piston mud pump fluid end components factory

Premium Oilfield Technologies takes the responsibility of listening to our clients’ concerns very seriously. Acting on those needs enables Premium to offer robust solutions to customer issues at the rig. The Caliber® DS-7500 Fluid Ends bring together our years of field experience and unmatched client interface to represent the NEW standard for your Gardner Denver pumps.

All modules and fluid end components offered by Acumen International are of high-strength, premium alloy steel, heat treated for a long working life and machined to precise tolerances. Each product is rated for all drilling operations up to 7500 PSI.

Manufacturing utilizes the latest technologies to produce accurate and uniform parts. All products offered are either OEM or completely interchangeable. All fluid end accessories are available for most triplex and duplex mud pumps.

For maximum performance and durability, our modules are made from individually forged, heat-treated alloy steel and feature an API 7 valve assembly for improved flow. Our L-shaped design features bore-seal technology for improved seal performance in higher pressures and is compatible with numerous “F-Series” drilling pumps including Honghua®, Bomco® Rongsheng®, Workforce® and other similar designs.

MKP offers a complete line of interchangeable fluid end modules and accessories for triplex mud pumps. Fluid ends and components are interchangeable to OEM’s such as National, Emsco, Gardner Denver, Bomco, Ideco and Oilwell. We offer both standard OEM style replacement parts and Two piece “L” Shaped fluid ends. Manufactured to the highest quality, our products offer the best performance and durability. 5000psi & 7500psi available.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Triplex: This mud pump is used for drilling applications needing high pump pressure. This model works by decreasing the working fluid volume being discharged to generate pressure for producing the flow. There are three pistons in the triplex pump, with the middle piston generating more pressure on the crankshaft. High piston load can lead to excessive pressure and crankshaft failure if the components are not properly sourced.

Quintuplex:Quintuplex mud pump is perfect for pumping fluid at the time of drilling operations. It works as a continuous duty return piston. This is used in terms of its external bearings to provide crankshaft support to ensure the proper functioning of the sheaves.

Duplex: These mud pumps ensure that the mud circulation reaches the well"s bottom from the mud cleaning system. Duplex pumps have binocular floating seals as well as safety valves.

Saigao offers high-quality OEM mud pump spares, consumables, expendables and spare parts. Our mud pump parts are made with the highest standards of quality, offering competitive pricing and exceptional durability.

Bonded-Nitrile Pistons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Replaceable Nitrile Pistons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Fluid-End Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Mud-Pump Gear Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

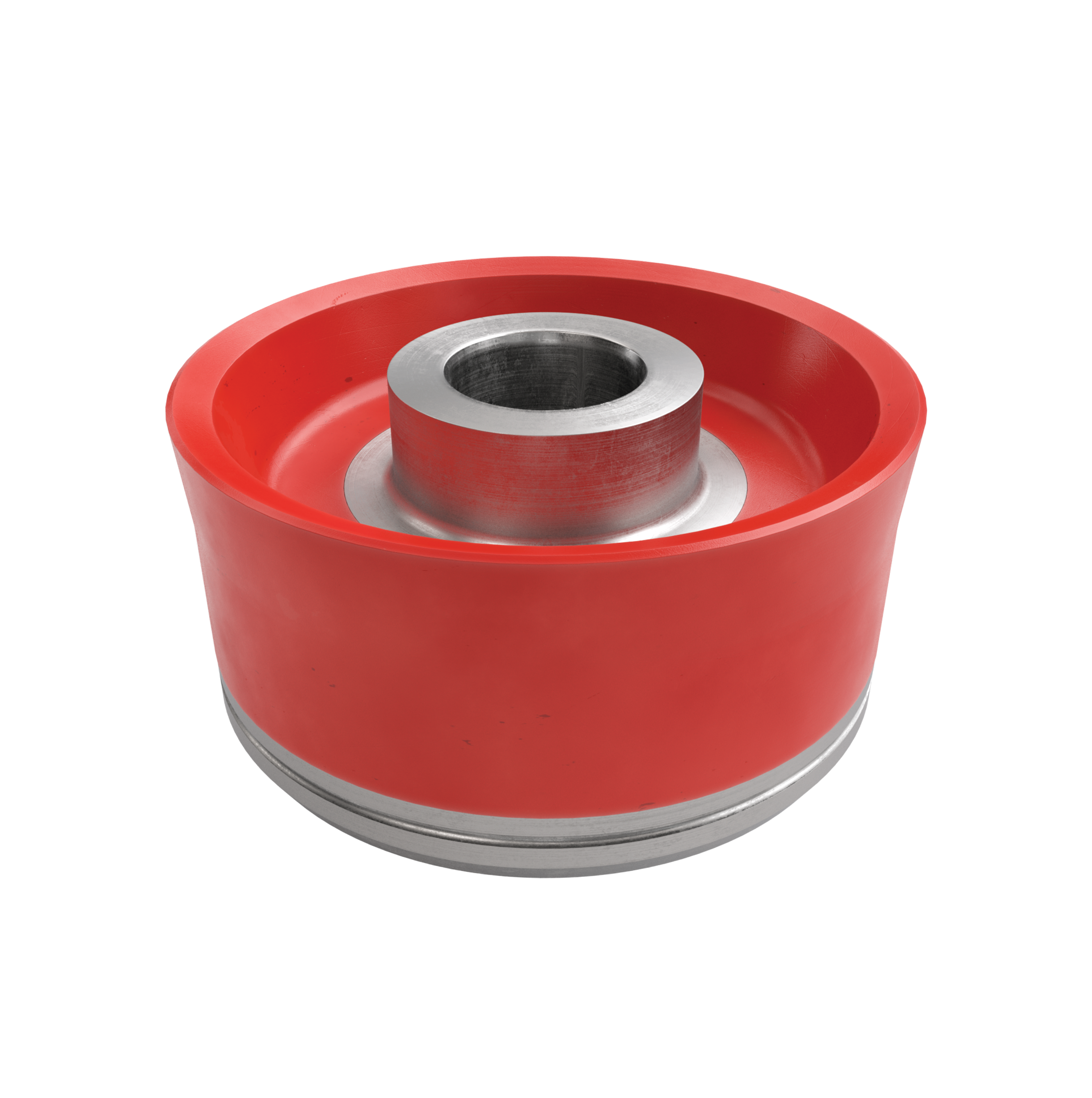

A Mud Pump may have many changeable parts, such as liner, piston, extension rod, pulsation dampener, valve, clamp, etc. Lake Petro could provide 100% interchangeable parts of many common brands of pump. We offer Liners with Ceramic (Zirconia and Aluminium oxide) and Steel (Metal and Bi-metal) materials. Piston assembly is the important spare parts and expendable parts of oil drilling mud pumps. Mud pump valve assy include valve body, valve seat, valve insert (valve rubber ). Pulsation Dampener is usually installed on the discharge line to reduce the fluctuation of pressure and displacement of the drilling mud pump. Fluid End Module is an important component of the hydraulic pump end of the mud pump.

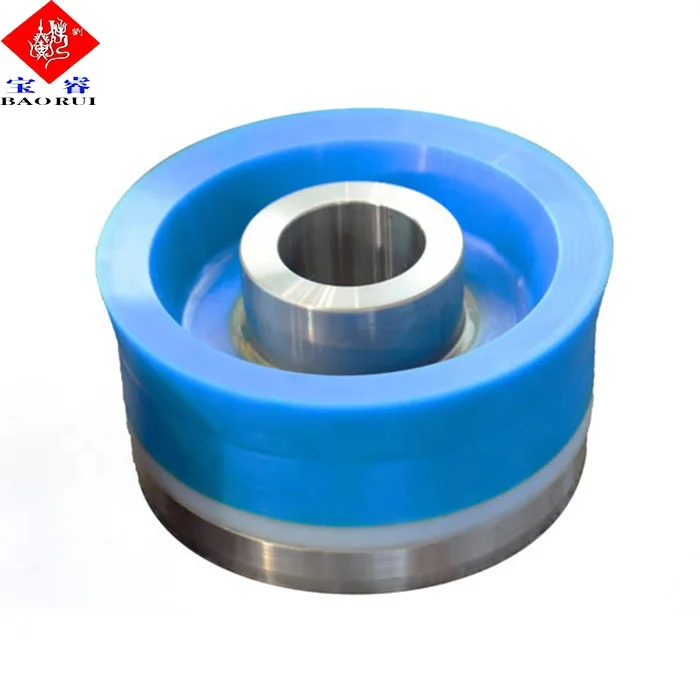

Baoshan manufacture full range of fluid end parts for mud pump,such as fluid end module,liner,piston,valve&seat,rod&clamp,etc. Every part meet OEM specs and API standard.

Whether onshore or offshore, well-drilling sites rely on a multitude of systems to successfully perform the drilling operation. The mud pump is a key component tasked with circulating drilling fluid under high pressure downhole. The mud pump can be divided into two key sections: the power end and the fluid end. The alignment of the power end to fluid end on mud pumps is key to achieving suitable life and performance of the piston and liner system.

Misalignment contributes to accelerated wear on both the piston and the liner, and replacing these components requires downtime of the pump. The traditional method of inspecting alignment is to remove the piston from the piston rod, stroke the pump forward and check the vertical and horizontal alignment of the piston rod OD to the piston liner ID with micrometers. This is a time consuming and cumbersome technique that was ultimately not well suited to troubleshoot and solve alignment issues.

“I’m a firm believer in Pinpoint’s Mud Pump Alignment Kit, having used it as well as the old manual methods and even Faro arms in troubleshooting pumps on offshore rigs. In the hands of someone who understands pump alignment it is a powerful yet portable tool.”

“We routinely utilize Pinpoint Laser Systems’ Mud Pump Alignment Kit. We have one service technician dedicated to pump alignments and have seen continued success correcting issues on pumps after numerous rebuild attempts by others proved unsuccessful.”

We manufacture mud pump fluid end parts ,such as fluid end module,liner,piston,piston rod,valve body,valve seat,etc.API standard.Welcome to send any inquiry to my mail mudpumppa...

Since 1969, Laxmi Udyog is manufacturing wide range of critical Fluid End Expendables which are best suitable for various mud pump makes, which includes Gardner- Denver, National, Oilwell or LEWCO and is catering to drilling contractors, operators and service companies worldwide.

Modern manufacturing technology and quality systems ensures that all the products confirms their best service and deliver satisfactory performance under any combination of pressures, abrasives, corrosive fluid and friction heat.

8613371530291

8613371530291