power tong operator texas factory

Magnum Manufacturing. has successfully mastered the design and manufacturing processes of creating a better hydraulic tong. By decreasing the weight of the tong and increasing the power, Magnum Power Tongs out perform the torque to weight ratio of any competitor. Constructed of premium quality materials, Magnum"s unique system delivers safe, efficient, and reliable performance on every job. Find out more..

Premiere, Inc. CRT / PRT Casing Equipment includes patent pending efficient equipment as Single and Dual Stage Diesel Power Units (DPU), the Magnum Manufacturing exclusive Multi-Grip Bowl and more. Technology at the Intersection of Obsession & Innovation. Find out more..

Magnum Manufacturing has released its latest invention in cutting edge tubular running technology. The Magnum Alignment Tool connects to any top drive and allows the operator to remotelyadjust the position of each joint of casing or tubing directly over the well bore.... Find out more..

The Magnum Tubular Flow Tool allows the operator to fill or circulate casing while it is being run into the well. Due to the large flow area it is designed to flow back conditions when float equipment is not being utilized. Our oilfield equipment is designed with safety in mind. Find out more..

Looking for a job? We are hiring! We have a variety of positions open, including Tong Mechanics, CNC Machinist, Fork Lift Driver, Secretarial – Eng. Dept, and Invoicing Clerk. We offer excellent benefits, including 401K Matching, Health Insurance, Life Insurance, and Paid Vacation / Holidays. Apply today by emailing jobs2@eckel.com or apply in person at Eckel Manufacturing Co., Inc., 8035 North County Road West, Odessa, TX.

2018 marks the 60th anniversary for Eckel. We are the oldest continuous leading manufacturer of world-class hydraulic power tongs and trusted for reliability, safety and high performance.

The Eckel Model 25 Hydra-Shift® HS-85 features a two-speed motor with two-speed gear train, producing 60,000, 80,000 and 125,000 ft-lb of torque respectively in low-low, at 2,500 psi. This tong easily handles ultra-heavy casing strings from 9 5/8 inches to 25 inches.

The Eckel Model 25 Hydra-Shift® HT-200 Tri-Grip®introduced features a two-speed motor with two-speed gear train, producing 200,000 ft-lb of torque respectively in low-low, at 2,500 psi. This tong easily handles ultra-heavy casing strings from 9 5/8 inches to 25 inches - featuring a three head Tri-Grip®biting system design which like the Tri-Grip®New Revised Version Backup encompasses the tubular to apply an evenly distributed gripping force. The additional head in the tong reduces the risk of radial deformation, die penetration, marking, and wear of the tubular by 1/3 at extreme torques...

The new 7.25 HS HT-80 for Drill Pipe and High Torque Casing Tong takes on the toughest job with make-up and break-out of drill pipe, drill collars and high torque casing with a maximum torque of 80,000 ft-lbs. The 7.25 HS HT-80 is available with a two-speed Hydra-Shift® motor coupled with a two-speed gear train providing (4) torque levels and (4) RPM speeds. The variable speeds can slowly or quickly spin tubulars 2-3/8 through 7 1/4 inch as necessary. Having exceptional gripping capabilities with rig dies for drill pipe or wrap-around dies that securely encompass the tubular limit potential for damage. The 7.25 HS HT-80 is also available with either Eckel Pyramid Fine Tooth dies or True-Grit dies. The 7.25 HS HT-80 is another of our tongs models that exceeds the competition in its class.

When applications demand the combination of size and high torque output up to 120,000 ft-lb, the Eckel Model 20 Hydra-Shift® UHT handles pipe from 7 inches to 20 inches. By utilizing a two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor, the operator has a more flexible choice of torque/rpm"s to work with during make-up or break-out.

The Eckel Model 14 Hydra-Shift® handles pipe from 4 inches to 14 inches and incoporates the Hydra-Shift® technology which provides smoother operating environment and a wider selection of torque/RPM"s that are available to the operator. The 14 Hydra-Shift® is capable of delivering 35,000 ft-lb of torque in low-speed, low-gear. Also available with hydraulic Tri-Grip®backup.

The Eckel Model 30 Hydra-Shift® features a two-speed motor with a two-speed gear train, producing 130,000 ft-lb of torque in low-low at 2,500 psi. Weight 9,000 pounds, this tong easily handles ultra heavy casing strings from 14 inches to 30 inches.

The Eckel Model 14 Hydra-Shift® handles pipe from 4 inches to 14 inches and incoporates the Hydra-Shift® technology which provides smoother operating environment and a wider selection of torque/RPM"s that are available to the operator. The 14 Hydra-Shift® is capable of delivering 35,000 ft-lb of torque in low-speed, low-gear. Also available with hydraulic Tri-Grip®backup.

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

For casing up to 22 inches, here"s a tong that has strong torqueing ability and will handle pipe sizes down to 7 inch. The tong utilizes a two-speed motor and a two-speed gear train, allowing the operator to correctly adjust the tong for the optimum torque and RPM needed for the current application. Maximum torque for the 22 Hydra-Shift® is 80,000 ft-lb.

For casing up to 20 inches, here"s a tong that combines surprising speed with an ability to handle smaller sizes economically (as small as 7 inches). The 20 Standard reaches peak efficiency at just 38 horse power input, thus requiring no "souped-up" power unit. Available torque: 42,000 ft-lb.

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 HS HD provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 Heavy Duty provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

The Eckel Model 25 Hydra-Shift® features a two-speed motor with two-speed gear train, producing 60,000 ft-lb of torque in low-low, at 2,500 psi. Weighing 6,290 pounds, this tong easily handles ultra-heavy casing strings from 9 5/8 inches to 25 inches.

A maximum torque up to 25,000 ft-lb and a small foot print design this tong meets your application requirements. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and rpm"s to work with during make-up or breakout. The 9 5/8 Hydra-Shift® HD is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

The Eckel 870 DPT combine power tong and Wedg Drive Tri-Grip®Backup, providing a single piece of equipment to replace several...one smooth continuous operation instead of numerous time-wasting steps at each connection...and a quick, safe means of tripping, replacing methods that endanger crew members and pipe string a like. For drill strings up to 8 inch collars, the model 870 offers over 75,000 ft-lb of torque for break-out and make-up operations, plus ample speed for spinning joints.

The Eckel Model 24 UHT features a two-speed motor with single-speed gear train, producing 95,000 ft-lb of torque in low speed, 25,000 ft-lb in high, both at 2,500 psi. Weighing 8,000 pounds, this tong easily handles ultra-heavy casing strings from 13 3/8 inches to 24 inches.

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

When applications require the combination of size and torque up to 18,000 ft-lbs, the Eckel 9 5/8 Hydra-Shift® (Narrow Body) meets these requirements. The narrow body design allows this tong to easily operate on smaller rig configurations. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and RPM"s to work with during make-up or breakout. The 9 5/8 Hydra-Shift® is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

When applications require the combination of size and torque up to 18,000 ft-lbs, the Eckel 9 5/8 Hydra-Shift® (Narrow Body) meets these requirements. The narrow body design allows this tong to easily operate on smaller rig configurations. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and RPM"s to work with during make-up or breakout. The 9 5/8 Hydra-Shift® is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

The 14 HS HT Tri-Grip®Tong is used for making up and break out casing and risers. Capable of handling tubulars from 4 in. to 14 in. (101.6 - 355.6 mm) in diameter with a maximum torque of 135,000 ft-lbs (183035.4) of torque capacity. A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. The tong features a three head - Tri-Grip®biting system design which like the Tri-Grip®Backup encompasses the tubular to apply an evenly distributed gripping force. The additional head in the tong reduces the risk of radial deformation, die penetration, marking, and wear of the tubular by 1/3 at extreme torques. The tong performs exceptional gripping capabilities with either Eckel True-Grit dies or Pyramid Fine Tooth dies.

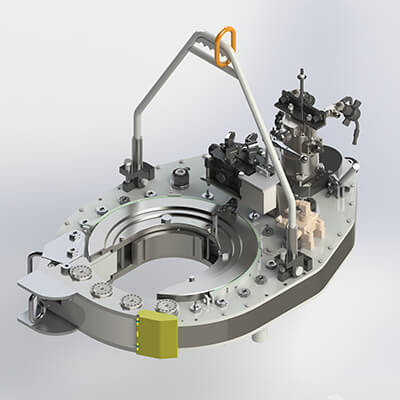

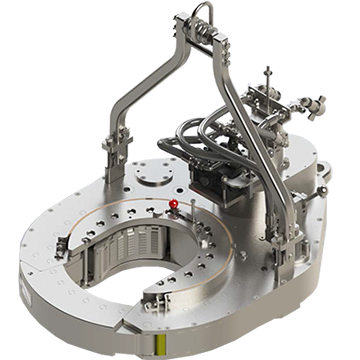

The Eckel Top Drive Casing Tong is a tool developed for use on hydraulic top drive rigs to provide a high quality connection while reducing tubular damage and providing a safer enviroment for crews. With an operating capacity of 4 1/2 inch through 10 5/8 inch, is connected to the output stem of the power swivel. After installation the tong becomes an integral part of the swivel, raising and lowering as a unit and transfering the power swivel"s RPM and torque to the pipe/connection. A guide attached beneath the top drive tong simplifies alignment of the collar within the tong. Once the collar of the pipe is enclosed within the top drive tong, the tong will grip the collar by operating the power swivel. Torque and rotational speed are controlled through the operation of the power swivel. Reversal of the power swivel will cause the tong jaws to release. Tong jaws are spring loaded to retract away from the collar. Utilizing three gripping jaws and a patented Eckel Cam Biting System to grip the pipe collar. The same type of proven biting system found in the industry leading Eckel Power Tongs. These jaws are spaced evenly about the circumference of the collar to provide even distribution of the gripping forces

The Oil & Gas Industry has needed a specialized power tong with an integral backup. This tong is sized small enough and has the right amount of controlable torque output. It is designed so as to properly grip small tubulars such as small macaroni type strings of tubing.

This tong incorporates Eckel"s Hydra-Shift® technology for smooth tranfers of power and speed directly to the tubular. Special built in torque control valving allows the operator to pre-set the maximum desired torque for the connection. This tong also incorporates our new Radial Lock Door. If you are looking for a tong for this lighter type of word look no further.

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

When applications require the combination of size and torque up to 18,000 ft-lbs, the Eckel 9 5/8 Hydra-Shift® (Narrow Body) meets these requirements. The narrow body design allows this tong to easily operate on smaller rig configurations. A two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor provides the operator a flexible choice of torque and RPM"s to work with during make-up or breakout. The 9 5/8 Hydra-Shift® is capable of handling a range of pipe from 2 3/8 inches to 9 5/8 inches.

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 Heavy Duty provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

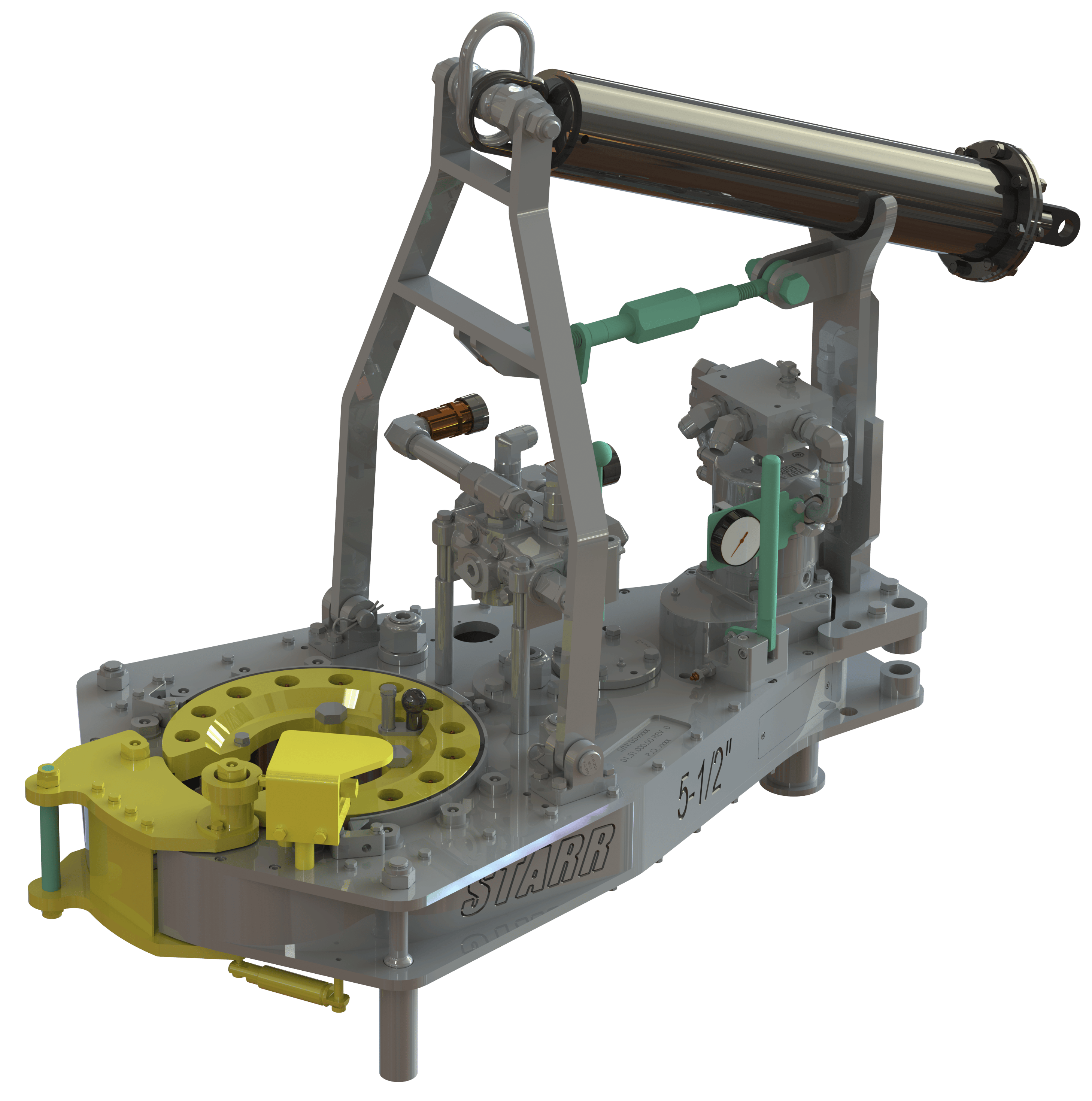

Compact Size...Big Torque...if this is what you are looking for in a power tong, look no further. Our 5-1/2 Hydra-Shift® is sized smaller in width than our 5-1/2 Standard model. Like all of our newly developed tongs, the 5-1/2 incorporates the Hydra-Shift® technology, allowing the operator to shift from high speed to low speed without having to manually shift the tong. You will see many years of trouble free operation, not to mention the smoother hydraulic shifting. With two models to choose from, Eckel has the right 5-1/2 Hydra-Shift® for your needs. The 5-1/2 Hydra-Shift® LS with a two-speed motor and a single-speed gear train is the original 5-1/2 Hydra-Shift® which has gained wide acceptance in the industry. Slide heads with rig dies are available for handling drill pipe tool joints.

Special applications and tough requirements demanded that we respond with a new tong designed and built with today"s pipe handling challenges in mind, the 8 5/8 Hydra-Shift® HT. By utilizing a two speed mechanical shift transmission in conjunction with the two speed Hydra-Shift® motor, the operator has a more flexible choice of torque/RPM"s to work with during make-up or break-out. At the beginning of the job, the operator will choose a tong gear ratio that is most appropriate for the current tubular connection and shift the variable speed motor handle into high or low as required. This tong also offers sliding heads with wrap-around dies which provides an evenly applied pressure to the pipe and a greater pipe gripping coverage which in return reduce tubular damage. This tong not only offers the operator the speed options down to the slow speed parameter now demanded by the pipe manufactures and oil companies, it also has the option of speeds of 100 RPM"s when required. Available torque: 40,000 ft-lb

When application demand a wide range of sizes, this tong handles pipe sizes 2 3/8 inches all the way to 7 5/8. Built around the 7 5/8 Standard, the 7 5/8 Heavy Duty provides a thicker rotary gear for more added strength, an additional idler gear, a larger pinion gear, and stronger bearings for load bearing capacity and durability.

Eckel Tri-Grip®an industry standard for reliable backup in make-up and break-out of tubular connections and optionally supplied with Eckel tongs. Eckel backups utilize hydraulic cylinders and a head arrangement that insures slip-free operation. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection. The Tri-Grip®uses two pivoting heads and one stationary while the cam backup uses two head to grip tubulars using a head and cam configuration that is similar to the method the tong grips tubulars.

The Eckel Closed Mouth Tongs uses three sliding heads with each head equipped with a wide angle wrap-around die. This provides a maximum gripping area of 342 degrees; on the pipe. The CMT"s utilizes the Hydra-Shift® shifting technology which allows the operator to shift from high to low speed without stopping the tong. Reversing the pipe rotation is effortless and done simply by pulling the tong control in the opposite direction. There is no need to physically take out the jaws and turn them over as there is with other brands of closed head tongs. The CMT"s also come with an optional backup that utilizes the same heads/dies as the tong.

The Model 4 1/2 UHT-13 is rugged, light weight tong capable of providing 8,500 ft-lb of torque at 2,500 PSI. The tong will handle pipe from 1.050 inches to 4 1/2 inches. A notable feature is the Eckel patented quick-change sliding head biting system that compensates for worn or under gauge pipe. Also available with an optional rod package for sizes 5/8 inch through 1-1/8 inches and your choice of manual type or hydraulic type backups.

For casing up to 17 inches, here"s a tong that combines speed and the ability to handle smaller sizes economically. If you are running 17 inch casing, give this tong a try. The 17 Hydra-Shift® features the two-speed motor and the two-speed gear train which allows for multiple selections of torque or RPM, not to mention the smoother operation of the tong.

The Eckel Model 14 Hydra-Shift® handles pipe from 4 inches to 14 inches and incoporates the Hydra-Shift® technology which provides smoother operating environment and a wider selection of torque/RPM"s that are available to the operator. The 14 Hydra-Shift® is capable of delivering 35,000 ft-lb of torque in low-speed, low-gear. Also available with hydraulic Tri-Grip®backup.

The Eckel 3500 Hydra-Shift® DTT (Dual Tubing Tong) provides fast, easy running on dual strings of 3 1/2 inch or smaller tubing. It grabs from the side, or head-on. Go ahead and torque it up; this tong is Eckel tough. And speed shifts are no problem, thanks to a patented Hydra-Shift® concept that eliminates clutching. The Model 3500 DTT Hydra-Shift® is packed with all the features you"ve come to expect from Eckel: quick-change sliding heads, self-aligning open throat.

Except for added torque (up to 24,000 ft-lb) and expanded pipe capacity (from 4 to 13 3/8 inches), the 13 3/8 Standard tong offers the same basic engineering and design as the smaller, lighter Model 10 3/4. Highly recommended where applications demand the ultimate in size range and torque output.

The big, capable Model 36 UHT easily produces 100,000 ft-lb of torque for makeup or break-out operations involving casing in sizes 16 inches through 36 inches. Weighing approximately 13,000 pounds, this casing tong is 81 inches wide and 135 inches in length. A two-speed motor delivers 16 RPM in high, 3 1/2 RPM in low range, both at 70 GPM.

The Eckel 870 DPT combine power tong and Wedg Drive Tri-Grip®Backup, providing a single piece of equipment to replace several...one smooth continuous operation instead of numerous time-wasting steps at each connection...and a quick, safe means of tripping, replacing methods that endanger crew members and pipe string a like. For drill strings up to 8 inch collars, the model 870 offers over 75,000 ft-lb of torque for break-out and make-up operations, plus ample speed for spinning joints.

Eckel has been at the forefront of this developing technology with the development of larger wrap-around type dies for many of its tong models. Wrap-Around Dies are symmetrically spaced from each other at all times insuring an equally distributed load on the tubular.

An excellent choice where applications demand the combination of size range and high torque output, the Eckel Model 14 UHT handles pipe from 4 inches to 14 inches. Upgraded in design and performance over the Model 14 HS, this tong is capable of delivering 65,000 ft-lb of torque. Also, available with Wedge Drive Tri-Grip®backup which handles pipe from 4 inches to 15.5 inches.

The Model 5 1/2 Standard is the first open-throat design in its size range to generate 12,000 ft-lb of available torque. Versatility is the name of the game here as this tong works well whether powered by a workover rig or a portable casing tong power unit. Options include manual backup or cam-type hydraulic backups.

When applications demand a wide range of sizes, the 7-5/8 Standard tong handles pipe sizes 2-1/16 inches all the way to 7-5/8. Its rugged design is based upon knowledge gained from the 5-1/2 model...combining an extremely compact, high torque concept with added versatility. Options include either manual backup or Tri-Grip®backup. Available torque: 15,000 ft-lb

For casing up to 20 inches, here"s a tong that combines surprising speed with an ability to handle smaller sizes economically (as small as 7 inches). The 20 Standard reaches peak efficiency at just 38 horse power input, thus requiring no "souped-up" power unit. Available torque: 42,000 ft-lb.

The Eckel Model 24 UHT features a two-speed motor with single-speed gear train, producing 95,000 ft-lb of torque in low speed, 25,000 ft-lb in high, both at 2,500 psi. Weighing 8,000 pounds, this tong easily handles ultra-heavy casing strings from 13 3/8 inches to 24 inches.

A two-speed Hydra-Shift® motor coupled with a two-speed gear train provides (4) torque levels and (4) RPM speeds. Easily shift the hydraulic motor in low speed to high speed without stopping the tong or tublar rotation, saving rig time.

A patented door locking system (US Patent 6,279,426) for Eckel tongs that allows for latchless locking of the tong door. The tong door swings easily open and closed and locks when torque

is applied to the tong. When safety is important this locking mechanism combined with our safety door interlock provides unparalleled safety while speeding up the turn around time between connections. The Radial Door Lock is patented protected in the following countries: Canada, Germany, Norway, United Kingdom, and the United States.

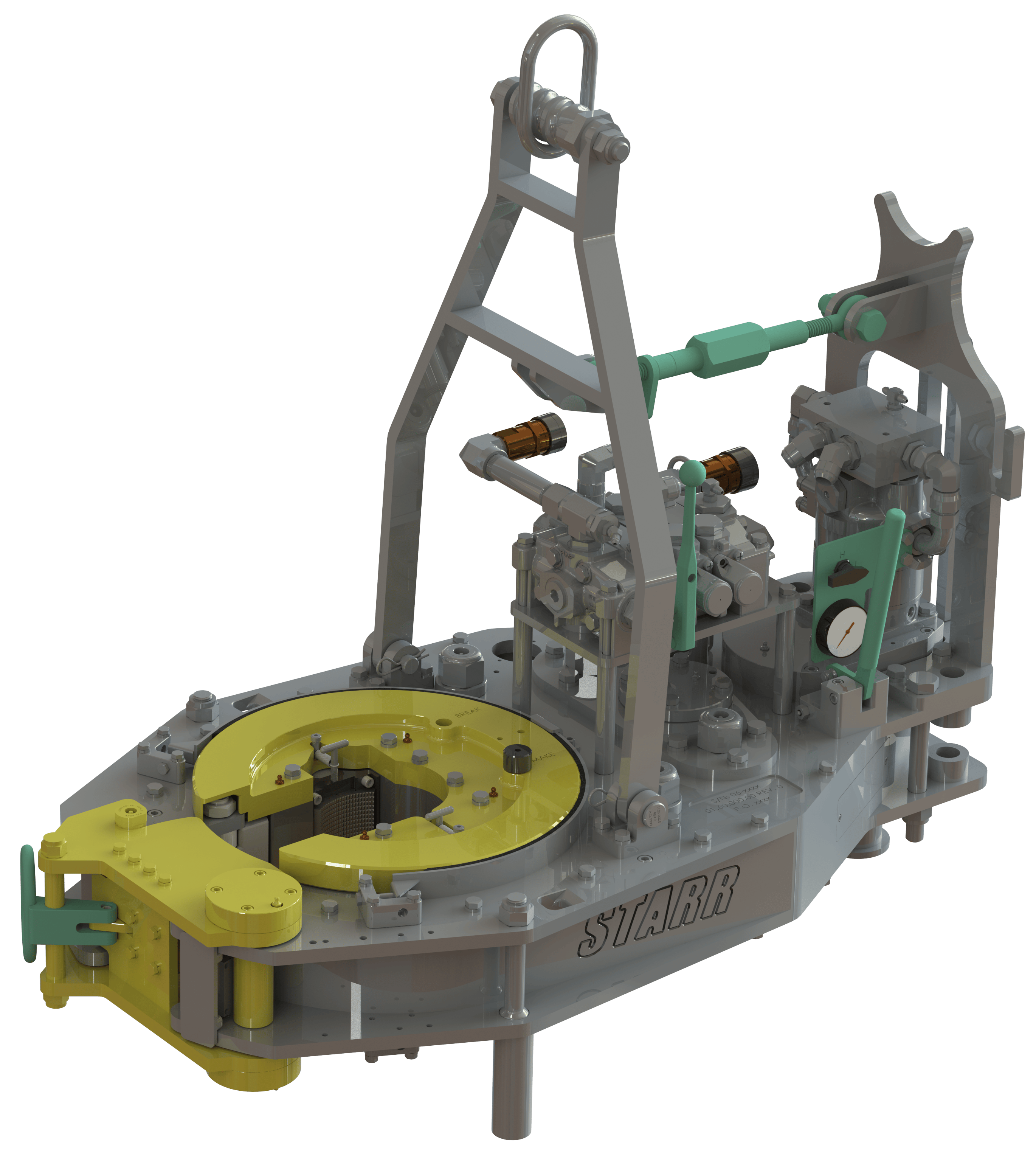

The field proven Tri-Grip® Backup features a three head design that encompasses the tubular that applies an evenly distributed gripping force. The Tri-Grip®Backup provides exceptional gripping capabilities with either Eckel True Grit® dies or Pyramid Fine Tooth dies. The hydraulic backup is suspended at an adjustable level below the power tong by means of three hanger legs and allowing the backup to remain stationary while the power tong moves vertically to compensate for thread travel of the connection.

I am chairman of the board, president and chief executive officer of Eckel International, the largest global providers of innovative and high performance hydraulic power tongs for the oil and gas industry. I am a second-generation family member involved in manufacturing of tongs. In 1993, as Eckel’s president, I launched an initiative to further reach out to Russia’s oil & gas needs. Today, I am directly responsible for the overall operations of the company, sales, and new market initiatives.

Since 1958 Eckel has been supplying power tongs to the worlds O&G industries– but how long have you been doing business in Russia and what specific solutions do you offer to the region?

Eckel specializes in the development of hydraulic power tongs for make-up and break-out of tubulars, with over 60 years of tubular connection experience. Our industry leading technology advancements are in some respects, a reflection on the industry requirements and their needs. Eckel has been in the process of designing tongs that required very high torques, advanced safety features, and automation.

Eckel in-house heating provides quality tempered steel while observing strict industry standards. This process assures high quality and rugged durable parts within Eckel power tongs. Eckel has won a world-wide reputation of providing first-class products that deliver years of trouble free service. Our tongs have operated trouble free in the harsh cold conditions of Western and Eastern Siberia and in the Far Northern Regions. Eckel’s hydraulic power units have a proven track record in some of the harshest surroundings in Russia such as the extreme hot and cold conditions of Russian and offshore environments.

Eckel has provided more than 500 Hydraulic Power Tongs to oil and gas companies and drilling contractors in Russia. In Russia, as well as in many other countries, the use of Corrosion Resistant Alloys (CRA) chrome tubulars are becoming more popular. Eckel is an industry leader in this specialized field tubular connections offering a line CHROMEBOSS® tongs along with Eckel Non-Marking True Grit® dies. True Grit® Dies utilize Tungsten Carbide grit coating which provides many more points of contact on the surface of the tubular than standard Pyramid Fine Tooth dies provide. Penetration depth less than half the depth that is permissible by the American Petroleum Institute (API). Eckel’s True Grit® dies use a dense Tungsten Carbide coating that is a metal like substance which does not flake or sheer off the face of the die. Operational on-site tests have shown that the life time of Eckel True Grit® wrap-around dies is three times longer than competing abrasive powder coated dies. The above equipment and components have been working in Russia several years and proved its advantages.

The hydraulic power tong market is very competitive in Russia, with both local and international suppliers competing for business. Why should a drilling contractor or operator consider using Eckel equipment?

Eckel has over 60 years of experience in this area, and is known for quality and reliability. Many of these tong manufacturers use the old Foster and Hillman Kelly that are 30-year-old designs. Eckel is at the forefront of this industry designing tongs that can handle today’s premium high torque connections. Our tong designs evolved to incorporate additional safety features, automation, and performance. Our new 7.25 HSHT-80 Drill Pipe / Casing and 9-7/8 HS-60 Casing tongs incorporates many of these features.

Eckel has been the leader in development of tubular gripping such as the development of larger wrap-around type dies for many of its tong models. Depending on the application, Eckel offers a coarse tooth, pyramid fine tooth, and our proprietary True Grit dies. Dies are available as rig die style and for thinner wall tubulars where point loading is a concern we offer wrap-around dies. All Eckel equipment is produced at our Odessa, Texas USA manufacturing facilities (ISO 9001:2008 certified) that encompasses 140,663 square feet (13068 square meters) ensures the highest quality.

Coralina Engineering and Capital Equipment and Trading Corporation (CETCO) has operations in Azerbaijan, and their specialists are intensely involved in this territory. CETCO specialist are successfully making inroads in the Azerbaijan territory offering Eckel power tongs and power units. Additionally, CETCO provides training, classes, assistance, and local experience in all practical aspects of tong operation and maintenance. CETCO is very optimistic for doing business in Kazakhstan region. We are actively working in this region at improving our relationships with existing and new customers.

Eckel continues to improve tong designs, reliability, functionality, and reduce operational costs to comply with today’s oil and gas industry requirements, and anticipate tomorrows industry requirement. A few examples are:

• One of the latest design of a new backup with Wedge Drive Type Tri-Grip which is used on the most of tong models. The WD Tri-Grip is a high-performance backup with no compromises that is available for specific applications. The Wedge Drive Tri-Grip handles the most demanding torques that larger casing and drill pipes demand.

• A new 7.25 HS HT-80 tong, that was introduced in the last half of 2016 for drill pipes and high torque casing pipes. We believe the 7.25 HS HT-80 tong is an extremely needed product for the Russian market. We anticipate the specifications of the tong will be of great interest and welcome surprise for our customers.

• In 2017, Eckel will release a couple of new product designs. The new 9-7/8 HS-60 Casing Tong available the 1st Quarter of 2017 offers efficient and reliable high rotational performance for torque turn jobs. With these high torque ratings, the 9-7/8 HS-60 Casing Tong is capable of properly handling all premium grade tubulars within its size range.

Available in the 2nd Quarter of 2017, a new tong positioner “Tong Handler” that is permanently mounted within the rig which provides a cost effective, safer, and reduced labor-intensive method of maneuvering tongs to the rotary table area on the rig floor.

Russian is a very large and great country with lots of attention dedicated to the oil and gas industries onshore and offshore. Today’s challenge is to have equipment that meets the needs and requirements of oil and gas companies and drilling contractors. Since our first tong delivery in 1978 and now with the assistance of Capital Equipment and Trading Corporation and Coralina Engineering, we have developed a good relationship with many Russian customers and a growing list of new customers. Oil production is not so easy however; we believe that we can solve the most difficult problems facing the oil and gas industries. I have enjoyed visiting Russia many times for work and pleasure.

K&S Power Tongs committs to providing quality casing services in a safe, reliable, cost efficient and timely manner. Safety is everyone’s full time job and we are committed to the prevention and elimination of all safety nad health hazards. All operators are specially trained and industry safety certified. Safety is never compromised. Unsafe acts are never tolerated and our employees are held accountable to work safe.

K&S Power Tongs offers coventional and integral power tong services, volant casing running tools, computer torque-turn systems, power thread washing, thread inspection, handling equipment rentals and light oilfield hauling.

The Model 300 Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong.

The Model 300M Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong. A feature unique to this model is the ability to breakout and make-up 1-1/8” rods without over torqueing.

The Model 500 Power Tubing Tong has a size range of 1-5/16” to 7”, joint make-up in 5 seconds, and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated. The Model 500 also features an adjustable clutch and air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power.

The Model 600 Power Tubing Tongs feature an adjustable clutch and is available in either air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power. The Model 600 permits joint make-up in 5 seconds and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated.

The Model RSHD Power Tubing Tongs are truly a heavy duty piece of equipment that is for the tough jobs. The Model RSHD has more steel weight and gussets added to the bottom in order to diminish chance of case spreading. This model features a customary chain-driven design, integral sprocket, and outer ring. Lastly, the Model RSHD utilizes a familiar jaw-and-bushing biting system.

The Model 700 features the highest torque of all the Power Tubing/Casing Tongs at 20,000 ft./lbs. at 2000 PSI. This model consists of a light drill pipe, tubing, and casing.

Caltex Oil Tools is a service company that has been in business since 2000. We provide specialty solutions for oil & gas operators and contractors. The company provides consultancy services and develops customized oil tools to solve complex down-hole problems on land and subsea.

You’re the one with the power – the power tongs, that is. You control the equipment that threads sections of drill casing to form the pipe that is placed hundreds of metres into the ground. When you arrive at site, the rig crew knows it’s time to get to work. Your strength and dexterity serve you well in this occupation.

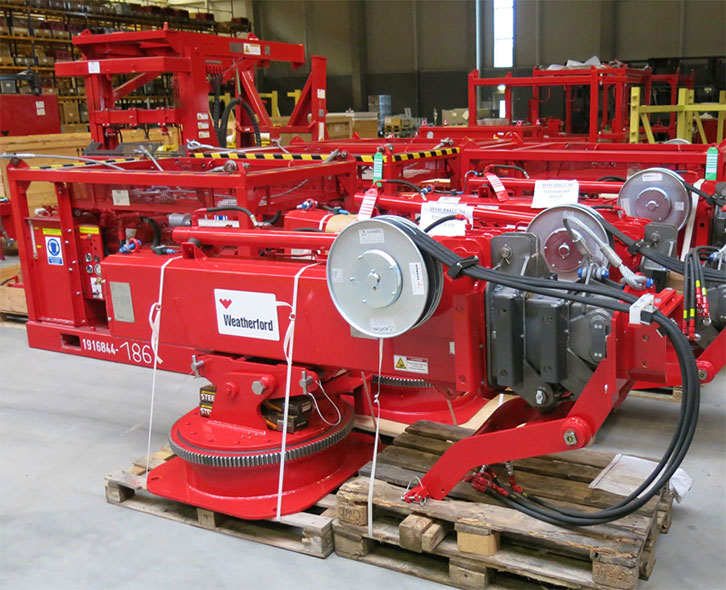

Power tong operators control the equipment that threads sections of drill casing into the wellbore. As a member of the oilfield well services team, they are responsible for operating power tongs, torque measuring equipment and tube/casing handling equipment at the well site. Casing is required to maintain an oil or gas well’s structural integrity, prevent the cross-contamination of water with other fluids and control well pressure during the drilling, production and maintenance of the well. Power tong operators must be able to transport equipment to and from the well location, safely rig in and operate the equipment, perform day-to-day inspections, servicing and maintenance of equipment, and complete all required paperwork accurately and on time.

8613371530291

8613371530291