scr mud pump in stock

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

All CategoriesAir compressors (2)Air compressor (1)Screw air (1)Attachments (2)Bucket (1)Screen (1)Backhoes (1)Excavators (1)Compactors (2)Compactor (1)Roller (1)Drill Rigs (1)Drilling (18)Brakes (1)Cat walk (1)Drilling Rig (1)Equipment (5)Mud Pits (3)Pipe wrangler (1)Pumps (3)Solids separation (3)Electrical Equipment (4)Circuit Breaker (1)Cutler Hammer (1)Eaton (1)Switchgear (1)Engines (24)Cores (2)Diesel (7)Drilling (2)Drilling Rig (1)Engine (5)Equipment (2)Natural Gas (2)Oilfield (1)Pump drive (1)Pumps (1)Generators (18)Cat (3)Diesel (7)Generator (7)John Deere (1)Heaters (3)Air heater (1)Blower (1)Indirect fired heater (1)Iron (2)Pipe (1)Sucker Rod (1)Man Camps (3)Man Camp (2)Rig House (1)Mud Pumps (27)1000hp (4)Cat (1)Diesel (2)Drilling (1)Emsco (3)Engine (1)Equipment (1)Mud pump (7)Pump (7)Natural Gas Compression (10)Compressor Station (3)Engine (1)Frick (2)Natural Gas (3)Waukesha (1)Oil Field (5)Bathroom (1)Shipping container (1)Substructure (1)Support Equipment (1)Tanks (1)Production (3)Injection (1)Pump (1)Pumping Unit (1)Rigs (1)Swabbing Unit (1)Road Graders (3)Blade (1)Road Grader (1)Service Trucks (1)Service Truck (1)Silos (2)Sand silos (1)Tanks (1)Support Equipment (19)Accumulator (3)Cat walk (1)Closing Unit (2)Drilling Rig (2)HPU (1)Koomey (2)Kubota (1)Mud pump (1)Oilfield (1)Pipe handling (1)Pipe rack (1)Pipe wrangler (1)Power Swivel (1)Tanks (1)Telehandler (4)Cat (1)Forklift (1)Reachlift (1)Telehandler (1)Trailer (4)Flatbed (1)Gooseneck (1)Step deck (1)Trailer (1)Valves (82)

The Baoji/Bomco F1000 Triplex mud pump has a max. working pressure of 5,000PSI and a 6-3/4" liner size. This model is the first choice for the medium and deep dr... More Info

The Baoji/Bomco F1600HL Triplex mud pump has a max. working pressure of 7,5000PSI and a displacement of 46.5L/S with 6" liner size. This model is the f... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Emsco/Bomco 1600 Mud Pump, Unitized 1600 Mud Pump Powered by Two GE 752 Motors Charging Pump, Liner Flush Pump, Relief Valve, Mud Gauge, Etc. ....Call For Price More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Mud Pumps - 1 - Rebuilt Gardner Denver PZ-9 Mud Pump Package, New Caterpillar C-27, 1050 HP diesel engine. Belt-driven. comes with pulsation dampener, discharge block, precharge, li... More Info

Mud Pumps - 1 of 3 used Gardner Denver PZ-8 triplex mud pumps. This would be a good rebuildable core. We also have new, rebuilt and good used pumps and packages available for sale ... More Info

Mud Pumps - Mud Pump Parts & Complete Units: Liners, Pistons, Rubbers, Rods, Valves, Seats, Springs, Inserts (Bean, BJ, CAT, EMSCO, Ellis Williams, FMC, Failing, GASO, Gardner Denver... More Info

Slow Circulation Rate is a circulation rate which will be used in well kill operation. Typically, slow circulation rate pressure (SCR) is recorded from each particular flow rate and the pressure represents pressure loss of the system while circulating. Since there are so many pressure gauges on the rig, you may get confused on the figures. In order to be at the same page for every personnel on the rig, the SCR should be recorded by the pressure gauge that we will use for killing the well.

Please always remember that SCR that you take for each time representing pressure loss at that time. I don’t recommend you to use it to estimate the initial circulating pressure.

In order to get the initial circulating pressure, you just simply bring the pump up to speed by holding casing pressure constant until you reach kill rate. Additionally, you will be able to calculate the actual SCR by calculation.

978 barrel capacity (two tanks) mud system with two (2) NOV Brandt King Cobra Shale Shakers, NOV Brandt desilter, NOV Brandt vacuum degasser, trip tank, and a 4’ x 20’ vertical gas buster.

Mud pump liner selection in today"s drilling operations seldom (at best) considers electrical implications. Perhaps, with more available useful information about the relationships between mud pump liner size and operational effects on the electrical system, certain potential problems can be avoided. The intent of this paper is to develop those relationships and show how they affect an electrical system on example SCR rigs.Introduction

There, seems to be little consideration for the relationships between liner size and demand on a rig"s engine/generator set(s). Yet, consideration for this relationship can prove to be very helpful to drillers and operators in efficiency of a rig"s electrical system. In order to develop the relationships and help drillers and operators understand the importance of each, relationships between liner size, pump speed, pump pressure, and electrical power will be developed. Only basic physical laws will be used to develop the relationships; and, once developed, the relationships are readily applied to realistic examples utilizing a mud pump manufacturer"s pump data. Finally, conclusions will be drawn from the examples.DEVELOPMENT OF RELATIONSHIPS BASIC RELATIONSHIPS

where HHP= Hydraulic horsepower, GPM = Mud pump volumetric flow rate in gallons per minute, and PST Mud pump output pressure in pounds peer square inch.

Hydraulic horsepower is reflected to the mud pump motor via a multiplier for mechanical efficiency. it follows that motor horsepower is then represented by

Preferred Pump offers the best rewards program in the water well equipment industry. Check out our social media pictures to see what you"ve been missing!

-Select-AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijan RepublicBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBrazilBritish Virgin IslandsBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape Verde IslandsCayman IslandsCentral African RepublicChadChileChinaColombiaComorosCook IslandsCosta RicaCyprusCzech RepublicCôte d"Ivoire (Ivory Coast)Democratic Republic of the CongoDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Islas Malvinas)FijiFinlandFranceFrench GuianaFrench PolynesiaGabon RepublicGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong KongHungaryIcelandIndonesiaIraqIrelandIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorwayOmanPalauPanamaPapua New GuineaParaguayPeruPhilippinesPolandPortugalPuerto RicoQatarRepublic of CroatiaRepublic of the CongoReunionRomaniaRwandaSaint HelenaSaint Kitts-NevisSaint LuciaSaint Pierre and MiquelonSaint Vincent and the GrenadinesSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth KoreaSpainSri LankaSurinameSwazilandSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTogoTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican City StateVenezuelaVietnamVirgin Islands (U.S.)Wallis and FutunaWestern SaharaWestern SamoaYemenZambiaZimbabwe

ENSCO 71 is a Jack-Up drilling rig which was originally constructed at the Hitachi Zosen shipyard in 1982. The original GE motor controls comprised five 1163 KVA generators and four 1800 ADC SCR units with associated auxiliary transformer feeders and jacking units. The SCRs were assignable to two 1600 HP twin-motor Mud Pumps, a twin motor 2000 HP Drawworks and a 1000 HP Rotary Table. A separate feeder drives a 1110 HP Top Drive. A fifth SCR was added by Hill Graham Controls in 1985 to power a third 1600 HP Mud Pump, which was cabled to the main busbars.

In early 2012, a decision was made to add a fifth 2500 KVA generator and an additional auxiliary transformer, to close-couple these to the main switchboard via a bus tie circuit breaker, and to include a dedicated feeder for the fifth SCR. A sixth SCR was also included in the switchboard extension to provide an alternative drive source for the third Mud Pump, effectively removing this load from the main switchboard. The switchboard extension, including full integration with the existing GE and Hill Graham equipment, was engineered and built by Zeefax.

Every Drilling Rig – offshore or land-based – will have a Power Control Room (PCR) on it – sometimes also known as an SCR (standing for Silicon Controlled Rectifier) System, which will form the functional heart of the power control of the drilling operations. Typically, the PCR or SCR will be a steel room about the size of a 40 foot container, inside of which will be a number of Motor Control Centres, Engine & Generator Controls, SCR Control cubicles, and other instruments and systems used for drilling purposes.

Historically, there were a number of worldwide manufacturers, producing these systems in various forms, although all are identified by their generic functional name of SCR Systems. Following the acquisition of Hill Graham Controls by Zeefax in 2007, we are now one of the very few remaining companies with the capabilities and expertise to manufacture and support legacy and new SCR systems.

SCR Systems typically operate at 600V – defined to a large extent by the operating voltage of the main drive unit used (GE752) – and clearly, these systems can be extremely dangerous if not operated correctly and carefully by suitably trained operators. It is therefore important that drilling engineers and operators are well trained and motivated in the use these SCR Systems, and it is important that the training they receive is a combination of academic knowledge, class room training, and on-the-job training.

The specification calls for an advanced SCR simulator which mimics the actual control consoles used in the operational system; this type of device would allow operators to experience as near as possible, the real life scenarios which would be experienced on a live rig. The simulator would effectively duplicate the actual control consoles, and may feature computer controlled programmable fault scenarios, which would allow operators to become familiar with the various controls in a safe and secure environment – before operating the live equipment.

In response to this,our Training Simulator is the world’s first full-size, fully-functional, fully-operational Drilling SCR Training Simulator, which has been designed with the full functionality of the real SCR. This equipment looks and feels like the real thing, and trainee engineers can learn all their skills, experiencing the field operations all with exactly the same components as in a real SCR System – but minus the dangerous high voltage. Furthermore, a key feature of the system is the addition of the on-board computer system, which mimics all of the signals that would come into this SCR system from the live engines and generators, including the motors running the mud pumps, the rotary table or the Drawworks, etc. and can also simulate a wide range of known faults, allowing trainees to experience first hand problem solving in the safety of the simulator, before they experience the live system.

The SCR system incorporates a combination of assignments which will allow training to be provided on Mud Pump, Drawworks, Shunt and Series motor combinations, motor load sharing, field supplies, dynamic braking, and auxiliary motor control.

Incorporated into the PCR is a standalone PLC training station with an HMI to allow trainees to be instructed in the use of PLC controlled SCR systems, including troubleshooting and component replacement.

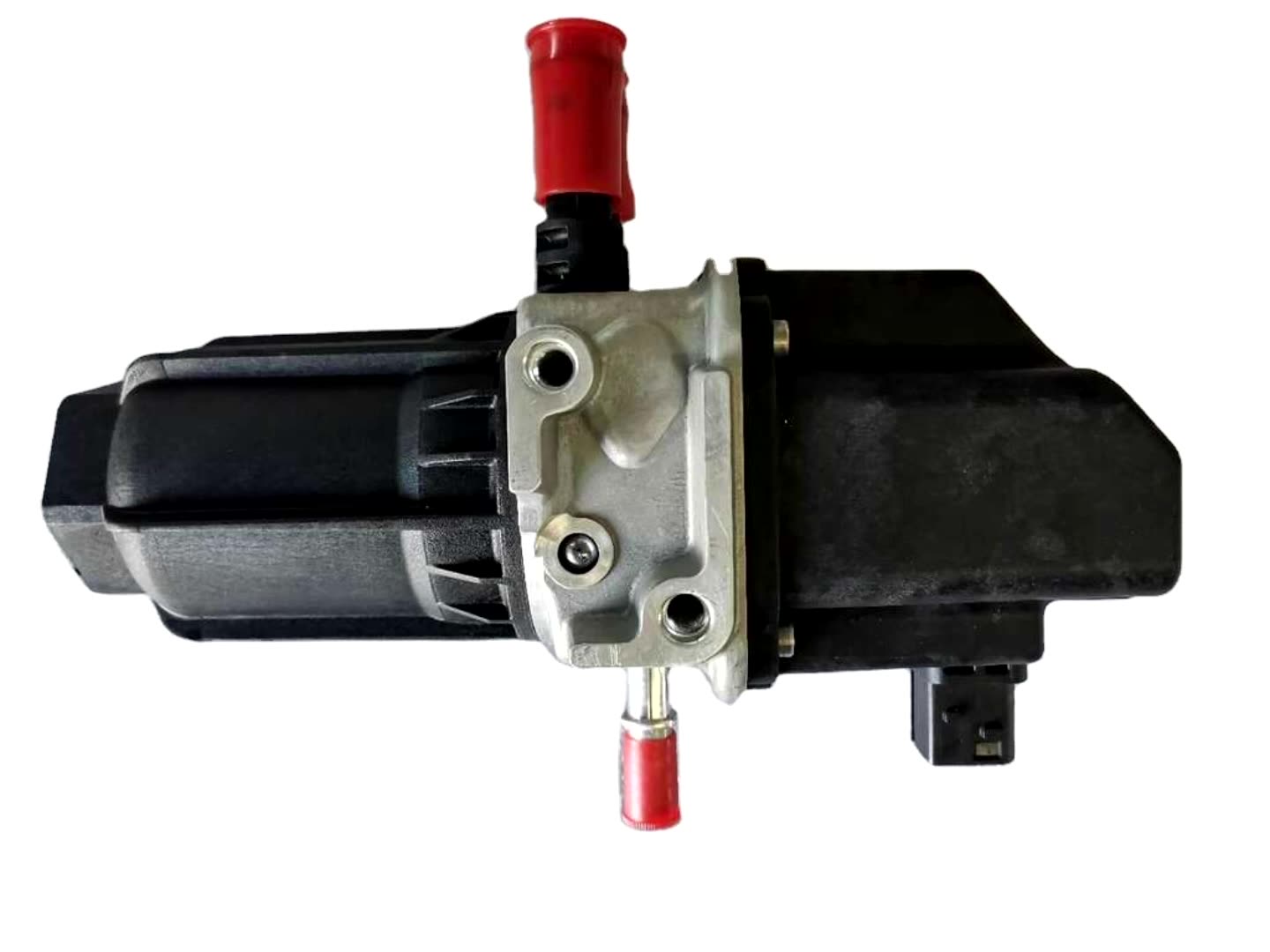

0002-0390-12 1K 25W Dual potentiometer assembly ROSSHILL for mud pump0002-0390-12 1K 25W Dual potentiometer assembly ROSSHILL for mud pump0002-0390-12 1K 25W Dual potentiometer assembly ROSSHILL for mud pump

We’ve been in a flurry of activity this year, crushing out upgrades on over thirty rigs selected for our 2017 Rig Upgrade Program. Most recently, our team in Nisku, Alberta cut the tape on the new-and-improved Rig 44, which was upgraded from a 750 HP SCR to a 1,000 HP AC-powered heavy telescopic double.

The combination of Rig 44’s high hook load, AC-power, 1,600 HP direct-drive mud pumps, and 7,500 PSI circulating system make it unique to our Canadian fleet. It’s also equipped with bi-fuel engines and a walking system capable of moving the rig with full setback (meaning the drill pipe is left in the derrick during the move).

FET manufactures a full range of valves and seats for every drilling and well-servicing application as part of our full line of Osprey® mud pump system solutions. All of our valves and seats can be used in water, water base, oil base and synthetic base mud applications. FET offers additional valves and seats not listed below, including drilling valves, frac valves and well service valves. FET’s QC standards for the dimensional and material specs are extremely rigid in comparison to other manufacturers. Contact your FET representative to learn more.

8613371530291

8613371530291