mud pump valve rubber in stock

A wide variety of mud pump valve inserts options are available to you, such as 1 year, not available.You can also choose from new, mud pump valve inserts,As well as from energy & mining, construction works , and machinery repair shops. and whether mud pump valve inserts is 1.5 years, 6 months, or 3 months.

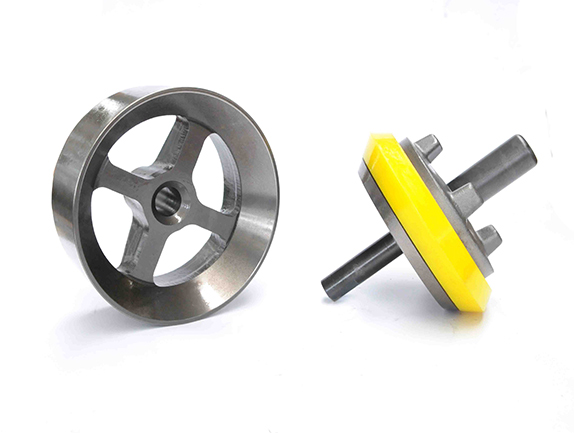

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

Offer an expansive range of valves and seats such as premium cross arms valve and seat, arms valve and seat. Full-open valve and seat, long-life bonded valve with urethane, ling-life valve with urethane. Wide choice of options available for requirements not met by hardened of stainless steel valves and elastomer -insert valve seats. He hardened steel liner service life surpasses 800 hour under the normal condition

The Stem Guided valve and seat and the Wing Guided valve and full open seat offers many advantages for today"s higher pressures and faster drilling operations.

Stem-guided valve &Tri-arm seat features greater fluid flow than four-arm seats, as well as it features an extra wide metal to metal seal on the valve flange. The serrated upper surface on the valve gives a longer non-breathing seal between valve body and insert while the rigid seat cross-arms give greater strength and positive sealing. The strong, thick, valve knock off nut holds the insert tightly reducing flex and breathing which lessens the chance of foreign matter getting between valve and insert.

Stem-guided valve & Cross-arm seat features an extra wide metal to metal seal on the valve flange. The serrated upper surface on the valve gives a longer non-breathing seal between valve body and insert while the rigid seat cross-arms give greater strength and positive sealing. The strong, thick, valve knock off nut holds the insert tightly reducing flex and breathing which lessens the chance of foreign matter getting between valve and insert.

Three-wing guided valves and full open seats features greater fluid flow than four-wing valves, the unibody forged valve features greater strength than traditional welded-wing valve. Innovative unibody valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts and easy installation.

Innovative unibody Four-wing guided valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts and easy installation. This combination will handle lost circulation material better than most conventional style valves and seats while the seating angle greatly improves flow characteristics and the heavy-duty load bearing capacity greatly improves service life.

The unibody forged Four-wing guided valve & Full open seat features greater strength than traditional welded-wing valve. Innovative unibody valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts and easy installation.

The main material of Valve Assembly is high quality alloy steels, such as 20CrMnTi, 20CrNiMo. The Valve Insert was made by newly high molecular materials, to make the mud pump spares to resisthigh-temperature, high-pressure, anti-friction and sulfur corrosion.

1). Technical Support and Production Ability: Although we are one relatively new company, but we have the most professional engineers with tens of years experience in mud pump. And we have hundreds of highly skilled workers working on the pump parts and pump assembling with numerous advanced machines. Our production ability has been siteaudited by supervising inspectorate like France BV (Bureau Veritas), DNV(Det Norske Veritas) and SGS-CSTC(Standards Technical Services Co., Ltd.)

2). Quality Assurance: Ten professional inspectors performstrict quality inspection from the initial forgings, castings, other rawmaterials, each finished machined parts until the final assembling of the pump. Each part assembled on the pump will be well tested and highly qualified. Andfor each pump finished, it will be running tested in our test center for atleast 4 hours. Quality certificate, Inspection report and testing report will beattached when pump is delivered. 12 Months quality guarantee will be offered for each pump.

3). Competitive Price:We are one of the top pump manufacturers in China. We have the greatest advantages in price. We can not offer you the lowest price in China, but most competitive price but with very good quality.

4). Quick Delivery: Usually we will keep some pump model in stock so that we can make fast delivery for clients with urgent need. For pump we do not have in stock, we can also deliver with 40 days.

Mud pump valve body and mud pump valve seat were produced according to API Specs as well as ISO9001 quality system by our company, were used high quality alloy steel 40CrNiMo、20CrMnTi, processed with overall forging and carburizing, the surface hardness HRC≥60; They were produced under accurate calculation and numerical control lathe, which makes dimensions of valve body and seat perfectly match each other, also were used many times by land and offshore platforms. The service life of valve body and seat are 4-5 times more than ordinary ones, which improves the working efficiency and decrease the cost and working strength.

Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). As to valve insert (valve rubber) material, we can provide Nitrile rubber (NBR) valve insert, polyurethane (PU)valve insert, compound polyurethane and HNBR.

Being a customer focused organization; we are engaged in offering a wide assortment of Mud Pump Valve Inserts. All our products are provided to clients in different sizes and specifications at most competitive prices. Further, these products are thoroughly checked by expert quality controllers on various parameters to determine flawlessness.

The valve assembly is the key component of the hydraulic end of the mud pump. The valve assembly consists of valve body, valve rubber, valve nut, guide frame, gland, clamp spring, steel ball, etc. (i.e. valve assembly with valve seat removed).

According to the inner hole form of the valve seat, the valve assembly can be divided into a through hole valve, a three-rib valve and a four-rib valve. The valve body and the valve seat of the valve assembly are carburized and quenched with high-quality bonded steel 20 Customer-relationship Management NTI, the surface hardness is greater than HRC60, and the conical surface is ground to ensure high roughness requirements and geometric dimensions.

Four-rib valve body is made of high-quality forged steel with high strength and hardness. The rubber is fixed on the valve body by the valve nut. The valve seat has high strength and impact resistance, and is suitable for high-pressure jet drilling. Compared with four ribs, the three-rib valve body seat has larger displacement, and can provide directly assembled valve body and valve rubber with long service life.

The rubber is made of polyurethane material, and the effective service time is more than 300 hours, which greatly improves the overall service life of the valve assembly.

Our company can produce all kinds of valve bodies and seats for F series, 3NB series and other series of drilling pumps. It supplies tens of thousands of sets of oil fields at home and abroad every year. The valve assembly consists of a valve body assembly and a valve seat. The valve body and valve seat supplied by our company are all made of high-grade alloy steel by integral die forging and are processed according to strict technological regulations.

The positive displacement mud pump is a key component of the drilling process and its lifespan and reliability are critical to a successful operation.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

Due to the nature of its operation, pistons, liners, and valve assemblies will wear and are considered expendable components. There will be some corrosion and metallurgy imperfections, but the majority of pump failures can be traced back to poor maintenance, errors during the repair process, and pumping drilling fluid with excessive solids content.

A few signs include cut piston rubber, discoloration, pistons that are hard to remove, scored liners, valve and seat pitting or cracks, valve inserts severely worn, cracked, or completely missing, and even drilling fluids making their way to the power end of the pump.

The fluid end of a positive displacement triplex pump presents many opportunities for issues. The results of these issues in such a high-pressure system can mean expensive downtime on the pump itself and, possibly, the entire rig — not to mention the costly repair or replacement of the pump. To reduce severe vibration caused by the pumping process, many pumps incorporate both a suction and discharge pulsation dampener; these are connected to the suction and discharge manifolds of the fluid end. These dampeners reduce the cavitation effect on the entire pump which increases the life of everything within the pump.

Poor maintenance — such as improper valve and seat installation — is another factor. Improper cleaning when replacing a valve seat can leave sand or debris in the valve seat area; preventing the new seat from properly forming a seal with the fluid cylinder, causing a pathway for a washout to occur. It is important to pull up on a seat firmly by hand and make sure it doesn’t pop out and is properly seated. The seats must be seated well, before resuming repairs. You should never reuse a valve seat if at all possible.

The fluid end is the most easily damaged part of the mud pump. The pumping process occurs within the fluid end with valves, pistons, and liners. Because these components are high-wear items, many pumps are designed to allow quick replacement of these parts.

A washout occurs when fluid and solids enter the area behind or underneath a valve seat and erode the sealing surface. Washouts are usually caused by one of three issues: a worn or cracked valve seat, improper cleaning of the valve seat and deck which creates a poor seat seal, and excessive sand content in your drilling fluid. Worn or cracked valve seats can allow fluid to enter the area around the valve seat and seat deck, creating a wash point on the valve seat and causing it to cut into the fluid cylinder and seat deck.

Additionally, the throat (inside diameter) can begin to wash out from extended usage hours or rather quickly when the fluid solids content is excessive. When this happens it can cut all the way through the seat and into the fluid end module/seat deck. This causes excessive expense not only from a parts standpoint but also extended downtime for parts delivery and labor hours to remove and replace the fluid module. With that said, a properly operated and maintained mud recycling system is vital to not only the pump but everything the drilling fluid comes in contact with downstream.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Unser Vertriebs- und Logistikpersonal reagiert prompt auf Ihre Anfrage und ist rund um die Uhr, 24 Stunden an 7 Tagen die Woche, erreichbar. In unserem großen Warenlager mit einem umfangreichen Lagerbestand führen wir die gängigsten Spülpumpen- Verbrauchsmaterialien und -Ersatzteile.

8613371530291

8613371530291