trenchless drilling rig and mud pump made in china

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

product and service for the customer. lt focuses on to supply best solutions for the overseas oilfield customer on equipment &spares maintenance and supply.

China has become main supplier for oil production countries,but Chinese equipment has some special features different from European and American countries,and there exits big language and cultural difference between China and other countries, so it has become one big challenge for the overseas customer to get the exact equipment and parts they need in a short time.However. BEYOND takes root in China, and has very good cooperation relationship with most of famous factories,plus strong technical support and good advantage in language.Therefore, BEYOND is quite capable to help the customer to solve this challenge.

BEYOND products cover but not limited to:China-make oil drilling rigs, workover rigs, wellhead and downhole tools, drilling tools, OCTG and other related equipment and parts.Meanwhile, BEYOND can offer technical services, personnel training and maintenance guide towards China-made drilling rigs. Onlv if it is what you need, BEYOND can get it for you: from best factories, with most competitive price and within shortest lead time. With“Professional & Efficient Customer Focus.Win-win Cooperation"as its operation principle, BEYOND believes that it will become your best cooperative partner in China.

2. NL hydraulic type security to adapt to bracket pool, water tank. The pump body submerged in liquid under the length of 1-2.5 meters for fixed or mobile carrier occasions sewage, construction of sewage, containing massive industrial liquid medium.

Apply to transportation of industrial wastewater and urban domestic sewage, but also can be used as a drain pump, paper pulp pump, a filtered rinse cycle condensate pump, irrigation pump.

Please try again in a few minutes. If the issue persist, please contact the site owner for further assistance. Reference ID IP Address Date and Time 406b4f95116c28dca247da206ca234ea 63.210.148.230 02/13/2023 08:56 PM UTC

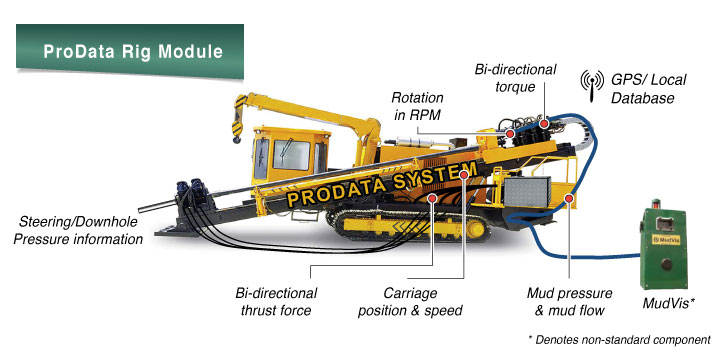

1.Hydraulic pilot control, provide comfortable operating performance and flexible regulation, first-class brand of hydraulic components to ensure the reliability of the machine hydraulic system.

2.Carriage and clamp using double floating patented technology can greatly protect the drill pipe thread, increase the service life of the drill pipe.

3.High-speed sliding systems, piston motor to achieve high and low sliding speed of carriage, increasing the ability to adapt the machine working conditions, promote construction efficiency.

4.Optional full-automatic pipe loader, drilling box can accommodate 40 piece of drill pipes(φ73), ensure one time reached 120 meters, efficient automation construction, reduce construction costs and labor intensity.

5.Support the diverse needs of customers, the machine can option configuration with the automatic (semi automatic) full-automatic pipe loader, automatic anchoring system, cab, air conditioning wind, cold start, freezing mud, mud washing, mud throttling and other devices.

The HDD drill rig is short for horizontal directional drilling rig, and the other name trenchless directional drilling rig. HDD Drill rig made in Huanghai Factory is an automotive travel drilling rig by means of rubber crawler. It is powered by hydraulic pressure. It is designed by advanced technology and has a simple and convenient structure. Besides, the drilling dig has a stable performance, high efficiency and low oil temperature.

Its main hydraulic component, motor and mud pump are domestic famous brands. As for the main machine, it is equipped with rubber crawler, which is solid and anti-wear. Thanks to the rubber crawler, the HDD drill rig, or horizontal directional drilling rig can work in the urban area. It can also move from the standard trailer by itself. This ensures the HDD drilling rig can move around easily in the drill site. This also ensures that the trenchless directional drilling rig can work within the possible drilling angle.

1. The diesel of the horizontal directional drilling rig has low emission. The design of the diesel is meant to reduce the noisy. The low emission and the less noisy make the drilling rig suitable for urban work.

4. The mud pump is powered by hydraulic pressure. The mud pump is manual transmission. The mud volume can be adjusted according to different geological conditions and drilling techniques.

Deep Hole Directional Drilling Rig is specifically designed to drill especially long directional drilling borehole in explosive underground environments. It is MA certified and currently operating in Chinese regularly drilling sub-horizontal direction holes in excess of 2000 meters.

When combined with our real-time survey tools (MWD), modular electrical connected cable assembly (MECCA) drill rod, mud pump crawler, directional drill bits and downhole motor, the system has the ability to track, guide and precise control borehole trajectory to accomplish the most challenging drilling requirements.

Deep Hole Directional Drilling Rig has a compact footprint mounted on tracks. Integrated drill unit combined with a feed frame that tilt can be adjusted from -10 degree to +20 degree. With features of high rotary torque (the rated torque is 12000N.m) and powerful push/pull force (max push/pull force is 250kN), the drill is capable for precise directional drilling operations in excess of 2000 meters. A maximum depth of 2311 meters borehole with 15 sidetracks was accomplished in Nov, 2017 Baode Coal Mine, Shenhua Group, one of the largest underground coal mines in the world. We believe this is the new depth record of underground sub-horizontal in-seam directional drilling.

Application of the rig includes directional drilling operations for gas drainage, water detection or discharge, grout injection, exploration of geological structure, detection of seam thickness, water injection into coal seam, etc. Technical parameters are listed in following table.

Hot Tags: deep hole directional drilling rig, China, manufacturers, suppliers, factory, wholesale, price list, buy, for sale, Drill Tools, Hydraulic Rigs, Drill Bits, Geophysical Instruments

.jpg_l.jpg)

The drilling fluid mixer is a supporting equipment for the drilling rig solids control system and the trenchless mud system. It can meet the weighting and preparation of the drilling rig solids control system from 1000 meters to 9000 meters. The mixer is composed of a centrifugal mud pump and jet mixing. The mixing hopper is connected with the manifold and valve and installed on the skid-mounted base. Single jet mixing device or double jet mixing device can be selected according to customer needs. >>Send an Enquiry sales@hlsolidscontrol.com

(1) Before use, open the inlet butterfly valve I and outlet butterfly valve II of the centrifugal mud pump. Then start the centrifugal pump. When the pump runs normally, open the inlet butterfly valve III of the funnel, then add the materials of drilling fluid (such as betonies and barite powder) and corresponding chemical additives (such as polymer) from the funnel to strengthen and make up the slurry.

(2) Before stop the centrifugal mud pump, close the inlet butterfly valve III of the funnel to prevent the instant pressure from lowering, resulting in overflowing of slurry from the surface of the funnel.

(3) When mud mixer stops working for a long term, close the suction inlet butterfly valve I, then loosen the pipe plugs under the casing of the sand pump and ones under the inlet pipe of the funnel to drain the slurry to prevent the pump body and pipeline from being blocked and frost cracked.

In 1996, Phillips China, Inc. (PCI) based in Shekou, People"s Republic of China, was faced with the decision to either submit a development plan for the Xijiang 24-1 Field in the 15/11 Contract Area of the South China Sea or to relinquish their rights to the field. The remote location of the field and the relative small size of the reservoir made this decision difficult. Several studies conducted over a number of years on various development scenarios indicated that any type of stand alone development, such as a small platform or subsea wells, would be uneconomical. It was, therefore, concluded that the only way of developing the 24-1 was to drill an extended reach well (ERW) from PCI"s Xijiang 24-3 Platform, over 8-km away. Such a well would have a world record horizontal reach.

One of the biggest concerns for the success of an ERW was whether the platform rig, which was designed for a 4573-m measured depth (MD) (3049-m true vertical depth (TVD)) development wells, could be upgraded sufficiently. Also of concern were the relatively remote location of the Xijiang operation, the lack of experience in ERW drilling in the area, the transitional step from drilling relatively shallow development wells to drilling a world record ERW, hole stability, torque and drag, directional control, logistics and weather.

This paper will describe the upgrade process performed on the drilling rig to enable it to drill and complete this record breaking well. It will include a post-well evaluation of the upgrades. In addition, it will describe the drilling and completion of the well and how PCI addressed all the concerns listed above.

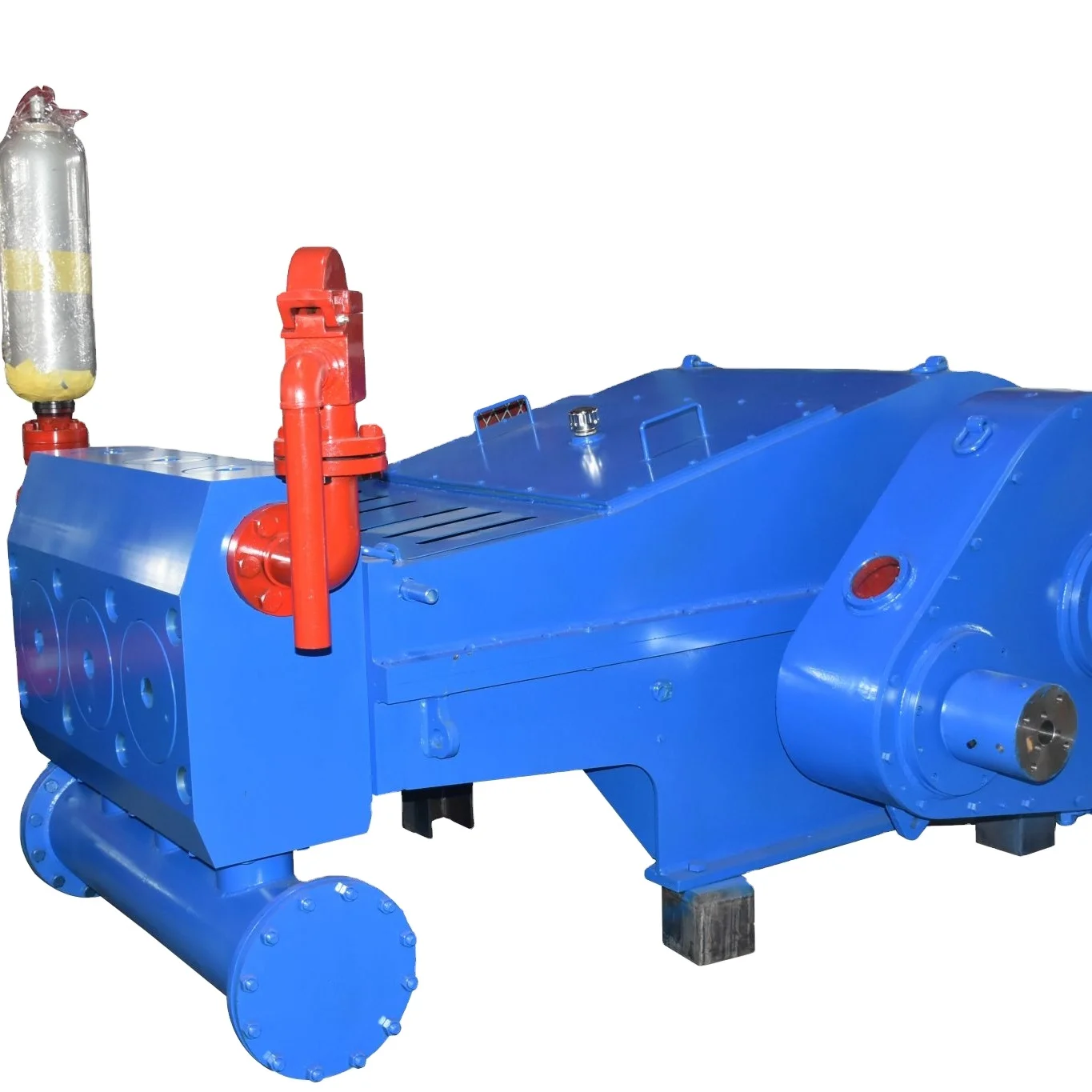

Mud pump manufacturers often provide two types of mud pumps. In fact, the power end and the hydraulic end of the pump are the same. The difference lies in the way the pump discharges the mud.

In the early 1990s, it was generally recognized that medium and small drilling rigs used text boxes:, high pressure (1800-2200ps i, ie 124-152bar) and low flow (5-25gpm, ie 19-95Lpm) pumps to send flushing fluid In the hole.

With the maturity of the drilling industry and the rich experience of operators, it has been found that higher mud flow and lower mud pressure are an excellent method for drilling. In some formations, high pressure and low flow are still the first choices, and have achieved the greatest success. However, in most areas, a higher flow rate can best ensure the cleanliness of the hole (removal of cuttings) and provide sufficient bentonite for formation plugging and lubrication.

When high pressure (800-1000psi, 55-69bar, and higher) and lower flow are required, plunger and sealing technology are used. The fluid pressure pushes the front part of the seal, pressing the seal around the smooth surface of the reciprocating plunger, preventing leakage. When the pressure is lower than 800-1000 psi (55-69 bar), the liquid flow pressure is not enough to promote this isolation, and the seal leaks. The leaked liquid carries sand and other abrasive solid particles into the well and collects between the seal ring and the plunger, causing rapid wear of the plunger surface and/or seal, and failure of good packing.

One advantage of the plunger and sealing technology is that the operator can adjust the leakage of the seal to a minimum until the pump can be used effectively and the borehole is completed.

Pumps with piston and liner technology work in the opposite way. In the case of low hydraulic pressure (less than 1200psi, that is, 83bar), the piston prevents leakage well. The diameter of the piston is usually larger than that of the plunger. It is an advantage to allow the pump to run slower when discharging the same flow rate.

The piston has two disadvantages. First, when the piston is damaged or starts to leak, the operator cannot maintain the status quo until repairs. Therefore, after an obvious leak, it usually must be repaired immediately. Second, the piston is suitable to run under cooling and lubrication. Therefore, a cooling and lubrication system must be used to increase the durability of the piston.

The cooling and lubrication system includes small centrifugal pumps, nozzles, pipes and collecting tanks. The system sprays a mixture of water and lubricant (non-foaming soap or liquid polymer) onto the back of the piston.

Many drilling rigs are equipped with plunger pumps. Plunger pumps are often used in applications where piston pumps should be used (mainly low pressure and high flow), and often have leakage problems. In order to help operators eliminate the leakage of these pumps, some pump manufacturers are developing conversion components that can change the pump from a plunger type to a piston type. Ask the manufacturer of your drilling rig or pump if it is available from stock.

From an economic point of view, when the plunger is no longer applicable and must be replaced, you should consider changing the pump from the plunger type to the piston type. The conversion component can be installed on site, and it is very easy to operate.

If your mud pump has a leakage problem, you should think about whether your pump is working under conditions or uses that do not meet the original design.

We understand that the most important factor in your drill rig"s effectiveness is the performance of its operator. To help make their workday as productive as possible, we"ve incorporated safety and comfort features into the new operator"s cab. The new cab ensures operator comfort with features like climate control, all around visibility, air suspension seat and easy to use controls.

As a China top oil drilling rig solids control system manufacturer: GN Solids Control now list the top 10 oil drilling rig manufacturers for your reference.

equipment in China, is the earliest established, largest and most powerful oil drilling rig and production equipment developer and manufacturer under CNPC, the largest research and production base of land rigs and series mud pumps in the world, and also the largest and most powerful base for R&D and production of wire ropes for special purposes in China.

Lanzhou LS-National Oilwell Petroleum Engineering Co. Ltd. (LS-NOW for short) is a Sino-American Joint Venture established between Lanzhou Petrochemical Machinery Equipment and Engineering Group Corporation (LS Group) and National Oilwell International, Inc. (NOI). Scope of business: design, develop and manufacture complete land and offshore drilling rigs and workover rigs, and provide equipment package, components, fittings, parts and full services.

Main products: serial drilling rigs that are electrical or mechanical or electrical-mechanical compounded driven and suitable for different applications such as land, shallow, offshore and desert and meet the requirements of drilling and workover services. The drilling depth ranged from 1000 to 9000 meters.

Sichuan Honghua Petroleum Equipment Co., Ltd., established in 1997, is a subsidiary of Honghua Group which has been listed successfully in the Stock Exchange of Hong Kong. The company has been engaged in research, design, manufacturing and general assembly of oil drilling rig and equipments for oil exploration and development. Now it is the world’s second land drilling rig manufacturer, and China ‘s largest exporter of drilling rigs.

The company owns five subsidiaries totally in home and abroad, with 3600 employees. Company headquarter is located in Deyang City, Sichuan, a heavy-duty equipment base in China, which covers an area of about 1,000 mus, and with more than 2,200 employees, annual output of 150 drilling rigs and 600 mud pumps etc. Its production capacity is up to 8 billion RMB production scale.

The company produces mainly various land drilling rigs for drilling 1000m to 9000m wells and offshore drilling modules– DC drive drilling rig, AC VF electric rig, mechanical drilling rig, composite drive rig, trailer mounted rig and independent RT electric drive drilling rig, as well as their matched equipments, i.e. drilling pumps, traveling block system, solid control system, electric control system etc.

RG PETRO-MACHINERY (GROUP) CO. LTD is one of the largest manufacturers for petroleum drilling rig equipment in China. It is a stock company, reorganized from Nanyang petroleum machinery plant (former No.2 Petroleum Machinery Manufacturing Plant of National Petroleum Industrial Ministry of China). As a former national technical equipment production base, authorized by former national economic and commercial committee of China, RG PETRO-MACHINERY (GROUP) CO. LTD has become a company for national new product trial production of China, light-duty drilling rigs production base of SINOPEC and a high-tech enterprise in Henan Province.

RG PETRO-MACHINERY (GROUP) CO. LTD, with its technical center, information center and quality inspection center at provincial level, has possessed 16 production plants for forging, metal machining, heat treatment, steel-structure manufacturing, general assembly, painting and new product trial production, and 3 comprehensive testing sites for drilling rigs as well as 2 Sino-American joint ventures and 2 share-holding joint ventures.

SJ Petroleum Machinery Co. , one of petroleum drilling rig and production equipment backbone manufacturers and Manufacturing Base for National Key Equipment (Workover, Cementing and Fracturing Equipment) recognized by National Economy and Trade Commission, has provided lots of advanced equipment to domestic customers in lieu of expensive imported equipment, and played an important role in increasing profits of petroleum industry and decreasing domestic oilfield development cost.

Our company Shandong Kerui Holding Group is located in Shengli Oilfield the second largest oilfield in China. Our company arranges a wide range of businesses covering the scientific research and manufacture of the petroleum drilling equipment and oilfield engineering technical service. The main products manufactured and supplied include drilling equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China.

The main products manufactured and supplied include oil drilling rig equipment, Oil pumping equipment, Special equipment for oilfield, Oilfield tubing system and auxiliary machines and tools. We can manufacture various workover rigs and drilling rigs with drill depth from 3000m to 9000m. All products meet API standard. Our company has been granted API Certificate, ISO 9001: 2000 Quality System Certificate, HSE Certificate, and also got International Petroleum Engineering Management qualification certificate issued by the Ministry of Commerce of China

(shanghai) petroleum equipment co., ltd. is established on august 2001. the 3h is the first rig manufacturer that introduces ship-building technology to the fabrication of petroleum equipment.

Shengli Oilfield Highland Petroleum Equipment Co., Ltd Established in 1992 was a private incorporated manufacturer of petroleum equipments located in Dongying city, Shandong province, the PRC. Through many years development, the company had been recognized and become well-known in petroleum industry achieved the superior position in the field of scale, product quality, technology ensuring and selling service and so on in petroleum equipment manufacturing in China. It possesses 3.5 billion RMB of total assets, owns more than 1,980 thousand square meters of plant area, China’s state-approved high-tech enterprise, China’s patent star enterprise, Shandong Province top 100 and excellent enterprise, Shandong Province unique petroleum equipment R & D center and over 370 engineers and technicians and 150 contracted noted specialists in ceeusro field.

Drilling Rig: Highland Company Drilling Rig Plant has advanced key facilities and assembly workshops for manufacturing rigs and it has enough test sites for assembling 12 sets of large scale drilling rigs at the same time,5 series (ZJ20~ZJ70, including 18 types) of drilling rigs have been developed and manufactured. These developed and manufactured products consist of mechanical drive, DC driven, AC VF drive and Electromechnical drilling rigs, which can handle the well with depth of 1500- 7000m in most of the large oilfields both at home and overseas.

Aug.,2009: Jiangsu Goodeng Engineering Assembling Co.,Ltd was built up and put into operation, which is the domestic horizontal directional drill manufacturing base with largest scale, most advanced equipments and harsh technology.

The key technology research and product development of industry support projects for GD8000-LL horizontal directional drill were passed through the identification and acceptance of results in Jiangsu Goodeng.

2013: The top of world GD1000 was successfully developed in Jiangsu Goodeng.Jiangsu Goodeng machine performed one-time success while crossing and back-pulling under main channel of Yellow River, and with the 3075M crossing length created two longest records: longest directional crossing and longest main channel crossing in Yellow River.

LEC mud pumps use hydraulic power to convert hydraulic energy into the power that can convey high pressure mud. It’s self-suction plunger pump. The parts without rotation make piston linear motion.

•High reliability: no rotating parts, less moving parts, longer free maintenance time, high abrasive resistance and self-lubricating ability, which decrease the operating cost. When the hydraulic power less than max. rated power, the pump will decrease the output power automatically thus make the pump safe.

8613371530291

8613371530291