relief valve for mud pump in stock

Relief valve mud pump is also called the centrifugal pump, a compressor, and a compressor. It has a series of pistons, this is done in the form of a centrifugal pump, with a compressor. It is usually used by hydraulic maintenance. The rotating pumps have different cuffs and suction cuffs.@@@@@

Relief valve mud pumps are specially designed for the rotation of the vehicle. There are many types of relief valve mud pumps, suitable for a rotating purpose, such as electric relief valve mud pumps. In the case of the different, pumps are suitable for a rotating process. They are suitable for rotating, there are various sizes and varieties of the pumps depending on the rotation pattern, but with a lesser water flow. On the other hand, there are various types of relief valve mud pumps that are specially designed for use in rotating processes. If the pump is suitable for a rotary motion, these pumps are suitable for a rotary process, and can be used on both sides of the vehicle. On Alibaba.com, there are various types of relief valve mud pumps, such as electric relief valve mud.

A wide variety of pressure relief valve for mud pump options are available to you, You can also choose from new, pressure relief valve for mud pump,As well as from energy & mining, construction works , and machinery repair shops. And whether pressure relief valve for mud pump is 1.5 years, 3 months, or {3}.

Drillmax Shear Relief valves are known for their dependability and effectiveness and are usually installed on the discharge end of the mud pump. When pressure exceeds the preset limit, the pin is sheared allowing the excess pressure to escape and be re-directed, preventing costly repairs. Different pin diameters are used to set the desired shear pressure. Once the problem is corrected, a new pin can be inserted to reactivate the valve.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Customers said they wanted long-lasting, easy-to-use valves and seats, and we delivered. Made from domestically sourced steel, GD Energy Products valves feature a two-piece friction-welded design, proprietary bonded inserts, and innovative geometry to deliver significantly longer life. GD Energy Products’ field proven Valves & Seats meet API Standard, and come with our “Ready Inventory” promise that we’ll have it in stock, when you need it.

Our full-open valves and seats are designed for use in GD Energy Products PZ, F-Series, and National 12P lines of triplex drilling pumps. This gives you options to use these parts across your whole fleet of pumps.

All rig mud pump systems use pop-off valves to protect the pump from over pressurization. The best that can be achived with a pop or relief valve is approximately +/- 10% repeatability. On a high pressure system, this can be a significant variance. Although the valves are resettable, they generally go at a lover pressure once tripped and reset. Not WOM’s Pump Saver.

Available up to 10.000 psi, and is more accurate that pop/relief valves. WOM’s Pump Saver features +/- 3% above 3.500 psi. New rupture discs can be easily and quickly replaced.

Pressure relief valves are installed on mud pumps in order to prevent an overpressure which could result in a serious damage of the pump and serious or fatal injury to personnel.

The discharge pressure is routed to the closer mud tank, via a 3” XXS line clamped strongly on tank side . Mud is flowing into the mud tank until line bled off, bearing in mind that minimum slope is required to avoid mud settling in pipe ( around 1 inch/meter).

Pressure relief valves are set usually to 90% of the maximum working pressure of the liners in use. Read carefully manufacturer chart for pressure setting versus size of liners.

Discharge pressure losses close to the maximum preset pressure.The Pressure relief valves are usually installed on a upper point of the discharge side of the mud pumps.

The pressure relief valve can be reset, if not damaged during the release of pressure. Special care should be taken if no working platform available to access the PRV.

MCM Pumps has been manufacturing Centrifugal Pumps since 1943. We originally supplied pumps to The Harrisburg Company for the oilfield industry. Since that time many pump companies have entered the marketplace that are interchangeable with our pumps such as Mission, Halco & Forum to name a few. For your pump needs, go with the original pump company that has been leading the way in centrifugal pumps since 1943.

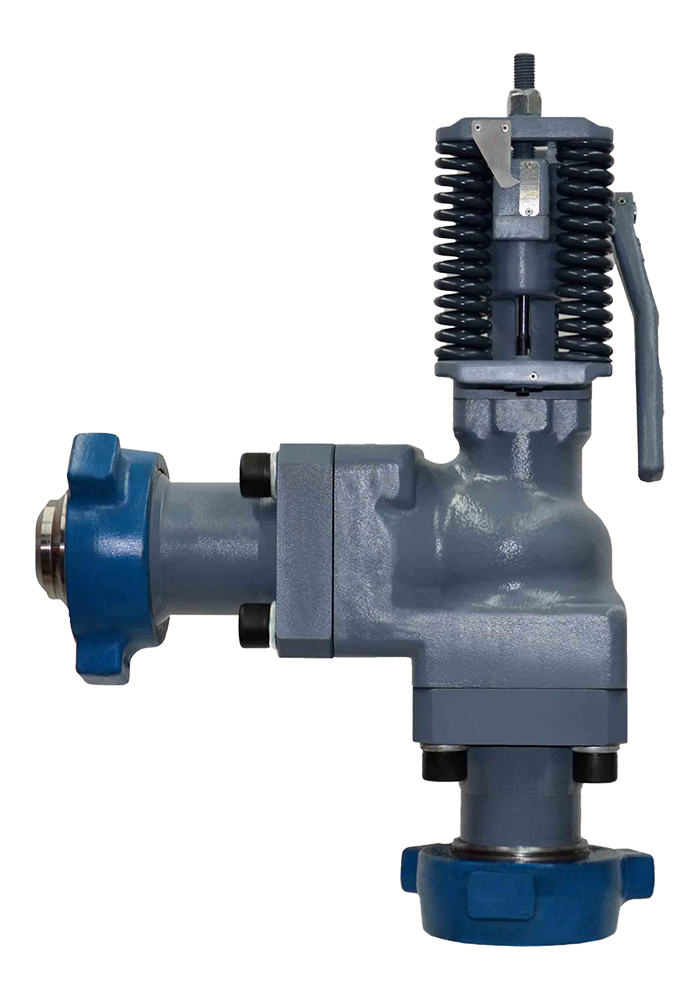

O’Drill MCM manufactures Demco & Oteco Style Shear Relief Valves in 2” and 3” sizes These valves are available in pressure ranges from 125 – 5,000 lbs for the Oteco style valves, and 2,750 – 5,000 lbs for the Demco style valves They are completely interchangeable, built with unsurpassed quality, and are available in stock at competitive prices.

O’Drill MCM manufactures Demco & Oteco Style 5K Mud Gate Valves in 2”, 3”, 4” and 5” sizes. They are completely interchangeable, built with unsurpassed quality, and are available in stock at competitive prices.

Our Float Valves are interchangeable with the Baker-Style Float Valves. They are available in F, G, and GA styles for standard and high-temperature applications.

O’Drill MCM manufactures Demco & Oteco Style Shear Relief Valves in 2” and 3” sizes These valves are available in pressure ranges from 125 – 5,000 lbs for the Oteco style valves, and 2,750 – 5,000 lbs for the Demco style valves. They are completely interchangeable, built with unsurpassed quality, and are available in stock at competitive prices.

O’Drill MCM manufactures Demco & Oteco Style 5K Mud Gate Valves in 2”, 3”, 4” and 5” sizes. They are completely interchangeable, built with unsurpassed quality, and are available in stock at competitive prices.

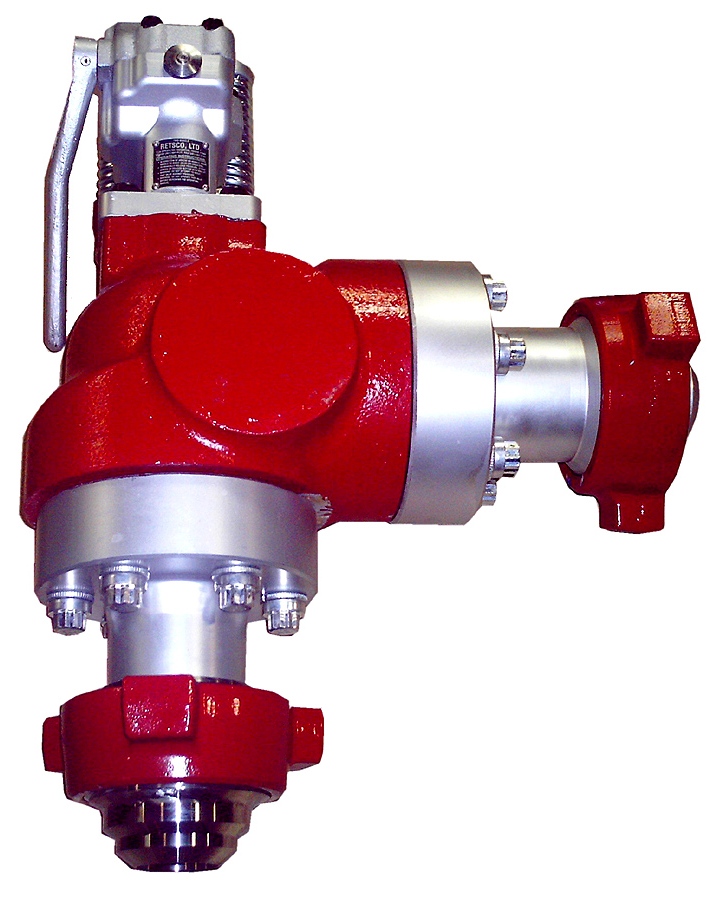

Our Reset Relief Valves are interchangeable with Cameron, Retsco & NOV-style valves. They are available in Type B and C classes. Type B valves are threaded, and can be set to 1,500 to 5,000 lbs. pressure ratings. The type C valves are flanged, or 1502/1002 union end connections, and can be set to 1,500 to 7,500 lbs pressure ratings.

O’Drill MCM Solids Control Equipment is renowned as some of the best in the industry. At Topco, we service and sell all makes and models of O’Drill MCM Solids Control Equipment, please inquire today and we can assemble a package for you!

The relief valve should be set to 50% greater than the normal operating pressure (70 psi for normal operations, but this value may vary depending on the specifics of the job).

It is recommended that the valve be located on the suction manifold of the pump, but may be located elsewhere on the suction line at the customer’s discretion.

The outlet line from the relief valve should gradually slope down to the tank level, and should be supported to prevent any dips or low spots where mud could collect, harden and potentially block flow.

It is recommended that a suction pressure relief valve be used in the suction line to prevent damage to either pump in the event of a high pressure surge occurring in the line.

Shear pin safety valve is used at the discharge part of the mud pump.JA-3 shear pin safety valve changes the discharging pressure by changing the position of the shear pin ,which is operation easy and work reliable.

A: First we discuss order details, production details. Then we issue you an PI for your confirmation. You will be requested to do pr-e paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25 days if we don"t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

It is recommended that a suction pressure relief valve be used in the suction line to prevent damage to either pump in the event of a high pressure surge occurring in the line.

JA-3 Shear pin relief valve can be connected in two ways, one is threaded connection, and the second is flange connection. It is an insurance of mud pump, before the pump working, determines the rated pressure according to the cylinder and piston specification, the safety valve cover off the shear pin on the clipboard into the pin hole. If the pump head pressure exceeds the rated pressure, shear pin will be cut and mud from the side of the vent valve, play a protective role.

Shear pin safety valve is used at the discharge part of the mud pump.JA-3 shear pin safety valve changes the discharging pressure by changing the position of the shear pin ,which is operation easy and work reliable.

It is recommended that the valve be located on the suction manifold of the pump, but may be located elsewhere on the suction line at the customer’s discretion.

The outlet line from the relief valve should gradually slope down to the tank level, and should be supported to prevent any dips or low spots where mud could collect, harden and potentially block flow.

The relief valve should be set to 50% greater than the normal operating pressure (70 psi for normal operations, but this value may vary depending on the specifics of the job).

A: First we discuss order details, production details. Then we issue you an PI for your confirmation. You will be requested to do pr-e paid full payment or deposit before we go into production. After we get the deposit, we start to process the order. We usually need 15-25 days if we don"t have the items in stock. Before production has been finished, we will contact you for shipment details, and the balance payment. After payment has been settled, we start to prepare the shipment for you.

The CORTEC Model CRV Choke Relief Valve (CRV) line offers users the safety, reliability and quick response function required to meet the demands of today’s drilling operations. Our robust designs are manufactured with superior performance and field serviceability in mind. CORTEC Model CRV Choke Relief Valves are compatible with API 6A and NACE MR0175 requirements. Full third-party review is available upon request.

Available with a range of options for orifice sizes, end connections and control methods, CORTEC is certain to have a CRV model to suit your application needs. Whether you’re configuring a deepwater Managed Pressure Drilling (MPD) system, protecting mud pumps or relieving frac systems CORTEC’s CRV line is designed and proven to provide the highest level of reliability in the industry. Hydraulic and pneumatic control packages are configurable to suit customer and project specifications

The CRV26 PRV is a product of the CORTEC Fluid Control division of CORTEC, which provides a complete line of high-end valves designed and manufactured according to specific project specifications. CRV26 PRV is engineered to protect drilling systems against the dangers of over pressurization and is the first of its kind to be rated to 10,000 PSI systems.

Stephen Corte, Vice President, CORTEC, said, “Automated PRVs provide the highest level of accuracy and reliability and are automatic or manually resettable for thousands of cycles. Our CRV26 PRV offers a competitively priced alternative to other remotely-operated PRV models, along with a degree of service life, precision and repeatability that conventional burst disks and manual spring reset valves cannot provide.”

The CRV26 PRV is suitable for frac system relief, mud pump relief and managed pressure drilling (MPD) and is compatible with API 6A and NACE MR0175 requirements.

Condor Pumps have been appointed exclusive NZ distributors for TTi Trans Tank International - Australia"s safest tanks and trailers - down load your TTi New Zealand catalogue by clicking on the image below

8613371530291

8613371530291