automated power tong american patent factory

This invention relates to the field of devices for rotating tubular members so as to make up or break out threaded joints between tubulars including casing, drill pipe, drill collars and tubing (herein referred to collectively as pipe or tubulars), and in particular to a power tong for the improved handling and efficient automation of such activity.

In applicant"s experience, on conventional rotary rigs, helpers, otherwise known as roughnecks, handle the lower end of the pipe when they are tripping it in or out of the hole. As used herein, the terms pipe and tubular are used interchangeably. The roughnecks also use large wrenches commonly referred to as tongs to screw or unscrew, that is make up or break out pipe. Applicant is aware that there are some other tongs that are so called power tongs, torque wrenches, or iron roughnecks which replace the conventional tongs. The use of prior art conventional tongs is illustrated in FIG. 1a. Other tongs are described in the following prior art descriptions.

In the prior art applicant is aware of U.S. Pat. No. 6,082,225 which issued Feb. 17, 1997 to Richardson for a Power Tong Wrench. Richardson describes a power tong wrench having an open slot to accommodate a range of pipe diameters capable of making and breaking pipe threads and spinning in or out the threads and in which hydraulic power is supplied with a pump disposed within a rotary assembly. The pump is powered through a non-mechanical coupling, taught to be a motor disposed outside the rotary assembly.

In the present invention the rotary hydraulic and electrical systems are powered at all times and in all rotary positions via a serpentine such as a serpentine belt drive, unlike in the Richardson patent in which they are powered only in the home position. In the present invention the pipe can thus be gripped and ungripped repeatedly in any rotary position with no dependence on stored energy and the tong according to the present invention may be more compact because of reduced hydraulic accumulator requirements for energy storage wherein hydraulic accumulators are used for energy storage only to enhance gripping speed.

Applicant is also aware of U.S. Pat. No. 5,167,173 which issued Dec. 1, 1992 to Pietras for a Tong. Pietras describes that tongs are used in the drilling industry for gripping and rotating pipes, Pietras stating that generally pipes are gripped between one or more passive jaws and one or more active jaws which are urged against the pipe. He states that normally the radial position of the jaws is fixed and consequently these jaws and/or their jaw holders must be changed to accommodate pipes of different diameters.

Applicant is further aware of United States Published patent application entitled Power Tong, which was published Apr. 5, 2007 under Publication No. US 2007/0074606 for the application of Halse. Halse discloses a power tong which includes a drive ring and at least one clamping device with the clamping devices arranged to grip a pipe string. A driving mechanism is provided for rotation of the clamping device about the longitudinal axis of the pipe string. The clamping device communicates with a fluid supply via a swivel ring that encircles the drive ring of the driving mechanism. Thus Halse provides for three hundred sixty degree continuous rotation combining a spinner with a torque tong. The Halse power tong does not include a radial opening, the tong having a swivel coupling surrounding the tong for transferring pressurized fluid from an external source to the tong when the tong rotates about the axis of the pipe. Halse states that having a radial opening in a power tong complicates the design of the power tong and weakens the structure surrounding the pipe considerably, stating that as a result, the structure must be up-rated in order to accommodate the relatively large forces being transferred between the power tong and the pipe string. Halse further opines that a relatively complicated mechanical device is required to close the radial opening when the power tong is in use, and in many cases also to transfer forces between the sides of the opening. The Halse tong is not desirable for drilling operations because there is no throat opening to allow the tong to be positioned around the pipe at the operator"s discretion. The pipe must always pass through the tong.

The power tong according to the present invention continuously rotates tubulars for spinning and torquing threaded connections. Continuous rotation is achieved through a rotating jaw (also referred to as a rotor) that has grippers that grip the tubular. Hydraulic and electrical power necessary for actuating the grippers is generated on board the rotor since the continuous rotation does not allow for either hydraulic or electrical external connections. A serpentine member such as a serpentine drive belt system turns the motors of an on-board hydraulic power unit and electric generators which may be AC or DC generators, to supply the grippers with the necessary hydraulic and electrical power.

The present invention includes a rotor rotably mounted in or on a rigid structural framework or stator frame. A main drive drives the rotor. The rotor may be supported and held in position by the use of opposed helical pinions/gears which support the rotor vertically and guide bushings which locate it laterally and support it vertically when the torque is low. The grippers, which may be actuated by hydraulic gripper cylinders, maybe held in position by links and guide bushings that can withstand the torque parameters of the tong. The gripper cylinders may be moved in a range of travel by an eccentric. This provides for a tong that can accommodate a large range of pipe diameters (3.5 inch drillpipe to 9-⅝ inch casing or larger). A centralizing linkage ensures that the pipe is gripped concentricly with the tong axis of rotation. The tong does not require a mechanical device to close the radial opening. The on-board power source and rotary control system allow the present invention to have fully independently activated and controlled rotary gripping of the tubular. It is capable of high torque for making and breaking and high speed for spinning, all within one mechanism. One embodiment of the present invention also overcomes the limitation of the spinning wrench engaging the stem area of the drillpipe which over time will cause fatigue in the stem area as the spinning and torquing according to the present invention is accomplished with the same jaw that engages the pipe on the tool joint. The throat of the jaws according to the present invention has an opening of sufficient diameter to accept a tubular. The throat cooperates with the opening to allow the power tong to be selectively positioned around the pipe at the operators" discretion.

FIGS. 18 and 19 are in diagrammatic plan view, a further exemplary embodiment of the nested transmission of the tong, showing the use, by way of example, of two stator sprockets, at least one of which is driven, having a serpentine member therearound and reaved over a pair of rotor sprockets on the throated rotor, the pair of rotor sprockets having a synchronizer therearound, the rotor sprockets driving a coupling mechanism coupling the power transfer from the serpentine member to gripper actuators on the rotor which articulate grippers at the rotor axis of rotation.

FIG. 19ais a partially cut-away section view along line 19 a-19 ain FIG. 19 showing one rotor (satellite) sprocket driving, by way of example, a pump and/or generator part of the power or energy transfer coupling between the serpentine member and the gripper actuators.

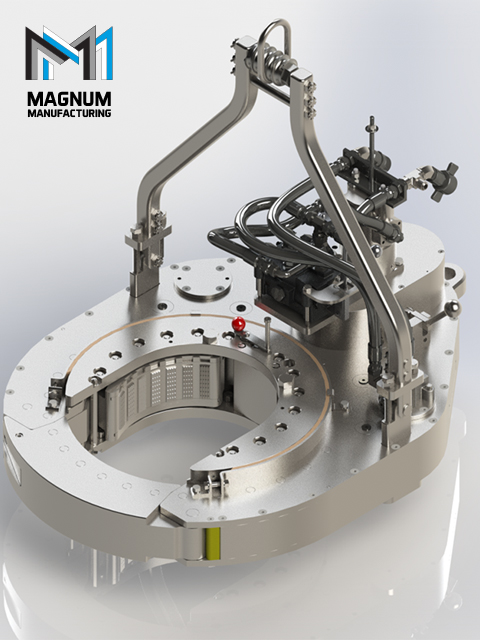

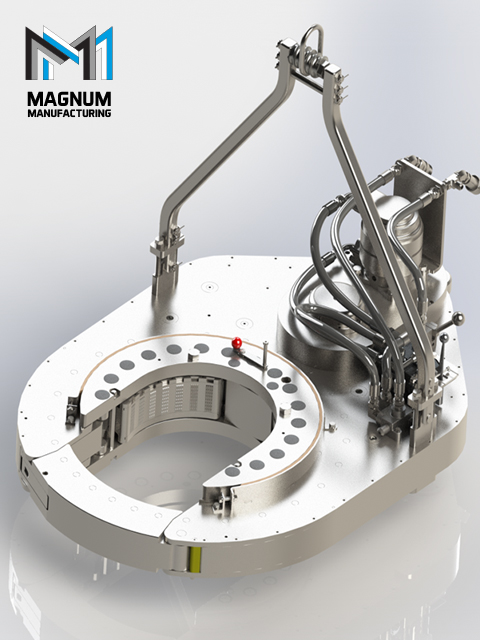

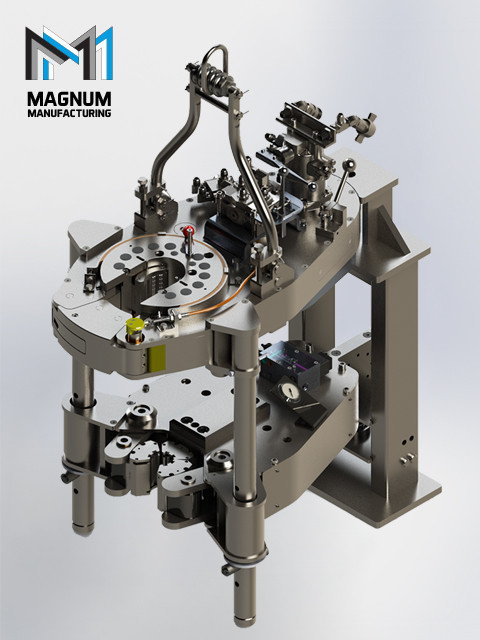

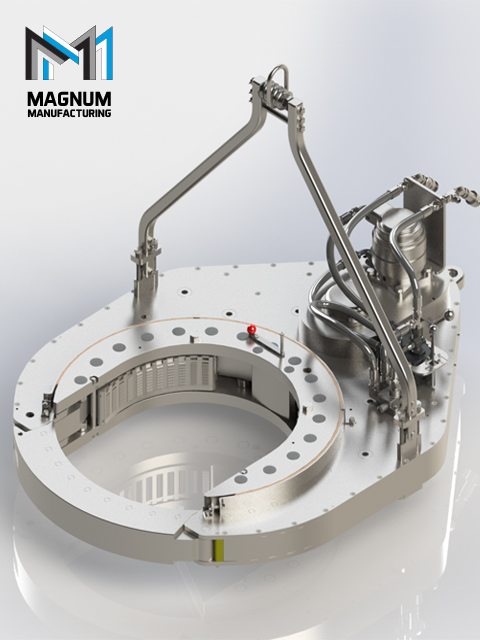

As seen in FIGS. 1 and 2, the power tong 6 may include three main sections mounted on a common axis A; namely a main drive section, a rotor, and a back-up jaw. Each of the sections contains actuators, as better described below. The main drive section 10 which provides at least part of a rigid stationary framework or stator frame is located above the rotor 22. The backup jaw 48, located below rotor 22, may also provide part of the stator frame. The rotor 22 rotates relative to the main drive and back-up jaw. Both the rotor and backup jaw clamp their respective sections of pipe. The rotor 22 is rotated by the main drive section 10 independently of the main drive section and backup jaw in the sense that the rotor 22 is self-contained, having on-board hydraulic and electric power generators to power on-board radial clamps or grippers (collectively herein referred to as grippers), and an on-board serpentine secondary power transmission, all configured to allow the insertion and removal of a pipe through a jaw opening from or into the center of the jaw, so that the pipe, when in the center of the jaw may be clamped, torqued, and spun about axis A of rotation of the rotor 22 while the other, oppositely disposed section of pipe is held clamped in the center of the back-up jaw 48.

As shown in FIGS. 1, 2 and 3 rotor 22 is housed within drive section 10, although this is not intended to be limiting as the rotor may be mounted so as not to be housed within the drive section and still work. The rotor 22 is cylindrical in shape and has an opening slot, which although illustrated as linear may be linear or non-linear, having a throat 38 for passing of a tubular along the slot thereby allowing the tong axis of rotation A to be selectively positioned concentric with pipe 8, provided the rotor 22 is rotated such that its throat 38 is aligned with the front openings 28 and 29 of the main drive section and back-up jaw, respectively. Center 40 of the yoke formed by the jaw and slot corresponds with axis A. The rotary jaw 22 has three gripper cylinders 44 a, 44 b, and 44 carranged radially, with approximately equal angular spacing around axis A, mounted between the two parallel horizontal planes containing rotor gears 30 aand 30 b. The number of gripper actuators, such as gripper cylinders 44 a-44 c, and associated grips or grippers may be more or less in number, so long as a tubular joint may be gripped or clamped at center opening 40.

A serpentine member such as serpentine drive belt 20 is driven by two serpentine drive motors 18, which may for example be hydraulic or electric motors. The serpentine member is mounted around so as to engage stator sprockets mounted on the stator frame. For example the stator sprockets may include drive sprockets 26 awhich are driven by serpentine drive belt 20 to collectively provide a secondary drive powering the grippers on the rotor 22. Drive sprockets 26 arotate serpentine drive belt 20 about idler sprockets 26 mounted to drive section 10. And the serpentine drive belt 20 also engages about rotor sprockets 32 a-32 fmounted on the rotor 22 as better described below. The rotor sprockets 32 aand 32 bmay be two generator drive sprockets. The rotor sprockets 32 cand 32 dmay be two pump drive sprockets. Rotor sprockets 32 eand 32 fmay be two idler sprockets. In the illustrated embodiment, which is not intended to be limiting as other embodiments discussed below would also work, the generator drive sprockets, that is, rotor sprockets 32 aand 32 b, transmit rotary power to generators 34. The pump drive sprockets, that is, rotor sprockets 32 cand 32 d, transmit rotary power to hydraulic pumps 36 by the action of serpentine drive belt 20 engaging the upper groove of rotor sprockets 32 a, 32 b, 32 cand 32 d. A synchronization belt, 28 a, connects the lower portions of the rotor sprockets 32 a-32 f. Thus as the rotor 22 rotates on axis of rotation A, even though serpentine drive belt 20 cannot extend across the throat 38 because such a blockage would restrict selective positioning of the pipe 8 along the slot into the tong, serpentine drive belt 20 wraps in a C-shape around the rotor sprockets 32 a-32 f. Serpentine drive belt 20, driven by drive sprockets 26 a, runs on pulleys 26, and on idler sprockets 26 band 26 cmounted to, so as depend downwardly from, main drive section 10. The extent of the C-shape of serpentine drive belt 20 provides for continual contact between serpentine drive belt 20 and, in this embodiment which is not intended to be limiting, a minimum of three of the rotor sprockets 32 a-32 fas the rotor rotates relative to the main drive section 10. The synchronization belt 28 amounted on the rotor maintains rotation of the individual rotor sprockets as they pass through the serpentine gap 29 seen in FIG. 4, that is, the opening between sprockets 26 band 26 c. Synchronization belt 28 asynchronizes the speed and phase of the rotation of each of the rotor sprockets 32 a-32 fto allow each of them in turn to re-engage the serpentine drive belt 20 after they are rotated across the serpentine gap 29 by the action of the rotor rotating relative to the main drive.

During operation of tong 6 the secondary drive (drive motors 18) and serpentine drive belt 20 run continuously to deliver power to the on-board pumps and generators by means of the rotor sprockets 32 a-32 d. Rotation of the rotor 22 by the operation of the primary drive acting on the pinions 56 and rotor gears 30 aand 30 bdoes not substantially affect the powering of the on-board accessories (pumps and generators) because drive belt 20 is run at substantially an order of magnitude greater speed than the speed of rotation of rotor 22. The rotation of the rotor only adds or subtracts a small amount of speed to the rotation of the rotor sprockets.

Upper rotor gear 30 aand lower rotor gear 30 bare parallel and vertically spaced apart so as to carry therebetween hydraulic pumps 36, generators 34, the rotor hydraulic system, rotor jaw electrical controls and the array of three radially disposed hydraulic gripper cylinders 44 a, 44 b, and 44 c, all of which are mounted between the upper and lower rotor gears 30 aand 30 bfor rotation as part of rotor 22 without the requirement of external power lines or hydraulic lines or the like. Thus all of these actuating accessories, which are not intended to be limiting, may be carried in the rotor 22 and powered via a nested transmission, nested in the sense that the C-shaped synchronization drive loop mounted on the rotor, exemplified by synchronization belt 28 a, is nested within so as to cooperate with the C-shaped serpentine drive loop mounted to the main drive, exemplified by serpentine drive belt 20.

Thus as used herein, a serpentine belt, such as the serpentine belt 20, driving a plurality of stator and rotor sprockets (as herein below defined), and as in the various forms of the stator and rotor sprockets found illustrated in all the figures herein, are herein referred to generically as a form of nested transmission. The nested transmission transfers power from the fixed stage to the rotational stage in a continuous fashion as, sequentially, one element after another of the rotational drive elements on the rotating stage are rotated through and across throat 38 and gap 29 allowing selective access of the tubular 8 to the center opening 40 of the stage.

For proper operation of the tong, it is desirable that the gripper actuators such as gripper cylinders 44 a-44 cclamp the tubular 8 substantially at, that is, at or near the rotational center axis of the tong. It can be readily seen that gripping the tubular 8 with a significant offset from the center axis would result in wobble or runout of the tubular when spinning in or out and could result in thread damage, excessive vibration, damage to the machine and inaccurate torque application.

It will be appreciated that the inboard ends of side gripper cylinders 44 aand 44 bmove in an arc as the gripper cylinders are extended or retracted. For the side gripper cylinders 44 aand 44 b, the geometry of reaction links 44 eis optimized to minimize deviation from the nominal gripper cylinder radial axis over the gripping diameter range to angles typically less than one degree. The gripper cylinders 44 aand 44 bwill however swing significantly from the nominal gripper cylinder radial axis, in the order of five degrees, when they fully retract to clear the throat 38. It is an advantage of the link design that it requires less stroke to clear the throat 38 due to the swing associated with the arc of reaction links 44 e, which ultimately allows a more compact rotor and hence a more compact tong. That is, the combination of the swing in direction C with the retracting stroke in direction D results in less of a stroke length required to clear throat 38 than merely using a retraction stroke without swing. The amount of swing is governed by the radius of arc E associated with rotation of the reaction links 44 eand the length of the required stroke in direction D.

The back-up jaw section 24 as shown in FIGS. 5, 5 a, 6 and 8 is typically mounted to a tong positioning system capable of holding the tong assembly level and enabling vertical and horizontal positioning travel. The tong may be pedestal-mounted on the rig floor, mast-mounted, track-mounted on the rig floor or free hanging from the mast structure. It may also be mounted at an angle for slant drilling application or with the pipe axis horizontal.

In the preferred embodiment, as seen in FIG. 10, the rotor hydraulic system 53 is a dual (high/low) pressure system or infinitely variable pressure system which produces high pressures (in the order of 10,000 psi) necessary for adequately gripping large and heavy-duty tubulars and for applying make-up or break-out torque, and lower pressures (2500 psi or less) to avoid crushing smaller or lighter-duty tubulars. Hydraulic pumps 36, rotationally driven as described above, are fixed-displacement, gear or variable displacement piston pumps. In the idle state, hydraulic pumps 36 charge one or more gas-filled accumulators 55 mounted in or on rotor 22 to store energy to enable rapid extension of the gripper cylinders 44 a-44 c. In this way, very fast gripping speeds may be achieved while keeping the power transmitted by the serpentine drive belt 20 drive low. That is, although the power supplied via the serpentine drive belt is small, the rotor hydraulic system must be able to intermittently supply a relatively large flowrate at low pressure for rapid advance of the gripper cylinders until they contact the tubular and also supply a low flowrate at very high pressure, in the order of 10,000 psi, to adequately grip the tubular for torquing operations.

In the schematic of the preferred rotor hydraulic system 53 of FIG. 10, system 53 has one or two gear or piston pumps 36 of relatively small capacity, within the power limitations of the serpentine drive belt. When there is no gripping demand, the pumps charge one or more gas-filled accumulators 55 to store energy for intermittent peak demands. The accumulators are optional, for the benefit of advance speed. The system is workable without accumulators provided the pumps are variable displacement. A load-sensing circuit with or without regenerative advance may also be used as would be understood by someone skilled in the art. A directional control valve 63 directs hydraulic pressure to the gripper cylinders. The directional control valve is solenoid-actuated with the solenoids controlled by the rotor control system. There are two flow paths from the directional control valve 63 to the extend side of the gripper cylinders. The first is the rapid-advance flow path which directs a large flowrate, in the order of thirty-five gallons per minute, from the pump(s) 36 and accumulator(s) 55 to the gripper cylinders at relatively low pressure, in the order of 2500 psi, for rapid extension of the gripper cylinders until they contact the tubular 8. The second is the high-pressure path in which pressure is regulated by a proportional pressure control valve 64 which is controlled by the rotary jaw control system of FIG. 11. The regulated pressure is supplied to an intensifier 65 which boosts the pressure by a factor in the order of 4:1 to supply high pressure, in the order of 10,000 psi, to the gripper cylinders. A check valve 66 prevents the high pressure fluid from flowing back into the rapid-advance low pressure flow path. The directional control valve 63 can also be solenoid actuated to direct fluid to the rod side of the gripper cylinders for retraction.

The use of high grip pressures, in the order of 10,000 psi, allows the use of compact gripper cylinders which results in a compact tong. By using the intensifier 65 to build the high grip pressure, no high pressure control valves are required.

It can be seen that in spite of the small input power, the hydraulic system can intermittently supply large flowrates for rapid grip cylinder advance and high pressures for high-torque operations. The system can regulate the grip pressure, adapting to the applied torque, for optimum gripping performance.

The rotor control system seen in FIG. 11 activates and de-activates the gripper cylinders at the operator"s discretion, regulates grip pressure and monitors system function without any power supply or control wires from or to the fixed part of the tong, because the rotor is fully rotatable and the open throat of the yoke precludes the use of any slip rings which are commonly used to transmit electrical power and control signals to a rotating element.

As seen in FIG. 11, one or two generators 34 are driven by the serpentine belt drive 20. They supply power, preferably 24 volts DC, to a programmable logic controller (PLC) 70, a radio communication link 71 and a number of sensors 73.

The radio communication link 71, which may advantageously be a Bluetooth™ device, communicates wirelessly with a similar radio communication link 72 mounted on the stationary section of the tong. The two radio communication links, 71 and 72, act as a wireless communication bridge between the main tong control system 74 and the rotor PLC 70.

The rotor PLC 70, as directed by the main tong control PLC 74, controls the output solenoids on directional control valve 63 to extend and retract the gripper cylinders 44 a-44 cand the proportional pressure control valve 64 to control the grip pressure. It also receives feedback from sensors 73 on the rotor for such parameters as (possibly including but not limited to) grip pressure, hydraulic pump pressures, grip position and hydraulic oil temperature.

When breaking out (unscrewing) drilling tubulars, it is often difficult to identify the axial location of the split where the two tool joints meet. It is imperative that the tong be positioned such that the split is located in the axial gap between the rotor grippers and the back-up jaw grippers. If either the rotor or the backup jaw grips across the split, the tool joint and the tong may be damaged and time will be wasted because the connection will not break out.

As shown in FIGS. 15 and 16, the actual face seam 200 between the mating connection shoulder faces 201 is only marginally visible when the connection is made up and it may be further obscured by drilling fluid. There is typically a shoulder bevel 202 adjacent to each shoulder face 201. The shoulder bevel 202 is typically machined at a 45 degree angle and has a radial dimension typically 2 to 6 mm. The two adjoining shoulder bevels 202 combine to form a connection split bevel V-groove 203. The connection split bevel V-groove 203 is usually sufficiently visible to identify the split axial location for placement of manual tongs in conventional drilling operations. But for a mechanized tong with its operator positioned several feet away from the pipe, it may be difficult to see. Furthermore, the tong may obscure the operator"s direct view of the split location. Time will be wasted in identifying the split location, traveling to it and verifying that the split is correctly located in the axial gap between the rotary and back-up jaws.

For automated pipe-handling operations, it is important for the machine to identify and travel to the correct axial location of the split without control intervention by the operator.

It can be seen that a reliable automated system to detect the location of the connection split would improve speed and efficiency of a mechanized tong and is mandatory for fully-automated tong operations.

A tandem configuration may be employed. That is, the optical tubular caliper can be accomplished with a pair of single point beam sensors positioned approximately 180 degrees apart, with each beam projected radially inward toward the tubular at the same elevation. Each sensor measures the radial distance to the pipe surface. The control system computes the sum of these distances. The difference between a fixed offset value and the computed sum represents the diameter of the tubular, approximately independent of the position of the tubular in the opening. The system can quickly and accurately measure the diameter of any tubular passing through the single point beams and transmit the diameter measurement to the tong control system. Furthermore, as the tong travels axially along the pipe, the tong control system can relate a series of such diameter measurements to the corresponding tong elevations as measured via the control system instrumentation described elsewhere. A diameter profile along the length can thus be created, effectively a virtual diameter versus axial position plot. The control system can compare this diameter profile to the known characteristic of the connection split bevel V-groove 203. When such a profile match is identified, the connection split is located and the corresponding tong elevation is recorded. The tong then travels the contact axial offset distance between the light band 705 axial mounting position and the desired split position between the rotary and back-up jaw grippers.

The control system is programmed to tune out irrelevant variations in the measured outside diameter, such as at the tool joint upset steps. It will also filter out diametral noise associated with surface irregularities such as hardbanding, tong marks or wear grooves.

As mentioned above, the power tong according to the present invention may be mounted in many ways on the drilling rig structure, or it may also be free-hanging from a cable. The mounting method ideally allows the tong to be accurately positioned around the tubular 8 at a large range of elevations, retracts a substantial distance from well center for clearance for other well operations, parks in a small area to minimize space usage on the drilling rig floor, keeps the tong level and allows the tong to be positioned to work at multiple locations such as the mousehole which may not be in the same plane as well center and the tong park location. The mounting system could be capable of rapid movement between working and idle positions but with smooth, stable motions. It should allow the operator to command horizontal or vertical movements or a combination.

Numerous tong or wrench mounting mechanisms exist in the industry. Most are Cartesian (horizontal/vertical) manipulators employing tracks, slides or parallelogram linkages for each motion axis. These mechanisms are simple to control because they directly actuate on the horizontal and vertical axes but they typically have a small range of motion which limits tong functionality and restricts mounting location on the drill floor. They have a large parked footprint which consumes scarce rig floor space and interferes with other well operations. And they have little or no capability to react torque applied to the tong or wrench by a top drive in the rig.

Thus in one preferred embodiment, a tong is preferably mounted on a manipulator 99 as shown in FIGS. 12aand 12b. A slewing base 100 is mounted to the drilling rig floor. A hydraulic slewing motor 101, via a gear reduction, can turn the slewing base up to three hundred and sixty degrees about the vertical axis. The internal bearings of the slewing base can support the weight and overturning moments of the manipulator structure and the tong. Slewing motor 101 may alternatively be electric, pneumatic or manually actuated.

The tong is pivotally mounted at the end of boom 103. The angle of the tong relative to boom 103 is controlled by linear actuator(s) 106. The inclination of the tong is monitored by angle sensor 109.

Various possible tong positions are selectively positioned between the extended operating position illustrated in FIG. 12aand the parked position of FIG. 12b. It can be seen that the manipulator 99 provides a large range of motion but can park the tong 6 with a small footprint.

The booms have significant lateral and torsional stiffness. This is advantageous over prior systems because the structure can react torque applied to the tong by a top drive in the rig, such as for back-up of drilling connection make-up. The tong can also apply torque to make up a bit restrained in the rig"s rotary table.

Manipulator 99 may be fully functional with manual controls for each of the four output actuators (slewing motor 101 and linear actuators 104, 105 and 106). However, it preferably has a control system as described below in which horizontal and vertical rates of tong travel are controlled in direct proportion to horizontal and vertical velocity commands by the operator and the tong is automatically kept level. The control system may also include the capability of optimized travel, including acceleration and deceleration control, to pre-defined locations.

The tong"s vertical and radial positions (relative to the slewing base) at any time are computed by the programmable logic control (PLC) 112 geometric constants and the boom 102 and 103 angles measured by angle sensors 107 and 108. The slewing orientation is measured preferably by an encoder 110 on the slewing drive. The tong"s three-dimensional position is therefore monitored at all times.

The preferred operators control console has a single 3-axis joystick 111 for control of the manipulator. The x-axis of joystick 111 controls the horizontal motions of the tong, the y-axis of the joystick 111 controls the vertical motions of the tong and the z-axis (handle twist) of the joystick controls the slewing motions of the assembly. The joystick commands may be discrete ON/OFF but are preferably analog/proportional on the x and y axes for finer control.

Horizontal motion of the tong requires movement of both boom 102 and boom 103, accomplished via linear actuators 104 and 105. The required output velocity signals to each of linear actuators 104 and 105 are computed in the PLC 112 in order to achieve the desired horizontal command velocity from the x-axis of joystick 111.

Similarly, vertical motion of the tong requires movement of both boom 102 and boom 103, accomplished via linear actuators 104 and 105. The required output velocity signals to each of linear actuators 104 and 105 are computed in the PLC 112 in order to achieve the desired vertical command velocity from the y-axis of joystick 111.

The control system may also have capability for automated travel to pre-defined locations such as well center, mousehole and parked position. When the operator commands automated travel to a desired pre-defined target location, the control system control acceleration, travel velocity, deceleration and landing speed for both horizontal and vertical axes to achieve optimum travel to the target, with minimum elapsed time and smooth, controlled motion.

In particular, in FIG. 18, serpentine drive belt 20′ is driven by at least one serpentine drive motor which may for example be at least one hydraulic motor. The serpentine drive motor drives at least one drive sprocket 26 a′ which, as before, provide a secondary drive via a plurality of rotor or satellite sprockets 32′ on rotor 22, and also drives a synchronizer between sprockets 32′ and a coupling such as pumps or generators, or a mechanical mechanism powering gripper actuators and corresponding grippers 44′, or directly acting on grippers 44′, on the rotor 22. As illustrated by way of example, a first drive stator sprocket 26 a′ rotates serpentine drive belt 20′ about a second stator sprocket which may be a second drive sprocket 26 a′ or an idler sprocket 26′ mounted to drive section 10. A tensioner 27 such as a tensioning idler sprocket, which may be considered a third stator sprocket, may be mounted to frame 60 so as to be resiliently biased against serpentine drive belt 20′ to tension the drive belt. A pair of satellite or rotor sprockets 32′ are mounted on the rotor 22. As seen in FIG. 18, the first and second stator sprockets are mounted on substantially opposite sides of the rotor. As the term is used herein, the first and second stator sprockets are arrayed substantially around the rotor. Third, fourth, etc stator sprockets would thus not have to be on one side or the other of the rotor, but would form part of the array of stator sprockets arrayed substantially around the rotor.

The rotor sprockets 32′ drive for example one or more on-board generators and/or one or more on-board hydraulic pumps (not shown in FIGS. 18 and 19). Synchronization belt 28 a′ may connect the lower or upper portions of the rotor sprockets 32′, with the serpentine drive belt 20′ then connecting the upper or lower portions of the rotor sprockets 32′ respectively. Thus as rotor 22 rotates about axis of rotation A even though serpentine drive belt 20′ cannot extend across the opening throat 38 because such a blockage would restrict selective positioning of the pipe 8 along the slot into the tong, serpentine drive belt 20′ wraps around or reaves so as to remain at all times in contact with at least one of rotor sprockets 32′. Drive sprockets 26 a′ are mounted to, so as to for example depend downwardly from, main drive section 10. As seen in FIG. 18a, the deflection of serpentine drive belt 20′ by the rotation of rotor sprockets 32′ provides for continual contact between serpentine drive belt 20′ and a minimum of one of the rotor sprockets as the rotor 22 rotates relative to the main drive section 10, wherein the deflection of serpentine drive belt 20′ tensions the portion of drive belt 20′ where it contacts tensioner 27. Upon return of the rotor sprockets to the position of FIG. 18, tensioner 27 takes up the slack in the drive belt 20′.

As seen in FIG. 19a, rotor 22, the rotor sprockets 32′, and one or more energy coupling 45 may be mounted within a rotary jaw frame 47 on, for example, bushings 49. Energy couplings 45 couple the energy being transmitted from the serpentine to the rotor sprockets 32′, and couples the energy to the grippers 44′ or gripper actuators (which in turn actuate the grippers). As stated above, energy couplings 45 may include pumps, generators, or mechanical drives such as direct mechanical linkages, but may also include the use of energy storage such as, without intending to be limiting, gas accumulators, batteries, capacitors, flywheels, which may then power actuation of the grippers when needed.

March 17, 1970 J. H. WILSON AUTOMATED PIPE TONGS l9 Sheets-Sheet 5 Filed May 1, 1967 VIIIIII Rm 5 .m a. m :W m /m mw u H hw m. 7 m p uildli|||J||1||i|||||||J |||J" W m w M 8 y 1 0 mm mm 00 mm March 17, 1970 J. H. WILSON AUTOMATED PIPE I"ONGS 19 Sheets-Sheet 4 Filed May 1, 1967 E m mF 1176 19/9/67 W/LFU/V INVENTOR.

BY W 51/15 105%! Ill March 17, 1970 J. H. WILSON AUTOMATED PIPE TONGS l9 Sheets-Sheet 5 Filed May 1, 1967 March 17, 1970 J. H. WILSON AUTOMATED PIPE TON-GS 19 Sheets-Sheet 6 Filed May 1, 1967 mww IN VENTOR.

AUTOMATED PIPE TONGS 19 Sheets-Sheet 10 Filed May 1, 1967 FIR JOHN HART WILSON INVENTOR ,L umv NOm Gm? QM Oh HIS AGENT March 17, 1970 J. H. WILSON AUTOMATED PIPE TONGS 19 Sheets-Sheet 11 Filed May 1, 1967 mN Wm (D Q JOHN HART WILSON INVENTOR.

AUTOMATED PIPE TONGS Filed May 1, 1967 19 Sheets-Sheet l5 mvsmom JOHN HART WILSON- March 17, 1970 J. H. WILSON AUTOMATED PIPE TONGS 19 Sheets-Sheet 16 Filed May 1, 1967 INVENTOR.

HIS AGENT March 17, 1970 J. H. WILSON AUTOMATED PIPE TONGS l9 Sheets-Sheet 18 Filed May 1, 1967 INVENTOR OHN HART W I LSQN HIS AGENT on mun u% 2m 3w! m9 n3 N3 w w mum mm 93 I r 0 r T an 03 com m on o ow wfi Q8. 02. N2. l gov wo dwown J r|..) 0%. 8 3 in. 2

US. Cl. 81-5734 Claims ABSTRACT OF THE DISCLOSURE Automated pipe tongs for making up or breaking out drill stem or pipe, such as used in conjunction with a drilling rig, which tongs are moved into and away from operating position on a wheeled carrier. The various operations of tongs are actuated by fluid cylinders, which fluid cylinders are programmed by a rotary cam programming control mechanism, to cause sequential action of certain cylinders, both for the opening and for closing the tongs and for moving the handle of one of the tongs arcuately to make up or break out drill stem or pipe. Two or more cams may be programmed to operate simultaneously, with the same operations being repeated each time the programming mechanism makes one complete cycle. The present programming device is so constructed as to stop when one cycle is completed. Provisions are made for stopping the programming mechanism at any point within the cycle and for manually operating valves to perform any phase of the operation. Further valves are provided to selectively render any portion of the operation inoperative. Further provisions are made to enable the entire programmed cam shaft to be removed and another programmed cam shaft installed to perform diflerent operations.

This invention relates to pipe tongs to be used for gripping pipe to enable pipe to be screwed together or unscrewed, and more particularly to power actuated pipe tongs which may be remotely controlled so the individual operating the tongs is relieved of openin and closing the tongs, of engaging the tongs on the pipe and of removing the tongs therefrom, as well as of moving the lever of the tongs arcuately about the axis of the pipe when the tongs are engaged on the pipe.

Various tongs have been provided heretofore which are operated both manually and by power, however, for the most part, these tongs had to be manually controlled to engage the pipe and manually swung out of engagement when the pipe was sufiiciently tightened.

The present tongs are so constructed that a single operator may operate both the tongs to enable automatic or mechanical engagement thereof with the pipe, from a non-operating position to an operating position, and then, after the tongs are in position to engage the pipe, power is used to close the tongs in gripping relation around the pipe. Furthermore, the apparatus for handling the tongs is actuated by fluid power, which rotates the pipe in either direction as desired, while the back-up tong is maintained in engaged gripping relation with a complementary joint of pipe so as to enable the entire work to be performed by remote control, and without danger to the workmen, as has been the case heretofore, in most instances, in the use of power actuated tongs.

The present tongs are used primarily in combination With a derrick, mast or the like, however, they are subject to adaptation to any phase of screwing together or unscrewing pipe, merely by changing the mounting to accommodate the particular pipe screwing up or unscrewing job to be done. The present tong is primarily used with drill pipe in the drilling of oil wells, which pipe consists of threaded joints, to enable the coupling of lengths of pipe together in the form of a drill stem, which may extend several hundred or several thousand feet into the earth strata to perform the operation of drilling an oil well by the rotary drilling method. In performing this drilling operation, it is desirable to have all pipe joints tightened securely and accurately, but not tightened to such extent as to cause the threads to gall or to strip.

An object of this invention is to provide power actuated tongs which may be swung into place around axially aligned lengths of pipe to enable the making up or breaking out of the threaded joints connecting lengths of pipe in end-to-end relation.

Another object of this invention is to provide a power actuated tong in which all control operations may be performed from a remote station, to enable the tongs to be guided onto the pipe, so as to surround lengths of axially aligned pipe to screw the pipe together, or to unscrew the lengths of pipe without manual assistance from the operator.

Still another object of the invention is to provide a power actuated tong for gripping lengths of pipe to be screwed together, wherein a cam and lever, operated under fluid pressure, closes the jaws of the tongs around the pipe in gripping relation to give a mechanical advantage.

Still another object of the invention is to provide a side opening tong which may be moved onto or off of a pipe from a side thereof without the necessity of having to draw the pipe through the tong.

Still another object of the invention is to provide a suspension system for a pair of tongs, whereby they can be moved into or out of engagement with a pair of axially aligned lengths of pipe in the same path each time the tongs are positioned thereon, thereby making it unnecessary for manual guidance of the tongs into the correct position.

Still another object of the invention is to provide a power actuated tong which may be readily regulated to take care of worn pipe or pipe of diflerent diameters.

Still a further object of the invention is to provide tong adjustment means to enable the attachment of the tongs to the pipe in such manner as to swing the tongs into place around axially aligned lengths of pipe in the same relation each time.

Still another object of the invention is to provide fluid power actuated cylinder means to rotate at least one of the tongs through an arcuate travel each time the fluid actuated cylinder plunger is reciprocated.

Still a further object of the invention is to provide a tong mounting system to enable the tongs to be moved into engagement with a pair of axially aligned lengths of pipe and be moved out of engagement with the pipe and out of the work area when the screwing or unscrewing operation has been performed.

The present invention relates to power tongs typically used in the oil and gas industry to make up and break apart threaded joints on pipe, casing, and similar tubular members.

Power tongs have been used for many years and are generally employed in the oil and gas industry to grip and rotate tubular members, such as tubular. The tubular members are gripped with high compressive forces while applying a high degree of torque to break apart or tighten threaded tubular member connections. In most cases, power tong designs employ a cam mechanism for converting a portion of the torque into a gripping (compressive) force normal to the tubular member. This conversion is often accomplished using a power-driven ring gear having an interior cam surface. As the ring gear rotates, cam follower (roller) on a jaw member rides upon the cam surface, causing the follower (and thus the jaw member) to move into contact with the tubular member. U.S. Pat. No. 4,404,876 discloses such an arrangement.

Most current power tong designs include a ring gear cam with an open slot or throat (“open-throat power tongs”), through which the tubular member passes to position the jaw members around the tubular member. However, some tong designs employ a ring gear cam that has no open throat and is thus a solid circular member. This solid circular ring gear design is generally referred to as a closed-head power tong.

When the drilling environment allows the use of a derrick or similar overhead structure from which a power tong may be suspended, an openthroat power tong is often a more efficient tool. Open-throat power tongs easily disengage and/or retract from the tubular member when the operator desires to raise, lower, or otherwise manipulate the tubular member.

On the other hand, a closed-head power tong is more difficult to retract from the tubular member because it has a closed throat and must pass over the end of a tubular member. However, there are common drilling environments where there is no structure from which an open-throat power tong may be suspended and insufficient workspace to engage and retract open-throat power tongs. In such environments, a closed-head power tong may be the only practical alternative. Closed-head power tongs are highly useful during operations where snubbing units are employed. Typically, closed-head power tongs are positioned over the drill string with the individual tubular members forming the drill string extending through a center aperture in the closed-head power tong. A tubular member is moved vertically through the center aperture until the threaded joints for connecting adjacent tubular members are in position to be made up (screwed together) or broken out (unscrewed).

To increase efficiency, as many successive tubular member connections as possible are made-up or broken out without interruption, i.e. having to move the center aperture of the tong out of alignment with the drill string. However, the drill string may include a down hole tool or other device that has a diameter greater than the diameter of the center aperture of the closed-head power tong. In these situations, the prior art closed-head power tongs typically require that the drill string be broken and any tubular positioned in the center aperture at that point be removed therefrom. The closed-head power tongs are then removed from alignment with the drill string, and the oversized tool is removed from the drill string or re-positioned vertically along the drill string above or below the power tong such that it is not required to pass through the power tong. The closed-head power tong can then be re-aligned with the drill string. To re-establish the connection of the drill string through the center aperture, the unconnected tubular joint must be positioned above or below the center aperture to reconnect to a continuous length of drill string.

What is need in the art is a closed-head power tong design which allows the center aperture to be readily increased in diameter without the necessity of removing the drill string from the center aperture. The closed-head power tong design should provide for center aperture enlargement with a minimum lost time and with such simplicity that unskilled workers could perform the task.

With the aforementioned considerations in mind, it is therefore an object of this invention to provide a power tong assembly used in connection with a conventional snubbing unit.

It is a further object of the present invention to provide a closed head power tong that is adapted to increase the gripping aperture therein to allow passage of objects having a diameter larger than the normal gripping aperture.

It is a further object of the present invention to provide a closed head power tong that may be quickly and efficiently operated without the necessity of removing the power tong from alignment with the drill string.

The invention herein comprises a closed-head power tong having a power tong body. The tong body has a ring gear positioned within the body, and the ring gear comprises at least one cam surface. The tong body also has a cage plate assembly comprising at least two mating inserts and a jaw aperture formed in at least one of the mating inserts.

The invention may also comprise a power tong body having a ring gear positioned within the body wherein the ring gear has at least one cam surface. A cage plate assembly is removably positioned at least partially within the body and configured to have a gripping aperture therein. The gripping aperture has first dimension and the cage plate assembly is adapted to increase the gripping aperture to a second dimension sufficiently sized to allow passage of an object having a dimension larger than the first dimension.

A method of making up or breaking one or more section of tubular members using the closed head power tong invention is also disclosed herein. The method comprises the steps of (a) removing the cage plate assembly from the power tong body, thereby increasing the diameter of the gripping aperture to allow passage of a tool; and (b) passing the tool through the power tong body a sufficient distance so that the cage plate assembly may be repositioned within the power tong body.

FIG. 1 illustrates the application of the power tong-back-up combination 100 used in connection with a snubbing unit 101 positioned over an existing well. Snubbing unit 101 is equipped with slip assemblies 160, 170 that are used in conjunction to raise and lower tubular members 110, 120 as is known in the art. Snubbing unit 101 may also be equipped with a hydraulic rotary table 180 that rotates equipment positioned thereon.

When lengths of tubular members are joined (“made-up”) or disconnected (“broken”), tubular members 110, 120 are passed through the respective gripping apertures 205, 901 (shown in FIG. 2b) in power tong 200 and back-up 300. When joint 130 (as seen in FIG. 1) is suitably positioned between power tong 200 and back-up 300, power tong 200 engages and grips first tubular member 110 and a back-up 300 engages and grips second tubular member 120. Power tong 200 rotates first tubular member 110 and back-up 300 grips and holds stationary second tubular member 120. Pipe joint 130 is made-up or broken, depending upon the direction of torque applied to first tubular member 110 by power tong 200.

Referring to FIG. 2b, closed-head power tongs 200 have a power tong body composed of lower plate 704 and an upper plate 802, both having a center aperture 801 passing therethrough as shown in FIGS. 7 and 8. FIG. 8 illustrates upper plate 802 and motors 103 operatively positioned thereon. A collar 803 having leg apertures 803 ais positioned at each corner of upper plate 802 to assist in the mounting and operation of power tong 200 on leg assembly 102 as described below and shown in FIG. 2b. FIG. 7 illustrates how motors 103 rotate respective gears 701, providing rotational energy to ring gear 600 through interaction of teeth 702 and teeth 601.

Referring back to FIG. 1, top plate 104 is positioned atop leg assembly 102 and fixes the position of legs 102 arelative to each other. Top plate 104 has a passageway 107 extending therethrough substantially aligned with gripping apertures 205, 901. Optionally, a tapered pipe inlet 105 is positioned atop top plate 104 and passageway 107 to guide tubular members 110, 120 into closed-head power tong 200 when tubular member 110, 120 are inserted into a well. As shown in FIGS. 2aand 4, a pipe inlet 402 is attached to mating inserts 301, 302 to guide tubular member 110, 120 into center aperture 801 in power tong 200 when tubular members 110, 120 are raised from a well.

FIG. 9aillustrates back-up 300, which comprises a body having a lower section 910, a cover 920 (shown in FIG. 9b) and two or more, preferably three, hydraulically powered jaw assemblies 904 positioned therein. As shown in FIG. 9a, jaw assemblies 904 have jaw carriers 903 with jaws 902 facing back-up power tong gripping aperture 901 through which tubular members pass. Jaw assemblies 904 are very similar to the jaw assemblies found in U.S. Pat. No. 4,649,777 to Buck, which is incorporated herein by reference. Back-up 300 mounts onto leg assembly 102 via apertures 905 that correspond to each leg 102 substantially as shown in FIG. 2b.

Referring to FIG. 1, closed-head power tong 200 and closed-head back-up 300 are positioned on snubbing unit 101 using leg assembly 102 that allows relative vertical displacement of the power tong unit 100. As seen in FIG. 2b, power tong 200 locks onto legs 102 ausing spring assembly 106 (shown in FIGS. 2cand 2 d) or any other suitable member known in the art.

The second end 249 of spring tube 230 has threads 247 that mate with corresponding threads 248 on spring retainer 246. The upper edge 256 of spring retainer 246 provides a shoulder upon which the first end 243 of spring cap 242 may rest. Spring 250 is positioned between shoulder 237 of spring cap 235 and shoulder 245 of spring cap 242. Upper power tong plate 802 is positioned above and may rest upon spring plate lip 236 so that the weight of power tongs 200 may be supported in part by each of the four spring assemblies 106 and so that spring 250 biases spring cap 235 and upper plate 802 away from end 249.

As power tong 200 grips and rotates first tubular member 110 and back-up 300 grips and holds stationary second tubular member 120, first tubular member 110 is either forced toward or away from second tubular member 120 by action of the corresponding threads at joint 130 on tubular members 110, 120. The construction and design of spring assemblies 106 allow power tong 200 to move vertically to accommodate the vertical motion of the tubular members 110, 120.

When a joint 130 is made-up, first tubular member 110 moves toward second tubular member 120. Accordingly, power tongs 200 move downward. Upper tong plate 802, already in contact with lip 236, forces spring cap 235 to compress spring 250. Note that in an “at rest” position, upper tong plate 802 rests upon lip 236 due to gravity. When the make up is complete and the jaw dies 610 release tubular member 110, the potential energy of spring 250 forces upper plate 802 (and hence power tong 200) back to its normal position.

Lower tong plate 704 moves upward and abuts lip 244, causing spring cap 242 to compress spring 250. When the joint 130 is broken and jaw dies 610 release tubular member 110, the potential energy in spring 250 forces lower plate 704 (and hence power tong 200) back to its normal position.

Referring to FIG. 2d, links 106A movably attach power tong 200 to two of legs 102 avia collar 111, spring tube 230 and spring assembly 106. Each of these legs 102 ais configured with one or more holes 240 that allow bolt 231 to insert through holes 233 in collar 111 and through holes 240 in leg 102 aBolt 231 fixedly positions collar III relative to leg 102 a.

Each link 106A comprises a first arm 112 that connects to collar 111 and a second arm 116 that connects to upper tong plate 802 (see FIG. 2b). Each arm 112, 116 connects to a third arm 113 which allows arm 112 to move vertically relative to arm 116, allowing power tong 200 to move vertically relative to legs 102 aas previously discussed. A locking pin 117 (shown in FIG. 2b) may be inserted through either pivot hole 114, 115 to prevent vertical displacement of power tong 200 by preventing third arm 113 from pivoting. Links 106A also help prevent the small amount of rotational movement that can occur by power tong 200 relative to legs 102 aIt is generally desirable to engage locking pin 117 when power tong 200 is being transported or handled to prevent unexpected movement between power tong 200 and back-up 300 from injuring workers or damaging equipment.

Referring to FIG. 10, cage plate assembly 204 generally comprises annular upper and lower cage plates 203, 202. FIG. 3 is a perspective view showing upper cage plate 203 but having lower cage plate 202 removed. While the following description refers primarily to FIG. 10, cross-reference to FIG. 3 will aid in understanding the subject matter discussed. Rollers 710 sit within power tong 200 and mount on shafts 711, which are held in place by nuts 712. Rollers 710 support ring gear 600 by supporting ring gear teeth 601 therewithin. Ring gear 600 is positioned between lower and upper cage plates 202, 203 using cam followers 330 mounted from respective plates 202, 203, with nuts 331 positioned in corresponding apertures 340, 341.

The embodiment of brake band 1125 as shown in FIG. 12 is similar to the brake band disclosed in U.S. patent application Ser. No. 08/897,185, which is incorporated herein by reference. Brake band 1125 is biased against brake ring 1205 using a spring 1134. Spring 1134 pivotally connects to brake arm 1111. Spring 1134 also pivotally connects to power tong lower plate 704 using spring retainer 1138 and pivot pin 1139. Brake band 1125 constantly maintains frictional resistance between brake band 1125 and brake ring 1205 during the entire operating sequence of power tong 200.

FIGS. 5aand 5 billustrate one embodiment of mating inserts 301, 302 used in cage plate assembly 204. FIG. 5aillustrates the mating inserts 301, 302 removed from cage plate assembly 204 and removed from within center aperture 801 in power tong 802. Viewing FIG. 5b, insert 302 comprises at least one male mating member 501, more preferably male mating members 501, 502 positioned at each mating side 505 of insert 301. Male mating members 501, 502 engage and abut female mating members 504 formed in the corresponding mating inserts 301, 302 as recesses. When mated, apertures 313 in inserts 301, 302 are substantially aligned with lower apertures 503 positioned in the lower male mating members 502 so that a pin 304 (see FIG. 3) or other suitable member, may be positioned therein to position mating inserts 301, 302 relative to each other.

FIGS. 5cand 5 dillustrate an alternate embodiment of the mating inserts 301, 302. FIG. 5cillustrates mating inserts 301, 302 removed from cage plate assembly 204 and removed from within center aperture 801 in power tong 802. As shown, inserts 301, 302 are simply sectioned and have only mating sides 505 awith no mating members to hold inserts 301, 302 together.

FIG. 5cillustrates gripping aperture 205 having its smallest diameter, referred to as a first dimension and marked as first dimension α in FIG. 5c. FIGS. 5dand 11 illustrate how sections 301, 302 can be removed from within center aperture 801 and detached to allow the passage of a downhole tool 150, having a dimension larger than first dimension α but smaller than the dimension β of center aperture 801 as best seen in FIG. 8. As used herein “dimension,” when used to refer to the size of an aperture shall mean the distance necessary for an object, such as downhole tool 150, to pass therethrough. When the downhole tool 150 has passed through power tong 200, sections 301, 302 reattach to each other using pin 304 and repositioned within center aperture 801.

As shown in FIG. 7, a ring gear 600 is positioned within power tong body on rollers 710 (see also FIG. 10). Ring gear 600 comprises outer gear teeth 601 that mate with the gear teeth 702 on gear 701, rotated by motors 103 as shown in FIG. 7. Viewing FIG. 6a, ring gear 600 further comprises cam follower slot 605 so that followers 330 (see FIG. 10) may be positioned therein. Slot 605 has one or more slits 603, 604 configured therein which receive a pin 602, commonly known as a reversing pin in the art. FIG. 3 illustrates how reversing pin 602 engages one of two apertures 602 aformed in cage plate 203.

While not shown in the Figures, one modification of the present invention could include the positioning of a conventional load cell thereon. The load cell could be used to measure the torque imparted to power tong 200 relative to back-up 300 during operation of the system. For example, a load cell is first affixed to power tong 200. A vertical pressure plate is then affixed to back-up 300 such that the pressure plate are adjacent to the load cell. When power tong 200 applies torque to a tubular, there is a tendency for power tong 200 to rotate relative to back-up 300. This tendency to rotate causes the vertical pressure plate to load the load cell. In this manner, the torque imparted to the tubular by power tong 200 can be measured. Those skilled in the art will recognize that this is but one way to measure torque. Load cells could be mounted in numerous ways upon power tong 200 to achieve the same effect. Moreover, the measurement techniques are not limited to load cells, hydraulic or otherwise. Many alternate devices for measuring loads could be employed to determine the torque imparted on the tubular.

This United States patent application is a continuation of Ser. No. 15/432,955, and further claims priority to U.S. provisional patent application Ser. 62/362,879, filed Jul. 15, 2016, for all purposes. The disclosure of that provisional application is incorporated herein by reference, to the extent not inconsistent with this disclosure. BACKGROUND—FIELD OF THE INVENTION

This invention relates to apparatus, and method(s) of use of same, in connection with the positioning of a power tong unit about a threaded tubular connection.

When the drill pipe is being run into a wellbore, or pulled from a wellbore, a power tong and backup unit is positioned around the threaded connection to screw together (“make up”) or unscrew (“break out”) the connection. The backup grips the box or lower tool joint, while the power tong grips and rotates the pin or upper tool joint.

Therefore, the vertical positioning of the power tong/backup unit is critical. While some leeway is available, it is readily understood that the unit must be positioned with reasonable accuracy with the power tong unit on one side of the “connection seam,” that is, where the faces of the pin and box tool joints meet; and the backup on the other side of the connection seam.

While the power tong/backup unit can be positioned by a human operator, for safety reasons and the ability to work in conjunction with automated systems it is preferred that some sort of remote positioning system be employed. One such system is disclosed in U.S. Pat. No. 6,965,230, owned by the Applicant of the present application. That system employs “eddy current” technology to sense the location of the connection seam via a magnetic eddy current. The connection seam is detected as an anomaly in the pipe surface; the system detects the vertical position of the connection seam, and positions the power tong/backup unit accordingly. Various anomalies in the pipe surface (other than the connection seam; for example, corrosion, tong marks, hard banding, etc.), and other factors, can affect the accuracy of the system. SUMMARY OF THE INVENTION

Another embodiment of the present invention comprises a means for reading an information tag, for example a Radio Frequency Identification or RFID tag, affixed to the tubular, namely to the tool joint, which contains information related to the dimensions and other aspects of the tubular connection. Such information may be of use in determining the distance between the information tag (or some other readily detectable reference point on the tool joint) and the connection face or connection seam. Such information may also be used in certain embodiments of the present system which monitor overall use of a drill string, including particular joints of pipe used on the rig, how their dimensions change over time, etc. In addition to or in lieu of the RFID tag, a “marker” could be employed on the tubular connection, e.g. any material which provides a significant difference in conductivity, as compared to the base pipe material. This could be, e.g., a ring of stainless steel embedded in the box side of the tool joint connection. It is understood that other materials could be used as well. The marker is disposed at a known distance from the connection face, hence detection of the marker location yields a clearly identified dimensional reference point from which the power/tong backup unit can be positioned. BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 5 is a top view of one embodiment of the present invention, showing the probe mounted on the power tong unit, and a tubular in position within the throat of the power tong unit.

FIG. 6 shows an exemplary power tong and backup unit, coupled to a power positioner, and also showing coupling to one or more digital processors which receive data from the eddy current measurement apparatus, process same to identify the location of the connection seam/connection face, in addition to other possible attributes, and signal the power positioner to position the power tong/backup unit accordingly.

While various power tong positioning systems can emb

8613371530291

8613371530291