power tong companies in alberta price

Universe Machine Corporation"s driving mission is to manufacture, modify or repair steel products for the oilfield, petrochemical and forestry industries. The company has been providing these services since 1965 and owes its success to a highly skilled workforce and a commitm…

At Ed"s Valve Servicing (Red Deer) Ltd., we"re known for quality workmanship. After 25 years of service in the Red Deer area, we understand that there"s no substitute for hard work and accuracy.

Pathmaker is an expanding Tubular Running Service company developed Industry professionals with remarkable TRS experience and expertise. We are family owned and operated and have been proudly serving Alberta and British Columbia Industry for over 40 years.

Dash Energy Services Ltd. provides complete tubular services, integral and conventional power tongs, CRT"s, computer torque monitoring, thread washing, 12 GPS equipped units and more, all provided with professional, competent service.;Dash Energy Services Ltd. has been in busine…

Ace Power Tongs & Energy Services serves Western Canada with computer torque monitoring, thread washing, CRT"s, integral and power tongs, GPS equipped units and more. Click our name to learn more about us.;Your choice for a complete tong, casing and tubing program is Ace Power …

When you need to put down or remove pipes for an oil drilling rig, trust Bitz Power Tongs Ltd. to handle the work. We have a variety of power tong trucks in Edson, Alberta, to meet the needs of your project. Our Canadian-owned and locally operated power tong and laydown unit com…

TriMark Tubular Ltd. delivers high-quality oil country tubular goods (OCTG) used for drilling and completions, plus gathering and transmission lines. We hold one of the largest inventories of OCTG and linepipe in Western Canada. TriMark provides complementary engineering experti…

Hill"s Power Tongs has provided Alberta with "First Class Tools All The Way - Any Time Night or Day", since 1975. Offering: Integral tongs and Computer torque monitoring We are certified: ISnetworld, ComplyWorks and COR. Offering 24 hour service. Please call or email.

Pro Torque Connection Technologies Ltd. offers a full line of casing running services: conventional and integral power tong equipment, Volant casing running tools, computer torque monitoring, casing crews, and thread supervision and inspection. We also offer top drive and iron r…

An oilfield service company, Hybrid Energy Services relies on the latest technology to create accountability and reduce liability for its clients. They offer a wide range of services, including the following: computer-analyzed torque monitoring, wireless torque sub, electroni…

Drifters Casing Service is a local leader for drilling and completions work in Grande Prairie, Whitecourt, and other areas in Alberta. You can count on us to provide services 24 hours per day as required.

Pathmaker is an expanding Tubular Running Service company developed Industry professionals with remarkable TRS experience and expertise. We are family owned and operated and have been proudly serving Alberta and British Columbia Industry for over 40 years.

Dash Energy Services Ltd. provides complete tubular services, integral and conventional power tongs, CRT"s, computer torque monitoring, thread washing, 12 GPS equipped units and more, all provided with professional, competent service.;Dash Energy Services Ltd. has been in busine…

An oilfield service company, Hybrid Energy Services relies on the latest technology to create accountability and reduce liability for its clients. They offer a wide range of services, including the following: computer-analyzed torque monitoring, wireless torque sub, electroni…

Drifters Casing Service is a local leader for drilling and completions work in Grande Prairie, Whitecourt, and other areas in Alberta. You can count on us to provide services 24 hours per day as required.

Tubular Optimization Services has always believed in providing exceptional global casing & tubing field running services while maintaining our customer"s invested tubular interests as our top priority. Specializing in premium connections, fiberglass lined, coated, chrome alloy a…

Universe Machine Corporation"s driving mission is to manufacture, modify or repair steel products for the oilfield, petrochemical and forestry industries. The company has been providing these services since 1965 and owes its success to a highly skilled workforce and a commitm…

At Ed"s Valve Servicing (Red Deer) Ltd., we"re known for quality workmanship. After 25 years of service in the Red Deer area, we understand that there"s no substitute for hard work and accuracy.

Ace Power Tongs & Energy Services serves Western Canada with computer torque monitoring, thread washing, CRT"s, integral and power tongs, GPS equipped units and more. Click our name to learn more about us.;Your choice for a complete tong, casing and tubing program is Ace Power …

When you need to put down or remove pipes for an oil drilling rig, trust Bitz Power Tongs Ltd. to handle the work. We have a variety of power tong trucks in Edson, Alberta, to meet the needs of your project. Our Canadian-owned and locally operated power tong and laydown unit com…

TriMark Tubular Ltd. delivers high-quality oil country tubular goods (OCTG) used for drilling and completions, plus gathering and transmission lines. We hold one of the largest inventories of OCTG and linepipe in Western Canada. TriMark provides complementary engineering experti…

Hill"s Power Tongs has provided Alberta with "First Class Tools All The Way - Any Time Night or Day", since 1975. Offering: Integral tongs and Computer torque monitoring We are certified: ISnetworld, ComplyWorks and COR. Offering 24 hour service. Please call or email.

Pro Torque Connection Technologies Ltd. offers a full line of casing running services: conventional and integral power tong equipment, Volant casing running tools, computer torque monitoring, casing crews, and thread supervision and inspection. We also offer top drive and iron r…

Our experienced and skilled power tong technicians play a major role in the safety and efficiency of a casing run. This makes the selection of your power tong service company a key component of overall performance.

ProTorque attracts and employs some of the industry’s most talented and experienced casing running technicians. Every detail of a casing run must be considered when looking for cost savings and efficiency; particularly on long production strings where every second counts while maintaining a safe operation. When making-up hundreds of connections, filling on the fly and selecting the correct handling equipment (air or hydraulic powered slips); we save time and effort on long challenging casing runs. ProTorque can meet handling requirements of up to 500 tons of hoist capability.

Our thread supervisors ensure the manufacturers specifications and API standards are being performed thus maximizing long term performance and preventing tubular damage.

Wolverine Group provides the best thread inspection processes in the industry. Not only are our field hands highly trained and experienced, they carry a great deal of pride in their work. Our thread supervisors, through our triple check process ensure the manufacturers specifications and API standards are being performed thus maximizing long term performance and preventing tubular damage.

In your work you rely on having suppliers who use the best equipment to complete your jobs. Among the most important pieces of equipment required for oil drilling and completions are power tongs. Drifters Casing Service is a local provider of power tongs services in Grande Prairie and Whitecourt areas with a reputation for expertise and reliability.

Eckel.Eckel is the one of the world’s leading power tong manufacturers. Each Eckel tong must pass a comprehensive compliance checklist so it’s ready to meet requirements in the field.

Universe. Since 1965, Universe Machine Corporation has supplied trustworthy steel products for the oilfield industry. Their quality standard system ensures that each power tong meets your application requirements.

We have many sizes of power tongs to fit the size of your pipe, from 2-3/8″ to 13- 3/8″. And our power tongs equipment offers a wide torque range to suit the job.

In addition to power tongs in Grande Prairie, we provide all other casing and tubing services you may need, including integral tubing tongs. You can also monitor your equipment with WinCatt Computer Torque Monitoring that we can provide and monitor on your behalf. All equipment can be used in drilling and completions work.

We’re your provider of oil field drilling and completions services that require power tongs and related oilfield equipment. Since 2000, our locally-owned and operated company has helped companies like yours get the work done right. Contact us for more information.

Afghanistan - AFGAlbania - ALBAlgeria - DZAAmerican Samoa - ASMAndorra - ANDAngola - AGOAnguilla - AIAAntigua and Barbuda - ATGArgentina - ARGArmenia - ARMAruba - ABWAustralia - AUSAustria - AUTAzerbaijan Republic - AZEBahamas - BHSBahrain - BHRBangladesh - BGDBarbados - BRBBelarus - BLRBelgium - BELBelize - BLZBenin - BENBermuda - BMUBhutan - BTNBolivia - BOLBosnia and Herzegovina - BIHBotswana - BWABrazil - BRABritish Virgin Islands - VGBBrunei Darussalam - BRNBulgaria - BGRBurkina Faso - BFABurma - MMRBurundi - BDICambodia - KHMCameroon - CMRCanada - CANCape Verde Islands - CPVCayman Islands - CYMCentral African Republic - CAFChad - TCDChile - CHLChina - CHNColombia - COLComoros - COMCongo, Democratic Republic of the - CODCongo, Republic of the - COGCook Islands - COKCosta Rica - CRICote d Ivoire (Ivory Coast) - CIVCroatia, Republic of - HRVCyprus - CYPCzech Republic - CZEDenmark - DNKDjibouti - DJIDominica - DMADominican Republic - DOMEcuador - ECUEgypt - EGYEl Salvador - SLVEquatorial Guinea - GNQEritrea - ERIEstonia - ESTEthiopia - ETHFalkland Islands (Islas Malvinas) - FLKFiji - FJIFinland - FINFrance - FRAFrench Guiana - GUFFrench Polynesia - PYFGabon Republic - GABGambia - GMBGeorgia - GEOGermany - DEUGhana - GHAGibraltar - GIBGreece - GRCGreenland - GRLGrenada - GRDGuadeloupe - GLPGuam - GUMGuatemala - GTMGuernsey - GGGuinea - GINGuinea-Bissau - GNBGuyana - GUYHaiti - HTIHonduras - HNDHong Kong - HKGHungary - HUNIceland - ISLIndia - INDIndonesia - IDNIreland - IRLIsrael - ISRItaly - ITAJamaica - JAMJapan - JPNJersey - JEJordan - JORKazakhstan - KAZKenya - KENKiribati - KIRKorea, South - KORKuwait - KWTKyrgyzstan - KGZLaos - LAOLatvia - LVALebanon - LBNLiechtenstein - LIELithuania - LTULuxembourg - LUXMacau - MACMacedonia - MKDMadagascar - MDGMalawi - MWIMalaysia - MYSMaldives - MDVMali - MLIMalta - MLTMarshall Islands - MHLMartinique - MTQMauritania - MRTMauritius - MUSMayotte - MYTMexico - MEXMicronesia - FSMMoldova - MDAMonaco - MCOMongolia - MNGMontenegro - MNEMontserrat - MSRMorocco - MARMozambique - MOZNamibia - NAMNauru - NRUNepal - NPLNetherlands - NLDNetherlands Antilles - ANTNew Caledonia - NCLNew Zealand - NZLNicaragua - NICNiger - NERNigeria - NGANiue - NIUNorway - NOROman - OMNPakistan - PAKPalau - PLWPanama - PANPapua New Guinea - PNGParaguay - PRYPeru - PERPhilippines - PHLPoland - POLPortugal - PRTPuerto Rico - PRIQatar - QATReunion - REURomania - ROURussian Federation - RUSRwanda - RWASaint Helena - SHNSaint Kitts-Nevis - KNASaint Lucia - LCASaint Pierre and Miquelon - SPMSaint Vincent and the Grenadines - VCTSan Marino - SMRSaudi Arabia - SAUSenegal - SENSerbia - SRBSeychelles - SYCSierra Leone - SLESingapore - SGPSlovakia - SVKSlovenia - SVNSolomon Islands - SLBSomalia - SOMSouth Africa - ZAFSpain - ESPSri Lanka - LKASuriname - SURSwaziland - SWZSweden - SWESwitzerland - CHETaiwan - TWNTajikistan - TJKTanzania - TZAThailand - THATogo - TGOTonga - TONTrinidad and Tobago - TTOTunisia - TUNTurkey - TURTurkmenistan - TKMTurks and Caicos Islands - TCATuvalu - TUVUganda - UGAUkraine - UKRUnited Arab Emirates - AREUnited Kingdom - GBRUnited States - USAUruguay - URUUzbekistan - UZBVanuatu - VUTVatican City State - VATVenezuela - VENVietnam - VNMVirgin Islands (U.S) - VIRWallis and Futuna - WLFWestern Sahara - ESHWestern Samoa - WSMYemen - YEMZambia - ZMBZimbabwe - ZWE

K&S Power Tongs committs to providing quality casing services in a safe, reliable, cost efficient and timely manner. Safety is everyone’s full time job and we are committed to the prevention and elimination of all safety nad health hazards. All operators are specially trained and industry safety certified. Safety is never compromised. Unsafe acts are never tolerated and our employees are held accountable to work safe.

K&S Power Tongs offers coventional and integral power tong services, volant casing running tools, computer torque-turn systems, power thread washing, thread inspection, handling equipment rentals and light oilfield hauling.

Our company offers quality services and competitive rates with strict guidelines to minimize impact on the environment and maximize utilization of safety skills. We offer a level of professionalism that builds solid relationships in this industry, growing to advance our equipment to meet the technology advancement in the oilfield.

Afghanistan - AFGAlbania - ALBAlgeria - DZAAmerican Samoa - ASMAndorra - ANDAngola - AGOAnguilla - AIAAntigua and Barbuda - ATGArgentina - ARGArmenia - ARMAruba - ABWAustralia - AUSAustria - AUTAzerbaijan Republic - AZEBahamas - BHSBahrain - BHRBangladesh - BGDBarbados - BRBBelarus - BLRBelgium - BELBelize - BLZBenin - BENBermuda - BMUBhutan - BTNBolivia - BOLBosnia and Herzegovina - BIHBotswana - BWABrazil - BRABritish Virgin Islands - VGBBrunei Darussalam - BRNBulgaria - BGRBurkina Faso - BFABurma - MMRBurundi - BDICambodia - KHMCameroon - CMRCanada - CANCape Verde Islands - CPVCayman Islands - CYMCentral African Republic - CAFChad - TCDChile - CHLChina - CHNColombia - COLComoros - COMCongo, Democratic Republic of the - CODCongo, Republic of the - COGCook Islands - COKCosta Rica - CRICote d Ivoire (Ivory Coast) - CIVCroatia, Republic of - HRVCyprus - CYPCzech Republic - CZEDenmark - DNKDjibouti - DJIDominica - DMADominican Republic - DOMEcuador - ECUEgypt - EGYEl Salvador - SLVEquatorial Guinea - GNQEritrea - ERIEstonia - ESTEthiopia - ETHFalkland Islands (Islas Malvinas) - FLKFiji - FJIFinland - FINFrance - FRAFrench Guiana - GUFFrench Polynesia - PYFGabon Republic - GABGambia - GMBGeorgia - GEOGermany - DEUGhana - GHAGibraltar - GIBGreece - GRCGreenland - GRLGrenada - GRDGuadeloupe - GLPGuam - GUMGuatemala - GTMGuernsey - GGGuinea - GINGuinea-Bissau - GNBGuyana - GUYHaiti - HTIHonduras - HNDHong Kong - HKGHungary - HUNIceland - ISLIndia - INDIndonesia - IDNIreland - IRLIsrael - ISRItaly - ITAJamaica - JAMJapan - JPNJersey - JEJordan - JORKazakhstan - KAZKenya - KENKiribati - KIRKorea, South - KORKuwait - KWTKyrgyzstan - KGZLaos - LAOLatvia - LVALebanon - LBNLiechtenstein - LIELithuania - LTULuxembourg - LUXMacau - MACMacedonia - MKDMadagascar - MDGMalawi - MWIMalaysia - MYSMaldives - MDVMali - MLIMalta - MLTMarshall Islands - MHLMartinique - MTQMauritania - MRTMauritius - MUSMayotte - MYTMexico - MEXMicronesia - FSMMoldova - MDAMonaco - MCOMongolia - MNGMontenegro - MNEMontserrat - MSRMorocco - MARMozambique - MOZNamibia - NAMNauru - NRUNepal - NPLNetherlands - NLDNetherlands Antilles - ANTNew Caledonia - NCLNew Zealand - NZLNicaragua - NICNiger - NERNigeria - NGANiue - NIUNorway - NOROman - OMNPakistan - PAKPalau - PLWPanama - PANPapua New Guinea - PNGParaguay - PRYPeru - PERPhilippines - PHLPoland - POLPortugal - PRTPuerto Rico - PRIQatar - QATReunion - REURomania - ROURussian Federation - RUSRwanda - RWASaint Helena - SHNSaint Kitts-Nevis - KNASaint Lucia - LCASaint Pierre and Miquelon - SPMSaint Vincent and the Grenadines - VCTSan Marino - SMRSaudi Arabia - SAUSenegal - SENSerbia - SRBSeychelles - SYCSierra Leone - SLESingapore - SGPSlovakia - SVKSlovenia - SVNSolomon Islands - SLBSomalia - SOMSouth Africa - ZAFSpain - ESPSri Lanka - LKASuriname - SURSwaziland - SWZSweden - SWESwitzerland - CHETaiwan - TWNTajikistan - TJKTanzania - TZAThailand - THATogo - TGOTonga - TONTrinidad and Tobago - TTOTunisia - TUNTurkey - TURTurkmenistan - TKMTurks and Caicos Islands - TCATuvalu - TUVUganda - UGAUkraine - UKRUnited Arab Emirates - AREUnited Kingdom - GBRUnited States - USAUruguay - URUUzbekistan - UZBVanuatu - VUTVatican City State - VATVenezuela - VENVietnam - VNMVirgin Islands (U.S) - VIRWallis and Futuna - WLFWestern Sahara - ESHWestern Samoa - WSMYemen - YEMZambia - ZMBZimbabwe - ZWE

2005 MACK CX613 Vision LAYDOWN T/A TRUCK-412,000 Miles, w/Integ. Sleeper, Mack Diesel, 18 Spd Deck, PTO, Hyd. System & Gear-o-matic Winches, Operators Cab w/Heater& AC, (Recent New Trough, Pole, Kickers & Rigging)

TRAILERS – 35 FT HI-BOY TILT TANDEM DUALLY 20,000 LB TRAILERW/ Hydraulic Outriggers & Live Roll, Electric Brakes, 19.5” Rubber 2003 Precision 20 FT T/A 14,000 LB EQUIPMENT TRAILER, RAINBOW 32’ G/N TRI-AXLE EQUIPMENT TRAILER w/Winch

FORKLIFTS -1985 TOYOTA LPG FORKLIFT 2FGG30 – 6000 LB, 3 stage Lift & Side Shift, Pneumatic Tires, 1981 NISSAN UFO3A35V FORKLIFT LPG 7000 LB, 2 Stage, Pneumatic Tires, 2-Stinger Attach. For Forklifts, Man Basket for Forklift

POWER TONGS -FARR - 13 3/8 TONG- 30,000 Ft/lb W/ JAWS: 13 3/8 “- 5 ½”, FARR/MCCOY 13 5/8 INTEGRAL TONG 35,000 Ft/lb (NEW) w/ BACKUPS AND JAWS: 13 3/8”-5 ½”, FARR/MCCOY 13 5/8 INTEGRAL TONG 35,000 ft/lb (NEW) w/ BACKUPS AND JAWS: 13 3/8 - 7", 2-FARR LW - 9 5/8 TONG -12,000 Ft/lb w/JAWS: 9 5/8” - 4 ½”, 2 -UNIVERSE - 9 5/8 TONG - 20,000 Ft/lb w/JAWS, UNIVERSE 9 5/8 INTEGRAL TONG 20,000 F/lb w/BACKUPS AND JAWS: 9 5/8”- 5 ½”, UNIVERSE 8 5/8 INTEGRAL TONG 19,000 Ft/lb 970703 w/BACKUPS AND JAWS: 9 5/8”- 4 ½”, UNIVERSE - 5 1/2 TONG15,000 ft/lb 970401 w/JAWS: 5 ½” - 4", 5 -UNIVERSE 5 1/2 INTEGRAL TONG 15,000 ft/lb w/BACKUPS, JAWS & DIES: 2 3/8 - 5 ½, BJ X HEAVY 13 3/8 MANUAL BACKUP , 3 ½” Power Tongs w/Backups, Note*ALL TONGS COME WITH TORQUE GAUGES*

4-Portable Pipe Handling Units / Skid Mt. Power Cat Walks 2500-3000 Lb Lift Cap. X 32Ft High (1-Located in Houston, Texas),2-350 Ton BJ Varco Air Operated Slips/Elevators – 7 5/8, 9 5/8, 13 3/8” w/Guides, Dies,& Interlocking Systems Back Up Tongs,Farr Winncat Torque Monitoring Computer Systems w/Electronic Load Cells, Torque Master Hydraulic Dump Systems,Power Thread Washers, Spiders,Include. Conventional, Single Joint Pick Up, YC, HYC, YT Slip Type, HYC, YC, YT Segments, CMSXL Button Dies, Surface Slips, Torque Gauges, Compression 24”, 26”, Pull 28”,30”,31”,36”, Circulating Equipment, Chicsans, Swages, 2-Type C Air Op Dog Collars, Drift Snakes, Etc

SHOP EQUIPMENT(Selling @ 10 AM) Waukasha VRG 2000 LPG Stationary Eng. w/Hyd. Power Pak Unit w/Skid, ALADIN 2260E Hi-Capacity Enviro-Friendly Parts Washer-3 Ph, 52”x72”, Hotsey 989 Ng Stationary Pressure Washer Steamer, KARCHER Pressure Washer/Steamer,2-Jib Crane 20 Foot w/ Electric Hoists, 11’x7’x9’ Open Face Spray Booth w/Fire Suppression, Horizontal Shop Air Compressor, Gym Lockers, Benches, Welders, Tools, Pallet Racking, Parts Washers, Grease Guns, Hand Wrenches, Pipe Wrenches, Spill Kits, Fire Extinguishers, Barrel Lifter & Dolly, 45 Gal DEF, 45 Gal Barrel Hydrex HV Hyd. All-Season Oil, Portable Air Greaser, Chains, Boomers, Electric Motors, Hyd. Winches, 112’x6000 Lb Eng. Shop Gantry, Sandblasting Cabinet, Set Hyd. Tanks, & Reels for Tong Truck, Oxy/Acc Sets, Web Slings, Chains, Shackles, Hyd. Jacks, Jack Stands, Bolts & Hardware, Bolt Bins, Shelving, Coats Rim Clamp Tire Machine, Coats Electronic Wheel Balancer, 2004 Westeel 2500 L Used Oil Tank, Fugi FM-VO-B Vertical Milling Machine – 1 Ph, Miller 251 Mig, Lincoln AC/DC, New $”x16’ Hyd. Ram, Thread Protectors, Operators Stands, 24 Pail API Thread Compound, Hammer Unions, & Much More

OFFICE FURNITURE & SUPPLIES– Quantity of Modern Office Furniture, Desks, File Cabinets, Chairs, Leather Sofas, Printers, Panasonic Telephone System, Coffee Room Equip., Folding Tables, & More

AUCTIONEERS NOTE: This is a complete dispersal of a prominent turn key business. It is good quality and well looked after. For more information and photos please see www.montgomeryauctions.com

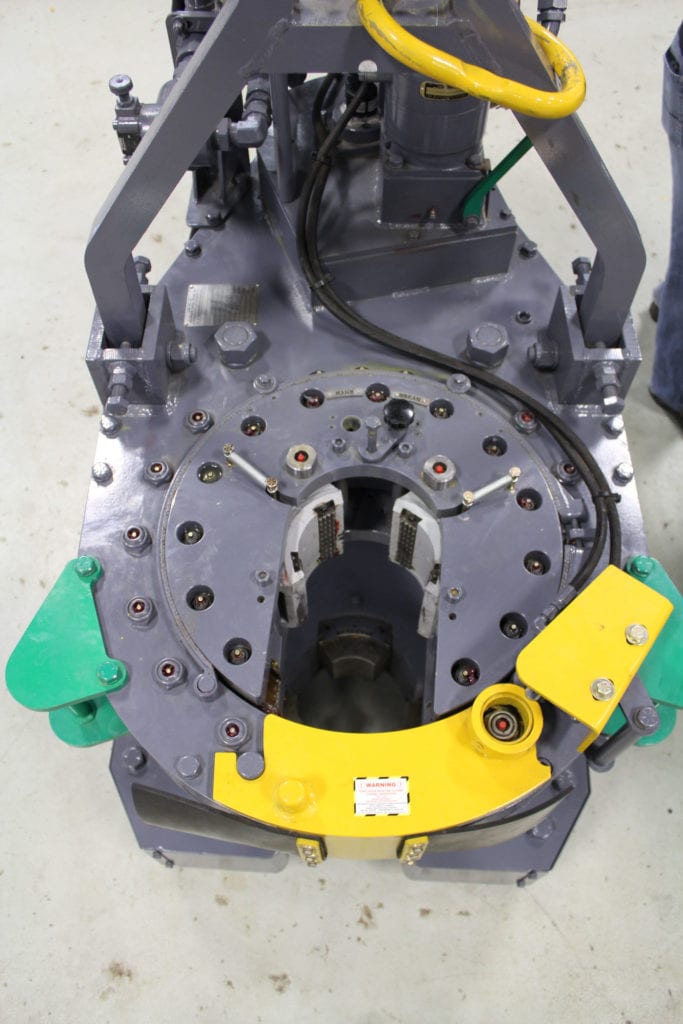

(From left) Ron Feigel, business development, and Fred Aleksic, product development manager, show off the company’s flagship power tong equipment. Images: Universe Machine

In 1960 a then 18-year-old Kurt Feigel Sr. immigrated to Canada with plans only to stay for a year or two. To earn a living he capitalized on his skills, and in 1965 established Universe Machine Corp. with two other people within a 2,000-sq.-ft. building in the Edmonton area. What started out as a small machine shop with a plan to move on shifted, and Feigel Sr. grew both his business and his family in Canada for decades to come. To this day Universe Machine remains in the hands of the Feigel family.

From its humble beginnings, the shop has always focused on heavy industry, including oil and gas. Today the shop has expanded both its operations and services to include more than 200 employees during peak times, and a more than 100,000-sq.-ft. facility. In decades past depending on market conditions, the company has branched out from a singular focus to include three divisions.

General manufacturing was the shop’s strength. However, in the late 1980s Universe machine found itself focused on product development. The shop designed and engineered a high-quality line of power tongs—a machine used on drilling rigs to screw and unscrew tubing or casing to a specific torque. It was this development that really pushed the shop to branch out into this new area of opportunity. Today Universe Machine’s power tongs and other related products are sold globally.

The 1980s also saw another significant shift for the shop. The company expanded into valve servicing, specializing in the service, modification, and repair of valves for many industries. Universe Machine boasts that this valve service division has grown to be one of the largest of its kind in all of Canada.

Throughout all the changes and iterations, the company took on, it continues to remain a family-owned business. In 2014 Kurt Sr. passed the reins to his son Kurt Jr., who became president of the company. A third generation of Feigels, including Kurt Jr.’s sons, are helping to continue the family legacy.

“We’ve been really fortunate to see steady growth over all these years,” said Ron Feigel, business development, Universe Machine. “We’ve spent 57 years in business, and while we’ve had some low points and struggled with market conditions, we’ve always come through stronger. We’ve chosen a slow and steady path, unlike other operations that just grew too fast and are no longer around anymore. We’ve remained and continue to thrive.”

The shop has spent decades honing its skills and expertise, focusing on the three divisions that have helped it grow: manufacturing, valve services, and products development. In that time the shop has taken on many unique projects, including machining the first heart implant valve for the University of Alberta, designing valves used in the NASA launch facilities, and producing valves for pipelines throughout Canada.

The shop started out as a job shop with manual machining, drilling, and welding capabilities. These core competencies have continued to this day while expanding to include extensive CNC machining, grinding, heat treatment, laser cladding, and plasma cutting services. The diversity in equipment and services allows the company to take on a range of challenging projects.

“Having highly skilled and dedicated workers, stringent quality control standards, and large equipment capacities has really set us apart from the competition,” said Feigel. “Our largest CNC machines can handle 50-ton workpieces. Our large, high-quality machines allow us to regularly work on massive, complex components.”

Universe’s manufacturing division focuses on modifying or repairing some of the biggest and most unique components in Canada. Because of this the shop requires extremely large and diverse machining equipment, including CNC machining centers and lathes, horizontal and vertical boring mills, milling machines, drill presses, surface grinders and shapers. It also provides full in-house engineering support, and its certifications include ISO 9001:2015, APEGA, ABSA, and COR. Beyond machining, the manufacturing division also provides laser PTA heat treating and cladding, robotic and B-pressure welding, fabricating, and millwrighting services.

The company is an authorized repair and modification center for numerous valve manufacturers and is the only Canadian-based member of the Valve Repair Council. This division provides specialized services ranging from hydro-testing, and trim changes and extensions to full valve refurbishing back to OEM specifications. The shop specializes in valves ranging from ½ to 72 in. in diameter. For valve modifications the shop provides CRN numbers and certified processes accordingly.

And while much of the shop’s work focuses on oilfield products and servicing, the company has expanded to also include other heavy industries like mining and forestry. Universe products require extreme and rugged testing by staff to ensure they can withstand the harsh conditions found in these sectors.

There is much discussion surrounding the nation’s reliance on fossil fuels and the significant push towards renewable energy. However, many reports including the International Energy Outlook by the U.S. Energy Information Administration show that while renewable energy is the largest growing segment across North America, petroleum and natural gas are the most-consumed sources of energy. In essence, fossil fuels will continue to dominate for much of the next half century.

“If we are to ensure secure, reliable, and affordable energy for the world’s increasing population, it would be prudent to shape energy policy with this in mind,” said Feigel. “While Universe Machine does a lot of work for the oil and gas sector, we also have diversified into forestry, mining, and other heavy industry segments.”

However, the oil and gas sector has always been extremely volatile. Local and global conditions can have significant impact on manufacturers, and companies that survive the market’s ups and downs of the market often are those with grit, determination, and innovation.

“Leaders must maintain growth no matter what phase of boom or bust the industry is in,” said Feigel. “Global competition and remaining competitive is a challenge. But another challenge is right here in our own back yard. When our own federal government is not truly interested in efficiently utilizing our vast natural resources to help stabilize our economy, but instead creates roadblocks like increased taxes and changing rules for businesses, that is an even bigger problem. Investment dollars will flow elsewhere.”

“However, the opportunities, creativity, and satisfaction the energy industry provides, thankfully, still seems to outweigh the negatives,” said Feigel. “Our highly skilled staff take great pride and find it rewarding to design, manufacture, repair, or modify the many interesting, challenging, and complex components we work on.”

And while Feigel acknowledged the importance of improving energy efficiency, including the mindful utilization of renewable energy, a realistic, wise, and balanced long-term transition plan that takes risk, reward, cost, and benefit into equal consideration is necessary.

“We need provincial and federal governments to actually support our oil and gas industry in Alberta and across Canada,” said Feigel. “This approach has been proven to create stability, instill confidence, and spur investment, which creates more jobs and economic growth over the long term. Natural resource wealth should be utilized on a parallel platform, creating long-term diversification, energy efficiency, and sustainability without slowing growth or causing economic hardship.”

Universe Machine specializes in valves ranging from ½ to 72 in. in diameter. This extremely large 42 in. valve body can easily be machined on its equipment.

The constant flux of the oil and gas industry has forced Universe’s management to find new ways to generate revenue and keep business as steady as possible. Investing in training, apprenticeships, and improving employee skills are a few ways the shop has remained competitive.

“Investing and incorporating new technology and focusing on research and development during the pandemic has led to extensive testing and improvements of our existing products,” said Feigel. “We’ve engineered a new line of compact, high-torque power tong equipment, which is currently being introduced to market. We also added a Toshiba TUE-200(S) vertical lathe with live tooling. All of this investment, including retaining skilled, long-term employees, signals to our employees and customers that we can be trusted to continue moving forward, even during difficult times.”

Universe Machine has taken the difficulties and economic downturns in stride. Rather than letting these times bring them down, management has always focused on investing in strengthening employees’ skills and in new equipment and services. This mindset has allowed the company to weather tough times and take advantage of opportunities during economic upswings.

“It appears that industry confidence is slowly returning. Along with higher energy prices, this is driving a sustained improvement and more positive tone for our industry, but it’s not without its challenges,” said Feigel.

Today Universe Machine is moving forward in the best way possible. Kurt Sr., with his decades of experience and wisdom, does his best to pass on that knowledge to his children, grandchildren, and shop employees. Mentoring young people has always been his passion. You can still find him in the office teaching anyone interested in learning tricks of the trade.

“With wise and dedicated mentors like Kurt Sr., the future looks bright as we transition to the next generation,” said Feigel. “We are fortunate to have many intelligent, educated, and hard-working young people in the business. We are continuing to see improvements in the oil and gas sector and hope that this will continue through 2022 and into 2023. As a business, we are not just surviving but thriving and look forward to continuing this trend.”

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

The present application is a non-provisional application that claims priority to a U.S. Provisional Application having U.S. Patent Application Ser. No. 61/893,819, filed Oct. 21, 2013, and U.S. Provisional Application having U.S. Patent Application Ser. No. 62/001,500, filed May 21, 2014, both of which are incorporated herein in their entireties by reference. FIELD

Embodiments of the present disclosure relate, generally, to apparatus and methods for making up and breaking out wellbore tubulars and, more particularly, to an integrated, electric tong system and methods of use at a wellbore. BACKGROUND

In the oil and gas industry, oil field tools, such as tongs or wrenches, are used to grip and rotate joints of tubulars (e.g., casing, drill pipe, other tubulars), particularly during makeup operations (e.g., threadably engaging, screwing together) or break-out operations (e.g., threadably disengage, unscrew). These oil field operations typically require a set of tongs, including an upper tong, which can be used to rotate an upper tubular for threadably connecting the upper tubular to, or removing the upper tubular from, a lower tubular, and a lower tong, which can be used to secure and hold stationary a lower tubular, to prevent its rotation in conjunction with the rotating upper tubular. The upper tong is commonly referred to in the industry as a power tong. The power tong comprises a mechanism or various components for gripping and rotating a tubular, while the body or housing of the power tong remains stationary. The lower tong is commonly referred to in the industry as a backup tong, and is used, as set forth above, for securing and holding a tubular stationary.

Typically, power tongs are hydraulically driven, which can include the use of hydraulic hoses connecting the power tongs to a hydraulic power unit or source for actuating or powering the jaws of the power tong. Valves are typically used to control the flow of hydraulic fluid or oil to the power tongs, for providing power to the power tong and gearbox, which in turn, operates the jaws of the power tongs for closing around a tubular and rotating the tubular. This type of hydraulic system, for powering the power tongs, can generally lack precision in the operation of the tongs, including the control of the speed of the rotation of the tongs and the torque applied to the tubular. In addition, this type of hydraulic system can pose environmental concerns, which can be associated with a leakage or spillage of the hydraulic oil.

In addition, the combinations of hydraulically powered power tongs and backup tongs are cumbersome and heavy tools. As such, hydraulic lift cylinders are typically required for moving and supporting the power and backup tongs, particularly when making up or breaking out a string of tubulars. Although existing units have combined a power tong with a backup tong, the lift cylinders are generally added, when rigging up in the field and operated separately.

Therefore, a need exists for an electric tong system that can be packaged and integrated into a single system, comprising a power tong, a backup tong, and a lift assembly, for minimizing rig-up time and expenses.

A need exists for an integrated electric tong system comprising a power tong, a backup tong, and a lift assembly, in which the motors for the power tong, backup tong and lift assembly can be operated and controlled by the use of a single driver. The electric tong system will enable greater precision in controlling the speed, torque, and direction of the rotation of the power tongs.

A need exists for an integrated electric tong system and methods of use comprising a power tong, backup tong and lift assembly, wherein the backup tong includes automated control for enabling greater precision in the movement of the backup tong components as well as the clamping and gripping of tubulars. In addition, a need exists for an automated electric tong system, comprising interlocking, capabilities for providing remote operation and additional safety features.

A need exists for an integrated electric tong system and methods of use comprising automation for remote operation of the electric tong system and for monitoring and analyzing the turns and torque data.

Embodiments of the present disclosure relate, generally, to an integrated, electric tong system that can be usable for threading and unthreading tubular members at a wellbore. The electric tong assembly can include a frame assembly that can comprise an upper frame and lower frame, wherein the lower frame can include a first vertical member and a second vertical member. At least one actuator can be connected to the upper frame and the lower frame for moving the upper frame with respect to lower frame, and the at least one actuator can be driven by a first electric motor. In an embodiment, the at least one actuator is a linear actuator. In an embodiment, the upper frame can comprise a U-shaped frame that can be moved telescopically in relation to the lower frame.

The electric tong system can further include a backup tong that can be connected to the lower frame, wherein the backup tong can be driven by a second electric motor and can comprise a central opening for receiving a lower tubular member, such that the backup tong can receive, clamp and grip the lower tubular member during threading or unthreading operations. The electric tong system can further include a power tong that can be connected to the backup tong, and the power tong can include a central opening for receiving an upper tubular member. The power tong can be driven by a third electric motor and can be used for gripping and rotating the upper tubular member during threading or unthreading operations. In an embodiment of the electric tong system, a single driver is used for controlling the first electric motor, the second electric motor and the third electric motor of the electric tong system.

The power tong can include a housing that comprises an opening, and a rotary mechanism located within the housing that also comprises an opening. The power tong can further include a plurality of jaws and a ring gear that can be operably connected to the third electric motor of the electric tong system. The power tong housing can include a door that can be rotatably connected to the housing and located proximate to the opening of the housing, wherein the opening of the housing and the opening of the rotary mechanism can align to comprise the central opening of the power tong. The power tong can further include a plurality of sensors that can be usable for sending a signal to actuate the plurality of jaws to secure the upper tubular member, when the openings of the housing and rotary mechanisms are aligned and the power tong door is closed. In an embodiment, the ring gear and rotary mechanism can be used to transfer torque from the third electric motor to the upper tubular member when the plurality of jaws are actuated.

The backup tong of the electric tong system can be usable for clamping and gripping a tubular member during threading and unthreading of the tubular member, for example, during make-up and break out operations. The backup tong can comprise a frame that partially defines a central opening that can receive the tubular member for threading or unthreading of the tubular. A door can be rotatably connected to the frame, and the door can rotate between an open position and a closed position, and partially define the central opening. A first linear actuator can be connected to the frame and to the door for use in rotating the door between the open position and the closed position. A latching arm can be rotatably connected to the frame, wherein the latching arm can latch the door in the closed position, and a second linear actuator can be connected to the frame and to the latching arm, wherein the second linear actuator an rotate the latching arm to latch the door in the closed position, and wherein the rotation of the latching arm progressively increases a force of contact between the door and the tubular member. The second linear actuator can be driven by an electric motor, and sensors can be operably connected to the first linear actuator and the second linear actuator for detecting the positions of the linear actuators and for activation/deactivation of the linear actuators.

The backup tong can further comprise a load cell, which can be located within the frame, and a J-shaped load transfer member that can include a first end connected to the load cell and a second end connected to the second linear actuator. In an embodiment, the load transfer member can be pivotably connected to the frame assembly and can transfer a proportion of force received from the second linear actuator to the capacity of the load cell.

In an embodiment of the backup tong, the frame can include at least one guide plate, and the second linear actuator can comprise at least one protrusion that can intersect with the at least one guide plate of the frame. In another embodiment of the backup tong, the central opening can be further defined by at least one gripping member for gripping the tubular.

Embodiments of the present invention can include a method for removing a plurality of tubulars from a wellbore, wherein the method steps can include: positioning an electric tong system onto a joint of tubulars, wherein the electric tong system can include: a frame assembly; a backup tong comprising a first opening, a first door, and a latching arm; and a power tong comprising a second opening, a second door, and a plurality of jaws. The joint of tubulars ca include an upper tubular connected to a lower tubular with a connector.

The steps of the method can continue by adjusting the frame assembly for aligning the first opening of the backup tong with the second opening of the power tong. The aligned backup tong can grip the lower tubular, and the aligned power tong can grip the upper tubular. The method can further include closing the first door and second door, wherein the first door can trigger a linear actuator to compress the first door against the connector, and the second door can trigger the plurality of jaws to compress the upper tubular against a rotary mechanism and operably connect the rotary mechanism to an electric motor through a low transfer gear. The steps of the method can further include rotating the aligned power tong until the upper tubular is disconnected from the lower tubular, and aligning the rotary mechanism with the second opening for opening the second door. The method can conclude by de-energizing the linear actuator to open the first door, and removing the upper tubular from the wellbore. The method steps can be repeated, as needed, for removing the plurality of tubulars from the wellbore.

In an embodiment, the step of closing the first door can further include actuating a second linear actuator, which can be connected to the frame assembly and to the latching arm, for rotating the latching arm to latch the first door in a closed position. The rotating of the latching arm can progressively increase a force of contact between the first door and the lower tubular.

In an embodiment, the interlock system of the electric tong system can include preventing the rotation of the aligned power tong, for disconnecting the upper tubular from the lower tubular, until after the first door has been closed. In addition, the interlock system can include locking the frame assembly in place and preventing any adjustments thereto until the first door has been opened. Further, the interlock system of the electric tong system can enable the performance of only one of the following steps at a time, including: adjusting the frame assembly, compressing the first door, or rotating the power tong. BRIEF DESCRIPTION OF THE DRAWINGS

In the detailed description of various embodiments usable within the scope of the present disclosure, presented below, reference is made to the accompanying drawings, in which:

FIG. 6A is a perspective, cutaway view of an electric motor and brake assembly for a backup tong in accordance with one embodiment of the present invention.

FIG. 9 is a perspective view of an electric tong system, driver box, and flush mounted spider in accordance with one embodiment of the present invention.

FIG. 15B is a side view schematic of the no side load reaction system for the tong system in FIG. 15A, in accordance with one embodiment of the present invention.

FIG. 15C is a plan view schematic of a horizontal member of the no side load reaction system for the tong system in FIG. 15A, in accordance with one embodiment of the present invention.

FIG. 15D is a plan view schematic of a tong of the no side load reaction system for the tong system in FIG. 15A, in accordance with one embodiment of the present invention.

FIG. 15E is a side view schematic of the reaction post of the no side load reaction system for the tong system in FIG. 15A, in accordance with one embodiment of the present invention.

Before describing selected embodiments of the present invention in detail, it is to be understood that the present invention is not limited to the particular embodiments described herein. The disclosure and description of the invention is illustrative and explanatory of one or more presently preferred embodiments of the invention and variations thereof, and it will be appreciated by those skilled in the art that various changes in the design, organization, order of operation, means of operation, equipment structures and location, methodology, and use of mechanical equivalents, as well as in the details of the illustrated construction or combinations of features of the various elements, may be made without departing from the spirit of the invention.

As well, the drawings are intended to describe the concepts of the invention so that the presently preferred embodiments of the invention will be plainly disclosed to one of skill in the art, but are not intended to be manufacturing level drawings or renditions of final products and may include simplified conceptual views as desired for easier and quicker understanding or explanation of the invention. As well, the relative size and arrangement of the components may differ from that shown and still operate within the spirit of the invention as described throughout the present application.

Moreover, it will be understood that various directions such as “upper”, “lower”, “bottom”, “top”, “left”, “right”, “inward”, “outward” and so forth are made only with respect to explanation in conjunction with the drawings, and that the components may be oriented differently, for instance, during transportation and manufacturing as well as operation. Because many varying and different embodiments may be made within the scope of the inventive concept(s) herein taught, and because many modifications may be made in the embodiments described herein, it is to be understood that the details herein are to be interpreted as illustrative and non-limiting.

Embodiments of the present disclosure relate, generally, to an apparatus and methods for making up and breaking out tubular joints and, more particularly, to an integrated, electric tong system and methods of use at a wellbore. The integrated electric tong system comprises a power tong, a backup tong, and a lift system (e.g., two actuators, a gearbox, a brake, an electric motor, interconnecting components and a telescopic frame), which are integrated into a single package and operated by electrical motors that can be controlled by a single driver.

The apparatus can include the use of switchgears and contactors for enabling the use of the single driver to control and operate the individual electric motors of the power tong, backup tong, and the lift system, as described above. The driver comprises the electronics and firmware required to control the speed and direction of the electric motor(s), and the driver can be housed in a separate aluminum box (i.e., driver box) that can be positioned in a safe area (i.e., nonhazardous area), away from the electric tong system.

The backup tong is located below the power tong of the electric tong system, and comprises a pneumatic cylinder for operation of a backup door. An electric motor can be mounted on the backup tong for operating a latch, located on the backup tong, which can be used for locking the backup door and applying a clamping force to a lower tubular during make-up or break-out operations. While the backup tong clamps and holds the lower tubular stationary, the power tong can rotate the upper tubular, which allows the power tong to apply torque to the connection joint between the upper tubular and the lower tubular.

The backup tong, which is used for the clamping of the lower tubular, can comprise a backup door(s) that can be closed pneumatically (i.e., use of a pneumatic cylinder) and tightened electrically. Specifically, an electric linear actuator can be used for applying a clamp force to the lower tubular, during make-up or break-out of the tubular joint connections. The clamp force can be sensed and measured by an electronic tension load cell that can be located in the backup tong and connected to a “J-shaped” member that can be pivotally connected to the backup case. A first end of the “J-shaped” member can be connected to the electrically-operated linear actuator, while a second end of the “J-shaped” member can be connected to the electronic tension load cell. The “J-shaped” member can be a lever that is used for proportioning the force from the electric linear actuator to the capacity of the electronic tension load cell.

The pneumatic backup door cylinder can comprise sensors, which can be used to detect when the clamping cylinder should actuate. The pneumatic backup door cylinder can further comprise a magnetic piston and two reed switches, wherein the reed switches are closed when the magnetic piston is moved near to them. When the backup door is closed, via the pneumatic cylinder, the reed switch, which is near the rod end of the pneumatic backup door cylinder, can become activated and the electric motor, which actuates a linear actuator, can become energized. The other reed switch can alert the backup control system when the backup door is open. The reed switches can also serve as position sensors on the pneumatic backup door cylinders. During an end-of-stroke condition, the electric linear actuator becomes de-energized, and a linear distance sensor, located on the piston end of the electric linear actuator, can be used for sensing rod position and, hence, an end-of-stroke condition.

In an embodiment of the electric tong system, the power tong can be located above the backup tong, and can be a conventional or hydraulic tong that is retrofitted to operate via an electric motor. The motor operating the power tong can be a servo-type motor that provides precise application of torque and speed. In an embodiment, the power tong is attached to a frame, which can be extended and retracted by an electrically operated lift system, as described above, for allowing vertical movement of the electric tong system.

Unlike conventional tongs, the automation of the electric tong system enables the operation of a selected sequence of functions through a single actuation (i.e., a push of a button can close the power tong door, latch the backup door and rotate the power tong). An operator box, which can be located at various positions on or about the electric tong system, including on the power tong, at the bottom of the tong, or on a floor stand, and remotely positioned with respect to the electric tong system, can be used to operate all of the functions on the electric tong system, including tong door open/close, backup open/close, lift up/down, high/low gear, rotate/cage plate align, manual/automatic mode, and make/break direction. In an alternative embodiment, the electric tong system can be operated remotely. A computer or computerized system can be used to monitor, receive and analyze the functions and output of the power tong, backup tong, and the lift cylinder of the electric tong system.

The automated and/or remote operation of the electric tong system provides many unique and/or safety features, including: (a) operation of the electric tong system from the rig floor or remotely (hand controller) to eliminate the need for an operator to be located on an operator stand (e.g., scaffolding) and the potential danger to the operator; (b) greater precision with regard to the control of the speed and direction of the motor(s) for the power tong and backup tong; (c) better torque control of the joint connection; (d) elimination of hydraulic power usage and related environmental issues; (e) safer operation during make-up and break-out operations by capability of an enhanced interlocking system; (f) Torque Turn system built into electric tong system for monitoring and analyzing data regarding the number of turns and the torque amount, with or without the use of a computer to record connections; (g) the transport footprint is about the same as a standard tong apparatus; (h) no side load reaction system; and (i) the ability to retrofit a conventional hydraulic tong with an electric motor and a gearbox to form the electric tong system.

Referring now to the drawings and more particularly to FIGS. 1-2, the Figures show an embodiment of a tong system (10) for making up or breaking out a string of tubulars, such as casing, drill pipe, or other tubulars. In this embodiment, the tong system or electric tong system (10) comprises a frame (12) that can comprise a generally U-shaped member (14) in telescoping engagement with frame members (16 a, 16 b), which can extend vertically in a generally parallel configuration. The frame may comprise horizontal base members (18 a, 18 b) that allow the electric tong system 10 to stand upright. The lower ends of the frame members (16 a, 16 b) may be rigidly attached to the base members (18 a, 18 b), while the upper ends of the frame members (16 a, 16 b) are attached to the U-shaped member, which can be connected to a lifting bracket (15). The frame members (16 a, 16 b) can be tubular or solid. Alternate embodiments of the frame assembly for the electric tong system are shown in FIGS. 16 and 17. The tong system (10) may be lifted via lifting lugs (20) through an adjustment screw formed on a top portion of the lifting bracket (15).

In this embodiment, a backup tong (30) is mounted to horizontal support beam(s) that attach(es) to the frame members (16 a, 16 b) and/or base members (18 a, 18 b). In an alternate embodiment, the backup tong can attach to a second or lower U-shaped member, which can attach to the lower end of the vertical frame members (16 a, 16 b) and/or the base members (18 a, 18 b). The backup tong (30), as shown in this embodiment of the electric tong system, will be further described in subsequent Figures. The power tong (50) and backup tong (30) can be connected to each other by a post (52) (e.g., torsion post), extending therebetween.

Conventional power tongs can include an “open throat” tong, in which the body and ring gear of the tongs have a window or opening for permitting a pipe or other tubular to be moved into and out of the central opening of the ring gear. Other conventional power tongs include a closed throat configuration, in which a pipe or other tubular must be inserted longitudinally into a ring gear opening. Open throat tongs typically have a gear train comprising two or more idler gears, while closed throat tongs may omit the idler gear(s) and drive the ring gear directly by the pinion gear. The idler gears are rotated, generally, by a gear that is rotated by a rotary power source, typically a hydraulic motor. The different gears, taken together, form a gear chain.

Power tongs generally comprise a housing, which can have a vertical slot with a vertical axis, which can be occupied by a pair of pipe or tubulars that are to be assembled or disassembled, during oil field operations. This type of power tong will generally have cam surfaces, disposed on the rotary gear, for moving the jaws, of a pair of jaw assemblies, in contact with a tubular. For example, drill pipe tongs often use hydraulic cylinders to engage the pipe, wherein a first set of hydraulic cylinders can include a pair of jaw assemblies usable to grip the pipe. The drill pipe tongs can also include a second set of hydraulic cylinders usable to rotate the pipe. A door, which is pivotally connected to the housing, may be closed during operation of the power tong. Each jaw assembly of a drill pipe tong can be powered, during a make-up or break-out operation, by one of said hydraulic cylinders, for gripping a first pipe and, thereafter, for positioning a second pipe for rotation. The pair of jaw assemblies can be mounted within cylindrical recesses provided, respectively, in the upper and lower portions of the housing. A pair of upper, laterally extending chambers and a pair of lower, laterally extending chambers can further comprise the housing.

In another arrangement, a conventional power tong can comprise a rotary, which is rotatably mounted in the housing. Relative rotation between the rotary and the housing can be inhibited by a device, such as a bolt, which is located on the power tong.

Other conventional power tongs can comprise two “passive” jaws that are fixed in the power tong, and a third “active” jaw that is advanced towards or retracted away from a pipe as desired. The active jaw may be mounted in a jaw holder, the radial extremity of which is provided with a roller which rests on a cam surface formed on a rotary. When the rotary rotates relative to the jaw holder, the roller rides along the cam surface and urges the jaw against the pipe with a force, which is a function of the slope of the cam surface. Once the jaw is firmly applied, the pipe and rotary rotate in unison. Power tongs may further use toothed dies, which are carried by the jaws, to transmit torque to the tubular connection. In yet another typical arrangement, the power tong may comprise a plurality of rollers that grip a pipe. The power tong may further comprise a belt(s), chain, and/or sprockets that function to rotate rollers or the rotary, depending on the arrangement.

Continuing with regard to the embodiment of the electric tong system, as shown in FIGS. 1 and 2, the embodiment includes the backup tong connected to the power tong by a lower end of a torsion post (52), which, as shown in FIG. 1, extends through a proximal end of the backup tong (30) and fixedly engages therewith. As shown in this embodiment, two support beams (53 a, 53 b) can connect the backup tong to the base members (18 a, 18 b). Two lift cylinders (54 a, 54 b) are shown extending between the base members and the U-shaped frame member (14). As depicted in FIG. 1, the lower ends of the lift cylinders (54 a, 54 b) may be connected to the base members (18 a, 18 b), while the upper ends of the cylinders are connected to the U-shaped frame member (14), whereby the extension of the lift cylinders (54 a, 54 b) can vertically extend the U-shaped frame member (14) from within the frame members (16 a, 16 b). The terms “backup” and “backup tong” are used interchangeably throughout this application for referring to the backup tong.

An electric motor (56, shown in FIG. 2), for example a servo-type motor, can be used to operate the power tong (50) for rotating or spinning a tubular during make-up or break-out operations. Once the lower tubular (e.g., casing, drill pipe or other tubular not shown) is gripped by the backup tong and the upper tubular is shouldered, the electric motor (56), located on the power tong (50) can apply high torque at a low speed to make-up a joint connection between the upper and lower tubulars. The electric tong system can comprise a first electric motor ((60), shown in FIG. 2) for moving the upper frame with respect to the lower frame for lifting purposes, a second electric motor ((82), shown in FIGS. 6 aand 6B) usable for back-up tong (30, shown in FIG. 2) operations, and a third electric motor (56) usable for power tong (50) operations. The electric motor (56), located on the power tong (50), can also operate to apply high torque at a low speed to break-out a joint connection, or operate at high speed and a low torque to unthread a tubular from a joint connection. Typically, for a 7⅝″ electric tong, the low gear provides a torque of about 30,000 ft-lb (Int.)/8,570 ft-lb (Cont.) at a speed of 5 RPM, while the high gear provides a torque of 10,000 ft-lb (Int.)/2,860 ft-lb (Cont.) at a speed of 25 RPM. Such a tong can weigh about 3000 lbs., have overall dimensions of 36″×60″×80″, and be classified for a Zone 1, Class 1, Division 1, Operating Area.

Referring to FIG. 2, the Figure shows an embodiment of the electric tong system wherein a motor, for example an electric motor (60) as shown in FIGS. 1 and 2, can be mounted to a horizontal upper portion of the U-shaped member (14). In this embodiment, the electric motor (60) drives a shaft (62), via an intermediate transmission, wherein the shaft, in turn, actuates the lift cylinders (54 a, 54 b). The depicted lift cylinders include actuators, (e.g., ball screw type linear actuators), each comprising an internal ball screw extending through the external cylindrical body, wherein rotation of an internal worm gear rotates the ball screw, causing it to extend from the cylindrical body.

In another embodiment of the electric tong system and as shown in FIG. 2, the lift cylinders can include an internally threaded sleeve, which can extend longitudinally through a cylindrical body, wherein rotation of the sleeve can force an internal shaft to extend from the cylindrical body. When the electric motor (60) is energized, the gear assembly (64) can engage the internal shaft of each of the lift cylinders (54 a, 54 b), causing the internal shafts of the lift cylinders (54 a, 54 b) to extend. As the internal shafts of the lift cylinders extend or telescope outwardly, the lift cylinders (54 a, 54 b) can extend the U-shaped member. Alternatively, as shown in FIG. 2, as the internal shafts of the lift cylinders retract or telescope inwardly, the lift cylinders can retract the U-shaped member into the frame members (16 a, 16 b). Therefore, when lifting lugs (20) of a lifting bracket (15) are attached to an external lift (e.g., crane or other external lift, not shown), the electric tong system (10) can be lifted or lowered to a desired height by retracting or extending the internal shafts of the lift cylinders (54 a, 54 b).

As further depicted in FIGS. 1-2, an enclosure or box (55) may be mounted to the frame (12) of the electric tong system to house such components as motor contactors, resolver relays, barriers, input/output modules, a controller, an alpha-numeric display, and several switches. The controller can receive input from an operator box, located on the electric tong system or remotely, such as on a stand on the rig floor, and the controller can send commands to all outputs for various operations and functions of the electric tong system. The operator box can comprise seven toggle switches mounted to the box for operating various functions, including open/close of power tong door, open/close of backup tong door, up/down movement of lift assembly, high/low gear operation, rotate/cage plate alignment, changing from manual to automation mode and vice versa, and change from make-up to break-out direction and vice versa.

FIGS. 3-5 depict an embodiment of the backup tong (30). As depicted in FIGS. 3 and 4, the

8613371530291

8613371530291