replace mud pump motor maintenance programs free sample

Pumps are often designed to operate at a single point known as the Best Efficiency Point (BEP). As components begin to wear, a pumps performance begins to decline, with operation away from this point leading to issues such as accelerated bearing or seal wear, vibration, excess temperature rise or cavitation. Quite often declining performance can start gradually, before quickly accelerating until failure if performance issues are not addressed in a timely fashion.

Corrective Maintenance is undertaken when failure has occurred. The unit may be leaking, efficiency reduced, pump stopped or motor tripped, leading to loss of production resulting in an urgent situation where parts must be sourced and fitted quicky.

Preventative Maintenance is inspection and repair scheduled at specific intervals (daily, weekly, monthly, yearly) or based on the number of hours run. Visual inspections are made externally and internally by dismantling the unit, replacing seals such as gaskets and mechanical seals, with pump parts checked for wear.

Differential Pressure:Check the operating pressure by calculating the difference between the inlet and outlet pressure of the pump ensuring it is operating on curve.

Excess Temperature – Check motor, bearing and casing temperature. Thermal imaging cameras can detect excess temperature quickly, without stoppage, dismantling or contact with the unit.

The “6 to 1 Rule” discovered by John Day Jr, (Manager of Engineering & Maintenance at Alumax South Carolina stated that the ideal ratio of Proactive Maintenance (PM) to Corrective Maintenance (CM) should be 6 to 1 - 6 PM checks to 1 RM check. If your ratio is below this then according to his theory it is being inspected too infrequently, above and inspections are too frequent.

Although Proactive Maintenance can seem to avoid the urgent costs and downtime associated with reactive maintenance, PM maintenance costs can be high due to the cost of labour in dismantling of complicated designs such as Progressing Cavity, or Triplex Plunger pumps which are often time consuming to maintain with more than one person required to undertake work.

On dismantling units, some seals require replacing regardless of condition, and excess spares can be required in case of gasket entrapment during assembly. Rental of specialist lifting equipment may be required and there can be situations where when inspected, pump parts do not require replacement.

MonitoringThe ideal situation is to ensure components are replaced before failure but not so far in advance that they have experienced little wear with valuable time spent on inspecting components which are otherwise fine.

This can be achieved through a monitoring device, where when the right data is collected, pump failure can be anticipated between 3 and 12 months in advance with an 80-95% accuracy.

With the average lead time on DN100 pumps, and units over 5 years old being 3 months or more, it is essential that spares are either on the shelf or failure is anticipated through advance ordering.

There are hazards during any maintenance activity. Always ensure the correct PPE is worn before attempting repair, that sufficient expertise is on hand and chemical data sheets of any fluid being pumped are checked prior to undertaking work. A full risk assessment should be completed in advance.

Hazardous FluidsIrritation, Chemical burns, ignitionEnsure when pump is opened the unit is cool, not pressurized, ignition sources are not present, and any fluids spilt are contained.

If inspection has been neglected for some time, then additional parts may require replacing than had the unit been inspected earlier, with some pump parts becoming beyond economical repair.

Enables planned work to be undertaken during lower activity levels and at lowest cost & risk.Pump has to be crucial within a process or above a certain size for monitoring to be cost effective

Thread Sealant –The use of semi-permanent thread sealant will ensure vitality important threaded fasteners such as bolts or screws on shafts, couplings or pump casings do not self-loosen due to vibration and become disengaged.

Interchangeable Spares –Our range of pumps are modular in design utilizing interchangeable spares, meaning on site stock holding of parts can be reduced by up to 80% further reducing slow moving stock.

Repair & Replace –Choosing to repair an existing pump within a process of vital importance, as well as replace, is a strategy we recommend for maximizing plant efficiencies and reducing downtime. Should unexpected pump failure occur, your process can be restored quickly.

Checklists & Logs –The use of checklists and logs ensures a fully repeatable process ensuring important maintenance intervals are not missed. Logs can provide valuable insight and reveal a pattern before failure occurs enabling easier troubleshooting.

indicates which areas should be checked, but note that a units maintenance routine is dependent on several factors such as hours of operation, duty, aggressiveness of pump medium, rpm of motor, temperature, inlet conditions and location of equipment.

Centrifugal pumps are one of the most popular pumping solutions in the world due to their highly efficient and simple design. However, just like any other pump, they can also suffer from pump failure and damage if preventive maintenance is neglected. So if you have invested in a centrifugal pump for your site, you need to ensure that you have a maintenance schedule in place, that will not only extend your system"s life but also reduce operating costs.

Even if you have invested in a high-quality centrifugal pump like Azcue, which means that you have a great pump solution in place, preventive maintenance is essential to keep your process running smoothly and prevent any unexpected downtime and costs. Centrifugal water pumps have hundreds of components that keep them running smoothly and are integral to providing effective pump operation. Therefore, consistent maintenance can not only prevent pump failures but also help your engineers to identify the source of the problem faster, as they will have enough maintenance history recorded to refer back to. To help you put together your centrifugal pump maintenance schedule, we asked our technical sales engineer for a good preventive maintenance strategy…

Don"t have time to read the whole article. Download our helpful infographic that you can use to implement a centrifugal pump maintenance schedule.Click here

If you have a centrifugal pump on-site and don"t already have a maintenance programme in place, then you are probably asking yourself all of these questions: How often do you need to perform routine maintenance or replace parts? Which pump components must be checked more often, and when should you schedule the pump maintenance? What spare parts do you need to stock to prevent any pump downtime?

Planning preventive maintenance of centrifugal pumps can be confusing, especially if you don"t know where to start. So we asked our technical sales engineers to give us their recommendations for a centrifugal pump maintenance schedule. Here is their advice and an example of a maintenance plan…

Best practice is to carry out a visual inspection of the pump installation on a daily basis. Spotting an issue early is one of the best troubleshooting methods and can preventing pump breakdowns. Here are some of the things to look out for:

Just like the daily inspection, you should look for any abnormalities but this time, pay close attention to the following centrifugal water pump components:

Carry out a visual inspection for any signs of leakage from the pump or pipework. If standby pumps are installed, turn on and run for at least 5 minutes to ensure operation.

Check for a sudden decrease in the efficiency of your centrifugal pump. This may be due to a broken shaft seal. Inspect the shaft seals for any physical signs of damage/leakage and replace the seal where necessary.

Following our centrifugal pump maintenance schedule, you will need to check the following pump components once a month to ensure that your pump is running efficiently and prevent any potential failure or damage:

Check coupling alignment. If significant misalignment is found, check seals and bearings for wear. Clean the pump and motor, so it"s free of oil and debris to allow ventilation and prevent overheating.

Less often but very important is to thoroughly inspect the whole centrifugal pump and consider changing some of the spare parts to ensure that the pump operates in optimal conditions. Here are our recommendations:

Dismantle the pump, inspect the wearing parts and replace them if necessary. Typical parts include: mechanical seal, wear rings, impeller, o-ring, gasket, shaft. Remove all auxiliary parts, including gauges and valves, clean and inspect.

Replace certain components such as the mechanical seals and impellers to prevent leaking and other issues. The best practice is to hold stock of typical wearing parts on-site to prevent any delay in maintaining your pump if any components fail.

Always make sure to create a maintenance schedule that is consistent with the manufacturer"s guidelines and keep in mind that certain components need to be maintained based on their service intervals:

Lubricate the bearing as per the service intervals (usually in operating hours) found in the pump manual. This may be required more regularly in high-temperature or dusty environments.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

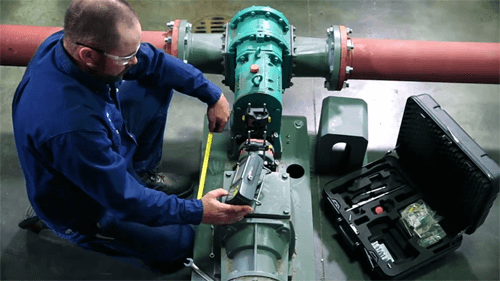

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Many things go into getting the most life out of your mud pump and its components — all important to extend the usage of this vital piece of equipment on an HDD jobsite. Some of the most important key points are covered below.

The most important thing you can do is service your pump, per the manufacturer’s requirements. We get plenty of pumps in the shop for service work that look like they have been abused for years without having basic maintenance, such as regular oil changes. You wouldn’t dream of treating your personal vehicle like that, so why would you treat your pump like that.

Check the oil daily and change the oil regularly. If you find water or drilling mud contamination in the oil, change the oil as soon as possible. Failure to do so will most likely leave you a substantial bill to rebuild the gear end, which could have been avoided if proper maintenance procedures would have been followed. Water in the oil does not allow the oil to perform correctly, which will burn up your gear end. Drilling mud in your gear end will act as a lapping compound and will wear out all of the bearing surfaces in your pump. Either way it will be costly. The main reasons for having water or drilling mud in the gear end of your pump is because your pony rod packing is failing and/or you have let your liners and pistons get severely worn. Indication of this is fluid that should be contained inside the fluid end of your pump is now moving past your piston and spraying into the cradle of the pump, which forces its way past the pony rod packing. Pony rod packing is meant to keep the oil in the gear end and the liner wash fluid out of the gear end. Even with brand new packing, you can have water or drilling fluid enter the gear end if it is sprayed with sufficient force, because a piston or liner is worn out.

There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components.

Liner wash fluid can be comprised of different fluids, but we recommend just using clean water. In extremely cold conditions, you can use RV antifreeze. The liner wash or rod wash system is usually a closed loop type of system, consisting of a tank, a small pump and a spray bar. The pump will move fluid from the tank through the spray bar, and onto the inside of the liner to cool the liner, preventing scorching. The fluid will then collect in the bottom of the cradle of the pump and drain back down into the collection tank below the cradle and repeat the cycle. It is important to have clean fluid no matter what fluid you use. If your liners are leaking and the tank is full of drilling fluid, you will not cool the liners properly — which will just make the situation worse. There is also usually a valve on the inlet of the spray bar. This valve should be closed enough so that liner wash fluid does not spray all over the top of the pump and other components. Ensure that the water is spraying inside the liner and that any overspray is not traveling out of the pump onto the ground or onto the pony rod packing where it could be pulled into the gear end. If the fluid is spraying out of the cradle area and falling onto the ground, it won’t be long before your liner wash tank is empty. It only takes a minute without the cooling fluid being sprayed before the liners become scorched. You will then need to replace the pistons and liners, which is an avoidable costly repair. Make a point to check the liner wash fluid level several times a day.

Drilling fluid — whether pumping drilling mud, straight water or some combination of fluid — needs to be clean. Clean meaning free of solids. If you are recycling your fluid, make sure you are using a quality mud recycling system and check the solids content often throughout the day to make sure the system is doing its job. A quality mud system being run correctly should be able to keep your solids content down to one quarter of 1 percent or lower. When filling your mud recycling system, be sure to screen the fluid coming into the tanks. If it is a mud recycling system, simply make sure the fluid is going over the scalping shaker with screens in the shaker. If using some other type of tank, use an inline filter or some other method of filtering. Pumping out of creeks, rivers, lakes and ponds can introduce plenty of solids into your tanks if you are not filtering this fluid. When obtaining water out of a fire hydrant, there can be a lot of sand in the line, so don’t assume it’s clean and ensure it’s filtered before use.

Cavitation is a whole other detailed discussion, but all triplex pumps have a minimum amount of suction pressure that is required to run properly. Make sure this suction pressure is maintained at all times or your pump may cavitate. If you run a pump that is cavitating, it will shorten the life of all fluid end expendables and, in severe cases, can lead to gear end and fluid end destruction. If the pump is experiencing cavitation issues, the problem must be identified and corrected immediately.

The long and the short of it is to use clean drilling fluid and you will extend the life of your pumps expendables and downhole tooling, and keep up with your maintenance on the gear end of your pump. Avoid pump cavitation at all times. Taking a few minutes a day to inspect and maintain your pump can save you downtime and costly repair bills.

The maintenance checklist, implemented a few months ago, covers equipment to monitor on a daily, weekly, and monthly basis. An area is devoted to tracking service truck miles, rig miles and hours, as well as welder hours to know when an oil change is needed. The goal is to not let any maintenance task fall by the wayside.

“It’s kind of brought about them (drilling crews) thinking of other things, recognizing other things, and having a mindset towards maintaining their equipment,” says Baker, owner of Apex Drilling LLC in Burley, Idaho, “and that’s the most important thing—having that mindset towards maintenance.”

Baker, president of the Idaho Ground Water Association, worked as a maintenance mechanic for nearly nine years at a potato processing plant before entering the water well industry. He worked at the plant under the supervision of a 20-year Air Force veteran who previously was a maintenance manager of intercontinental ballistic missile sites in the Midwest. Baker credits those years for helping him get keyed in on being proactive with equipment maintenance.

“I learned a lot about preventative maintenance and things you start looking for,” Baker says. “If you know about some of these small things before they become big things, then you don’t have downtime on the jobsites.”

Months into implementing the maintenance checklist, Baker is seeing his drill crews take ownership by noticing minor issues on their four drill rigs and making note of them. The crews then look at the list and fix the issues during half a day in the shop while they’re in between jobs, or at a jobsite when time allows for it.

Factoring into the maintenance of his equipment is the fact that Baker is using a higher-grade oil and additives package rather than what the manufacturer recommends. Also, every 200 to 300 hours of use, he has equipment oil samples (engine, hydraulic, and compressor oils) sent and analyzed by a lab in Salt Lake City, Utah. The lab runs an International Organization for Standardization (ISO) cleanliness analysis and designates a code to how clean the oil is and the results dictate when Baker needs to change the oil in his equipment.

“Hydraulics, pumps, and motors have an ISO cleanliness code on the oil,” Baker explains. “If you run that hydraulic system within that cleanliness code at 70 degrees in a controlled environment, you’re going to get 10,000 hours out of your pumps.

“When putting the pumps on mobile equipment, it cuts it in half, so you get 5000 hours on pumps because they’re working in the extreme heat, cold, and dirt. As long as you maintain that cleanliness code in your oil, you can expect 5000 hours, but as soon as you go one code dirtier in your oil, you cut that in half. If you can operate one code cleanlier you can double it, and so we’re trying to operate in a manner that is not necessarily normal in an effort to try and get our equipment to last longer. Ultimately, it reduces our cost of maintenance.”

Sprowls, president of the Ohio Water Well Association, also shared how hydraulic oil in the GEFCO 40K came back with elevated metal content. He says nothing indicated that the hydraulics were acting up, but the oil sample prompted further investigation which revealed a hydraulic pump failed prematurely.

Sprowls stresses that maintenance needs to be intentional where time is made for it. He makes a point that being proactive is less stressful than reacting to an engine replacement in a customer’s front yard. After all, it’s much easier to work on the machines in a climate-controlled shop or gravel lot with no mud.

“What I’ve done for routine items is put a value on them that is relevant to our industry,” he shares. “Most drilling is accounted for by the foot, so I will analyze what kind of drilling I’m doing and put a footage on it. For example, I grease the rig every so many feet of overall drilling. If I’m mud drilling, the mud pump and swivel get greased very well, no matter the footage. Air drilling may be more frequent on the swivel due to the temperatures.

“The main reason Layne is dedicated to a robust equipment inspection/maintenance program is the safety of our employees,” Snelten says. “If we can keep our equipment safe to operate, it reduces the hazards to our employees and helps prevent injuries. They go home to their families at the end of the day in the same condition they came to work.

“We’ve made incredible strides in our safety performance over the past four years, and we see equipment maintenance as a required component to our continued safety evolution to not just maintain industry leading safety performance, but achieve true world-class safety.”

Beyond improved safety, Layne sees additional benefits of an aggressive maintenance and repair program achieving increased employee engagement, client appreciation and recognition, decreased maintenance costs, decreased downtime, increased productivity and profitability, and differentiation from the competition.

Layne rolled out a new maintenance program in 2021 for its several thousand pieces of equipment—drill rigs, pump rigs, trucks, trailers, and support equipment—and for the roughly 350 field staff who operate them.

The program consists of daily, monthly, and annual inspections of the drill rigs, pump rigs, and service trucks. Inspection items include fluid levels, wire ropes, sheaves, frame welds, controls, emergency stops, etc. A copy of the inspection goes to the field superintendent and mechanic and repairs

The program also presents Layne with information to determine action steps for a piece of equipment. If a piece of equipment continues to have persistent maintenance issues, and its records show maintenance costs are excessive, the question becomes: Is it better to perform a mid-life rebuild where another seven to 10 years can be gained, or is it better to replace it?

Everyone agrees that reactive maintenance is probably the worst pump reliability strategy. Maintaining equipment only after it breaks can mean unexpected downtime, emergencies, rush charges, overtime, and replacement of expensive parts.

The best pump reliability strategy is not either preventive or predictive maintenance, it’s a combination of the two, strategically applied. In this post, we’ll discuss the differences between predictive and preventive maintenance and when it’s best to use them.

Many operators rely heavily on “reactive” maintenance rather than preventing and planning for future repairs. As discussed in our eBook, 36 Ways to Kill Your Pump, “reactive” maintenance accounts for unplanned equipment downtime and increased costs.

Preventive and predictive maintenance programs extend the overall life of the equipment and result in fewer unplanned breakdowns. The choice is not one or the other, it’s a combination of the two.

Preventative maintenance is any variety of scheduled maintenance to a pump or other piece of equipment. Generally, it includes scheduled routine maintenance, such as equipment calibration, greasing, oil change, and analysis.

One of the biggest ways to prevent failures is to make sure your equipment is properly aligned and balanced. Misalignment and pump unbalance are the two most common reliability problems for rotating equipment. Laser alignment also fits within this category since its a service completed upon installation, setting the pump up for success.

These programs are designed to keep your maintenance costs low by preventing costly failures before they happen. If you need a preventative maintenance checklist, you can download one here.

Up to 50% of damage to rotating machinery is directly related to misalignment. Misalignment can cause increased vibration, premature seal and bearing failure, and increased power consumption. An unbalanced pump causes similar issues, such as vibration, which can be easily avoided with the right preventative maintenance measures.

Predictive maintenance services are used to monitor the condition of equipment over time. Vibration analysis, for example, measures the vibration of the equipment while it is still in service. This allows the technician to see the change in vibrations over time to predict when a problem may occur, and why.

Predictive maintenance should be part of routine maintenance for pumps and rotating equipment that absolutely can NOT go down. Operators and maintenance managers get a glimpse into the future life of the pump as it"s running today. This allows them to plan for repairs and avoid unexpected downtime.

Not all pumps are equally important in a manufacturing process, so not all pumps should receive the same maintenance plan. It wouldn’t make sense to spend time and money on vibration analysis for a pump in a non-essential application.

Before creating a maintenance plan, place the pumps into categories. This will help determine how much time and money to invest in each one. Use these categories to get started:

Regularly maintaining pumps will extend the life of your pump. When a pump is properly maintained, the parts that need replacing are usually the less expensive wear parts.

Check shaft alignment – believe it or not, shaft alignment can change! Thermal growth and machine movement due to load shifts can cause pumps to move out of alignment.

Up to 50% of damage to rotating machinery is directly related to misalignment. That’s huge. Machine vibration, bearing damage, premature seal wear, and coupling damage are all examples of issues pumps experience when misaligned.

For the most accurate alignment, we always recommend laser alignment. It’s the most accurate method available (to .0001), and once familiar, an operator can align a pump/motor very quickly. It is the most expensive method to get into if doing alignments in-house and can be difficult to learn at first. But when looking for long-term results, the laser align method is the better choice.

Precision rebuild or precision maintenance is the practice of rebuilding a pump as close to OEM specifications as possible. Attention to detail is required for precision rebuilds.

Precision rebuilds are proven to reduce failures and should be a central piece of a pump reliability strategy. If the team lacks capacity, tools, or expertise to rebuild pumps to OEM standards, look for a capable local shop.

Add taps with isolating ball valves into piping on the suction and discharge sides of the pump. Use these to mount pressure indicators to ensure the pump is performing properly.

Read the pump manual and follow each step in the procedure. The procedures therein give the best possible instruction for long and trouble-free life for the pump.

Upon start-up, record the pump performance baseline data – amps, suction pressure, discharge pressure. This is handy when troubleshooting issues, should they arise.

Vibration monitoring is a very helpful tool for predicting pump failures. Some manufacturing facilities have a vibration technician on staff to take readings on critical pumps. These technicians may read the results themselves or send them to a firm that can interpret the readings and provide a report.

Unfortunately, this is not a skill easily attained by a maintenance team. It requires expensive equipment and a great deal of training to be an effective vibration technician. Unless the facility has a large population of critical equipment, this is a service best hired out.

Arguably the most important piece of a preventative/predictive maintenance plan... The TRAINING! Training isn’t just for the maintenance team, it’s for everyone in contact with pumps, operators especially! Failure prevention is everyone’s responsibility.

The maintenance team is the keeper and protector of equipment in the facility. Train operators on the signs of failure so they can report it quickly. Show them how to properly start-up or shut down a pump and how their actions will affect other parts of the system.

If all these steps were do-able by a maintenance team alone, everyone’s reliability goals would be already met. Some of the steps we’ve laid out require specialized training, tools, or specialized training on tools to make them effective. It’s likely the team doesn’t possess all these as they’re expected to know how to fix every machine in the plant. Hire outside help where it makes sense.

Look to a preventative maintenance program and predictive maintenance measures to save on annual maintenance costs and unscheduled downtime. We recommend working with your local equipment supplier to schedule a preventative or predictive maintenance program for your pumps.

Need more information about our preventative and predictive maintenance services? We are happy to help businesses in Wisconsin and upper Michigan. Got a noisy, underperforming pump? Consider our FREE Bad Actor Pump Assessment!

Heavy Machinery is the most expensive construction equipment you own. It’s also the costliest to repair or replace. This guide will show you how to save money and extend the life cycle of your equipment with regular maintenance best practices.

We’ll identify commonly overlooked areas of maintenance, and identify simple things you can do to greatly impact the long-term value of your most vital equipment. Even the most powerful and dependable Cat® machinery requires basic attention to ensure it provides the exceptionally long service life and unmatched productivity of Cat construction vehicles.

Being proactive in your heavy equipment maintenance schedule helps prevent expensive downtime. Regular maintenance helps predict when failure is likely to occur, allowing you to find a solution to problems before they happen.

An example is an $80,000 machine that requires approximately $24,000 in maintenance and repair costs during 5,000 operating hours. By implementing sound preventive maintenance tips, this maintenance cost drops by 25 percent to $18,000.

A successful preventive maintenance program extends construction equipment life and minimizes unscheduled downtime caused by equipment breakdown. Benefits from a proper PM program include:

Preventive maintenance is more than regular maintenance like lubricating and changing and filters. A proper preventive maintenance (PM) program is all-inclusive. It’s an intentional approach to equipment management from the time equipment is purchased until the end of its useful life.

Sudden failure is when machinery breaks without warning. Usually, the reason is obvious. The part is then fixed or replaced, and the equipment is returned to service.

Intermittent failure happens sporadically. This stoppage happens randomly, and it can be difficult to identify the cause. Intermittent failure is frustrating, costly in downtime and usually can be prevented by anticipating the cause and addressing it during maintenance.

Gradual failure is entirely preventable by doing routine maintenance and inspections. Wearing parts and components are noted to be near the end of their lifespan and are replaced before failure occurs.

Thermally induced failure is where extremes in temperature cause break-downs in the equipment. This usually happens during large temperature fluctuations such as when a machine is being started in cold weather and is being warmed up. It also occurs when equipment is overheated. Extremely hot or cold periods can be prepared for during maintenance, and thermal failure can often be prevented.

Erratic failure is the most difficult to predict and detect. This occurs at random times and under varying conditions. Most erratic machinery failures are the result of sudden overloads on hydraulic or electrical systems. With electronic components, many erratic failures come from software or hardware malfunctions that are preventable by using diagnostic equipment during regular machinery maintenance.

Anticipating failure is at the heart of all preventive maintenance programs. Thorough knowledge of your machinery’s systems is the key to anticipating what’s likely to fail if proper maintenance is ignored. Cat Preventive Maintenance Agreements from MacAllister Machinery help you anticipate and predict problems before they leave your equipment inoperable.

Thorough product knowledge is invaluable when it comes to implementing an effective preventive maintenance program. Often, gaining this vital information is as simple as finding it in the machine’s equipment manual that has been researched and documented to isolate issues and prescribe the proper preventive maintenance.

Owner’s manuals are also a great source of troubleshooting information. Not only do manuals prescribe maintenance steps and techniques, but they often have bullet-point itemization or flow charts of what to do during malfunctions.

Another valuable resource for getting to know your machines inside out is to involve the machine operators. Unless you’re on the controls on a daily basis, you’re not likely to have the intimate knowledge of each machine’s idiosyncrasies and quirks. Daily operators get a “feel” for the machine. Operators sense when something’s amiss, and they’ll tell you. Listening to them and appreciating their input is a wise preventive maintenance strategy.

Stopping operation and dealing with a suspected problem between scheduled maintenance periods can be an enormous savings in failure costs and subsequent losses.

Knowledgeable machinery operators are more productive and cause less wear on machinery than untrained workers. Knowledgeable operators are also going to be safer to themselves and others working nearby. Properly trained operators will be more respectful of their equipment and more likely to look after it before, during and after construction duties. That’s going to save you money in repairs and replacement.

Operator training should be built into your preventive maintenance program. Operators have to know more than just how to start and run their machinery. They need to be aware of what routine, day-to-day maintenance tasks are required and how to perform them without fail.

Operator training can include a review of the operator’s manual, demonstration of the systems and all controls. Testing can be a part of training as well to ensure operators have acquired the right skills including pre and post operation maintenance tasks.

All Cat equipment we handle at MacAllister Machinery is supplied with detailed manuals from the factory that include a heavy equipment maintenance schedule. This extremely valuable resource has been painstakingly assembled through the knowledge, talent and experience of Cat designers and engineers. No one knows more about the right maintenance intervals for their machinery than Cat.

Factory-recommended maintenance intervals are a minimal standard and are based on normal operating conditions. This may vary depending on local climate and specific site environmental concerns like dust, mud, humidity, ice, snow, rain and excessive temperature fluctuations. It can also vary according to the operator load that’s put on the machine.

Following factory-recommended maintenance intervals and keeping precise records is important not just for economical operation of your machinery, but also to protect your warranty.

Keeping detailed service records is an important component in your preventive maintenance plan. It’s impossible to mentally keep track of what type of servicing has been done on your machinery, and that includes when maintenance was done and when it needs to be done again.

Documented service records let you keep an accurate picture of a particular machine’s history. Routine and regular interval servicing should be written in a booklet kept in your maintenance facility or even in the machine itself. This should include the date, what type of servicing was performed, what parts were replaced, when the next regular servicing is required and notations as to any peculiarities or irregularities that were observed.

Service records don’t just provide a chronological record of the maintenance of machines. Detailed maintenance records give you documented proof that your machinery has been maintained according to the manufacturer’s recommendations. This is important for daily operations, but it also strongly supports any warranty claim where there may be a dispute that mechanical failure was caused by neglect to perform the required maintenance.

Documenting your service tasks can be done by using a pen on paper ledger. It can be on a computer file using a spreadsheet or stored in a manual file kept in your office drawer along with other paperwork associated with the machine. Small booklets placed on the machine are common. Whiteboards on office walls are another simple and proven technique for seeing heavy equipment maintenance schedules at a glance.

A heavy equipment maintenance checklist is highly recommended to aid in remembering tasks and ticking them off as servicing is complete. Organize check-sheets with each itemized task associated with certain intervals. That might be daily, monthly or seasonally. It also may be according to machine time where certain hourly milestones need specific attention.

Documenting your machinery servicing lets you plan for future tasks. This includes being reminded to order replacement parts, fluids and filters, as well as scheduling maintenance that needs outsourcing to a dealer where shop-time is required or a dealer site visit is requested.

Lights:If your vehicle has any lights — headlights, brake lights, warning lights, etc. — they should be inspected to ensure they are working properly. Any burned-out bulbs should be replaced.

Air filter:Check the oil filter to see if it is dirty and needs to be replaced. These filters should be replaced regularly anyway, but a dirty filter can make your engine run poorly.

Covers and guard:Any existing safety covers or finger guards should be inspected to ensure they are in good shape. Any damaged covers should be removed and replaced.

Preventive maintenance can help catch small problems before they become big ones that might completely sideline your equipment. It might take a few extra minutes every day, but it’s worth it in the long run.

MacAllister Machinery provides site inspections and in-shop service as part of our preventive maintenance programs included in a Customer Value Agreement. We also provide diagnostic technology with technical analysis to thoroughly inspect each major system of your machine. Including this extensive computer diagnostic lets you automatically record if you’ve completed maintenance tasks like scheduling fuel, oil, coolant and hydraulic fluid sampling.

Perhaps nothing is so important, and so often overlooked in machinery maintenance, as fluid levels. Analyzing engine oil, fuel, coolant and hydraulic fluid tell an internal tale describing the health of your machine. These analyses are also indicators of maintenance effectiveness and predictors of potential failures.

Condition monitoring should be an overall part of your preventative maintenance plan to prevent breakdown and avoid unnecessary repair costs that rob you of efficiency and profit. Partnering with MacAllister Machinery delivers the support you need to complete projects on time and under budget. Cat Condition Monitoring is a proactive approach to collecting and analyzing data crucial to the health of your fleet.

Equipment Inspections — The most effective way to identify maintenance issues is through frequent inspections. We’ll not only assist in analyzing data collected, but we’ll also train your team to learn how to spot and correct maintenance issues before they contribute to costly breakdowns and repairs.

Historical Data — Cat condition monitoring includes collecting, organizing and responding to equipment service reports and historical documentation. We analyze the data and make accurate recommendations for maintenance, inspections and repairs that reduce operating costs and increase lifecycle performance.

Site Assessment — There are many internal and external factors that combine to impact your bottom line. Site condition assessment evaluates everything from long-term equipment performance and maintenance history to work environments and seasonal weather conditions for deeper insight into how to be more productive.

Regular care and preventive maintenance of machines are priorities for heavy equipment. That includes routine machinery maintenance you do as the owner as well as outsourced maintenance with assistance by Cat equipment professionals like you’ll find at MacAllister Machinery.

MacAllister Machinery offers an all-in-one solution for managing your fleet of Cat equipment at a cost that makes sense for your budget. It’s called a Cat Preventive Maintenance (PM) Agreement, and it will keep your equipment operating at peak performance through comprehensive preventive maintenance

As your authorized Cat dealer for Indiana and Michigan, we offer state-of-the-art capabilities in preventive maintenance. We’ll assist in analyzing your heavy equipment, applications and requirements to help build a customized plan to improve the efficiency of your fleet, save you money and improve your ROI. Fill out a MacAllister Machinery contact form today to request maintenance on your machinery.

Pumps tend to be one of the biggest energy consumers in industrial operations. Pump motors, specifically, require a lot of energy. For instance, a 2500 HP triplex pump used for frac jobs can consume almost 2000 kW of power, meaning a full day of fracking can cost several thousand dollars in energy costs alone!

So, naturally, operators should want to maximize energy efficiency to get the most for their money. Even a 1% improvement in efficiency can decrease annual pumping costs by tens of thousands of dollars. The payoff is worth the effort. And if you want to remotely control your pumps, you want to keep efficiency in mind.

In this post, we’ll point you in the right direction and discuss all things related to pump efficiency. We’ll conclude with several tips for how you can maintain pumping efficiency and keep your energy costs down as much as possible.

In simple terms, pump efficiency refers to the ratio of power out to power in. It’s the mechanical power input at the pump shaft, measured in horsepower (HP), compared to the hydraulic power of the liquid output, also measured in HP. For instance, if a pump requires 1000 HP to operate and produces 800 HP of hydraulic power, it would have an efficiency of 80%.

Remember: pumps have to be driven by something, i.e., an electric or diesel motor. True pump system efficiency needs to factor in the efficiency of both the motor AND the pump.

Consequently, we need to think about how electrical power (when using electric motors) or heat power (when using combustion engines) converts into liquid power to really understand pump efficiency.

Good pump efficiency depends, of course, on pump type and size. High-quality pumps that are well-maintained can achieve efficiencies of 90% or higher, while smaller pumps tend to be less efficient. In general, if you take good care of your pumps, you should be able to achieve 70-90% pump efficiency.

Motor efficiency is also an important factor here. Motor efficiency depends on the fuel type, whether electricity or hydrocarbon, which in turn depends on availability and cost.

AC motors can achieve 90%+ efficiency when converting electrical to mechanical energy. Combustion engines are much less efficient, with typical efficiency ratings coming in at ~20% for gasoline and ~40% for diesel. Your choice of engine or motor type will depend on the availability and cost of fuel or electricity in your area.

Electric motors are more efficient than combustion engines, but site location and the cost of fuel can make the choice of combustion engines more practical.

Now that we have a better understanding of the pump efficiency metric, let’s talk about how to calculate it. The mechanical power of the pump, or the input power, is a property of the pump itself and will be documented during the pump setup. The output power, or hydraulic power, is calculated as the liquid flow rate multiplied by the "total head" of the system.

IMPORTANT: to calculate true head, you also need to factor in the work the pump does to move fluid from the source. For example, if the source water is below the pump, you need to account for the extra work the pump puts in to draw source water upwards.

*Note - this calculation assumes the pump inlet is not pressurized and that friction losses are minimal. If the pump experiences a non-zero suction pressure, or if there is significant friction caused by the distance or material of the pipe, these should be factored in as well.

You"ll notice that the elevation head is minimal compared to the discharge pressure, and has minimal effect on the efficiency of the pump. As the elevation change increases or the discharge pressure decreases, however, elevation change will have a greater impact on total head.

Obviously, that’s a fair amount of math to get at the pump efficiency, considering all of the units conversions that need to be done. To avoid doing these calculations manually, feel free to use our simple pump efficiency calculator.

Our calculations use static variables (pump-rated horsepower and water source elevation) and dynamic variables (discharge flow and pressure). To determine pump efficiency, we need to measure the static variables only once, unless they change.

If you want to measure the true efficiency of your pump, taking energy consumption into account, you could add an electrical meter. Your meter should consist of a current transducer and voltage monitor (if using DC) for electrical motors or a fuel gauge for combustion. This would give you a true understanding of how pump efficiency affects energy consumption, and ultimately your bank account.

Up until this point, we’ve covered the ins and outs of how to determine pump efficiency. We’re now ready for the exciting stuff - how to improve pump efficiency!

One of the easiest ways to improve pump efficiency is to actually monitor pumps for signs of efficiency loss! If you monitor flow rate and discharge (output power) along with motor current or fuel consumption, you’ll notice efficiency losses as soon as they occur. Simply having pump efficiency information on hand empowers you to take action.

Another way to increase efficiency is to keep pumps well-maintained. Efficiency losses mostly come from mechanical defects in pumps, e.g., friction, leakages, and component failures. You can mitigate these issues through regular maintenance that keeps parts in working order and reveals impending failures. Of course, if you are continuously monitoring your pumps for efficiency drops, you’ll know exactly when maintenance is due.

You can also improve pump efficiency by keeping pumps lubricated at all times. Lubrication is the enemy of friction, which is the enemy of efficiency (“the enemy of my enemy is my friend…”).

A fourth way to enhance pump efficiency is to ensure your pumps and piping are sized properly for your infrastructure. Although we’re bringing this up last, it’s really the first step in any pumping operation. If your pumps and piping don’t match, no amount of lubricant or maintenance will help.

Pipes have physical limits to how much fluid they can move at a particular pressure. If pipes aren’t sized properly, you’ll lose efficiency because your motor will have to work harder. It’s like air conditioning - if your ductwork isn’t sized appropriately for your home, you’ll end up paying more on your energy bill.

In this post, we’ve given you the full rundown when it comes to calculating and improving pump efficiency. You can now calculate, measure, and improve pump efficiency, potentially saving your business thousands of dollars annually on energy costs.

For those just getting started with pump optimization, we offer purpose-built, prepackaged solutions that will have you monitoring pump efficiency in minutes, even in hazardous environments.

8613371530291

8613371530291