triplex mud pump design pricelist

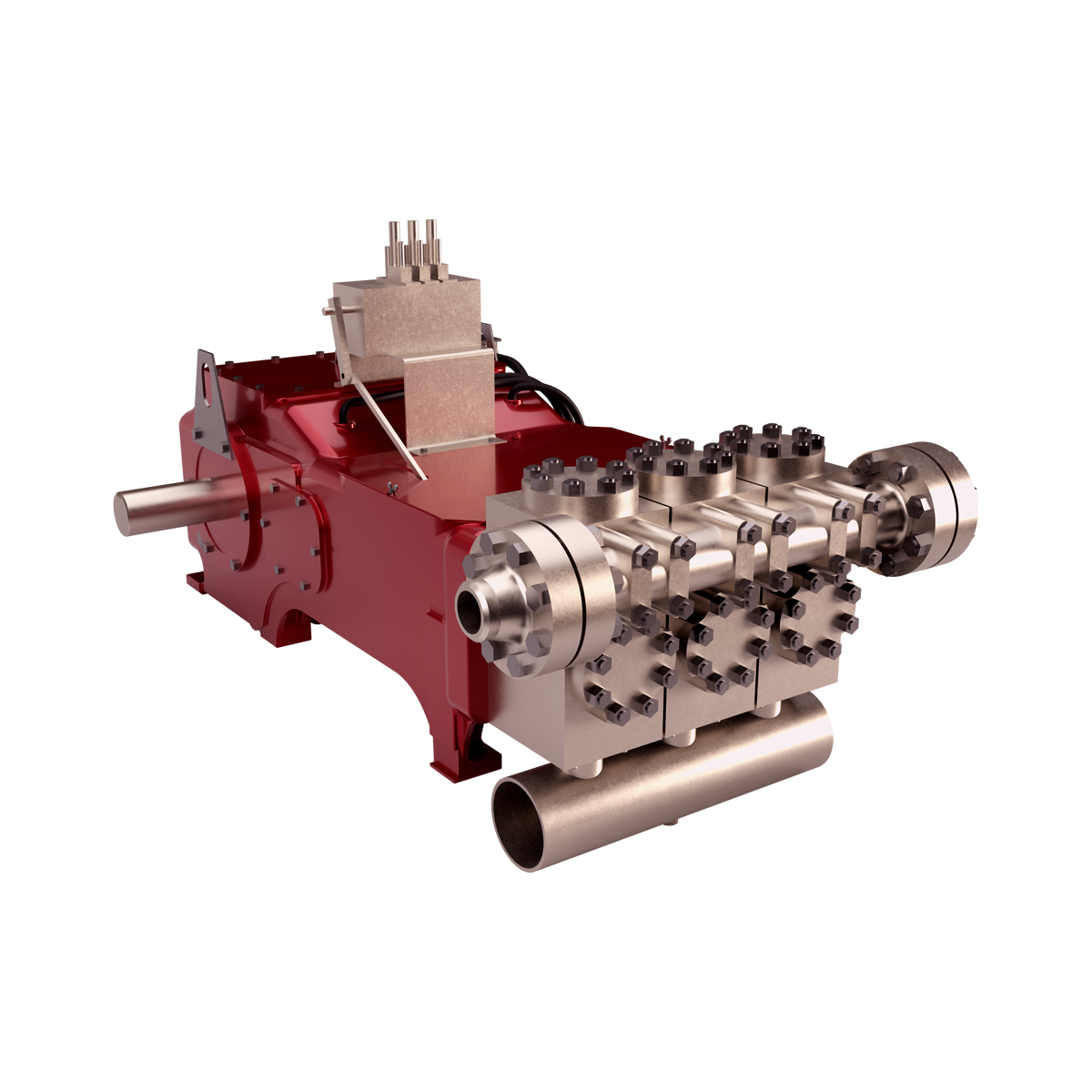

NOV 12-P-160 Mud Pump is rated at 1600 input horsepower (1193 kw) at 120 strokes per minute, with a 12-inch (304.8 mm) stroke. Multiple liner sizes allow pressures and volumes to handle circulation requirements in deep drilling applications.

Flexibility: Compact engineering provides higher efficiency in less space. The NOV 12-P-160 Triplex Mud Pump light weight and flexible design make it easily adaptable to a variety of rig configurations. This provides flexibility as drilling requirements and conditions change.

Fluid End Modules: NOV offers a choice of fluid end modules and valve covers for every P Series pump model to select the fluid end module that exactly matches drilling requirements. All pump models can be equipped with either the standard or premium forged, two-piece interchangeable fluid modules

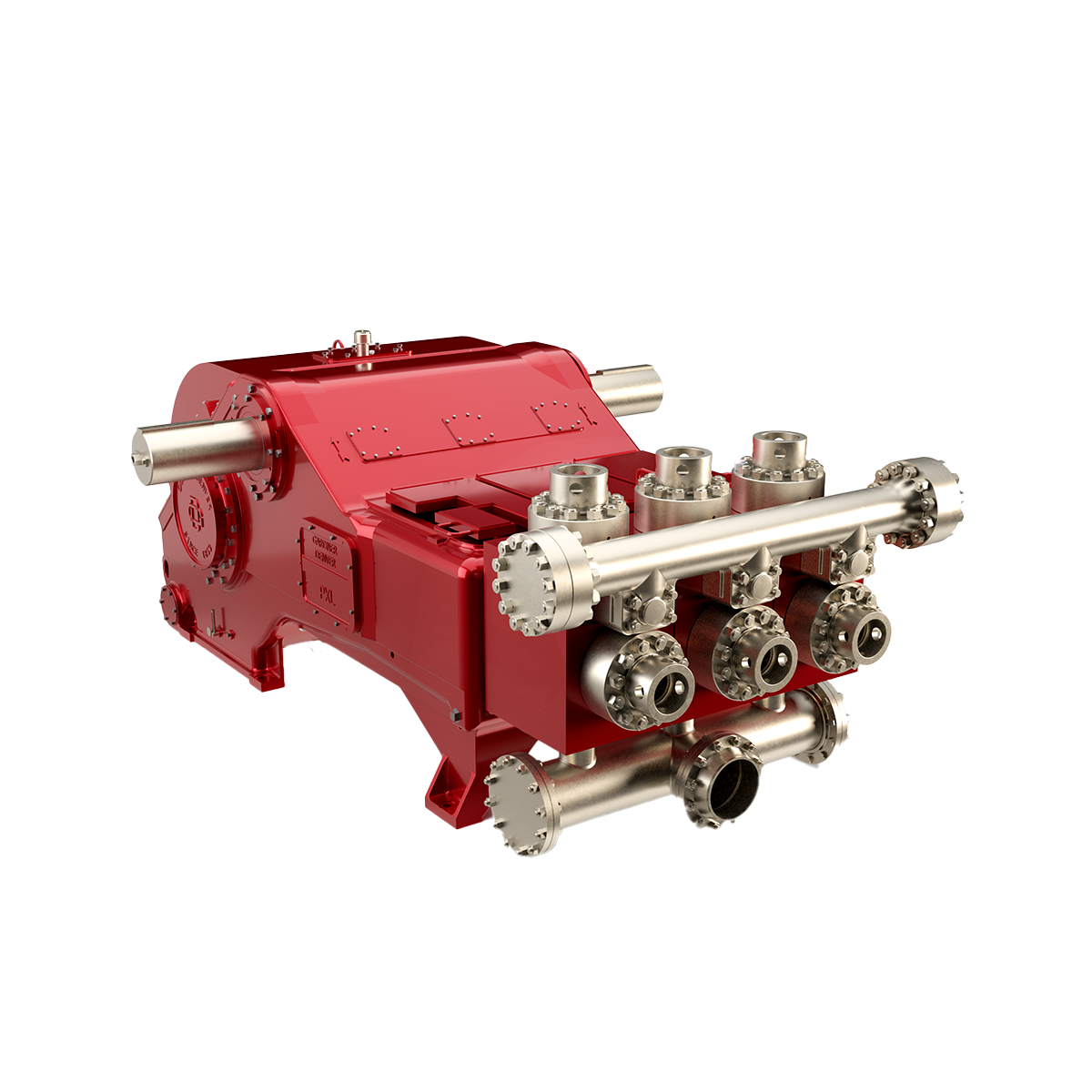

The NOV FC-1600 Triplex Mud Pump is made of rugged Fabriform construction and designed for optimum performance under extreme drilling conditions. It is compact and occupies less space, yet delivers unequaled performance. The pumps are backed by several decades of design and manufacturing experience, and are considered leaders in the field.

NOV FC-1600 Triplex Mud Pump is conservatively rated at relatively low rpm. This reduces the number of load reversals in heavily stressed components and increases the life of the fluid end parts through conservative speeds and valve operation.

The NOV FC-1600 Triplex Mud Pump design provides an inherently balanced assembly. No additional counterbalancing is required for smooth operation. No inertia forces are transmitted to the pumps’ mountings.

A Triplex Mud Pump sometimes referred to as a drilling mud pump or mud drilling pump. NOV FC-1600 Triplex Mud Pump is a reciprocating piston/plunger pump designed to circulate drilling fluid under high pressure (up to 7,500 psi) down the drill string and back up the annulus. A mud pump is an important part of the equipment used for oil well drilling.

The 2,200-hp mud pump for offshore applications is a single-acting reciprocating triplex mud pump designed for high fluid flow rates, even at low operating speeds, and with a long stroke design. These features reduce the number of load reversals in critical components and increase the life of fluid end parts.

The pump’s critical components are strategically placed to make maintenance and inspection far easier and safer. The two-piece, quick-release piston rod lets you remove the piston without disturbing the liner, minimizing downtime when you’re replacing fluid parts.

Since the modern mud (or slush) pump was built approximately 60 years ago, the industry has widely accepted the three cylinder or triplex style pump. Triplex mud pumps are manufactured worldwide, and many companies have emulated the original design and developed an improved form of the triplex pump in the past decade.

As in all single acting pumps, the piston exerts a load on the crankshaft. The load is then transmitted to the crankshaft main bearings, which are set in their retainers in the pump frame or housing (see Figure 2).

That the crankshaft is subjected to extreme bending loads and stress concentration areas is one of the drawbacks of the triplex design. Experience shows that all triplex pumps eventually exhibit crankshaft cracking if the operator is using the pump at higher loads and pressures, which is now common as drilling contractors are facing deeper, longer sections to drill. In the past, drillers rarely pushed the performance limitations of triplex pumps; 5,000 psi rated pumps were usually only operated at a maximum of 2,800 psi 90 percent of the time. Now contractors are encouraged to run pumps at the much higher pressures around 4,300 psi, only leaving a safety margin below the pressure relief valve setting. This means the crankshaft is subjected to extended maximum load, which inevitably shortens time to failure, probably exponentially.

Some may suggest that an increase in the number of pistons to improve flow rate will also reduce piston load. Although the middle piston load may be reduced for the same overall pump horsepower, the distance from the main bearings to the middle cam increases, which is not advantageous. For example, a five cylinder pump with the middle cam 50 in from the main bearing will have the same bending moment as a triplex with a 30 in middle cam to bearing distance. However, installing bearings close to the cams can reduce the cyclic failure problems on any pump.

For the drilling industry, the problem with this design is that few have managed to design a crankshaft where bearings can be installed anywhere other than at the crankshaft ends. Consequently, most pumps currently available have crankshafts unsupported close to the middle cam. With the middle area of the crankshaft unsupported, crankshaft failure is inevitable.

A triplex pump with a large load acting on the middle of the crankshaft of approximately 120,000 lbs and a typical distance of about 30 in from middle cam to either main bearing will exert a bending moment of 300,000 lb-ft on the crankshaft adjacent to the main bearing. If the bearing is not spherical, the bending moment where the shaft meets the bearing will coincide with the point on the shaft that the crank can no longer bend because it is restricted by the fixed bearing, which creates huge stress concentration. That load comes and goes cyclically every revolution of the pump. If the pump is rotating at 100 rpm or strokes, then in one week of drilling the crank will experience one million cycles of 300,000 lb-ft effectively switching on and off.

Another symptom of crankshaft deflection or bending is abnormal main gear wear patterns. The high unsupported load in the middle of the crankshaft effectively bows the shaft and consequently the bull gear is moved off alignment, and a strange wear pattern may appear on the gears. Although this is an undesirable occurrence, it is of little importance compared with crankshaft failure. It does explain abnormal wear on a pump used continuously at high pressure.

A pump that addresses these issues may be the solution. A quadraplex has minimal bending moments due to the close proximity of the main bearings to every cam (see Figure 7).

A fully assembled crankshaft is the best and only way to install multiple bearings close to the cams. Even though there is minimal flexure in this design, spherical bearings eliminate stress concentration or point loading. With cam to bearing distances no more than 10 in, the bending moment on a quadraplex crankshaft will be one quarter that of the triplex or five cylinder pump.

In an environment where few advances have been made in mud pump technology in the last 50 years, designers in the mud pump sector of the drilling industry can develop workable solutions to the problems and limitations inherent in triplex pumps.

The future of mud pump design will involve a solution to excessive crankshaft bending moments and address other needed areas of improvement, including piston speed, module replacement in the field, quality of discharge pressure and smoothness of flow-all combined with ease of transportation.

GDEP is the original creator of the drilling pump and continues to set the standard for durable, high-quality drilling pumps that can withstand the world’s toughest drilling environments. Starting with our PZ7 and rounding out with the market"s most popular pump, the PZ1600, our PZ Series of pumps are the perfect choice for today"s high-pressure drilling applications.

A mud pump is a reciprocating piston or plunger device designed to pump drilling fluid under high pressures and volumes down the drill string of a drilling rig. The main functions of drilling fluid are to provide hydrostatic pressure to prevent formation fluids from entering and to stabilize the bore, to keep the drill bit cool and clean, to carry drill cuttings back out to the surface, and to suspend the drill cuttings while drilling is paused or during the pullback process.

Mud pumps consist of two main sub-assemblies- the fluid end and the power end. The fluid end performs the pumping process with valves, pistons, and liners, or plungers and stuffing boxes- depending upon the type used. These components are considered expendables, and are designed to be easily replaced in the field. The power end contains the eccentric or crankshaft, along with the connecting rods, and cross heads/slides.

Tulsa Triplex is a Tulsa Rig Iron company. We manufacture pumps from 100 to 600 horsepower that are designed to be easily maintained and are capable of being completely rebuilt. Our pumps feature a smaller footprint and lighter weight than competing models, making them completely legal load size and weight in most instances. They are available as a bare pump, with chainbox, or a complete skidded package.

Manufactured to withstand the toughest drilling and environmental conditions, our K-Series triplex mud pumps are ideal for all drilling applications. This legacy product features a balanced forged-steel crankshaft and Southwest Oilfield Products ‘L” Shaped modules which is essential to minimize wear, noise, and operating vibrations. These attributes are essential when drilling deeper high pressure formations, long laterals and when handling corrosive or abrasive fluids and slurries.

Every American Block triplex mud pump is manufactured and fully load tested before leaving our manufacturing campus, and is available in sizes ranging from 800 HP to 2200 HP. The American Block K1600 HP Mud Pump is also available in a 2000 HP up-grade version, when more HP is needed in the same 1600 HP footprint.

Positive displacements pumps are generally used on drilling rigs to pump high pressure and high volume of drilling fluids throughout a drilling system. There are several reasons why the positive displacement mud pumps are used on the rigs.

The duplex pumps (Figure 1) have two cylinders with double acting. It means that pistons move back and take in drilling mud through open intake valve and other sides of the same pistons, the pistons push mud out through the discharge valves.

When the piston rod is moved forward, one of intake valves is lift to allow fluid to come in and one of the discharge valve is pushed up therefore the drilling mud is pumped out of the pump (Figure 2).

On the other hand, when the piston rod is moved backward drilling fluid is still pumped. The other intake and discharge valve will be opened (Figure 3).

The triplex pumps have three cylinders with single acting. The pistons are moved back and pull in drilling mud through open intake valves. When the pistons are moved forward and the drilling fluid is pushed out through open discharge valves.

On the contrary when the piston rods are moved backward, the intake valve are opened allowing drilling fluid coming into the pump (Figure 6). This video below shows how a triplex mud pump works.

Because each pump has power rating limit as 1600 hp, this will limit capability of pump. It means that you cannot pump at high rate and high pressure over what the pump can do. Use of a small liner will increase discharge pressure however the flow rate is reduces. Conversely, if a bigger liner is used to deliver more flow rate, maximum pump pressure will decrease.

As you can see, you can have 7500 psi with 4.5” liner but the maximum flow rate is only 297 GPM. If the biggest size of liner (7.25”) is used, the pump pressure is only 3200 psi.

Finally, we hope that this article would give you more understanding about the general idea of drilling mud pumps. Please feel free to add more comments.

Explore a wide variety of triplex mud pump on Alibaba.com and enjoy exquisite deals. The machines help maintain drilling mud circulation throughout the project. There are many models and brands available, each with outstanding value. These triplex mud pump are efficient, durable, and completely waterproof. They are designed to lift water and mud with efficiency without using much energy or taking a lot of space.

The primary advantage of these triplex mud pump is that they can raise water from greater depths. With the fast-changing technology, purchase machines that come with the best technology for optimum results. They should be well adapted to the overall configuration of the installation to perform various operations. Hence, quality products are needed for more efficiency and enjoyment of the machines" full life expectancy.

Alibaba.com offers a wide selection of products with innovative features. The products are designed for a wide range of flow rates that differ by brand. They provide cost-effective options catering to different consumer needs. When choosing the right triplex mud pump for the drilling project, consider factors such as size, shape, and machine cost. More powerful tools are needed when dealing with large projects such as agriculture or irrigation.

Alibaba.com provides a wide range of triplex mud pump to suit different tastes and budgets. The site has a large assortment of products from major suppliers on the market. The products are made of durable materials to avoid corrosion and premature wear during operations. The range of products and brands on the site assures quality and good value for money.

We design and manufacture robust, functional, reliable high pressure pumping equipment for mud injection applications around the world. Every Calder Waste Injection unit incorporates the proven inherent attributes of quality and reliability whilst matching individual installation requirements. The well service mud pumps are designed to operate over a wide range of flows and pressures for the injection of seawater and slurries consisting of drill cuttings, drilling muds and sand into subsea strata as demanded by the offshore drilling industry worldwide.

We have the experience and skills to engineer a cost-effective solution to your mud pump requirements in a range of operating environments utilising the best engineering practices, and designing the system to be either diesel, electric or hydraulically powered.

8613371530291

8613371530291