reciprocating mud pump in portuguese in stock

A mud pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi (52,000 kPa)) down the drill string and back up the annulus. A duplex mud pump is an important part of the equipment used for oil well drilling.

Duplex mud pumps (two piston/plungers) have generally been replaced by the triplex pump, but are still common in developing countries. Two later developments are the hex pump with six vertical pistons/plungers, and various quintuplex’s with five horizontal piston/plungers. The advantages that Duplex mud pumps have over convention triplex pumps is a lower mud noise which assists with better Measurement while drilling and Logging while drilling decoding.

Use duplex mud pumps to make sure that the circulation of the mud being drilled or the supply of liquid reaches the bottom of the well from the mud cleaning system. Despite being older technology than the triplex mud pump, the duplex mud pumps can use either electricity or diesel, and maintenance is easy due to their binocular floating seals and safety valves.

A mud pump is composed of many parts including mud pump liner, mud pump piston, modules, hydraulic seat pullers, and other parts. Parts of a mud pump:housing itself

Duplex pumps are used to provide a secondary means of fuel transfer in the event of a failure of the primary pump. Each pump in a duplex set is sized to meet the full flow requirements of the system. Pump controllers can be set for any of the following common operating modes:Lead / Lag (Primary / Secondary): The lead (primary) pump is selected by the user and the lag (secondary pump operates when a failure of the primary pump is detected.

Alternating: Operates per Lead / Lag (Primary / Secondary) except that the operating pump and lead / lag status alternate on consecutive starts. A variation is to alternate the pumps based on the operating time (hour meter) of the lead pump.

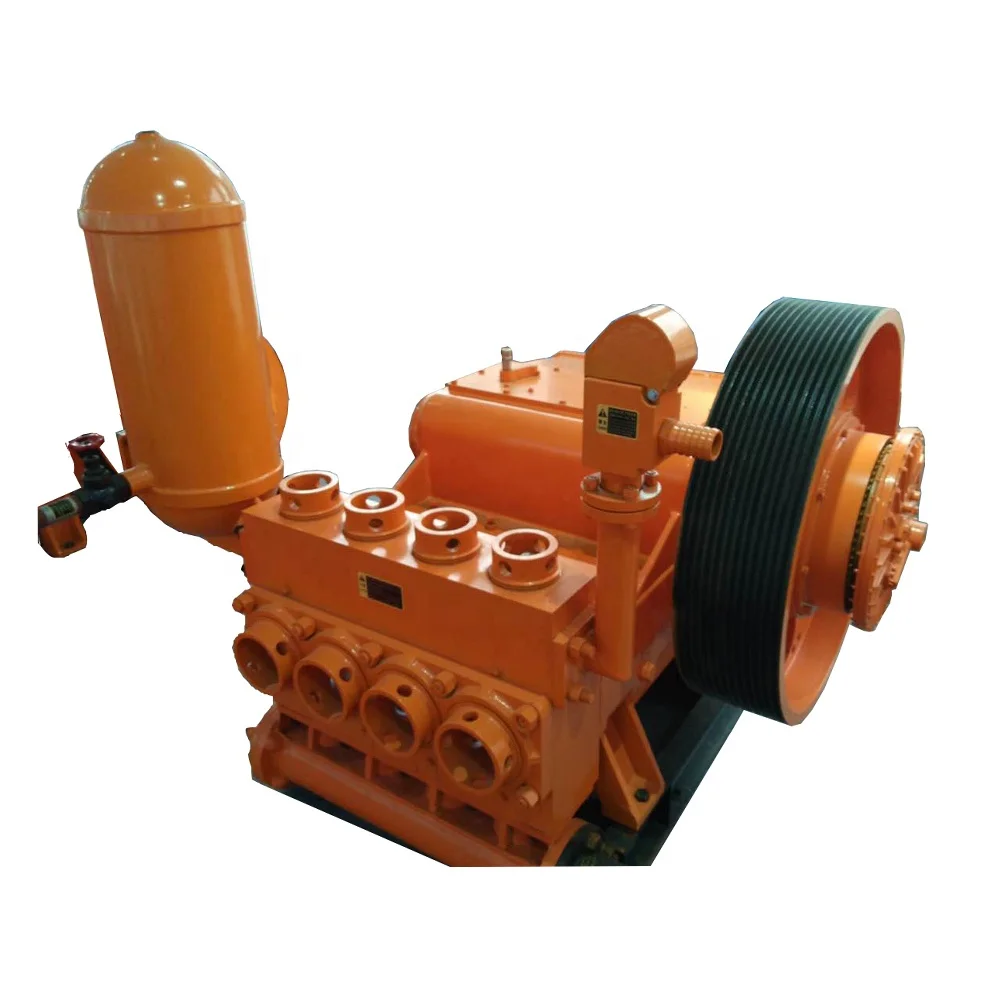

The NOV FC-1600 Triplex Mud Pump is made of rugged Fabriform construction and designed for optimum performance under extreme drilling conditions. It is compact and occupies less space, yet delivers unequaled performance. The pumps are backed by several decades of design and manufacturing experience, and are considered leaders in the field.

NOV FC-1600 Triplex Mud Pump is conservatively rated at relatively low rpm. This reduces the number of load reversals in heavily stressed components and increases the life of the fluid end parts through conservative speeds and valve operation.

The NOV FC-1600 Triplex Mud Pump design provides an inherently balanced assembly. No additional counterbalancing is required for smooth operation. No inertia forces are transmitted to the pumps’ mountings.

A Triplex Mud Pump sometimes referred to as a drilling mud pump or mud drilling pump. NOV FC-1600 Triplex Mud Pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Triplex plunger-type mud pumps feature a reciprocating, positive displacement pump design utilizing three plungers to safely transfer high-viscosity fluids under high pressure over an extended depth. Although they have many industrial applications, these pumps have become an essential part of oil well drilling rigs where they’re used to provide smooth discharge of mud and debris from oil wells.

In addition to their use in drilling and well service operations, mud pumps are also frequently used to handle corrosive or abrasive fluids, as well as slurries containing relatively large particulates, in applications like commercial car washes, wastewater treatment, cementing, and desalination operations.

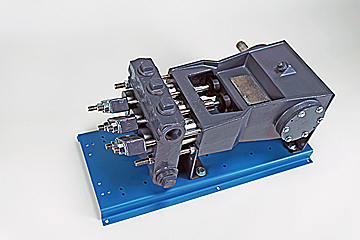

DAC Worldwide’s Representative Triplex, Plunger Mud Pump Dissectible (295-418) is an economical, conveniently-sized triplex plunger-type mud pump assembly that teaches learners hands-on maintenance activities commonly required on larger mud pump assemblies used in upstream oilfield production operations.

For example, mud pump assembly is used on well sites maintain downhole backpressure, to lubricate the rotating drill bit, and to help recycle and remove rock debris resulting from drilling activities. These heavy-duty, high-pressure pumps require regular refurbishment, inspection, and repair in the field.

DAC Worldwide’s dissectible mud pump assembly is a realistic sample that’s similar in geometry, design, and operating characteristics to the larger varieties learners will encounter on the job. DAC Worldwide chooses popular name-brand pumps for its dissectibles to ensure industrial and oil and gas training relevancy.

Using the dissectible mud pump, learners will gain hands-on experience with the operating principles, regular maintenance activities, and nomenclature/parts identification at a more convenient scale in the classroom or lab.

Technical training is most effective when learners can gain hands-on practice with industry-standard components they’ll encounter on the job. The Representative Triplex, Plunger Mud Pump Dissectible features a wide variety of common, industrial-quality components to provide learners with a realistic training experience that will build skills that translate easily to the workplace.

The Representative Triplex, Plunger Mud Pump Dissectible is a sturdy unit with a complete triplex, reciprocating, 20+ bhp plunger pump with .75" plunger, 1.5" stroke, and 3" cylinder sleeve. The unit allows for complete disassembly, assembly, and inspection, including removal of plungers, packing, and valves.

The dissectible mud pump comes with a formed-steel, powder-coated baseplate. It can also be mounted on a compatible DAC Worldwide Extended Electromechanical Workstation (903). Each unit comes with the manufacturer’s installation and maintenance manual.

Application of High Pressure Reciprocating Pumps can be noticed in pharmaceutical, waste water treatment and also in other industries. This range of pumps is suitable for heavy duty applications. These pumping systems are driven by diesel fueled engine/electric motor/gas engine. Operating pressure, diameter of pump and its weigh vary as per different models. Operating pressure of these equipments can be adjusted by using their built in speed reduction gear. Provided High Pressure Reciprocating Pumps are well known for their ergonomic appearance, functional stability and user friendly mechanism. Standard of this array of pumps has been checked as per its operating cost, longevity, performance, noise generation level, diameter and structural strength.

A mud pump (sometimes referred to as a mud drilling pump or drilling mud pump), is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi or 52,000 kPa) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling and manufactured according to API specification 7K.

The advantages of the drilling mud pump include the ability to move high-solids-content fluids laden with abrasives, the ability to pump large particles, ease of operation and maintenance, reliability, and the ability to operate over a wide range of pressures and flow rates by changing the diameter of pump liners and pistons.

The fluid end includes cylinders (module), valve assembly, cylinder liners, piston assembly, suction manifold, discharge manifold, piston rod, pulsation dampener assembly, etc.

As an important equipment for oilfield drilling operation, a drilling mud pump delivers circulating high-pressure drilling fluid or drilling mud to the bottom of the oil well, flushes the bottom of the well, breaks the rock, cools, lubricates and clean the drill bit, and carries the cuttings back to the ground.

The drilling mud is also used to suspend and carry out drill cuttings from the drill bits as it is brought in and out of the hole. This ensures that the drill bit does not clog and overheat, and makes the entire drilling operation smooth and safe.

Rotational power is supplied to the mud pump through an external power source like a diesel engine or electric motor. The power end of the mud pump converts the rotational energy through a crankshaft to a reciprocating motion of pistons.

The pistons move back and forth in mud pump liners, exerting a force on the cylinder chamber. During the retraction of the piston, valves open to allow the fluid to be drawn into the cylinder. Once the piston has fully retracted, it is pushed back into the cylinder.

At this time the intake valves are closed and the exhaust valves open, allowing the piston to force the fluid out of the cylinder under pressure. Once the piston reaches its maximum depth into the cylinder, the exhaust valves close and the process repeats.

For Fluid End: piston rod clamp, piston rod, piston assembly, cylinder cover, liner, liner flange, wear plate, cylinder, valve assembly, valve cover, valve guide, flashboard assy., cylinder cover flange, cylinder head, gaskets, studs, nuts, seal rings, pulsation dampener, bladder, discharge manifold, suction manifold, etc.

As one of the world"s leading pump manufacturers, Sulzer provides a wide range of products for engineered, configured, and standard pumping solutions as well as essential auxiliary equipment. We are renowned for our state-of-the-art products, performance reliability and efficient solutions.

Crosshead: A system which creates linear reciprocating motion derived from the crankshaft’s rotary motion through the connecting rod. The reciprocating motion of the crosshead is applied to the piston via the extension rod.

A crosshead is a mechanism used in large reciprocating engines to eliminate sideways pressure on the piston. The crosshead of mud pump produced by our company is made of high quality wear resistant with special techniques. It features little deformation, higher precision and very little tolerance.

The crosshead is the critical part on the power end of the mud pump. It slides in the upper and lower guide plates, motivating the intermediate draw bar to deliver driving force to the hydraulic end. One of its ends fixes the intermediate draw bar. The cavity connects the small end of the connecting rod through cross head pin.

The material of the crosshead is nodular cast iron with the strength of extension of more than 600MPa, which ensures high intensity and abrasive resistance.

Crosshead has high accuracy and precious dimension and no deformation. Besides F-500 mud pump that is cylindrical structure, upper and lower guide structures are used for other mud pumps, so that the concentricity can be adjusted by adding space under the lower guide. Flange-bolts with pinhole fit are used for connecting crosshead to extension rod.

A: First we discuss order details, production details. Then we issue you an PI for your confirmation. You will be requested to do pr-e paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25 days if we don"t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

BW400/10 mud pump is a horizontal three cylinder reciprocating single acting piston pump.Advanced product design, reasonable structure, high pressure, flow, multi-file variable, energy saving, light volume, efficiency, plant life, safe operation, easy maintenance.

BW series mud pump is widely used in mining, drilling, coal, railway, highway, water conservancy and hydropower, bridges, high-rise buildings, foundation reinforcement works.

They are also the main equipment of the geological survey,the main role in the process of core drilling boreholes is to supply fluid(mud or water),making it circulate during drilling and carry rock waste back to the ground,in order to achieve and maintain the bottom hole clean and lubricate drill bits and drilling tools with cooling.

In our after sales service system, We establish perfect control system strictly according to ISO-9000 series, in this system, technology date and problem solve solution and preventive measures will be provided in any maintain project, all the spare parts will be used in new OEM products with installation instructions, packing list, manufacturer"s instruction, qualification and Warranty certificate.

We provide "one equipment & one case, endless service, namely the after sales service begin from the order confirmation, last for the working life of the equipment.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

Are you going to be using a pressure washer for high-pressure applications? Blasting oil and fats off concrete or brick walls? Removing graffiti from the outside of your building? Cleaning your industrial machinery?

Or maybe you’re going to be using a pressure washer for lower-pressure applications? Washing the sides of your house? Washing the family car? Washing the mud off your kids in the backyard—okay, that one is probably a criminal act, so don’t do it. Soft washing your roof?

Different types of pumps have different applications they work best for. The text below describes the differences and similarities between types of pumps, and the different applications each is best suited for.

For the most part, these two types of pumps function the same way. Both are reciprocating positive displacement pumps which pull water through an intake valve and into a chamber and push it—pressurized—back out through an outflow valve. These valves are engineered to be one-way only, meaning the intake valve will only open under negative pressure and the outflow valve will only open under positive pressure.

Duplex pumps have two pistons or plungers while triplex pumps contain three. This means duplex pumps must move faster to generate the same pressure levels as triplex pumps, consequently wearing their parts faster, and often causing a pulsating effect.

Triplex pumps last longer because each individual component has to do less work. Furthermore, the flow of water from triplex pumps is more constant, lessening the components’ strain even more.

Plunger pumps use a reciprocating plunger to pressurize water and force it through the outlet valve. The plunger is normally made out of hard ceramic, which is very durable and resistant to wear.

The plunger is attached via connecting rod to a rotor. As the ceramic plunger reciprocates out, it creates suction pressure drawing fluid through the intake. As the rotor turns, the plunger is pushed back down to send fluid through the outflow valve.

Similar to plunger pumps, piston pumps use reciprocating pistons to pressurize water and force it through the outlet valve. The difference between a piston and plunger pumps is the high-pressure seal. In a piston pump, the seal is attached to and reciprocates along with the piston.

Because of this, piston pump seals wear out faster and cannot handle as much pressure compared to plunger pumps. As the seal wears out, the power washer will suffer from reduced pressure buildup, resulting in a weakened stream and inefficient operation.

Pump failure is rarely the cause of power washer problems. The leading causes of pressure washer problems are system restrictions, which cause the pump to fail.

If the inlet hose or valve is not getting enough water to the pump, air is sucked in—this is called cavitation. When this mixture of water and air bubbles is pressurized it creates small explosions, damaging the pump and its components.

The easiest way to combat cavitation is to install a quality inlet valve and filter. This is especially true if the inlet source is a water tank, where many larger particles may sit and settle. If you are using particulates, such as sand, to assist with surface cleaning, make sure to use an appropriately-sized filter mesh to prevent clogging; you must also make sure your pressure washer has enough power to make sure the sand does not wash back into the machine, whereby ruining the pump.

Taken care of properly, with regular maintenance checkups, your pressure washer pump should last at least as long as the hour-rating it’s supposed to last for as per the owner’s manual. As we’ve said, actual pump failure is rarely the cause of the problem, but rather the result. Give us a call or submit a contact form with your questions, and we’ll do our very best to give you the right answer.

Continental Emsco Drilling Products, Inc., which consisted of Emsco drilling machinery and Wilson mobile rigs, was purchased by National-Oilwell, Inc on July 7, 1999. To our knowledge, no pumps have been manufactured and sold under the Emsco brand name since National-Oilwell acquired them.

Fairbanks Morse pumps are currently manufactured in Kansas City, Kansas. Fairbanks Morse is a division of Pentair ever since August, 1997 when Pentair purchased the General Signal Pump Group.

Gaso pumps are manufactured by National Oilwell Varco. Gaso was acquired as "Wheatley Gaso" by National-Oilwell in the year 2000. At the time, Wheatley Gaso was owned by Halliburton.

Skytop Brewster pumps are no longer available as new pumps. Skytop Brewster(Cnsld Gold), a unit of Hansen PLC"s Consolidated Gold Fields subsidiary, was acquired while in bankruptcy by National-Oilwell, Inc. in November, 1999.

If you are supplying pump supplies, you can find the most favorable prices at Alibaba.com. Whether you will be working with piston type or diaphragm type systems, reciprocating or centrifugal, Alibaba.com has everything you need. You can also shop for different sizes small mud pump wholesale for your metering applications. If you operate a construction site, then you could need to find some concrete pump solutions that you can find at affordable rates at Alibaba.com. Visit the platform and browse through the collection of submersible and inline pump system, among other replaceable models.

A small mud pump comes in different makes and sizes, and you buy the tool depending on the application. The pump used by a filling station is not the one you use to fill up your tanks. There are high flow rate low pressure systems used to transfer fluids axially. On the other hand, you can go with radial ones dealing with a low flow rate and high-pressure fluid. The mixed flow pump variety combines radial and axial transfer mechanisms and works with medium flow and pressure fluids. Depending on what it will be pumping, you can then choose the small mud pump of choice from the collection at Alibaba.com.

Alibaba.com has been an excellent wholesale supplier of small mud pump for years. The supply consists of a vast number of brands to choose from, comes in different sizes, operations, and power sources. You can get a pump for residential and large commercial applications from the collection. Whether you want a water pump for your home, or run a repair and maintenance business, and need a supply of Small mud pump, you can find the product you want from the vast collection at Alibaba.com.therther it is for refrigeration, air conditioning, transfer, or a simple car wash business, anything you want, Alibaba.com has it.

8613371530291

8613371530291