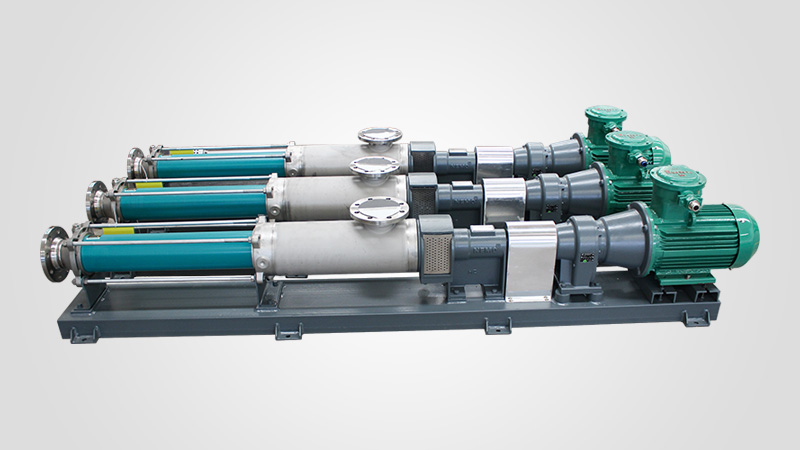

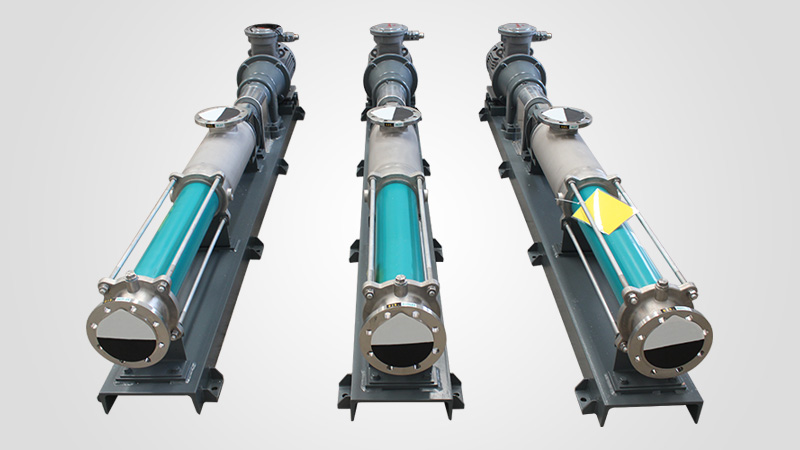

progressive cavity mud pump factory

Sulzer offers a range of progressing cavity pumps for demanding positive displacement process applications. Our pumps provide a near constant flow rate and suction lift capability for handling wastewater sludge, slurries, viscous and shear thinning non-Newtonian fluids.

Progressive cavity pumps are nowadays available in different geometries, owing to their increasing use in various industrial applications. The degree of product entry into the cavity, the degree of sealing and efficiency between the cavities vary across these geometries. The standard geometry is suited for highly viscous and thick material, however, MXQ progressive cavity pumps have elongated geometry with a large surface contact between the stator and the rotor. This large surface contact helps improve the efficiency of the progressive cavity pump.

Elongated Profile Rotor and Stator: The overall diameter of the rotor and stator is decreased, whereas the pitch is increased. The performance and shelf life of the progressive cavity pump depends on the surface speed at the periphery of the rotor against the stator. This speed is termed as rubbing velocity, which can minimize the life expectancy of the pump’s rotor and stator. All MXQ progressive cavity pumps are designed to have low rubbing velocities, which has improved their life by 40% than standard pumps available in the market.

Universal Cardan Joint (3-year Warranty):During the operation, the progressive cavity pump’s rotor has three different centers of rotation. As the centerline of the rotor is offset from the centerline of the drive shaft, a drive connection cannot be made easily. This type of connection is established using a flexible type drive. In many progressive pump designs, this flexibility is achieved using a pin joint or a gear joint. However, in MXQ progressive cavity pumps, the hollow shaft utilizes the Universal-Cardan joint design. This joint helps minimize the dependence on hollow tube configuration, improves angularity, as well as reduces the required length of connecting rods.

Universal joint used in MXQ progressive cavity pumps is lubricated with synthetic temperature stable lubricant, and is offered with a 3-year warranty.

A progressive cavity pump is a type of positive displacement pump transfers fluid by means of the progress, through the pump, of a sequence of small, fixed shape, discrete cavities, as its rotor is turned. This leads to the volumetric flow rate being proportional to the rotation rate and to low levels of shearing applied to the pumped fluid. These pumps are commonly used for fluid metering and pumping of viscous or shear-sensitive materials.

A progressive cavity pump can also act as a motor when fluid is pumped through the interior. This method is commonly used in oil well drilling. Mud motor (Mud Pump or Drilling Motor) refers to a Progressive Cavity Positive Displacement Pump placed in the Drill string to provide additional power to the bit while drilling. The PCPD Pump uses Drilling Fluid (commonly referred to as Drilling Mud) to create eccentric motion in the power section of the motor which is transferred as concentric power to the drill bit (well). The Mud Motor uses different rotor and stator configurations to provide optimum performance for the desired drilling operation, typically increasing the number of lobes and length of power assembly for greater horsepower.

inspection of progressive cavity pump stators. Based on our BEMIS™ technology, the sensors provide extended range capability that is required to operate over a wide range of stator sizes. This system is now in commercial use for the manufacture of oil field mud pumps. The tool can also be employed for the inspection of stators as they are prepared for deployment in the field. LTC’s progressive cavity pump inspection system is a valuable tool for manufacturing quality control and for ensuring the safe, useful life of drill strings.

Roto Pumps is a noted Progressive Cavity Pumps manufacturer. High Pressure Progressive Cavity Pumps are also known as Single Screw Pumps, these pumps have been built and designed to transfer liquids with different chemical properties and variable viscosities. These pumps can be customized as per the application requirement. These pumps function with the help of precision mechanized single external helix metallic rotor and double internal helix elastomer stator. The fluid gets transferred through the cavities formed by the turning of the rotor within the stator.

The working principle of these pumps involves the rotation of the single helix-shaped rotor within the stator. A sealing line is developed along the axis of the rotor owing to the positioning of the rotor and the stator, which upholds in both static and compelling conditions. Several cavities are formed along the suction and the discharge end of the pump by the rotation of the rotor. These cavities transfer the fluid within the pumps.

UT Pumps & Systems Pvt Ltd is an ISO 9001-2008 certified company for design and development of Positive Displacement pumps as per designs acquired from European manufacturers by virtue of Joint Venture partnerships. Known as a solution providing company with presence in almost all industries for a wide range of applications

HYDRO PROKAV PUMPS INDIA PRIVATE LIMITED is one of the Leading Manufacturers and Exporters of various types of Positive displacement Pumps based in In

SEEPEX metering and dosing pumps are a range of precision pumps that have a metering accuracy of +/- 1%. The pumps are found in a variety of industrial and municipal applications and are especially suited for low pulsation delivery of low to viscous media as well as chemically aggressive media and media containing solids.

The biggest characteristic of progressive cavity pump is that it is especially suitable for conveying sensitive liquids which cannot be sheared, squeezed or stirred, that is, non-Newtonian liquids which will show thixotropic properties when subjected to shearing. It is not only suitable for transporting medium with low viscosity such as water, but also especially suitable for transporting suspension containing solid particles or short fibers and medium with very high viscosity.

When the fluid with high viscosity and poor fluidity is input, we need to pay attention to whether it can flow into the pump fast enough. If it cannot, it will easily cause the dry grinding and volumetric efficiency of the pump to change. So we need to pay attention to the speed of the fluid being conveyed and its viscosity.

In order to ensure the life of the progressive cavity pump, we usually control the speed to a low level so that a large flow will not be generated. If you need to increase the flow, usually add a variable frequency drive (VFD) or stepless speed reducer. Speed and flow are often proportional. But the maximum flow rate of the progressive cavity pump in our factory can reach: 300m³/h;

The progressive cavity pump is a positive displacement pump. It has only one screw rotor, which has slight interference fit with the rubber stator. Screw pumps also need at least two screw rotors to cooperate, and usually there are three or five screw rotors to cooperate. The name is also named after the number of screw rotors. For example, a pump with two screw rotors is called a twin screw pump.

Comparison of the media conveyed by different types of screw pumps:Twin screw pump can transport lubricating, non-lubricating, corrosive and medium containing certain magazines, even used for oil, steam and liquid mixed transportation. Commonly used for conveying various oils, water, emulsion, paste, asphalt and chemical media, etc.

Five-screw pump is suitable for low-pressure and high-flow conditions, conveying lubricating medium, and it is more sensitive to impurities in the medium than three screw pump.

Screw pumps are not made of rubber like progressive cavity pumps, but almost all of them are made of metal. Performance: Screw pump can deliver larger flow and pressure.

Due to the slight interference fit between the stator and the rotor of the progressive cavity pump, it is not allowed to run dry. Once the dry running of the pump is not stopped in time, the stator will burn out immediately. Therefore, it is necessary to fill the pump cavity with the medium, and the medium in the system cannot be interrupted.

Special situation: When installing the pump, if you don’t know whether the motor is in the forward or reverse direction, you can run the pump 1-2 times in dry mode.

It was invented by French engineer MoiNeau, so it is called Mono Pump. It has many nicknames. Sometimes we will call it helical rotor pump, eccentric screw pump, PC Pump or PCM Pump, Crank Rod Pump and Snake Pump. In China, it is also called single screw pump and thick slurry pump. No matter how many nicknames it has, it belongs to positive displacement pump.

In 1930, when aviation pioneer René Moineau was designing compressors for early jet engines, he discovered that this principle could work efficiently for pumping fluids. So he cooperated with Robert Bienaime of Gevelot Group to establish PCM Pompes in 1932 and developed the world’s first known progressive cavity pump.

When the viscosity or thickness of the liquid is higher than that of water, which is not suitable for centrifugal pump delivery, use progressive cavity pump.

When the suction conditions of the pumping applications are not ideal and when the suction pressure is lower than 28 inches of mercury (Hg), the progressive cavity pump can pump, but the centrifugal pump cannot.

When transporting sensitive liquids that cannot be sheared, squeezed or agitated, the speed of the centrifugal pump is too high, which will easily damage the fluid structure.

When the liquid contains solid particles, centrifugal pumps or other positive displacement pumps are easy to wear or block. At this time, because the stator and rotor of the progressive cavity pump has a wear resistance design, it will be more suitable for this application.

The main working parts of progressive cavity pump are stator and rotor. Because of the special geometric shape of stator and rotor, when assembled together, several separate sealing cavities will be formed. When the motor drives the rotor to move, the medium in each sealing cavity will be continuously and uniformly transported from the suction end to the extrusion end with constant volume.

Progressive cavity pumps have self-priming performance and good suction performance, and the self-priming height is generally 2-5 meters (taking water as the test); When transporting sludge or medium with high viscosity, self-priming installation is generally not recommended, but natural inflow is recommended.

The customer is required to provide the flow rate, output pressure or head of the fluid to be transported, and to inform the physical and chemical properties of the fluid in as much detail as possible, and then the factory will select and recommend for you based on experience. Because of improper selection of progressive cavity pumps, it is easy to cause many problems in use. The right pump can create more value and reduce costs for you.

Products: Progressive Cavity Pumps, ANSI Process, Centrifugal Pumps, High Pressure, Sanitary 3A, Hygienic, Metering, Rotary Gear, Vertical turbine, Submersible, Air Operated Diaphragm, Non Clogging, Food Transfer, Screw, Slurry, Rubber lined, Cleaning, Split Case Pumps

DXP Cortech offers a range of progressive cavity pumps from Seepex, including group N pumps, which are the basic product group of all Seepex progressive cavity pumps. These progressive cavity pumps can be used in almost any of industry to pump low-to-highly viscous media, with or without solids.

Sydex is a modern, global manufacturer of progressing cavity pumps, grinders and macerators. We provide extensive expertise and knowledge throughout the World, enabling us to become totally focused on our customers’ needs from manufacturing through ...

Compact and versatile, the FM range brings you all the advantages and performances of progressing cavity pumps, in a light, compact and economical ...

Sydex is a modern, global manufacturer of progressing cavity pumps, grinders and macerators. We provide extensive expertise and knowledge throughout the World, enabling us to become totally focused on our customers’ needs from manufacturing through ...

PCM was founded in 1932 by René Moineau, the inventor of the Progressing Cavity Pump (PCP). For more than 85 years, PCM has been offering high quality, cost effective fluid handling solutions based on low life-cycle costs to our customers in oil & ...

The PCM Moineau A progressing cavity pump is a culmination of our unrivalled industry expertise and our unwavering commitment to provide the best fluid handling ...

PCM was founded in 1932 by René Moineau, the inventor of the Progressing Cavity Pump (PCP). For more than 85 years, PCM has been offering high quality, cost effective fluid handling solutions based on low life-cycle costs to our customers in oil & ...

MXQ MW-Series is 100% equivalent to Moyno 34401 Wobble Rotor Equivalent Pump. MXQ MW-Series pumps are compact and light weight, designed for transfer duties in both domestic and industrial applications. They provide ...

If your municipal lift station pumping challenges are the high cost of personnel and the cost of energy, check this out: Here are some of the personnel cost savings: The DIP System® will end lift station cleaning, Ends pump removal to clean out ...

If your municipal lift station pumping challenges are the high cost of personnel and the cost of energy, check this out: Here are some of the personnel cost savings: The DIP System® will end lift station cleaning, Ends pump removal to clean out ...

We offer a complete line of Progressing Cavity Pumps for the commercial waste water and industrial markets. Our goal is to offer quality products and service at a competitive ...

Model CP Pumps are great for low GPM and viscosity applications and can pump many different types of materials. It’s a low cost pump that is compact and has many drive options. Continental ...

We offer a complete line of Progressing Cavity Pumps for the commercial waste water and industrial markets. Our goal is to offer quality products and service at a competitive ...

Roper Pump Company began as a hand-operated well pump manufacturer in 1857 and has developed into a leading manufacturer of external gear pumps, progressing cavity pumps, flow dividers, and mud motor power sections. The company is part of the ...

Sometimes you need a pump that can handle higher pressures, viscosities and torque. Applications like these require the 70300 or 70600 models which feature oversized drive ends. For the 70300 the next larger drive end design is used ...

Roper Pump Company began as a hand-operated well pump manufacturer in 1857 and has developed into a leading manufacturer of external gear pumps, progressing cavity pumps, flow dividers, and mud motor power sections. The company is part of the ...

Pacific Alloy Casting produces replacement rotors for progressive cavity pumps used by the solid waste and construction industries. Our abrasion- and impact-resistant chrome iron rotors come in a ...

Liberty Process Equipment specializes in Progressive Cavity Pumps for industry. The progressive cavity pump is a positive displacement system that is useable in a variety of difficult pumping applications with solids content or highly-abrasive ...

The Freedom LFF3 Series is your best choice for Sanitary Progressive Cavity Pump applications. Designed for food-grade installation,these pumps have been designed to handle fluids ...

Liberty Process Equipment specializes in Progressive Cavity Pumps for industry. The progressive cavity pump is a positive displacement system that is useable in a variety of difficult pumping applications with solids content or highly-abrasive ...

Since it was founded in 1969, WANGEN PUMPEN has continued to grow, expanding from its beginnings as a small family business into a medium-size company with a workforce of over 200 staff. This is due among other things to a special promise which we ...

The changing of wear parts with very few actions, without removing the pump from the pipeline system thanks to Service in Place. The Xpress pump range has been specially developed for easy maintenance and to ...

Since it was founded in 1969, WANGEN PUMPEN has continued to grow, expanding from its beginnings as a small family business into a medium-size company with a workforce of over 200 staff. This is due among other things to a special promise which we ...

Shanley Pump and Equipment, Inc. is an International Pump distributor. We offer specialty pumps and industry-leading service to the pump market. We offer specialty pumps and pump products manufactured by pump companies that are recognized worldwide ...

Shanley Pump and Equipment, Inc. has a full staff of trained engineers around the continental US that can repair or replace your nonfunctioning system as easy as you making a phone call to us! Our 25 years of experience have made us ...

Shanley Pump and Equipment, Inc. is an International Pump distributor. We offer specialty pumps and industry-leading service to the pump market. We offer specialty pumps and pump products manufactured by pump companies that are recognized worldwide ...

Process Pump Sales, Inc, is a leading nationwide distributor of high quality products manufactured in Europe. We offer a comprehensive mix of product lines that are divided into 3 categories: Hydraulic Pump Group, Industrial Pump Group, and ...

The PCM Series IVA progressive cavity pumps are specially designed to handle heterogeneous and highly viscous products up to 1,000,000 cps. The IVA series is equipped with one or two force feed ...

Process Pump Sales, Inc, is a leading nationwide distributor of high quality products manufactured in Europe. We offer a comprehensive mix of product lines that are divided into 3 categories: Hydraulic Pump Group, Industrial Pump Group, and ...

Flowrox is known for its reliable industrial solutions for demanding process conditions. With almost 40 years of experience in elastomer technology, Flowrox is the benchmark for heavy duty valves, pumps and systems. We are known to be the reliable ...

The Flowrox progressive cavity (PC) pumps" C-series is designed for the most demanding industrial slurry and paste pumping applications. Due to its unique features and patented ...

Flowrox is known for its reliable industrial solutions for demanding process conditions. With almost 40 years of experience in elastomer technology, Flowrox is the benchmark for heavy duty valves, pumps and systems. We are known to be the reliable ...

The L4-P / L6-P series offers the same features and benefits of the L4-D / L6-D series, yet utilizes a progressive cavity pump. The progressive cavity ...

The Series 6000PC Polymer Feeder has all the features of the Series 6000. The 6000PC has the increased reliability of the progressive cavity metering pump. The pump has no check ...

We carry multiple lines of progressive cavity pumps for industrial use including sanitary, heavy-duty and general purpose solutions. Our pump parts are interchangeable with some of ...

The CG and CK 2000 Series Models are designed to handle the heavier applications of sewage, industrial waste, polluted liquids and slurries. Incorporated into this more rugged pump is a drive train using crown gear joint connections to the rotor and drive shaft.

The vertical design has the same superior performance as the horizontal. Designed and engineered specifically for confined spaces and fluid supplies above the pump. A great option at the same economical cost as regular CP Pump.

CPML Pump End Kits are preassembled for a convenient “Bolt and Go” installation to any C Face Motor of your choice. Our unique feature makes this a fast and easy way to perform maintenance on our CPML Pump. Available with horizontal or vertical suction housings.

Progressive cavity pumps is an extremely versatile positive displacement pump that can be used in a multitude of pumping applications. The best application for a progressive cavity pump is when the liquid contains abrasive solids. Most other types of positive displacement pumps can’t pump solids very well or for very long due to their close tolerances and all metal designs. A progressive cavity pump is designed to last longer than all other pumps on abrasive applications.

These type of pumps transfers fluid by means of the progress, through the pump, of a sequence of small, fixed shape, discrete cavities, as its rotor is turned, which in turn enables nearly pulsation free pumping. The mechanical efficiency and volumetric efficiency goes up when the viscosity increases, lower power and more flow with progressive cavity technology.

Anderson Process is proud to partner with longtime progressive cavity pump manufacturers who are leading the industry in positive displacement progressive cavity pump technology. Our brands include Continental Ultrapump, Flowrox, Flux, Roto Pumps and Standard Pump to offer a large selection of positive displacement progressive cavity pumps for nearly any industrial and sanitary process application.

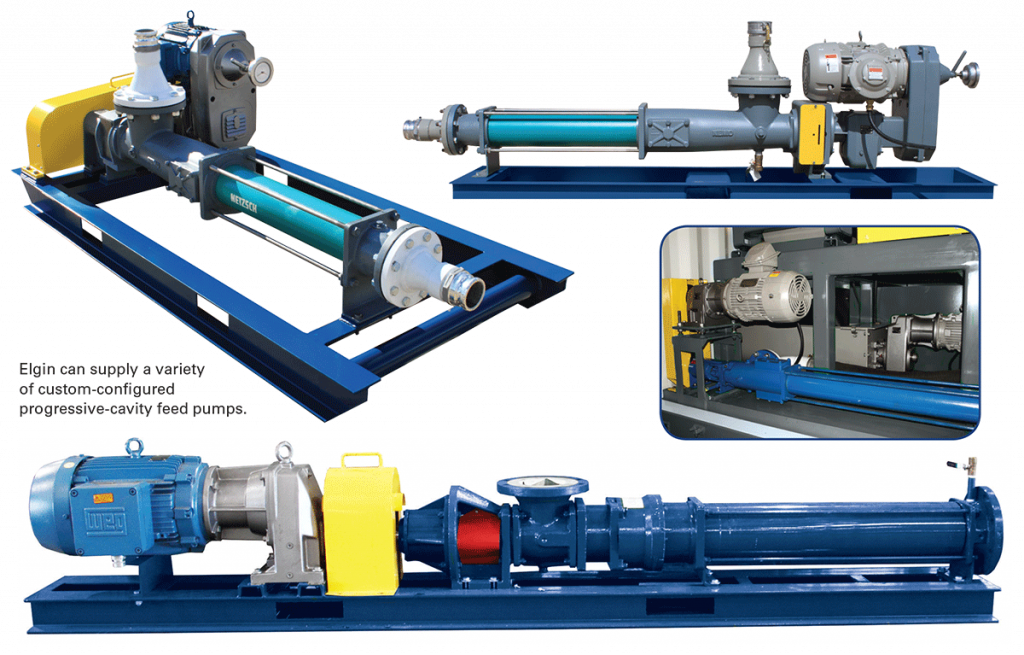

Moyno® 2L6 CDQ Progressing Cavity Mud Pump Complete pump, CDQ components The Moyno® pump is one of the most versatile pumps available. It has been proven in thousands of applications over the past 50 years. It is backed by the experience gained over the years, both in application and manufacturing know-how. The Moyno® progressing cavity pump is a single-screw rotary pump. The pumping action is created by the single helical rotor rolling eccentrically in the double threaded helix of the stator. In its revolution, the rotor forms in conjunction with the stator a series of sealed cavities 180 degrees apart. As the rotor turns the cavities progress from the suction to the discharge. As one cavity diminsihes, the opposing cavity is increasing at exactly the same rate. Thus, the sum of the two discharges is a constant volume. The result is a pulsation-less positive displacement flow with no valves.C – Cast Iron

The new generation of FLUX progressive cavity pump VISCOPOWER F 570 for Industry & Hygienic with planetary gear is suitable to pump thin to medium viscous media. The ...

The Eccentric screw pump HD-E-SR in the Pure version transfers the advantages of the Drum pump for viscous media quite simply to the high-viscosity range. The positive ...

The B70V SanitaryPlus food pump is a powerful positive displacement pump for heavy-sensitive, viscous and viscous media up to the limits of flowability. It pumps liquid foodstuffs, ...

The B70V SanitaryPlus food pump is a powerful positive displacement pump for heavy-sensitive, viscous media with and without fiber or solids content up to the limits of flowability. It pumps ...

Reduce maintenance and sanitisation time at your facility with the SaniForce Drum Pump, designed for easy cleaning with quick tri-clamp connections, minimal moving parts and easy transferability.

... NEMO® progressing cavity pump is especially interesting where pumps are installed in wear intensive applications requiring more service and maintenance work. Up to 66 ...

... or abrasive, with the NEMO® BY progressing cavity pump even difficult substances can be conveyed gently and with low pulsation, regardless of fluctuations in pressure and viscosity. In ...

... SY progressing cavity pumps are used in demanding applications for continuous, pressure-stable, gentle and low-pulsation conveyance as well as dosing in proportion to speed in nearly ...

ViscoTec dispenser 3VMP15, as a volumetric dispensing pump for larger volumes, ensures smooth and reliable product supplying of abrasive, high-filled or shear sensitive material - with a repeatability of +/- 1 %!

ViscoTec dispenser 3VMP22, as a volumetric dispensing pump for larger volumes, ensures smooth and reliable product supplying of abrasive, high-filled or shear sensitive material - with a repeatability of +/- 1 %!

... slurries that jam up lobe pumps or progressing cavity pumps with ease. It also imparts very low shear forces to the pumped product, far lower shear than lobe pumps ...

Mag Drive series are the first progressing cavity wobble stator pumps to offer magnetic drives. The proprietary, magnetic coupling design performs well in hazardous applications ...

Compact C Pump delivers reliable performance to the maximum duty requirements of your application in a compact package. Features include suction lift capability up to 28 feet, positive ...

For nearly 50 years, versatile L-Frame pumps have stood the test of time meeting thousands of application challenges with performance-enhancing, cost-saving features.

Thanks to the hopper and auger, the KST progressive cavity pumps are suitable for pumping high viscosity products, doughs, pastes and liquids with suspended particles.

... manufactured by Nova Rotors, is a range of progressing cavity pumps. This pump is completely reversible and has a wide pumps range. It features a one ...

The hopper pump from Nova Rotors s.r.l. come with a feeding conveyor that is ideal for transferring products that are highly viscous, and are characterized with a high solid percentage that starts at 17%. This device ...

The N series is a flanged pump that is ideal for use in heavy-duty operations such as transporting raw, primary, secondary, and thickened sludge before the filter press. The unit has a rated flow capacity lesser than ...

Mag Drive series are the first progressing cavity wobble stator pumps to offer magnetic drives. The proprietary, magnetic coupling design performs well in hazardous applications ...

Its solid drive shaft makes the 70500 the pump of choice for handling anything with a tendency to set up -- and eventually build up -- in a hollow-shaft model. That includes thermosetting adhesives, concrete, ...

With seepex pumps of the BN range, the drive is flange-mounted directly on the pump. The combination possibilities were expanded and enhanced in dialog with well-known drive manufacturers. The design ...

... gentlest, most hygienic food sanitary pump. It"s been especially designed for food applications, featuring a patented body design developed using advanced computational fluid dynamics. This progressing ...

The LL6 Progressive Cavity Pump is ideal for abrasive applications such as use in hydraulic fracking fluids and drilling mud pumping applications. The LL6 is one of the most popular sizes for the L-Frame PC Pump by all pump manufacturers. It has a proven track record of excellence in pumping fluids and as a mud pump for platform installations.

Liberty Progressive Cavity parts are direct aftermarket replacement pump parts for the *Moyno® L6 frame, *Tarby® TL6 frame and *Continental CL6 Series frame of progressive cavity pumps. Fracking and drilling mud pumps work under high-pressures with solids laden content, the LL6 can achieve flow rates from 0-47 GPM (5.20 Gallons per 100 revolutions) up to a top pressure of 225 psi.

The LL6 is a standard flanged progressive cavity design manufactured in cast iron or 316 stainless steel casings and designed in 1, 2, and 3 stages for 75, 150, and 225 psi discharge pressures. Higher discharge pressures are available, please contact a Liberty representative for more information.

The LL6’s simple hardened pinned joint drive assembly is a proven design that can handle the most difficult fluid pumping applications. The LL6 Rotors are typically tool steel or 316 stainless steel with a hard chrome plating for added durability and resistance to fracking fluids and the grit from mud pumping. All other wetted parts are either carbon steel or 316 stainless steel.

The Dura Pump team is often approached with one frequently-asked question: what manufactures are there of progressive cavity pumps? In our latest blog, we set out the main manufacturers of progressive cavity pumps for the UK market. Read the full piece below and don’t forget tovisit our blogfor more pump industry insights!

The manufacturer of Mono pumps and parts is Novo. This company manufactures a wide product range suitable for the pumping of fluids within the wastewater, chemical, food, beverage, paper, mining, mineral processing, marine, agricultural and oil & gas sectors.

Mono pumps was founded in 1935 in London, UK and has since expanded its manufacturing and operations internationally. They were also the original producers of the EZstrip range of progressive cavity pumps – a real household name.

They have a large range of progressive cavity pumps for the food and beverage industry, environmental engineering, oil & gas and pharmaceuticals as well as many manufacturing applications. Seepex was founded in 1972 and has continued to expand globally ever since.

Netzsch pumps are a versatile, innovative, high-performance brand providing a wide range of progressive cavity pumps, under the NEMO range, including many specialist solutions to the environmental and energy, food and pharmaceutical, oil and gas, chemicals and mining. Netzsch progressing cavity pumps offer you continuous, pressure-stable, gentle and low-pulsation pumping of a wide variety of media.

Roto Pumpshave been manufacturing progressive cavity pumps for more than 50 years and are ranked among one of the top 10 companies in manufacturing positive displacement pumps. With a state of art manufacturing facility, they are continuing to increase their product portfolio covering a wide range of applications, such as chemical, defence, wastewater treatment and agriculture industry.

The Sulzer brand was founded, by the Sulzer brothers, in 1834 and its headquarters are currently based in Winterthur, Switzerland. Sulzer offers a wide range of progressive cavity pumps, capable of providing near constant flow rate and suction lift for handling wastewater sludge, slurries, viscous and shear thinning non-Newtonian fluids.

PCMpumps go by the slogan ‘keep it moving’, and their commitments to attaining the highest level of quality, with products and service to the Oil & Gas and Food & Industry markets certainly demonstrate this.

For around 85 years, PCM has been offering high-quality, cost-effective fluid handling solutions all based on low life-cycle costs. PCM progressive cavity range is centralised around their Moineau brand, with advanced technology ensuring that they can operate at a higher pressure than other positive displacement pumps.

We’re passionate about sharing our knowledge and expertise around virtually all categories of pump products. If this blog didn’t provide the information you were looking for,contact a member of our helpful teamwho will be happy to help.

8613371530291

8613371530291