mud pump valve rubber manufacturer

A wide variety of mud pump valve rubber options are available to you, such as 1 year, not available and 3 years.You can also choose from new, used mud pump valve rubber,As well as from energy & mining, construction works , and machinery repair shops. and whether mud pump valve rubber is 1.5 years, 6 months, or unavailable.

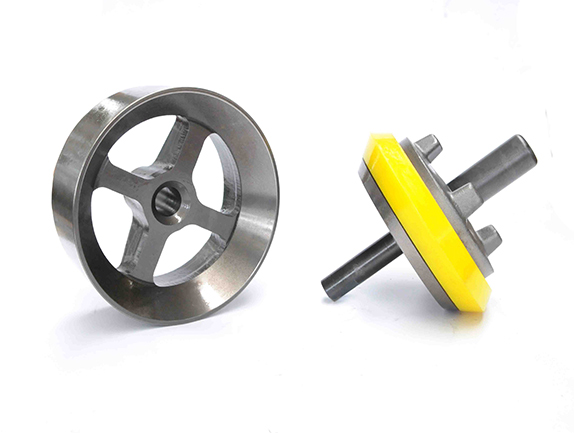

Valve rubber is a parts used in the mud pump valve. Different types of valve insert for different valves can be provided, such as Full open valve rubber, three web valve rubber, four web valve rubber. And different materials can be provided for customers to suit for their different oil drilling operations, such as PU valve rubber, NBR Valve rubber, and HNBR valve rubber etc.

Mud pump valve body and mud pump valve seat were produced according to API Specs as well as ISO9001 quality system by our company, were used high quality alloy steel 40CrNiMo、20CrMnTi, processed with overall forging and carburizing, the surface hardness HRC≥60; They were produced under accurate calculation and numerical control lathe, which makes dimensions of valve body and seat perfectly match each other, also were used many times by land and offshore platforms. The service life of valve body and seat are 4-5 times more than ordinary ones, which improves the working efficiency and decrease the cost and working strength.

Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). As to valve insert (valve rubber) material, we can provide Nitrile rubber (NBR) valve insert, polyurethane (PU)valve insert, compound polyurethane and HNBR.

Mud Pump Valve & Seat are made of premium alloy steel through one-piece forging and carburizing treatment processes, thereby ensuring high intensity. In addition, the precise calculation is performed and CNC machining is conducted for the dimensional matching of the valve seat and valve body working angles to enhance the service life of the valve body and valve seat. Our valve products are able to work smoothly in normal mining and digging conditions for over 400 hours.

Also known as Nova Tech Valve or Roughneck Valve or High Pressure Valve. Full open Seat & wing guided Valve design features a large metal-to-metal bearing area for long life, directly casted urethane insert on valve body results in a perfect round shape that prevents premature failures of the insert. The insert is casted around the serrations, thus failure due to tears from the serrations are eliminated Most importantly the insert is not stretched over the valve during installation; there are no residual stresses left, to shorten insert life.

Offer an expansive range of valves and seats such as premium cross arms valve and seat, arms valve and seat. Full-open valve and seat, long-life bonded valve with urethane, ling-life valve with urethane. Wide choice of options available for requirements not met by hardened of stainless steel valves and elastomer -insert valve seats. He hardened steel liner service life surpasses 800 hour under the normal condition

The Stem Guided valve and seat and the Wing Guided valve and full open seat offers many advantages for today"s higher pressures and faster drilling operations.

Stem-guided valve &Tri-arm seat features greater fluid flow than four-arm seats, as well as it features an extra wide metal to metal seal on the valve flange. The serrated upper surface on the valve gives a longer non-breathing seal between valve body and insert while the rigid seat cross-arms give greater strength and positive sealing. The strong, thick, valve knock off nut holds the insert tightly reducing flex and breathing which lessens the chance of foreign matter getting between valve and insert.

Stem-guided valve & Cross-arm seat features an extra wide metal to metal seal on the valve flange. The serrated upper surface on the valve gives a longer non-breathing seal between valve body and insert while the rigid seat cross-arms give greater strength and positive sealing. The strong, thick, valve knock off nut holds the insert tightly reducing flex and breathing which lessens the chance of foreign matter getting between valve and insert.

Three-wing guided valves and full open seats features greater fluid flow than four-wing valves, the unibody forged valve features greater strength than traditional welded-wing valve. Innovative unibody valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts and easy installation.

Innovative unibody Four-wing guided valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts and easy installation. This combination will handle lost circulation material better than most conventional style valves and seats while the seating angle greatly improves flow characteristics and the heavy-duty load bearing capacity greatly improves service life.

The unibody forged Four-wing guided valve & Full open seat features greater strength than traditional welded-wing valve. Innovative unibody valve design eliminates snap rings, plates or keepers providing reduced maintenance by snap-on valve inserts and easy installation.

High quality Red NBR Insert Mud Pump Valve ASSY AH36001-05.12A.03 Polyurethane Casting from China, China"s leading Mud Pump Valve product market, With strict quality control Mud...

Outer Diameter2 TO 7 INCHWe are one of the leading manufacturers and suppliers of a quality-approved range of Mud Pump Piston Cup. Precisely designed, these products are made using quality components that are obtained from the authorized vendors of the market. Moreover, our products can be customized as per the specifications laid down by the customers.

ShapeROUNDBeing a customer focused organization; we are engaged in offering a wide assortment of Mud Pump Valve Inserts. All our products are provided to clients in different sizes and specifications at most competitive prices. Further, these products are thoroughly checked by expert quality controllers on various parameters to determine flawlessness.

Revata Engineering offers very high quality and precision machined sleeved bi-metallic liners finished to relevant API dimensions. They are available for various pumps, manufactured by Oil Well, National, Gardner Denver, Omega, Ellis Williums, Bournedrill and others.

Piston Assemblies are available both in single and double acting type. They are available for different models of pumps manufactured by Oil Well, National, Gardner Denver, Omega, Ellis Williums, Bournedrill and others. Piston rubber of piston assemblies are manufactured by using very high strength polymer with very tough fabric backing. Special care is taken for accurate dimensions of Piston body to ensure very long life. Revata Engineering"s piston assemblies give very long life even under extreme working conditions.

Valve Assemblies consisting of Valve Seat, Valve Body, Valve Spring & Valve Insert are available for different models of pumps manufactured by Oil Well, National, Gardner Denver, Omega, Ellis Williums, Bournedrill and others. Special care is taken for the dimensional matching of valve seat and valve body working angles for ensuring very high life even under extreme working conditions. Valve Inserts are made out of high quality polyurethane material.

Revata Engineering manufactures Valve Cover Gaskets & Packing out of special grade of rubber compounds for the specific applications. The rubber compound has been developed by our Research & Development team after intensive research and customer inputs. Packings, require skill-full manufacturing technique have also been developed after intensive application research and now they are rated as one of the best in the market.

Revata Engineering manufactures Pulsation Dampeners using a blend of Hydrogenated Nitrille Rubber most suitable for such application, strongly bonded with metal wherever required.

Other items like Piston rod, Lantern Ring, Liner Wear Plate, Liner Gasket, Wiper Rod, Oil Seals, Valve Guide, Bushing, Liner Wear Plate Gaskets, are also available for different models of pumps of Oil Well, National, Gardner Denver, Omega, Ellis, Williums, Bournedrill and others.

Valve Seat, Valve Body and Valve Nut are manufactured by using forged carbon steel / stainless steel as per the requirement of the users, suitably hardened grounded finished and hard-coated, wherever required. Special care is taken for dimensional matching between Valve Seat and Valve Body working angles to ensure long-life under severest of working conditions. Inserts are available in polyurethane and other polymers to suit customers’ requirement.

8613371530291

8613371530291