.

Our industry-recognized centrifugal pumps, gate valves, drill pipe float valves, and wash pipes provide you with robust systems that meet the high-pressure demands of today’s drilling landscape.

Technology giants like HP, Microsoft, Apple and Amazon may not seem like the typical consumers of pumps for process wastewater, back wash and cooling processes. But Wastecorp is seeing much more pump inquiry activity from contractors and high tech end users in California’s Silicon Valley, New York’s Silicon Alley and data centers across the country.

pumps and systems for HP’s state-of-the-art research facility. HP’s facility seeks to reduce IT sprawl, increase energy efficiency and reduce power consumption, all in an effort to help their consumers focus on innovation instead of worrying about their carbon footprint.

Wastecorp went right to work for HP designing and manufacturing twoMud Sucker 3B Series Professional diaphragm pumps to pump cooling tower condenser water, also called backwash pumps. The pumps were designed to continuously pump the condenser water between 60-80°F. In keeping with HP’s goal of exploring new strategies for reducing the environmental impact of next-generation data centers Wastecorp designed the mud Sucker with energy saving Siemens 3 phase motors and Sew Eurodrive gear boxes. Hp’s Mud Sucker’s were designed in an inline-piping configuration to save space at the facility. Santoprene diaphragms were included to help maximize component life with higher temperature liquids being constant.

As more technology companies design data centers and data storage facilities to house the servers that power the 21st century economy, Wastecorp’s Mud Sucker product line is providing the pumps and packaged wastewater systems to help these companies achieve power reduction goals for process wastewater pumping, while gaining the latest pump technology to solve backwash pumping problems. Tech companies and contractors can reach Wastecorp at 1-888-829-2783 or info@wastecorp.com

Centerline Manufacturing is committed to the highest level of customer service quality. Every Centerline pump is comprehensively and repeatedly tested at diverse pressure levels to assure that it goes to our customer in perfect operational order. Centerline technicians work to ensure that our customers fully understand the operation of the model being delivered. If a customer"s pump is down, we understand the importance of timely response and parts availability. Centerline technicians will assess the problem and make repairs to bring the pump back into new specification. The Centerline mud pump technicians are well versed and qualified to operate and repair any product that is provided to the customer.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

Houston, Texas -- To eliminate equipment compatibility issues and the prospect of additional spare-parts inventories for drilling contractors, the LeTourneau Ellis Williams Company (LEWCO) can factory-equip its heavy-duty W-Series and general-duty WH-Series mud pumps with virtually any major brand of fluid end module. Customers not specifying a particular brand receive LEWCO"s standard one-piece or two-piece fluid end modules made of quenched and tempered forged steel, featuring "off the shelf" expendables readily available from domestic and international sources.

LEWCO mud pumps are in-house manufactured. For maximum quality assurance -- with job-ready performance verified in advance -- every pump is tested under full load prior to shipment, in the company"s fully equipped, million-dollar "mud pump laboratory." LEWCO pumps provide input ratings of 300 to 3,000 horsepower (224 kW to 2,237 kW) and deep-drilling discharge pressures as great as 7,500 pounds per square inch (527 kg/cm2). Their premium components include a pressurized lubrication system that force-feeds lubricant to all power-end bearings including upper and lower crosshead slides; a balanced forged steel crankshaft that reduces noise and vibration and helps extend component life throughout the pump; and a robust frame of double-wall, welded-steel, mounted on a heavy-duty oilfield skid.

The LeTourneau Ellis Williams Company builds high-performance mud pumps for oil and gas drilling (on land and offshore), petroleum production and processing, well-servicing, and horizontal directional drilling; as well as ancillary drilling products including pulsation dampeners; drawworks; rotary tables, transmissions, and drives; and swivels. Located in Houston, Texas, LEWCO is a wholly owned subsidiary of LeTourneau Incorporated, a leading manufacturer of self-elevating offshore drilling rigs, forestry equipment, and wheel loaders.

For more information, contact the LEWCO Sales Department at 6500 Brittmoore Road, Houston, TX 77241-1343; telephone 1-888-MUD-PUMP (683-7867), fax 713-856-5341; e-mail pumps@lewco-equip.com. Or visit www.lewco-equip.com.

Distributor of engineered fluid handling pumps, packaged pumping systems, repairs, parts, & integrated pump control systems. Mud pumps, chiller/condenser pumps, plumbing pumps, boiler feed systems, in-line circulators, condensate systems, sump & sewage pumps, end suction pumps, submersible sump & sewage, non-clogs & grinders, self primers, packaged lift stations, variable speed pump systems, metering pumps, chemical injection systems, chemical mixing systems, peristaltic pumps for chemical feed, high viscous & shear sensitive fluids, self primers, stainless steel, trash pumps, hot oil pumps, vertical turbine pumps, sanitary pumps, marine pumps, industrial pumps, ANSI end suction, vertical cantilever, double suction, non-clogs, progressive cavity pumps, helical gear pumps, well pumps, lab pumps, hose pumps, control valves, check valves, air release valves, tanks, pressure vessels.

Introducing the industry’s first cordless powered loading pump for drywall mud. Designed to fill all automatic taping and finishing tools. PowerFill totally eliminates the need to manually pump. Now you can quickly fill with just the push of a button.

Never Hand Pump Again. Single-button pumping eliminates fatigue and injury associated with manual pumping. Pumps up to 3.5 gpm for lightning-fast filling and up to 55 gallons on a single battery charge for all-day filling. Programmable to refill tools automatically with Precision Fill.

The contractor-proven pump technology and cordless power capability found on Graco automatic drywall mud pumps helps reduce fatigue while maximize efficiencies on interior drywall or texture jobs. Finish every drywall job faster and never hand pump again with Graco PowerFill 3.5 Cordless Loading Drywall Pumps.

8613371530291

8613371530291