hydraulic power tong 40 000 supplier

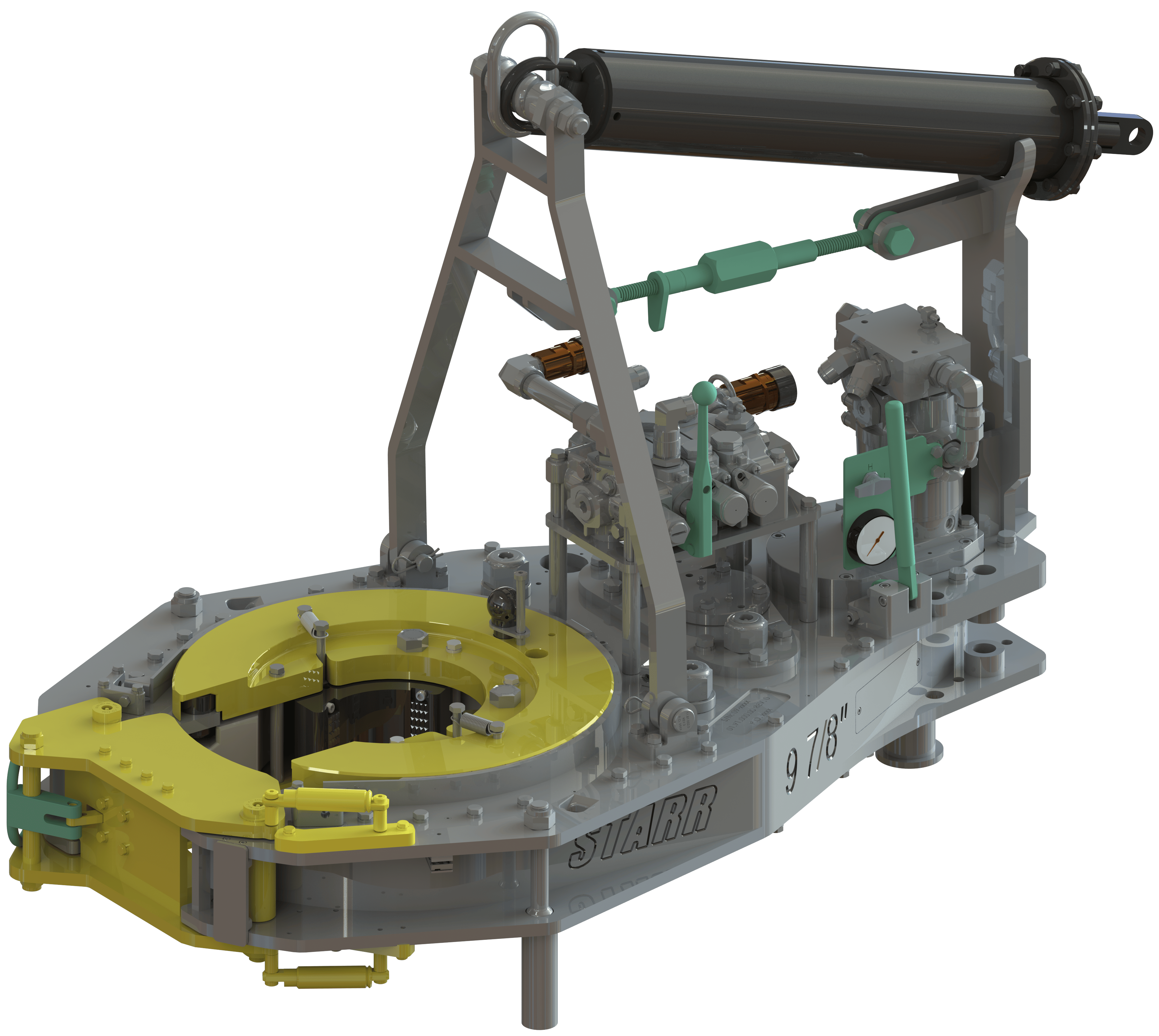

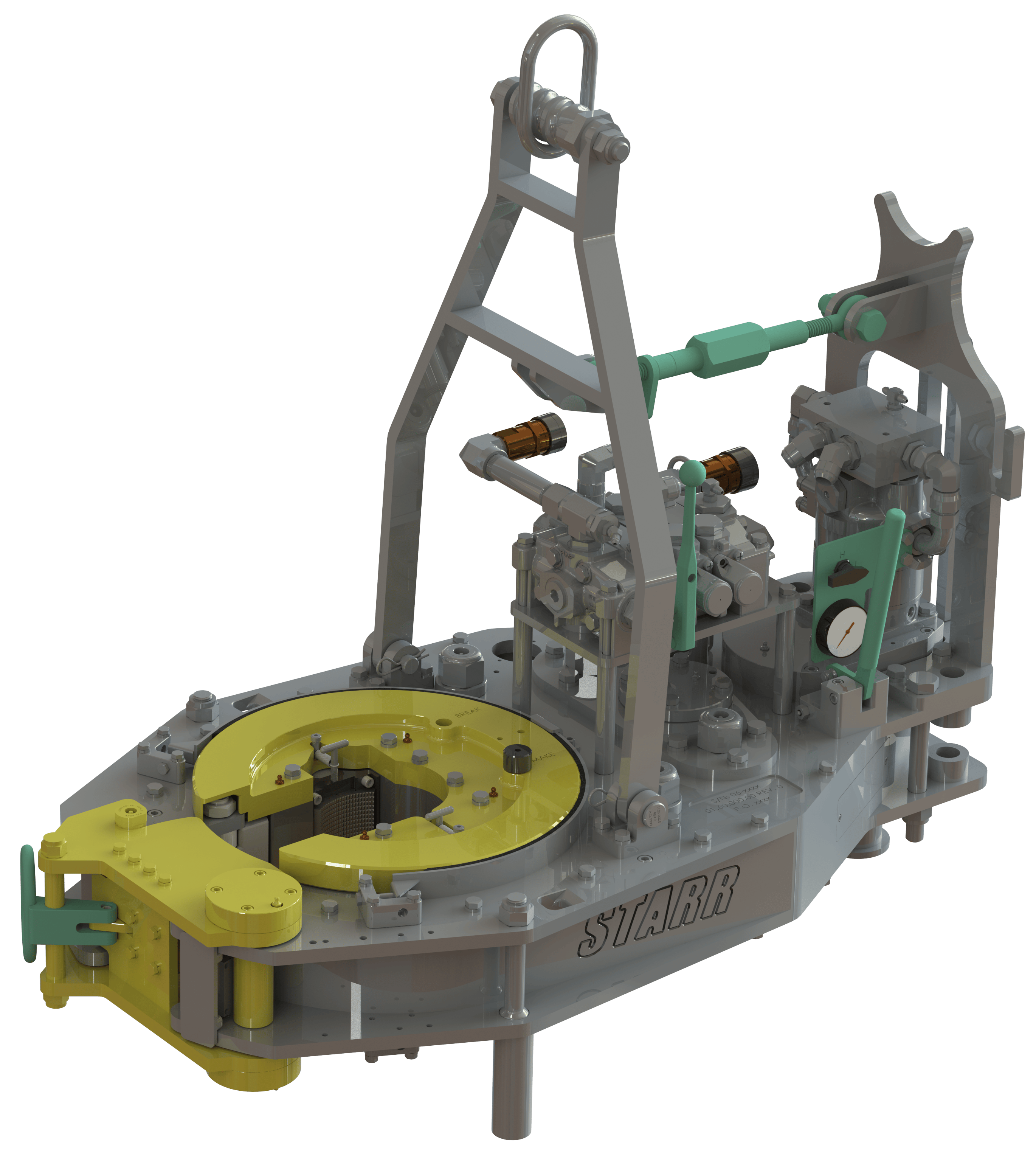

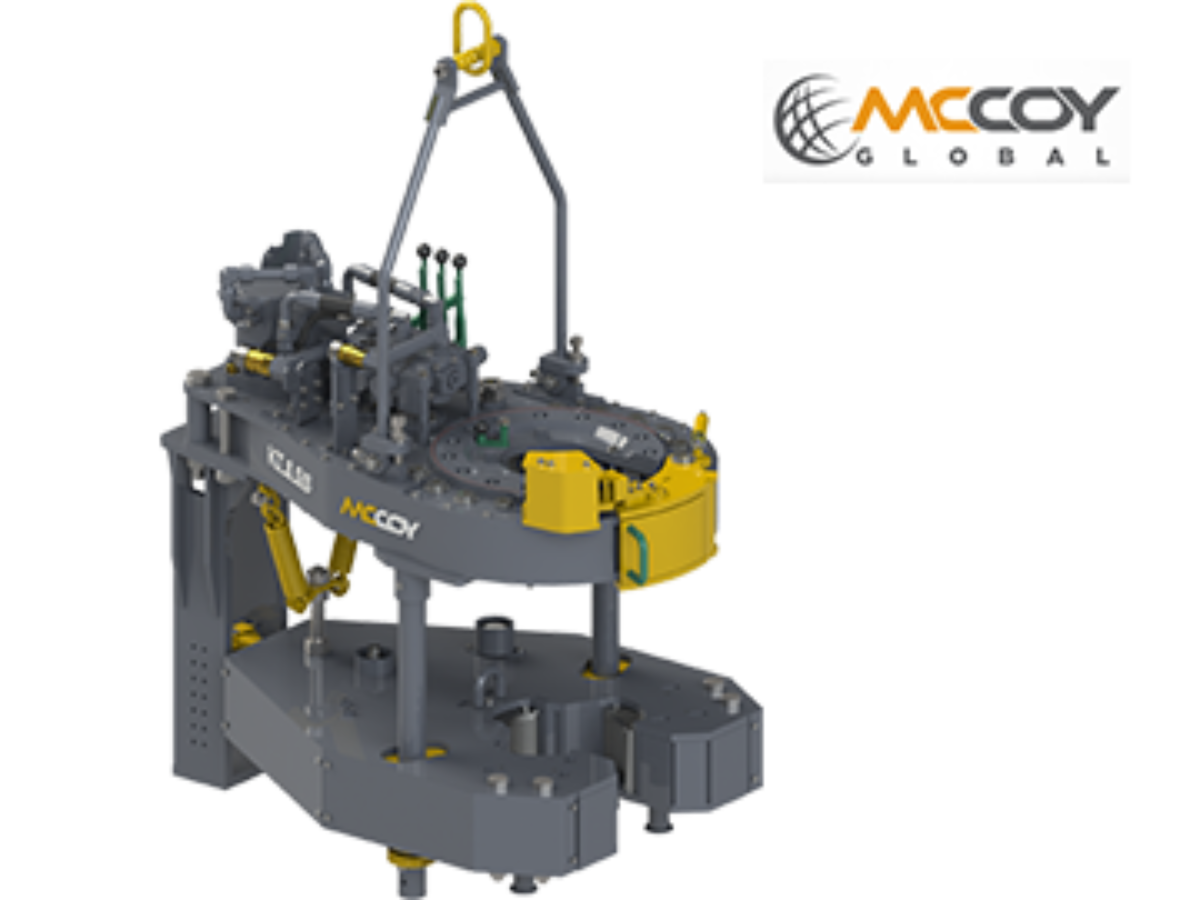

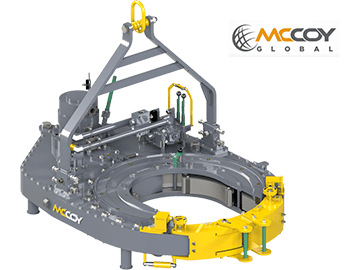

The 9-5/8” power tong with Rineer GA15-13 two-speed hydraulic motor, motor valve, lift cylinder valve, rigid sling, FARR® hydraulic backup, configured for compression load cell.

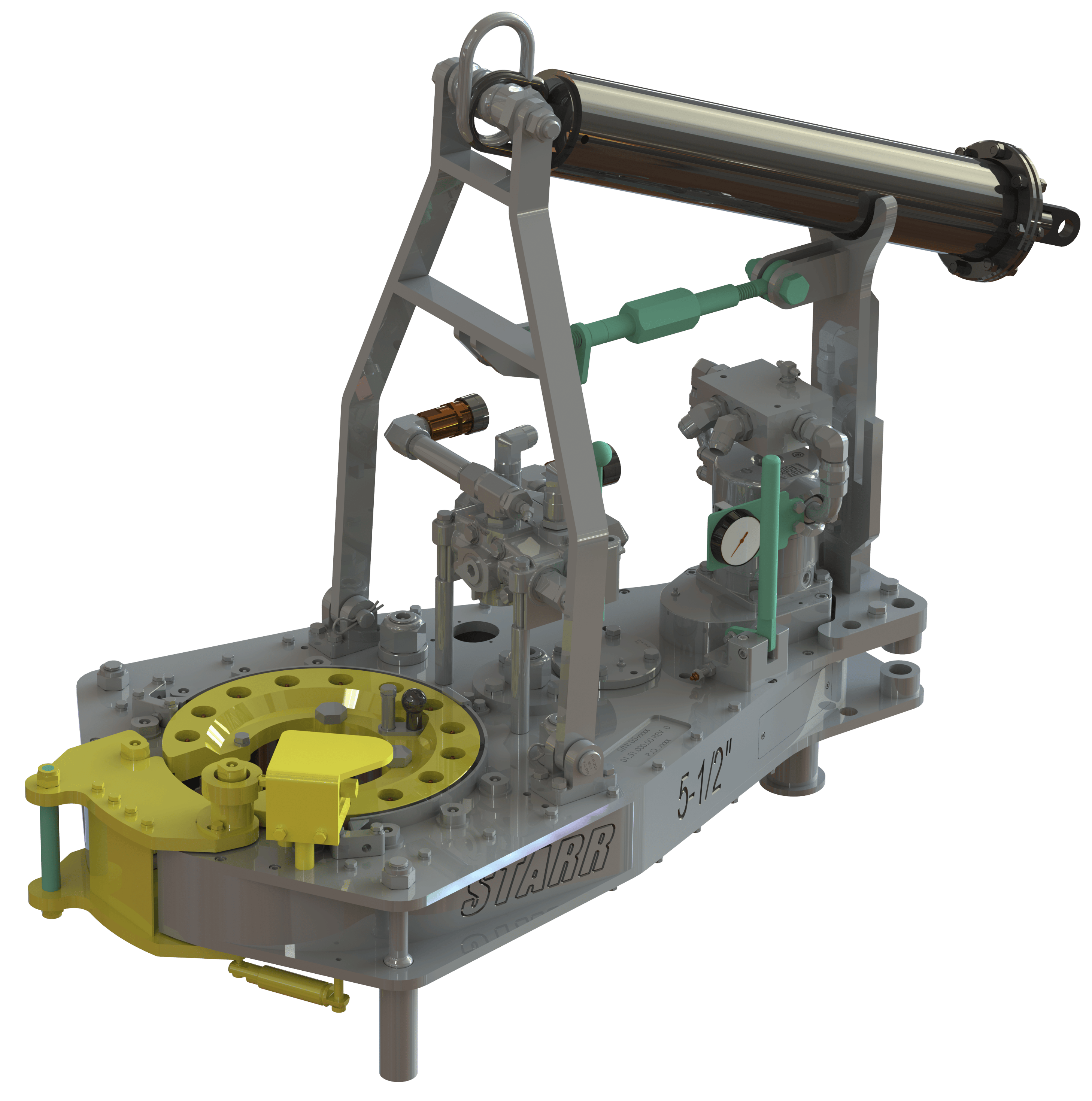

Power tongs are an essential tool in the drilling industry and are used to make up, break out, apply torque and to grip the tubular components. We are distributors for both Starr Power Tongs and McCoy Global hydraulic power tongs in multiple sizes and torque ranges from high torque to low torque that can be used to run both casing, drill pipe and tubing. When determining which power tong is best for your project, you will want to select the power tong that best fits your tubular size ranges and torque required.

All of our power tongs are available with either the McCoy\\\\\\\\\\\\\\\"s patented WinCatt data acquisition software recently updated to the MTT systems or AllTorque\\\\\\\\\\\\\\\"s computer monitoring system for all the torque and turn control system needed in today\\\\\\\\\\\\\\\"s market for the making of tubular connections. Discover our wide selection of McCoy and Starr casing tongs, tubing tongs and power tongs for sale below!

The 9-5/8” power tong with Rineer GA15-13 two-speed hydraulic motor, motor valve, lift cylinder valve, rigid sling, FARR® hydraulic backup, configured for compression load cell.

Casing Tongs provide make-up and break-out capabilities when running casing tubular in the drill hole to maintain well integrity. Casing tongs are available for various sizes from 5-1/2" to 36" and designed to handle high torque casing or lightweight casing. Available models: Standard, Hydra-Shift, High Torque, and Ultra High Torque with torques ranging from 15,000 ft-lbs up to 200,000 ft-lbs. Consistent operations between models reduce employee training.

Eckel�s 9⅞ HS-40 Tubing / Casing providing high torque and high continuous rotational torque that you can trust within a compact operational footprint featuring SPACE SAVER® technology.

The 9⅞ HS-40 Tubing / Casing is the result of months of engineering and extensive stress analysis that insures higher performance, reliability, and long life. Eckel 9⅞ HS-40 provides world-class performance with up to 40,000 ft-lbs maximum torque. The tong features our new patented CASE STIFFENER technology that enhances overall torque output. Having a high full 360� rotational torque and speed-shifting capability insures the tong can makeup special torque-turn connections that require continuous rotation. A two-speed Hydra-Shift® motor is coupled with a two-speed gear train to provide (4) torque levels and (4) HS- speeds allowing the operator remarkable control of the connection.

Tong dimensions are a critical design aspect that our engineers worked to reduce for today�s smaller rigs. The result was having one of the industry�s smallest operational footprints tongs for its capacity and torque. The patented SPACE SAVER® door that hydraulically opens vertically, allowing for the tong to work in a much smaller operational area on rig floors and is also less labor-intensive operating. The door opens to the opposite side of the tong operator, allowing full view of the tong throat area while positioning the tong on the tubular. A fast 2-second door operation is all that is required to open or close the door.

The safety door interlock prevents tong operation when the tong door is open. Now enclosed within the tong body, providing tamper-resistant concealment from operator circumvention. Accidental damage of the door interlock by hydraulic fluids, tubular connection, or other external forces is also greatly minimized. A front panel provides access to the door inter-lock for any maintenance required

The 9⅞ HS-40 Casing Tong offers exceptional gripping capabilities handling tubular size from 3½ - 9⅞ in. (88.9 - 250.8) and WD Tri-Grip® Backup size 3½ - 11 in. (88.9 - 279.4). An innovative design allows you to choose either sliding heads or pivot heads configuration upon order. Wrap-Around dies are offered which securely encompass the tubular to limit potential for damage. Therefore, you are assured of your down hole tubular connection integrity.

Our power tongs are built to last. With 2 motor options for the 9-7/8” hydraulic power tong, you crew can reach rated torque at 2,500 psi. Which means, the tools can reach 40,000 ft-lb or 60,000 ft-lb of torque on every single joint, every day.

With an investment like this, you don’t want one malfunctioning part to be the reason why your equipment isn’t performing. That’s why we build our tongs to be serviceable, high in quality. By using an ISO 9001:2015 quality system, we maintain a close eye on our products.

We offer modular spring hangers, which attach to the tong bridle and act as a hanger for the tong. In-turn, providing thread compensation to limit stresses during makeup. Give us a call today for pricing and shipping details.

We are committed to delivering innovative designs and high performance powers tongs for the oil and gas industry. With 90% of all tong components manufactured and heat treated in-house, you are assured reliability and confidence on your next job with an Eckel tong!

Casing Tong is a fast, safe, and accurate gear driven tong for making up and breaking out 7” to 24“ diameter casing. With a 48” handle, the tong can produce up to 50,000 lb-ft of torque.

A wide variety of hydraulic power sucker rod tong options are available to you, such as energy & mining, construction works and manufacturing plant.You can also choose from 1.5 years, hydraulic power sucker rod tong,As well as from provided, {2}, and {3}. and whether hydraulic power sucker rod tong is kazakhstan, russia, or egypt.

Established in 1958, Eckel is globally recognized as the leading manufacturer of hydraulic power tongs and hydraulic power units for the world’s oil and gas industries. We offer a full line of hydraulically operated drill pipe tongs, casing tongs, tubing tongs, hydraulic backups, hydraulic power units, and tong positioning equipment. Eckel delivers a comprehensive range of tongs from 2-1/16 through 36 in. for the most demanding onshore and offshore environments. Eckel Tri-Grip® backup is an industry standard for reliable make-up and break-out of tubular connections. Eckel’s cutting-edge designs, quality, and rugged durability have won us a world-wide reputation of a first-class product that insures years of trouble free service.

From our main manufacturing facilities in Odessa, Texas, USA (ISO 9001:2008 certified) essentially every part is designed and manufactured. The facility encompasses 140,663 square feet and houses the latest in design tools and numerically controlled machines and heat treating ovens.

Eckel high-performance tongs operate in some of the toughest operating environments around the world performing drill pipe, casing and work-over activities on onshore and offshore locations. Eckel is highly involved in drilling, well servicing, and work-over operations.

We offer a full range of high quality casing and tubing, drill pipe tongs for use in all types of oil and gas drilling, well completion and well servicing activities. Our tongs have been engineered for the high operational torques today’s that premium connections require. Eckel tongs continue to advance the technology of tool service and setting industry standards.

Our renowned free floating Tri-Grip® hydraulic backup provides unparalleled backup performance and is one of the industry’s closest tong mounting backups that minimize pipe bending. The backup utilizes three biting surfaces to insure a secure grip on the tubular to prevent tubular rotation.

Our remotely operated tongs provides a mean to control the tong for make-up and break-out operations. The tong is based upon the standard tong and backup configuration with the exception of hydraulic cylinders on the unit for remote control of the operations of the tong and backup. The functions include the tong door, backing pin, mechanical gear shift, power tong rotation, motor speed and backup gripping. Totally hydraulic with no electrical or electronic devices.

Eckel’s standard diesel or electric power packages at 65 GPM and 2,500 psi (246 LPM / 172 bar) are widely recognized for dependability and long, trouble-free service. Eckel will customize hydraulic power systems in the shortest possible time to meet “nonstandard” requirements for space, fluid flow, auxiliary power, and portability. Diesel driven units are optionally supplied with automatic shutdown systems to prevent engine run away when explosive gases are present. Additional shut downs include engine oil temperature, oil pressure, and fan belt breakage. All controls are either air, mechanical or electrical.

Tongs - Power - STARR 9-7/8 TONGS 40K AND 60K MODELS AVAILABLE, WITH OR WITHOUT INTEGRAL BACKUP. TOOLS ARE SOLD WITH ONE YEAR WARRANTY. ACCESSORIES ARE AVAILABLE IN STOCK ON REQUEST. C... More Info

8613371530291

8613371530291