diverter overshot packer made in china

The diverter assembly is the uppermost component of the riser system.It is not used to shur or seal the well completely, but to either direct the teturing drill fluit or control the blowout and surface layer gas, when encountering the gas, the diverter can close off around drillpipe or casing,and open the special direction vent line on board at the same time

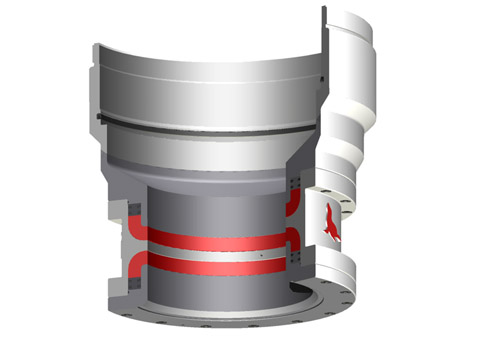

Cameron diverters are fully customizable for your floater and jackup rig operations, respectively. Designed for reliable, efficient use, each system consists of a housing, outlet valves, running tools, controls system, diverter assembly, overshot packers, and storage skids.

The CF-A diverter supports up to 75.5-in rotary tables and has a hang-off capacity of up to 2,500,000 lbm. It uses a single annular packing element with a pressure rating up to 500 psi. The CF-A diverter features four hydraulic locking dogs that reduce hosing and simplify operation. It eliminates the need to secure hoses to the diverter assembly while providing hydraulic fluid for the operations.

The CF-B diverter supports up to 47-in rotary tables and is qualified up to 2,000 psi. Packers can be split and hinged to allow them to be changed out with pipe in the hole. J-slot type running tools are entirely mechanical and require no hydraulics.

D eep well programs on the Arabian peninsula present unique challenges during the initial phase of drilling operations.Shallow gas pockets may be encountered that require managedwell bore control that is not currently available on existing land rigs.Utilizing feedback from the Saudi Arabian Oil Company (SaudiAramco), Dril-Quip, Inc. has developed the Arabian DiverterSystem (ADS) to address these challenges.The ADS (patent pending) is a portable diverter installed on theconductor and establishes a pressure-tight seal to enable controlleddiversion of any gas pockets that might be encountered. This divert-er system integrates three elements – the diverter housing, packingelements and an overshot spool-type connector – into a unitizedprotection device. The ADS incorporates safe, reliable field-proventechnology and performance features into a 500-psi-rated workingpressure design.Elastomer packers in the diverter close and seal around pipesuspended through the rig’s rotary table, isolating the rig floor fromfluids and gases flowing from the well bore. Large outlets locatedbelow the packers control and divert the flow to a designated area.Hydraulic controls for the diverter system are incorporated into therig’s BOP control system. Valves with hydraulic actuators aremounted on each of the diverter outlet lines to control the move-ment of fluids and gases through the system.The handling and test tools provided facilitate testing, operationand maintenance of the system.

FEATURES• Large-bore diverter accommodates 36" drift• A range of split insert packers provides well bore protection during both drilling and casing operations• Split packer design also facilitates running selected packer elements through a 37-1/2" rotary table• Split insert packer design simplifies installation via weight-set, lock-ring style auto-locking components; no hydraulics required• Overshot radial bolt connector features quick, easy make-up using standard impact wrenches• Overshot connector packer seal is hydraulically energized for reliable control of the well bore fluids• Engineered, designed and operated in accordance with applicable API industry standards• Adaptable to most land drilling rigs• Complete ADS diverter and valve system available from single source (Dril-Quip)

Packer Lockdown Ring Packer Load Ring Main Packer Assembly Main Packer Operation Port Main Body

10" Split Packer 18" Split Packer 27-1/2" Split Insert Packer 32-1/2" Solid Insert Packer Diverter Housing Retrieving Rod Assembly Handling Tool 10" Release Ring 18" Release Ring 27-1/2" Release Ring Tool Joint Pin Diverter Test Tool Diverter system valves not shown in illustration.

Main PackerThe Main Packer is housed in the main body of the diverter, andconsists of a tubular elastomer seal with metal rings molded oneach end. The one-piece packer is retained in the main body ofthe diverter by the packer lockdown, retaining and load ring.The Main Packer functions the insert packers when the diverteris closed. Hydraulic pressure deflects the packer toward the bore,which in turn deflects each of the insert packers installed. TheMain Packer is only removed during maintenance operations. 10" Split Insert PackerSolid Packers and Split Insert PackersThe Solid and Split Insert Packers land in the main body ofthe diverter and are designed to close and seal around variouspipe sizes. The packers consist of a tubular elastomer seal withmetal rings molded on each end. The Split Insert Packers aresplit in half so that they can be installed or retrieved whilepipe is suspended through the rotary table. A spring-loadedlockdown ring is bolted to the top of the packer and retains it inthe previously installed larger packer. Tapped holes in the topof the lockdown ring permit the swivel insert retrieving rodsto release the lockdown ring and recover the packer assemblywhen necessary. Each Split Insert Packer has two alignment slotslocated at the top of the packer to orient the packer assemblysuch that the split between the two halves is offset 90° from the 18" Split Insert Packersplit between the two halves of the previous size. All packers arerated to 500 psi.10" Split Insert PackerThe 10" Split Insert Packer incorporates J-slots on the ID tointerface with the Packer Handling Tool. The packer is operatedwith 925 psi and has a minimum closing diameter of 4-1/2".18" Split Insert PackerThe 18" Split Insert Packer lands in the 27-1/2" Solid Packerand is normally run with the 10" Split Insert Packer. The packeris operated with 850 psi and has a minimum closing diameter 27-1/2" Split Insert Packerof 9-5/8".27-1/2" Split PackerThe 27-1/2" Split Insert Packer lands in the main body of thediverter. It is operated with 750 psi and has a minimum closingdiameter of 26".32-1/2" Solid Insert PackerThe 32-1/2" Solid Insert Packer lands in the main body of thediverter housing. It is operated with 750 psi and has a minimumclosing diameter of 28". 32-1/2" Solid Insert Packer

4Operations Easy, simple Diverter Housing installation Test the Overshot and Diverter Packers The integral Overshot Packer is an adapter The integral Overshot Packer and Split spool that stabs over and provides a Insert Packers are tested with the Packer molded elastomer seal around the field-cut Handling and Diverter Test Tool. 36" conductor casing. A field-welded ring on the conductor OD provides a shoulder for the overshot spool radial bolt-type connector to contain any end-load forces in the event of a shallow gas encounter.

Step 1 Step 2 • Install conductor casing • Test system components with Packer • Weld ring on upper section of casing Handling and Test Tool • Install ADS Diverter System • Retrieve Test Tool • Make up Radial Bolt Overshot Connector • Energize Overshot Packer element

5Reliable managed bore protection Reliable managed annulus duringduring drilling operations casing installationThe Split Insert Packers can be installed The Split Insert Packers are retrievedassembled together with the Packer and the 32-1/2" Solid Packer isHandling Tool or individually with the installed to provide protection duringRunning and Retrieving Rod Assembly. surface casing installation.Hydraulic pressure applied to the MainPacker element functions the InsertPackers closed as required during drill-ing operations.

Step 3 Step 4 • Run drill bit • Run surface casing and cement • Reinstall Packer assembly • Nipple down ADS Diverter System • Drill out for surface casing • Nipple up BOP stack • Retrieve bit and bottom hole assembly

Lifting-Lower and releasing overshot is a fish tool in the casing which fishes fractured tubing and drill string. If fish drill string is stuck heavily and hard to complete fish work, while need to release fish, may get back the tool by bumping drill string down and lift directly.

Lifting-lower and releasing overshot is composed of top sub, bowl, guide pin, guide sleeve, joint sleeve,plug, roller pin, slip, guide, as shown in the figure. Box thread of top sub is connected with drill stem, pin thread is connected with the bowl, The bottom of bowl is connected with guide, An inner cone in the bowl matches the slip, Box thread of guide sleeve is connected with joint sleeve, track trenches are milled on another outer surface: three long trenches and three short trenches act as guiding and reversing ,When guide pin locates in long trench is in the condition of fish ,When guide pin locates in short trench is in the condition of release, Joint sleeve is two petals formation ,It makes slip and guide sleeve connection and by roller pin act as bearing, The inner surface of slip has fish thread, guide is on the bottom and can make fish introduce into slip successfully.

With our company"s perfect marketing system and network channels, the sales volume of the Stock Linear Motion Industrial Slide, Stainless Steel Knurled Shaft For Toy, Plastic Mould Camera Gopro Holder keeps increasing year by year.We take leading technology, excellent quality, and reasonable price as our survival tenet, and pursue 100% customer satisfaction as our goal to provide customers with the most competitive Nitride Steel Oil Drill Diverter. The scale of production and modern storage conditions are our important guarantee to provide customers with first-time delivery. Our strong sense of social responsibility makes us more aware of the meaning of rigor and prudence. Our company is willing to provide high-quality products for customers all over the world with first-class quality, first-class service and first-class reputation. We are committed to creating a corporate family with ideals, spirit, character and culture. Our company is strong and committed to becoming an influential company in the industry. Our equipment varieties, models, to provide customers with good service. We uphold the "customer-centered" business philosophy, and constantly improve the ability to meet customer requirements. We let the employees establish the idea of safety first and prevention first, and enhance the safety awareness and self-protection ability of the employees.

WebMinimum inside diameter of 27-1/2" (including secondary housing) allows use of 26" bit Run or retrieve diverter, spacer spool and overshot packer assembly without having to connect or disconnect...

After years of hard work, our sales network is quite sound and our Horizontal Linear Shaft Support Linear Rail Shaft Support, Flexible Shaft Coupling CNC Stepper Motor Shaft Coupler sells well in domestic and international markets. We"re well-known as one of the leading Nitride Steel Oil Drill Diverter manufacturers and suppliers in China. If you"re going to buy high precision Nitride Steel Oil Drill Diverter made in China, welcome to get more information from our factory. Also, customized service is available.

Completion equipment was then installed to hydraulically isolate the junction. This was achieved by running single string production packers below the junction in each lateral. Separate tubing strings were then tied-back, through the junction, to a dual string production packer above the junction. This resulted in the level 5 junction, ie.; a junction with mechanical and pressure integrity. The well was then completed as a dual string completion to surface.

3 THE. IN-* OFFS^ WJS. ADER FOR RELIABLE RILLING EQUIPMENT Introduction Vetco Gray has been a leader in supplying drilling equipment to the oil and gas industry since 1906, when Regan Forge began manufacturing crown blocks and traveling blocks for the California exploration market. Today, we are the world"s leading supplier of marine drilling riser systems with more than 65% of the global market. Our legacy of technology development and innovative solutions puts us in the forefront of offshore drilling, especially for deepwater exploration. Vetco Gray supplied the complete drilling riser system for the world"s first, and to date, only, exploration well in water depths greater than 10,000. We provide a complete line of Capital Drilling Equipment for fixed platform, jackup and floating rig applications. Table of Contents Diverters for Jackup & Platform Drilling Units KFDJ 3 KFDJ Model J 4 Diverters for Floating Drilling Units KFDS 5 CSO: Complete Shut-Off 5 Drilling Riser System Components Telescopic Joints 6 Tensioner Support Rings KT 7 SDL and SDL with Fluid Bearing.. 8 Marine Riser Couplings MR-6HSE 9-10 MR-6H SE Riser Adaper 10 MR-6E 11 HMF Class E, F, G, H, J 12 Subsea Connectors H-4 Connectors: Wellhead & LMRP ExFH-4 15 EH-4 15 ExFHAR 15 DWHDH-4 15 SHDH-4 16 VX-2, VGX-2 and VT-2 Gaskets Composite Material Risers 19 Aftermarket Support Riser Inspection (RADAR) 20 Facilities Locations Ancillary Riser Equipment Spiders 13 Intermediate Flex Joint 14 Single Flex Joint 14

4 \ Diverters for Jackup & Platform Drilling Units KFDJ Diverter Systems KFDJ Diverter Complete protection while running casing strings and drilling hole is provided by a full range of insert packer sizes, all of which use a "J" type running tool. Available with a rotating insert which provides low pressure packoff on the kelly or drill pipe during drilling. Features The fixed support housing, a proprietary feature, is securely bolted to the rotary beams and provides fixed outlets for flowline, fill-up line and vent lines. The support housing allows installation of outlets up to 20" diameter to virtually any configuration. Diverter, spacer spool and overshot packer assembly may be pulled or run without connecting or disconnecting the flowline, fill-up line and vent lines. Mudline suspension hangers and bit sizes up to 27.41" for 37-1/2" rotaries or 36.41" for 49-1/2" rotaries can be run without removing the diverter assembly. Diverter, spacer spool and overshot packer each fit through a 37-1/2" rotary table. Minimum bore through the standard support housing is 36-1/2" ID for the 37-1/2" in rotary installation. Optional 37-1/2" bore is available. The overshot packer on the bottom of the diverter spacer spool assembly reduces the nipple-up time normally required to weld flanges or hubs to casing. Dimensional Data - Standard Hookup KFDJ with 12" Nominal Outlets* Rotary Table А в С D E F All dimensions in inches. * Number and size of outlets are optional. <25Vetcogray

5 Diverters for Jackup & Platform Drilling Units KFDJ Model "J" Diverter Systems KFDJ Model "J" Designed with all the field proven features of the standard KFDJ diverter, but with fewer hydraulic connections, Vetco Gray"s KFDJ Model "J" diverter system has a "J" lock between the diverter and the support housing. The Model "J" requires only 3 hydraulic functions: energizing/venting the diverter packer, the flowline seals and the overshot packer. The "J" slots in the support housing align the diverter outlets with the housing outlets. A mechanical latch secures the diverter in the housing and the handle position provides a clear visual indication of lock engagement. Features Simplified design All components of the support housing and the diverter assembly area heavy wall construction for pressure containment and erosion protection during high velocity, multi-phase flow Full size range of insert packers Custom designed for specific applications KFDJ Model "J" Diverter KFDJ "J" Diverter (Handling Tool) Dimensional Data -Standard Hookup KDFJ "J" with 12" Nominal Outlets* Standard handling tool has a 4-1/2" IF API tool joint box up and pin down, but can accommodate other tool joints as desired. The optional test tool provides the means to pressure test the entire diverter system. Rotary Table A В С D All dimensions in inches. * Number and size of outlets are optional. E

6 Diverters for Floating Drilling Units KFDS Diverter Vetco Gray is the market leader for diverter systems in the offshore drilling market. For 25 years, Vetco Gray has provided KFDS Diverter technology with field-proven protection from shallow gas blowouts. Compact: the Diverter Support Housing, overboard lines and associated valving are permanently installed on to the Rig structure. The Diverter Assembly is run and retrieved through the rotary table with the marine riser. Rf 1 Г Flexible: Variable outlet sizes and orientations can accommodate most any rig design. Valving is external, allowing for rig design variation and valve/actuator preferences. Vetco Gray is a single-source supplier for a complete system, including diverter assembly, controls and valves. An integrated package, engineered to specific requirements, will provide maximum safety, efficiency and savings. Diverter Insert Diverter Housing CSO Diverter Flow Lino Running ^^k pressum " Energized Proflle FlowLine Seals Diverter Assembly pherical Element Diverter Housing Standard housing has multiple outlets, up to 20" diameter. Features Housing accommodates large diameter riser buoyancy modules Complete open-hole shutoff with 20" through-bore second closure time on pipe or open hole 500 psi rated system Control system maximum operating pressure of 1,500 psi High capacity systems available for supporting the Riser String from Diverter Housing in emergency hangoff situations Connection block enables hydraulic operating functions to be quickly attached or disconnected Standard housing holds multiple outlets, up to 20" diameter Outl.tNom.(»n.) Spherical Element Minimum Dimensions (S^vetcogray Standard housing has multiple outlets, up to 20" diameter Flex Joint Crossover Flange Running Tool Profile

7 Drilling Riser System Components Telescopic Joint Vetco Gray telescopic joints compensate for heave and offset of the vessel and are available for all riser systems. Available for MR-6E, MR-6H SE, and HMF riser systems ^ИСГ Maximum rated riser tensile load capacity in locked position ^ & Hydraulic latch release for inner and outer barrels available Dual split/solid packer elements Fixed or rotating integral tensioner rings Prepped for non-integral SDL, SDC and KT tensioning rings Fluid or roller bearing prep (S^vetcogray

9 Drilling Riser System Components SDL/SLS Tensioner Support Ring Features & Benefits Riser tensioner lines remain attached to the SDL/SLS Ring so riser tensioning lines remain properly spaced out at all times Hydraulically disconnects from the Telescopic Joint and locks to a mating profile on the bottom of the Diverter Support Housing for convenient out-of-the-way storage The SDL/SLS Ring is full opening to the Diverter Support Housing The SDL/SLS Ring may be used with a Telescopic Joint Fluid Bearing, allowing the drilling vessel and tensioners to rotate relative to the riser string Telescopic Joint is run and pulled through the rotary table without disconnecting the tensioning lines from riser tension ring Hydraulic piping for lockdown/storage dogs remains permanently connected Diverter Stow Dogs {shown out or phase) SDL Tensioner Support Ring Tensioner Ring Pad Eyes Hydraulically Actuated Riser Support Dogs SDL Tensioner Support Ring with Optional Fluid or Roller Bearing Fluid Bearing Assembly Fluid Monitor Line Fluid Fill / Return Line Features & Benefits Incorporates field-proven SDL/SLS Ring technology Low breakout torque values with high tension loads Fluid bearing has a carbon/teflon backup bearing Pressures in the fluid bearing can be observed and controlled via a hydraulic monitoring and replenishment circuit Stop Ring to prevent overpressuring Telescopic Joint Outer Barrel (S^vetcogray

8613371530291

8613371530291