trenchless drilling rig and mud pump price

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

SHANDONG BEYOND PETROLEUM MACHINERY CO.,LTD. is established on request of customer and aimed to supply best product and service for the customer. It focuses on to supply best solutions for the overseas oilfield customer on equipment & spares maintenance and supply. China has become main supplier for oil production countries, but Chinese equipment has some special features different with European and American countries, and there exits big language and cultural difference between China and other countries, so it has become one big challenge for the overseas customer to get the exact equipment and parts they need in a short time. However, BEYOND takes root in China, and has very good cooperation relationship with most of famous factories, plus strong technical support and good advantage in language. Therefore, BEYOND is quite capable to help the customer to solve this challenge.

tools, OCTG and other related equipment and parts. Meanwhile, BEYOND can offer technical services, personnel training and maintenance guide towards China-made drilling rigs. Only if it is what you need, BEYOND can get it for you: from best factories, with most competitive price and within shortest lead time.

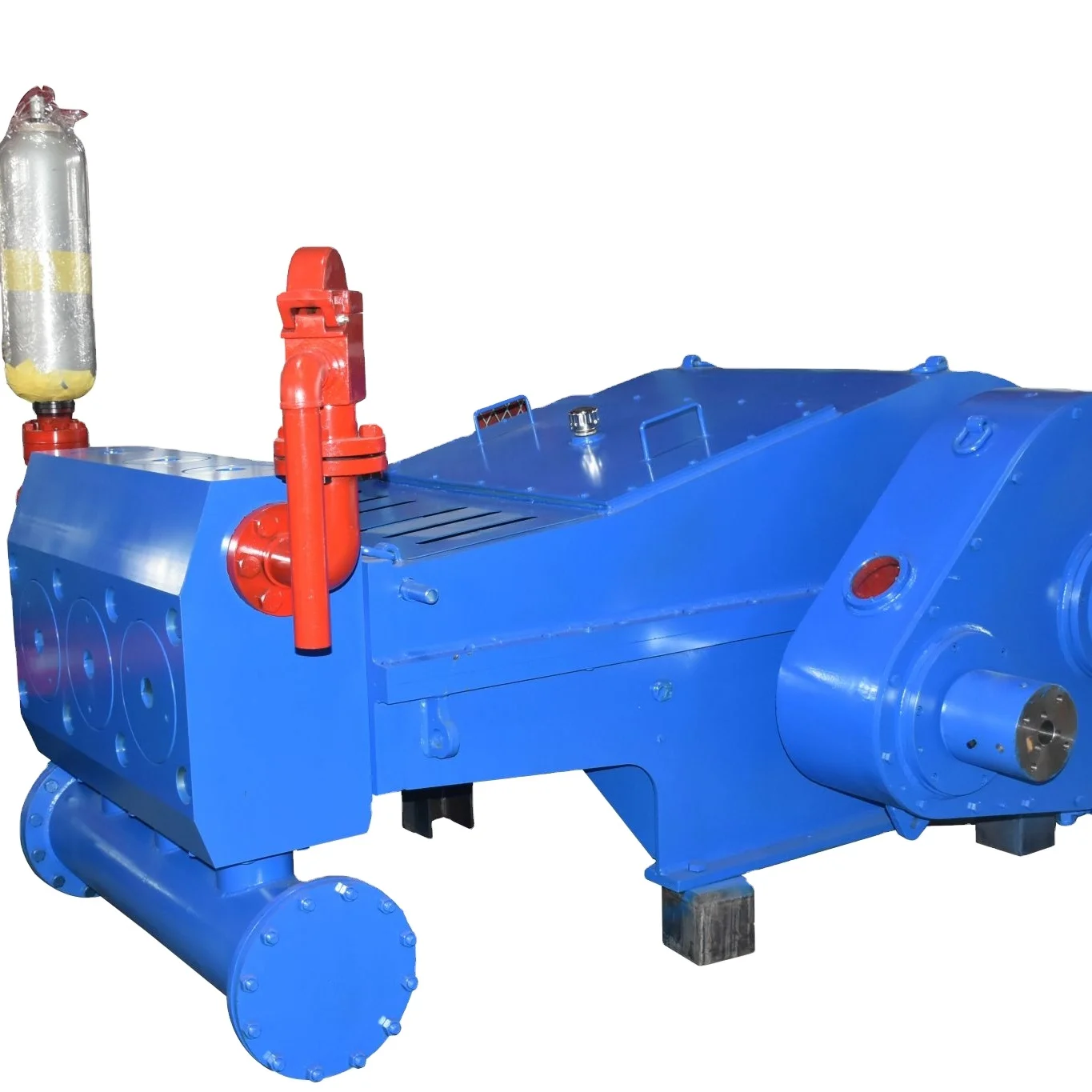

Trenchless mud pump, also referred to as horizontal directional drilling pumps provides an essential service to the HDD industry. They are an integral component to the operation; comparing with oil well, they must be built at high flow and low pressure in mind.

Based on this property, Beyond trenchless mud pump was launched as the customers require. Our current HDD mud pump ranges from 1800L/min(475GPM) to 2800L/min(740GPM) at pressure of 9Mpa/1300PSI. It is compact in weight and size, range from 4800kg-7800kg, 6.76CBM-1.92CBM. The pump can be assembled with engine and transmission system on the same skid for easy operation and transportation.

Another attractive point, it is much more cost-effective than F-500 mud pump which is commonly used in the market. It can save your cost not only on the pump itself, but also on the cost of engine and transmission since it is only 300KW and 7.8 metric ton in weight. Also it can save your fuel cost after it starts to run at site.

Working with Beyond means having an expert team to support you throughout the life cycle of your pump. Contact us today for consultation to find out the best solution for your HDD PUMPS.

Horizontal Directional Drilling (HDD) is a trenchless method for installing pipes and cables underground. The process involves boring a tunnel beneath the surface where trenching is not practical.

Boring underground requires drilling fluid that combines water and bentonite clay to help remove cuttings, stabilize the bore, cool the cutting tools, and lubricate pipe string. As the process comes to life, the drilling pump rotates the drill bit which then removes the material. As the drill bit is rotating, the pressure and fluid produced by the drill pump helps stabilize the tunnel. The mud extracted from this process is then filtered and reused for drilling fluid.

HDD is a process usually deployed when installing pipes and cables underneath roads, rivers and other types of infrastructure. Therefore, most jobs come with a challenging set of parameters that demand high rates of accuracy, efficiency, and effectiveness. Equipment manufacturers and end-users can trust our +160 years of experience manufacturing pumps for both petroleum and industrial industries.

Our HDD industry pumps offer higher flow rates at slower speeds, ranging from 200 to more than 1000 gpm at pressures exceeding 2000 PSI. Through this more efficient operation, we can help extend the life of our pumps and consumable parts, even in the most demanding HDD projects.

Our lineup of dedicated high pressure HDD pumps come in a lightweight design that eases the burden of transportation and setup while also maximizing their power potential. With max rod loads ratings up to 53,000 and horsepower up to 800 BHP, our HDD high flow pumps can handle tough jobs with ease.

Partnering with GD Energy Products for your HDD equipment also means having an expert team to support you throughout the lifecycle of your pump. We have field service technicians who can come to you with solutions, as well as 24-hour customer service and our Parts on Demand program that ensures you never run out of pump parts when you need them.

It’s all-in service of ensuring that every HDD pump you get from GD Energy Products meets our performance standards and exceeds yours. With easy access to aftermarket parts and consumables, HDD companies can trust they have a truly reliable pump at a lower total cost of ownership (TCO).

Horizontal Directional Drilling (HDD) is a steerable trench-less method of installing underground pipes, conduits and cables in a shallow arc along a prescribed bore path by using a surface-launched drilling rig, with minimal impact on the surrounding area. Directional boring is used when trenching or excavating is not practical. It is suitable for a variety of soil conditions and jobs including road, landscape and river crossings. Installation lengths up to 2000 m have been completed, and diameters up to 1200 mm have been installed in shorter runs.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Sitting at my desk and looking at the beautiful fall colors out my window, I can only think of one thing: “When will the first snow fly?” Being a permanent resident of the great white north, this is inevitable. For the horizontal directional drilling (HDD) industry, it signals higher labor costs, lower production rates, frozen fingers, toes, hoses, pumps and a boon to the -40C windshield washer fluid industry.

Knowing that you will be sending drilling crews out in this weather, being prepared is key to keeping the drill turning. Keeping a careful eye on the temperatures at this time of year is a priority. As soon as the mercury starts to flirt with the 0 C mark, the call goes out to winterize your equipment and until further notice this will be done diligently every day and every night. Care must be taken to ensure that equipment is not freezing up during breaks, lunches, tool changes and maintenance, as well. The time and cost required to keep gear from freezing and the investment of antifreeze fluids is a drop in the bucket in comparison to a frozen mud pump and the resultant downtime.

I’ve learned a lot having spent a winter working for a contractor in these conditions. A further nine years selling pump casings, tooling and drilling fluids in the winter has taught me that common sense coupled with standard operating procedures designed for winter drilling goes a long way. Now that I am focused on the drilling fluids industry, I can tell you that there is not a fresh water-based drilling fluid that will not freeze. Therefore, I have compiled a few tips and tricks I’ve learned along the way.

Drill rigs must be equipped with block heaters, this is a no brainer, at -15 C most rig engines won’t even turn over, and the days of putting a charcoal hibachi under the oil pan are long gone.

Mud pumps and systems must be purged with antifreeze fluids at breaks, lunches, tool changes and at the end of day diligently. At -15 to -20 C it takes 10 to 15 minutes to freeze a mud pump. A new frame for a power pump or a complete pump replacement for a small rig can cost a contractor $10,000 to $20,000 based on the speed to get running again.

In extreme winter temperatures and on longer shots contractors will build temporary shelters over the drill rig and mud systems (recyclers, mix tanks) and heat them with electric or diesel-powered heaters.

If the drill truck will not be used for a few days or you don’t trust your heating system it’s best to dump all fluids out, and winterize your mix pump with antifreeze.

Drill support trucks should be insulated and have a diesel-powered or electric heater. If using diesel powered heaters ensure you have enough fuel supply to last 72 hours or have it connected directly to the truck fuel tanks and make sure operators fill up before parking for the weekend.

Extra tooling to have on hand include – tiger torches and spare propane tanks, small plumbers type propane torches and Gensets to power back up electric heaters and the drill rig’s block heater.

Mud supply hoses — my preference is lay flat style hoses. If the hose slushes up it can be rolled up and purged easy enough. I’ve found once rigid hoses freeze up the only way to purge the hose is with a hot water pressure washer or to thaw out in the drill support truck. Ensure you have at least two or three back up hoses on hand with a few fittings and collars for repairs.

Keeping your support truck tidy and clean is key, slipping on iced-up mud or other detritus and tools happens too often, even getting out of the truck can be precarious so watch your step.

A few notes on the drill rigs, in the small to medium class, cabins are either non-existent or an option that is too costly. Some manufacturers offer a soft cab (tarps) foldable option, some contractors make their own to at least keep the operator from wind, rain or snow. Also, some manufacturers offer after-market slip on seat and control handle heaters.

Operators, locators and laborers should have proper winter personal protective equipment, boots, coveralls, gloves/mitts, face shields and suitable clothing. All employees should know the signs of frostbite.

Keep all liquid drilling fluids in a heated area to prevent them from freezing. The effectiveness of some additives, such as 30 per cent PHPA polymers are reduced once frozen and thawed.

Mud pumps and systems must be purged with antifreeze fluids at breaks, lunches, tool changes and at the end of day diligently. This picture of the cracked pump clearly shows the damage that freezing can do.

Keep in mind that when drilling in urban areas, you are only able to drill as long as your locate lines are visible. Once they are buried in a major snowstorm, drilling may be delayed or cancelled. At times some contractors will keep on drilling, but labor costs rise dramatically if you have to dig out your locates in 3- to 4-ft snowbanks.

Mobilizing drill rigs during large snowfall events is also a challenge especially for short shots where frequent mobilization is required. In other areas, winter freeze up actually triggers the start of the drilling season. This is true for areas that are not accessible during warm weather months.

As the winter season can be long in Canada and the northern United States, winter drilling is a regular occurrence like “Hockey Night in Canada.” The adherence to a standard operating procedure for winter drilling and maintenance goes a long way. These extra steps will prevent equipment from freezing and ensure successful and injury free drill shots.

Directional drilling is a broad term used to describe any boring that doesn’t go in a straight line vertically down. In fact, even in a vertical well, it might be necessary to deviate to avoid a geological formation or a previous stuck pipe, then return to the original path. In this instance, the driller uses sidetracking techniques.

In conventional drilling for oil and gas, the drill bit, drillstring, pipe and casing all go down in a straight line. If a driller aims away from the 180-degrees down, that’s technically directional drilling. Nowadays, however, it’s more likely that there’ll be a series of one or more carefully planned directional changes along the wellbore.

Directional drilling techniques have been employed for almost 100 years now. Over the past few decades, technological improvements have meant that angles, turns and underground distances covered are amazing feats of engineering.

Techniques such as multilateral, horizontal and extended reach drilling (ERD) are enhanced oil recovery (EOR) methods that can increase the yield of a downhole dramatically. It’s possible for ERD specialists to drill for more than 10 kilometers/6.2 miles. Students of petroleum engineering often get shown illustrations and diagrams that look like tree roots. If we imagine the rig as the trunk of the tree, the directional possibilities of the roots are endless. Even the branches of the roots are comparable to multilateral drilling.

Multiple down holes can be drilled from the same rig, minimising surface disturbance and environmental impact. Also, these boreholes can extend up to a mile down, and for more than five miles at shallower angles. In an oilfield with dispersed deposits, a large radius can be tapped, maximising the expensive asset which is the rig. Rigs and crews have day rates that run into the hundreds of thousands of dollars, one rig working up to five or ten square miles is very cost-effective in comparison to having a dozen or more vertical rigs, which may or may not be tapping into the same accessible reservoir deposits.

Geologists and engineers use terms such as an ‘oil reservoir’ or a ‘hydrocarbon reservoir’ to describe underground pockets of resources. Scientific terms give a label to help everyone understand each other, but Mother Nature has different ideas about the way she organises things.

People who perform well plans such as seismic geologists, geoscientists, exploration engineers and CAD experts join together to give the best idea of where oil and gas deposits may lie. Their estimates are based on different types of surveys, and past experience. What they’re unlikely to do is pinpoint the exact place where they’d access the maximum amount of resources.

When we see reservoirs of water, we can imagine dropping a giant straw into the middle and sucking up the entire lake. The flat surface area of the water and the likelihood of human-made dams and walls might give us a false idea of the topography of an underground reservoir. The bottom of the lake would provide a better insight into the random geometry of the dispersed resource. For example, if your imaginary straw happened to touch a shallow gravel bar in the middle of the lake, you might only extract a small percentage of the water.

On top of this randomness related to upper, lower and outer dimensions, there are plenty of other possibilities:By drilling at an angle, more of the reservoir gets explored, since they tend to form horizontally (between formations) not vertically.

The deposit might not resemble a reservoir at all, it might be oil-saturated sand or shale. Directional drilling is especially valuable in shale, where the formation can be explored to follow richer seams.

There’s some other reason why the reservoir is inaccessible from above, such as the surface land being a town, mountain, nature reserve or area of special scientific interest (SSI).

Rather than the oil and gas settling in a single deposit, it’s in separate distinct pockets, not clearly joined to each other. This can occur where there are multiple bed dips or altitudes.

It’s common to find deposits below salt domes or fault planes, where the driller faces increased technical risk. Horizontal drilling can avoid salt domes, and reduce pressure on equipment near fault lines.

In fact, these ‘irregular’ reservoirs are very common. Now that relatively fewer elephant reservoirs are being discovered, and technology improves, directional drilling becomes more critical each year.

Another use for directional drilling is in the event of an uncontrolled, or ‘wild well’. If you imagine a well that has broken through the blowout preventer and is gushing, how can you cap it?

This depends on the amount of underground pressure. In some instances, a second control well is drilled so that it intercepts the same point where the original wellbore meets the reservoir. Once the new directional well is completed, it can be pumped with kill fluid.

If the well pressure isn’t too severe a relief well can help to release gas so that the original gusher reduces in intensity, allowing it to be controlled. Mud and water are pumped in from a different angle, to get the first well under control and back to proper working order.

It’s not possible to see hundreds of metres underground, in fact, the drillers and engineers rely entirely on technology to ‘see’ where they are going. A directional driller has a guide that has been created by the engineers and geologists. Every 10-150 metres, (with 30-40 being typical), survey data is sent back to make sure that the original ‘blue line’ well path is being followed.

Directional drilling software receives input from multiple measurements while drilling (MWD) sensors in the drill bit, and at any branches or junctions. (Other measurement tools include Electromagnetic MWD and Global Positioning Sensors (GPS)). In addition to MWD technology, mud loggers use logging while drilling (LWD) sensors and software. The drill bit has vibration sensors that can detect the type of formation being drilled at any point. Collars can be added along the length of the well, sending back information to the surface regarding torque, weight and bending.

From the surface, electromagnetic sensors can also track the progress of the drill bit. When all of the data from the drill bit, collars, motors and the surface equipment enter the control panel, a complete representation occurs.

As well as being able to know what is going on, even a mile along the drill bore, drilling engineers can make adjustments in real-time that ensure that everything is going to plan. This is especially relevant when unexpected things occur concerning geology or severe equipment stress.

If you were to imagine the mechanics of directional drilling without seeing the technology, you might wonder how the drill could suddenly change direction. Since the motor that turns the drill is at the surface, how can the drill string continue to rotate at 360 degrees while going around a corner?

We now have downhole drilling motors, that can drive the drill bit in a completely different direction to the usual 180-degree downhole starting point. Turbodrills and rotary steering drills are employed in directional situations where they’re best suited.

The rotational speed of the drill and the weight and stiffness of the drillstring can also be used to influence direction. One of the original methods was jetting, a high-pressure nozzle shot water or drilling fluid from one edge to the drill bit, creating a weaker side in the formation.

Another traditional method was to use a whipstock. A whipstock is a type of wedge that can redirect the drill. At the desired depth the drill is withdrawn to the surface, a whipstock gets put in place, then the drill goes back down and gets redirected by the whipstock. Next, the drill is brought to the surface again, the whipstock pulled out and then drilling resumes and the bore changes path.

Drill bit sensors can tell the driller about external weight, and rotary speed that can also be used to influence the trajectory. Mud motors can also be used to change direction. With a steerable drill pipe, there’s a bend near the bit. The drillstring stops turning, and then there is plenty of time to use chosen directional techniques to reposition the bit to the desired trajectory. When it starts spinning again, it’ll start going in the direction that it’s now pointing towards. (More about steerable mud motors in the next section).

Specialised drillbits are used to improve performance and reduce the chance of failure. Schlumberger supply directional PDC drill bits for both push- and point-the-bit rotary steerable systems. Horizontal Technology, Inc. provides ‘Varel High Energy Series bits’ designed for the unique, rigorous conditions of horizontal directional drilling.

Mud Motors. Downhole steerable mud motors get positioned near the drill bit, which has a bend in it. What happens is that at the correct depth the drillstring stops rotating, then drilling fluid is pumped through the mud motor so that the drill bit starts to turn just due to the force of the liquid. This mud pressure pushes the drill bit into a different angle, and also begins to bite into the formation at a different angle to the central well trajectory. Once the sensors verify that the drill bit is pointing in the right direction, the drillstring starts to turn again.

Rotary Steerable Systems (RSS). Directional drilling by using the mud motor means that often the drill pipe needs to be slid forward while the drill is motionless. A rotary steerable system can drill and steer at the same time. This means that previously inaccessible formations can be accessed.

Custom whipstocks that work with downhole motors don’t need removing in between drilling. These are a significant advance on the old fashioned ones previously mentioned. More time can be spent drilling, and less time removing the drill bit and conventional whipstock.

Networked or wired pipe. The Intelliserve system from National Oilwell Varco is a broadband networked drilling string system. It can transmit data from the sensors back to the surface.

Well integrity is perhaps the most crucial aspect of directional drilling. Drilling at deeper, or extended distances, and especially changing direction causes a number of additional engineering challenges and stresses on the equipment.

For example, a downhole drilling motor will always be far smaller and less powerful than one connected to a robust drilling rig above ground. It’s more likely to fail, or have insufficient torque or speed to get through challenging geological formations.

The drillstring itself will be less stressed when going in a straight line, every degree of turn add extra friction and unbalanced pressure. If drillstring integrity isn’t maintained, the drillstring can snap or get jammed. It could mean that a brand new set of equipment is needed, and a new well might need to be drilled again in a slightly different direction.

Maintaining hydraulic pressure, and wellbore cleaning is much more challenging with these types of wells. Modern directional drilling equipment is so advanced, it can cope with high pressure/high-temperature HP/HT conditions, a mile away, after the wellbore has changed direction.

Computer simulation programmes are used to simulate the well plan. 2D and more recently 3D modelling programmes give the geoscientists and engineers a visualisation of the planned path. This software is created based on previous knowledge, current seismic and magnetic data, supplemented with real-time data from the MWD instruments.

There are a few different types of directional drilling. Multilateral drilling is where a downhole bore has multiple lateral (90 degrees) offshoots. For example, a well might be 1000 metres in depth but have numerous lateral wells connected to it. Extended reach drilling (ERD) is categorised by ever longer wellbores drilled from the rig.

Land tenders offer the right to explore and extract resources from a particular square meterage of land. It’s possible to purchase a lease for an oil patch, then drill horizontally into neighbouring territory. Close to a national border, it’s been known for drillers to drill into another country.

This is different from straightforward situations, where two territories happen to tap into the same reservoir. The industry has guidelines and regulations. Simultaneous operations (SIMOPS) and combined operations (COMOPS) have strict procedures for situations where well interference can occur.

Of course, the majority of horizontal drilling is done for good reason, not to cross borders of ownership or sovereignty. Sometimes horizontal directional drilling is the only possible way to tap a reservoir, such as the case of dilling under a town or nature reserve. Other times it’s a cost-saving exercise, to drill under a salt dome or mountain. Lastly, drilling horizontally can be the best way of maximising extraction by reaching more sections of a reservoir.

Serial Energy Entrepreneur. Webmaster at drillers.com. Founder of Out of the Box Innovations Ltd. Co-Founder of Natural Resource Professionals Ltd. Traveller and Outdoorsman, Husband, Father. Technology/Internet Geek.

With high-capacity pumps and HDD rigs with higher drilling-fluid-flow capacities, the down-hole mud motor has become the tool of choice for directionally drilling in rock. The drilling-fluid requirements to power mud motors are much higher than for mixing and transporting cuttings; however, the majority of the fluid can be recycled and reused. The important factors in classifying mud motors for HDD applications are the output torque, fluid volume requirements, and length. Length is important because the tracking equipment is located in the drill string, which may be as much as 26 feet behind the drill bit and thus difficult to track with the desired accuracy.

Mud motors achieve directional control by using a maximum 3-degree bend located approximately 5 feet behind the bit. The drill operator can obtain more aggressive steering if the distance from the bit to the bend is shortened and a greater bend angle is used. The bend is oriented in the desired direction, and the entire assembly is pushed to attain the steering corrections while only the bit rotates. The drill string and bit are rotated and pushed for drilling straight. One significant difference in drilling with a mud motor is that the drill string should rotate at less than 50 rpm because the assembly oscillates in the bore when rotated and may be severely damaged or prematurely worn if rotated at excessive speeds. The rotation should start slowly and carefully after steering. This allows the assessment of restrictions that may prevent the bent assembly from freely rotating in the bore and prevent expensive damage to the mud motor.

hard rock. If hard rock is expected and properly tested, proper selection of equipment can be done before construction begins. Rock may become an obstruction when it is unexpected and tooling has been selected for soils or if the rock encountered is much harder than anticipated. In these cases, the bit may be changed to one capable of cutting the harder rock. Higher-capacity mud motors and pumps may also be required. These modifications can be time-consuming and expensive.

A mud motor is no more effective than the volume of fluid, which generates power, that is pumped through it. If the mud flow is on the low side of specifications, the mud motor will have low bit speed and a slower penetration rate. As the pumping rate increases toward the maximum of the flow specification, the motor is more powerful and efficient. This is why it is essential to match the mud motor with the available deliverable mud flow from the pump. Most mud pumps used in the directional boring industry run at higher speeds to operate mud motors. However, mud pumps lose operating efficiency as the mud viscosity increases and the effect of entrained air in the mud increases. The pump does not completely fill during the suction phase, resulting in a drop in the volume of fluid being pumped.

Most pressure-fed piston or plunger pumps generally have a 96 to 97 percent volumetric efficiency. The loss in efficiency largely results from the valves not opening and closing instantly. The efficiency goes down as mud viscosity increases and drops significantly if air is in the mud. Air in the mud can reduce pump efficiency to 50 percent or less. The main cause of entrained air is the design of the mud-cleaning system. Mud is cleaned by agitation, which mixes air into it. Higher-viscosity mud results in more air entrapment. The cleaning system must provide enough time for the mud to expel this air before it enters the suction manifold of the pressure pump. In addition, small internal diameters of piping and hoses cause pressure losses as pumping rates increase. This reduces the pressure available for the motor, causing a decrease in motor torque and slower boring.

Small inside-diameter drill pipe also tends to require a higher surface mud-system pressure to offset piping losses. Mud-flow rates provided by manufacturers are usually a calculated volume based on pumping water at 100-percent efficiency. Air in the mud, the size of the restricted passages, mud viscosity, and the length of the various restrictions reduce the true working efficiency of the pumps.

Mud pumps can have two or three cylinders depending on the application and sometimes more than one pump can be run together when large amounts of mud are being circulated. A powerful motor is used to drive the pump.

Pulsation dampers on the discharge end of the pump smooth out the surges caused by the pistons discharging mud. Pumps can be designed for differing operating conditions by adjusting the size of the pistons and setting the discharge pressure.

"6000円引き!アディダス スタンスミス クリアグラナイ(スニーカー)が通販できます。値下げ不可ですアディダスオリジナルスadidasoriginalsSTANSMITH24cmホワイト/ネイビー定価16000円新品未使用タグあり、箱なし国内アディダス直営店購入!確実正規品!スタンスミスの大人気カラー!6000円引きの破格!!beamsロンハーマンユナイテッドアローズなどでも取り扱いモデル!三代目jsoulbroth"

To do this job right, it takes a special person. Someone willing to wake up every morning, laugh in the face of Lady Luck, and go the distance. Because, you know, out in the field with the right team at your back, success is anything but lucky.

MTI is a full-service company providing equipment, parts, and service to the oilfield, HDD (Horizontal Directional Drilling), geothermal, mining and water well drilling industries.

We manufacture a complete line of solids control equipment including; mud reclaimers & mud recyclers, shale shakers, de-silters, de-sanders, and pump packages, all for sale or for rent, allowing us to achieve a higher standard of excellence.

A large inventory of parts and accessories , and knowledgeable staff makes Mud Technology the smart choice for operators needing fast-turnaround times and competitive pricing.

Our staff is available to assist you with complete line of parts, including pump parts, shaker screens and drilling mud all available at competitive prices. As we are just a phone call away, we are available to answer questions and assist you with troubleshooting while you are in the field.

8613371530291

8613371530291