progressive cavity mud pump in stock

Moyno® 2L6 CDQ Progressing Cavity Mud Pump Complete pump, CDQ components The Moyno® pump is one of the most versatile pumps available. It has been proven in thousands of applications over the past 50 years. It is backed by the experience gained over the years, both in application and manufacturing know-how. The Moyno® progressing cavity pump is a single-screw rotary pump. The pumping action is created by the single helical rotor rolling eccentrically in the double threaded helix of the stator. In its revolution, the rotor forms in conjunction with the stator a series of sealed cavities 180 degrees apart. As the rotor turns the cavities progress from the suction to the discharge. As one cavity diminsihes, the opposing cavity is increasing at exactly the same rate. Thus, the sum of the two discharges is a constant volume. The result is a pulsation-less positive displacement flow with no valves.C – Cast Iron

Moyno® 3L6 CDQ Progressing Cavity Mud Pump Complete pump, CDQ components The Moyno® pump is one of the most versatile pumps available. It has been proven in thousands of applications over the past 50 years. It is backed by the experience gained over the years, both in application and manufacturing know-how. The Moyno® progressing cavity pump is a single-screw rotary pump. The pumping action is created by the single helical rotor rolling eccentrically in the double threaded helix of the stator. In its revolution, the rotor forms in conjunction with the stator a series of sealed cavities 180 degrees apart. As the rotor turns the cavities progress from the suction to the discharge. As one cavity diminsihes, the opposing cavity is increasing at exactly the same rate. Thus, the sum of the two discharges is a constant volume. The result is a pulsation-less positive displacement flow with no valves.C – Cast Iron

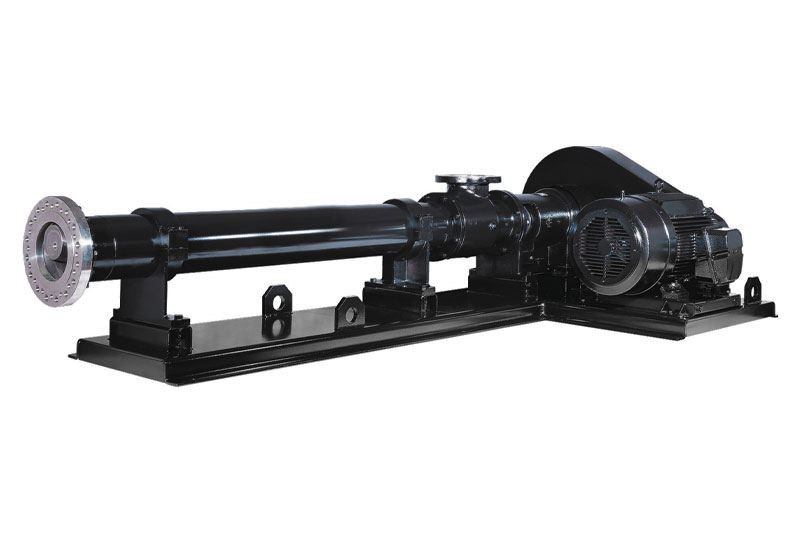

The Liberty Process LL8 Progressive Cavity Pump is ideal for abrasive pumping applications such as drilling fluids with sand and grit common in fracking operations. As a Mud Pump, the LL8 Series is a popular model on many mobile pumping rigs in use today. Replacement mud pump parts are available as well from our stock and work on other popular manufacturers models.

LL8 parts are direct drop in aftermarket replacements that work with the *Moyno® L8 series, the *Tarby® TL8 series and *Continental® CL8 Series*. The Liberty unit is a low-cost, maintenance free, dependable drop-in replacement progressive cavity unit.

The Liberty LL8 is a standard flanged pump design manufactured with cast iron or 316 stainless steel pump casings designed in 1, 2, and 3 stages for 75, 150 and 225 psi discharge pressures and a flow rate of 18 up to 100 GPM.

The LL8 is a modular design with simple hardened pinned joint drive assembly. LL8 Rotors are typically hardened tool steel or 316 stainless steel with a hard chrome plating for long life in abrasive pumping applications.

All other wetted parts are either carbon steel or 316 stainless steel. Stators are available in many elastomer materials such as Buna Nitrile, Natural Rubber, EPDM and Viton. The standard seal design is a set of gland packing with a lantern ring set and flush connections. Mechanical seal options for this progressive cavity pump are readily available.

The LL8 represents one of the most popular progressive cavity pumps available for the transport of drilling mud with easily replaceable in-stock parts.

For over 25 years, Liberty Process Equipment has been the leader in the field of economically priced Progressive Cavity Pumps and Progressive Cavity Pump replacement parts in North America.

Liberty specializes in Progressive Cavity Pumps for industry. The progressive cavity pump is a positive displacement system that is extremely flexible in its usability in a variety of specialized fields with difficult pumping applications such as viscous and highly-abrasive media. The design offers a pulsation-free, self priming operation that allows solids contents up to 50% to be moved without shearing.

When it comes to moving fluids with suspended solids content such as sludge"s or biosolids or thickened abrasives such as grouts or slurries, the PC Pump is the best choice for your application. Liberty can supply both the multiphase progressive cavity pumps and replacement parts to keep your PC Pump operating optimally for a lower price than other suppliers and OEM"s and can even offer you full pump packages with motors and baseplates if your job requires it.

Progressive cavity pumps have been one of the regular choices for wastewater treatment industries. These pumps are designed for transporting abrasive and highly viscous fluids in wastewater streams. Thus, the unique designs of these pumps make them ideal for pumping thickened liquids such as waste activated sludge. At times, sludge contains pump...

Liquid ring vacuum pumps are increasing in popularity and availability nowdays. These pumps are also referred to as liquid piston rotary pumps and water ring water piston pumps. Why so? Because they utilize liquid as a piston, and water is the most common choice of liquid in these pumps, hence the name. Nowadays, these pumps are widely preferred...

Are you facing any kind of performance issues when operating your progressive cavity pumps? Are they not running as efficaciously as before? Then, it’s the time for you to do a detailed inspection and conduct a failure analysis to render the right kind of repairing or troubleshooting. So, the question is, where to start and how to go about it?...

Progressive cavity pumps are one of the important types of positive displacement pumps used across various industries for transferring different types of solids, as well as air-entrained and multiphase liquids. These pumps are specially designed for applications that may involve abrasive and corrosive fluids. Owing to their several beneficial...

Progressive cavity pumps are a crucial part of oil & gas, pulp & paper, chemical, food & beverages, and wastewater treatment industries. They work on the principle of rotary positive displacement. Progressive cavity pumps are especially designed to handle viscous fluids and slurries with solids and particulate matter at a constant...

A progressive cavity pump is referred by different names, such as eccentric screw pump, progg cavity pump, or cavity pump. These are positive displacement pumps, which are most commonly used in fluid handling systems. The special design of these pumps allows the user to use it efficiently in a number of industrial applications. Are you...

In the coating industry, various types of pumps are used for pumping abrasive fluids. The pumps often suffer from rapid wear and tear due to the presence of particulates in these fluids. Highly viscous fluids are known to choke the pump, and disrupt its operations. Sometimes, the steel shafts may break during the operation due to choking....

Pump packages are cost effective due to the benefits associated with space efficiencies, ease of installation, single source responsibility and streamlining of the manufacturing process. MXQ has executed numerous turn-key pump packages, resulting in vast experience in the design, fabrication, installation, start-up and commissioning. We pride...

Recognizing the need for longer pump life in progressive cavity (PC) style pumps, MXQ has standardized on a unique rotor and stator profile that has proven extremely beneficial to PC pump users. Simply stated, the pitch of the rotor and stator has been increased while the overall diameter has decreased. One...

Progressive cavity pumps are one of the popular types of positive displacement pumps used in various industrial applications. The pumps are designed to suit various application requirements. There are various US-based manufacturers who offer these pumps, however, the ones offered by MXQ USA have gained immense popularity. Why are these pumps...

The Shanley SEP Progressive Cavity Pump is an extremely versatile positive displacement pump with a non-pulsating flow that can be used in many different pumping applications. The SEP pump is specially designed for abrasion resistance in tough pumping applications and can pump up to 60% solids. The SEP pump is also ideal for liquids with higher viscosities, or thickness, than water. The gentle pumping action of the SEP pump makes it great for pumping sheer sensitive fluids. The SEP pump is also used for pumping fluids with varying viscosities, for pumping against varying discharge pressures and for pumping applications requiring varying flows using a speed controller. Most commonly used for sludge and polymer at sewage treatment plants, feeding filters and filter presses, centrifuges, feeding oil water separation equipment, food pumping applications like honey, juice concentrate, grapes in wineries, crude oil, viscous chemicals, bilges on ships, coal water slurries and much more.

The Shanley SEP Pump is a progressive cavity pump in 1 and 2 stage design. It’s resilient and tested design is optimal for demanding pumping applications. It’s ruggedized universal joints with wear bushings are sealed and lubricated from the pumped liquid to provide long service life. The SEP pump is available with equal wall stators for lower starting torque and higher discharge pressures.

SEEPEX metering and dosing pumps are a range of precision pumps that have a metering accuracy of +/- 1%. The pumps are found in a variety of industrial and municipal applications and are especially suited for low pulsation delivery of low to viscous media as well as chemically aggressive media and media containing solids.

SEEPEX metering and dosing pumps are a range of precision pumps that have a metering accuracy of +/- 1%. The pumps are found in a variety of industrial and municipal applications and are especially suited for low pulsation delivery of low to viscous media as well as chemically aggressive media and media containing solids.

In addition to our patented split suction chamber, we’ve removed the tie bars, designed a new positive torque split coupling rod and added a captive support foot. That means faster, easier maintenance for you without sacrificing any pumping performance.

The EZStrip™ transfer pump can be quickily and easily disassembled, de-ragged, and maintained in place. This can reduce maintenance time by more than 93% for significant cost savings.

Sulzer offers a range of progressing cavity pumps for demanding positive displacement process applications. Our pumps provide a near constant flow rate and suction lift capability for handling wastewater sludge, slurries, viscous and shear thinning non-Newtonian fluids.

• The Progressing Cavity Pump features the only double-seal pin joint in the industry. With improved technology, the “donut” style joint seal has been enhanced. By providing a “boot”, the joint is sealed with amazing reliability. When installed correctly, the boot clamps compress the boot to seal each joint with more than one inch of linear sealed surfaces. This greatly minimizes the potential for contamination of the joint.

• As with centrifugal pumps, we have created a modular design in the Progressing Cavity Pump. This modular design minimizes the need for customers to stock a wide variety of components. In doing so, it is now very easy to change the pumping elements, and alter the pumping characteristic of the Progressing Cavity Pump.

• Unlike most progressive cavity pumps sold in the United States, approximately 98% of the components in our Progressing Cavity Pumps are manufactured in the United States by craftsmen who take great pride in their workmanship.

The Nova Rotors DV series of vertically immersed progressive cavity pump is designed for installation in deep wells and tanks. This vertically immersed pump is excellent at transferring high viscosity fluids and fluids containing solids in suspension.

The column length is customisable depending on application requirements. The long version requires an additional cone bracket at the end of the column to ensure the pump is stable and to avoid any unwanted vibrations. This vertically immersed positive displacement pump is capable of achieving flow rates up to 600m³/hr and pressures up to 48 bar.

The casing of this vertical positive displacement pump can be constructed from various materials including cast iron, stainless steel 304, stainless steel 316 and duplex stainless steel. The rotor is available in stainless steel 420, 304, 316 and duplex, while the stator can be supplied in NBR, EPDM, FPM, HNBR, Hypalon and PTFE. Such a wide range of material choices makes this pump series extremely versatile and capable of pumping a vast range of fluids.

Sealing options for this vertical helical rotor pump include gland packing, gland packing with flushing, single mechanical seal, single mechanical seal with quench, double mechanical seal, single or double cartridge seals and API rated sealing systems.

This vertical progressive cavity pump is Atex certified for handling flammable fluids and installation in non-safe areas. API 676 certification is also available if required.

This vertical progressive cavity pump is ideal for many applications in the industrial and marine markets, including; fuel transfer, oil transfer, sewage transfer, bilge water transfer, bio-waste, waste water transfer, sludge transfer, marine and agriculture.

Liberty’s Millennium Heavy-Duty Progressive Cavity Pumps are designed for challenging applications like heavy and abrasive sludges, greases and slurries in sewage and reclamation processes as well as Return Activated Sludge (RAS), Thickened Waste Activated Sludge transfer (TWAS) and sludge dewatering and chopper transfer pumping in wastewater facilities. The Millennium series is well suited for the waste-oil and crude oil reclamation and transfer industry. Special wear coatings like titanium or other exotic coatings are available upon request.

All Millennium Series parts such as Rotors and Stators or Wetted parts such as Connecting Rods and Seals dimensionally interchange as aftermarket replacements with other popular manufacturers pump models like the Moyno® 2000 Series and the Tarby® Century V Series, and the Continental® CG Series of Progressive Cavity Pumps, potentially saving you and your facility thousands of dollars in replacement part costs yearly. Over 500 wastewater, waste-transfer, and dewatering facilities in North America currently use Millennium parts in their daily service.

8613371530291

8613371530291