power tong operator texas in stock

Texas International Oilfield Tools (TIOT) offers a free standing test stand for testing of hydraulic casing and tubing power tongs. The test stand is designed to resist torque applied by a power tong through a test mandrel.

The test stand is an air operated device that utilizes a hydraulic active dual spring disc brake chamber in order to apply friction force (“brake” action) to the rotating (or stationary) test mandrel mechanism. The power tong is tested by applying torque to the test stand’s mandrel. The test stand’s brake is activated by pushing and twisting clockwise the red control box button on the control box. A brake foot pedal is supplied as backup for the mini power unit. Using the control box mounted on the test stand, the black knob regulates pressure.

The terms VARCO, VARCO-BJ, and BJ are trademarks of Varco I/P, Inc., National Oilwell Varco, L.P., or their affiliates. Texas International Oilfield Tools is not an authorized distributor of any Varco I/P or NATIONAL OILWELL VARCO product. Texas International Oilfield Tools is not affiliated with Varco I/P, Inc., National Oilwell Varco, L.P., or their affiliates. Varco I/P, Inc., National Oilwell Varco, L.P., and their affiliates do not endorse any Texas International Oilfield Tools’ products or replacement parts.

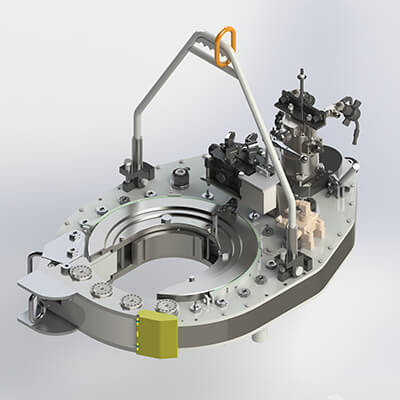

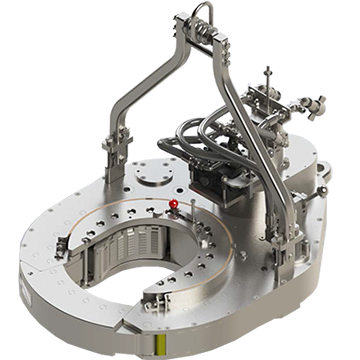

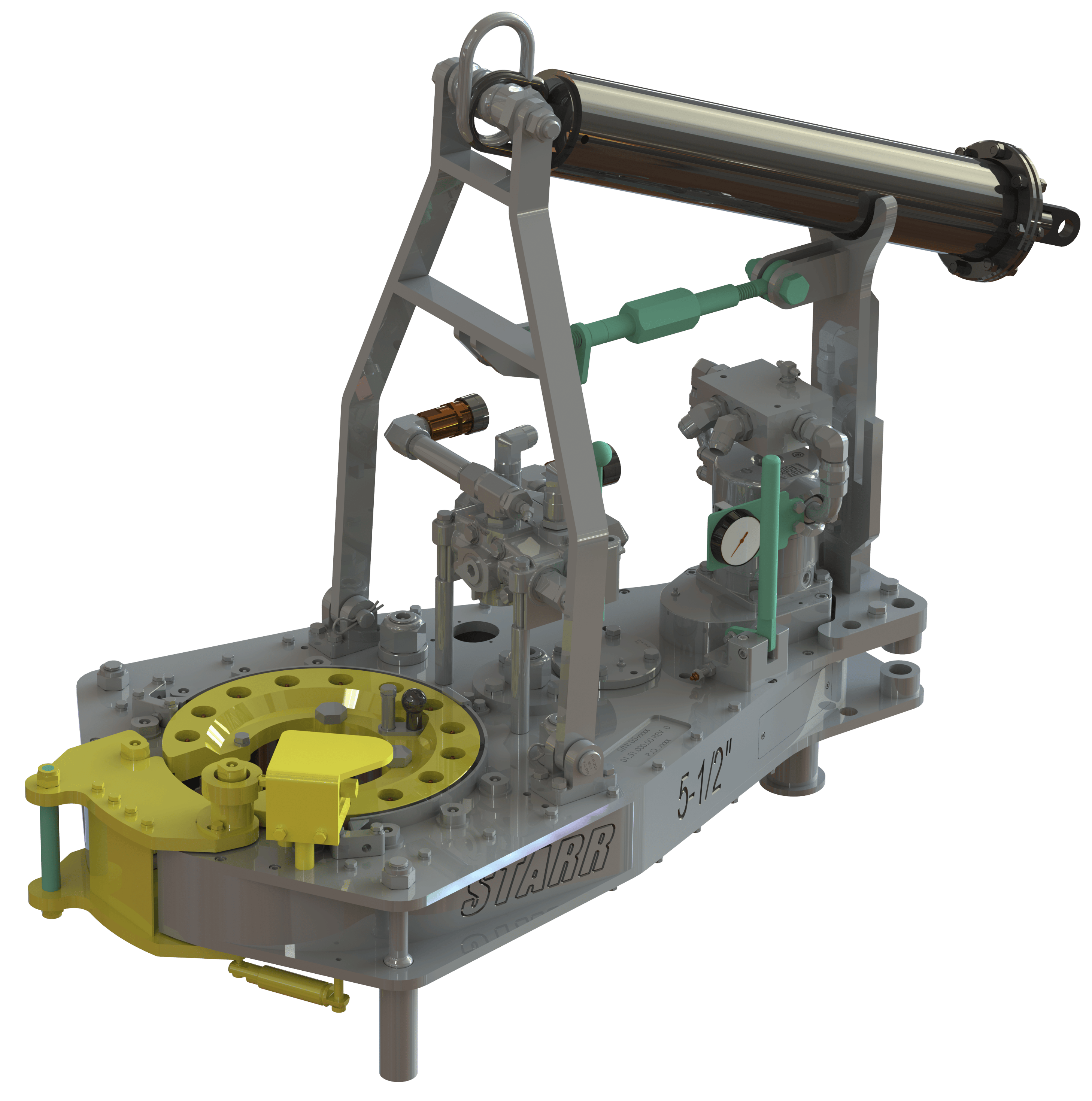

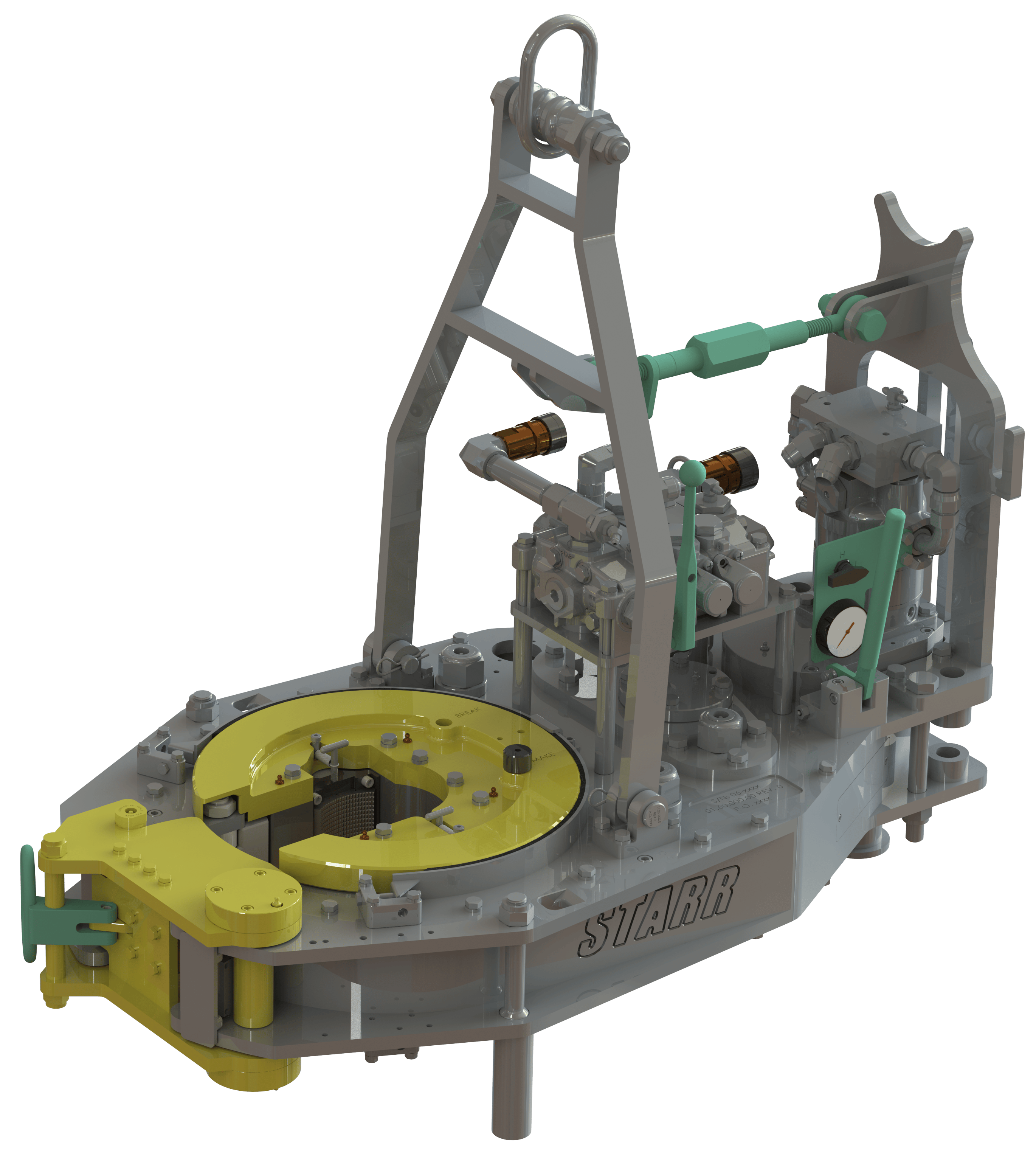

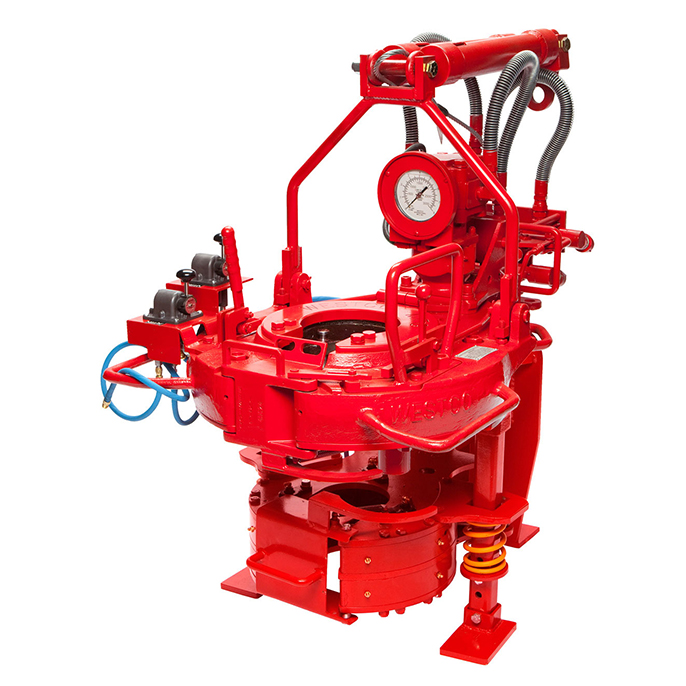

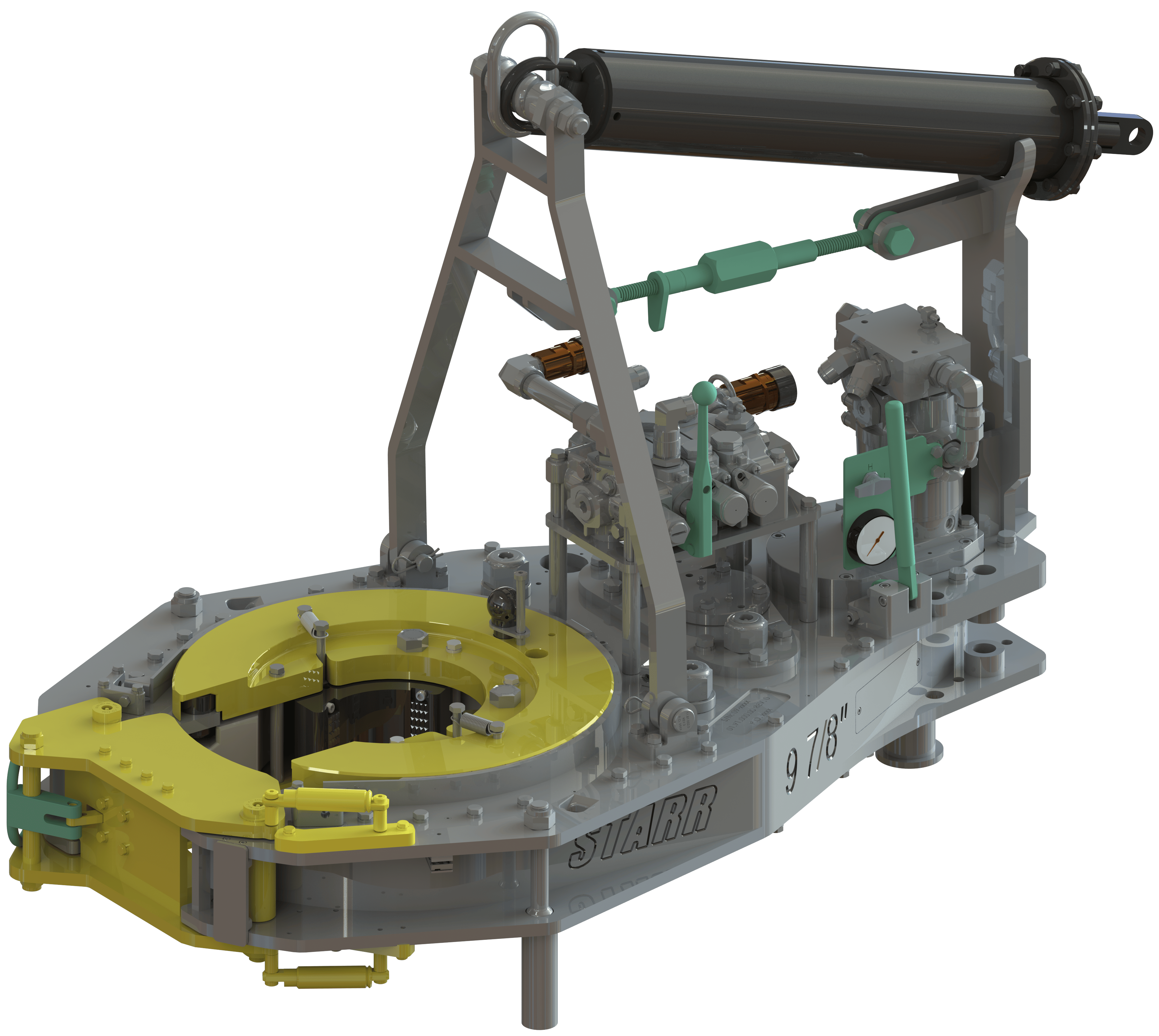

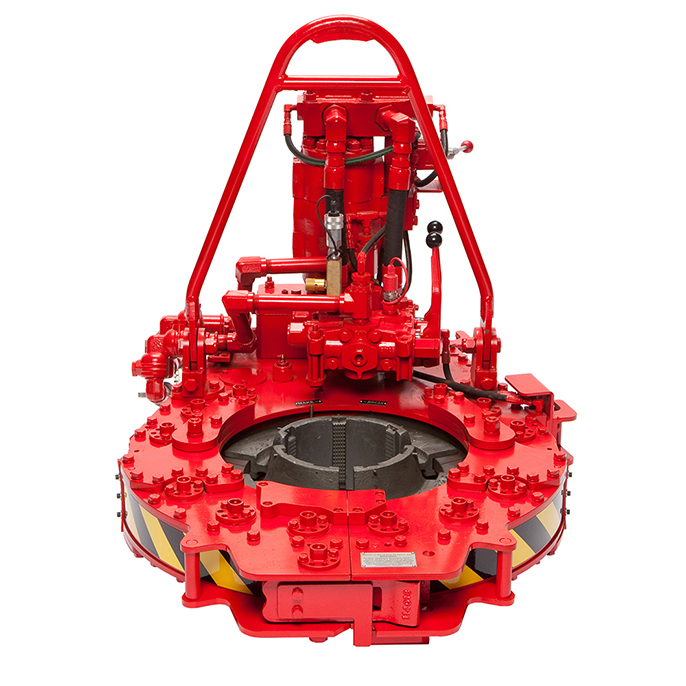

Power tongs are an essential tool in the drilling industry and are used to make up, break out, apply torque and to grip the tubular components. We are distributors for both Starr Power Tongs and McCoy Global hydraulic power tongs in multiple sizes and torque ranges from high torque to low torque that can be used to run both casing, drill pipe and tubing. When determining which power tong is best for your project, you will want to select the power tong that best fits your tubular size ranges and torque required.

All of our power tongs are available with either the McCoy\\\\\\\\\\\\\\\"s patented WinCatt data acquisition software recently updated to the MTT systems or AllTorque\\\\\\\\\\\\\\\"s computer monitoring system for all the torque and turn control system needed in today\\\\\\\\\\\\\\\"s market for the making of tubular connections. Discover our wide selection of McCoy and Starr casing tongs, tubing tongs and power tongs for sale below!

Magnum Manufacturing. has successfully mastered the design and manufacturing processes of creating a better hydraulic tong. By decreasing the weight of the tong and increasing the power, Magnum Power Tongs out perform the torque to weight ratio of any competitor. Constructed of premium quality materials, Magnum"s unique system delivers safe, efficient, and reliable performance on every job. Find out more..

Premiere, Inc. CRT / PRT Casing Equipment includes patent pending efficient equipment as Single and Dual Stage Diesel Power Units (DPU), the Magnum Manufacturing exclusive Multi-Grip Bowl and more. Technology at the Intersection of Obsession & Innovation. Find out more..

Magnum Manufacturing has released its latest invention in cutting edge tubular running technology. The Magnum Alignment Tool connects to any top drive and allows the operator to remotelyadjust the position of each joint of casing or tubing directly over the well bore.... Find out more..

The Magnum Tubular Flow Tool allows the operator to fill or circulate casing while it is being run into the well. Due to the large flow area it is designed to flow back conditions when float equipment is not being utilized. Our oilfield equipment is designed with safety in mind. Find out more..

Unscrew or tighten pipes, casing, tubing, and pump rods, using hand and power wrenches and tongs. Frequently exposed to moving mechanical parts, hand tools and…

Unscrew or tighten pipes, casing, tubing, and pump rods, using hand and power wrenches and tongs. Frequently exposed to moving mechanical parts, hand tools and…

Knowledgeable of mechanical systems and be skilled at working with hand and power tools. Operate machinery and/or power tools. High School diploma is required.

Assembles parts per manufacturing outlines in specified relationship to each other, using hands, tweezers or tongs. Understanding the sub-assembly process.

Maintains tubing, rod tongs and hand tools on the rig. Dismantles and repairs oil field machinery using hand tools and power tools. Ability to lift up to 75lbs.

Ability to use hand and power tools. Ability to use hand and power tools. Ability to use hand and power tools. High school diploma, GED or equivalent.

Use hand and power tools to assembly the HVAC system in a professional manner. Candidate must be dependable and report to the project site each workday on time…

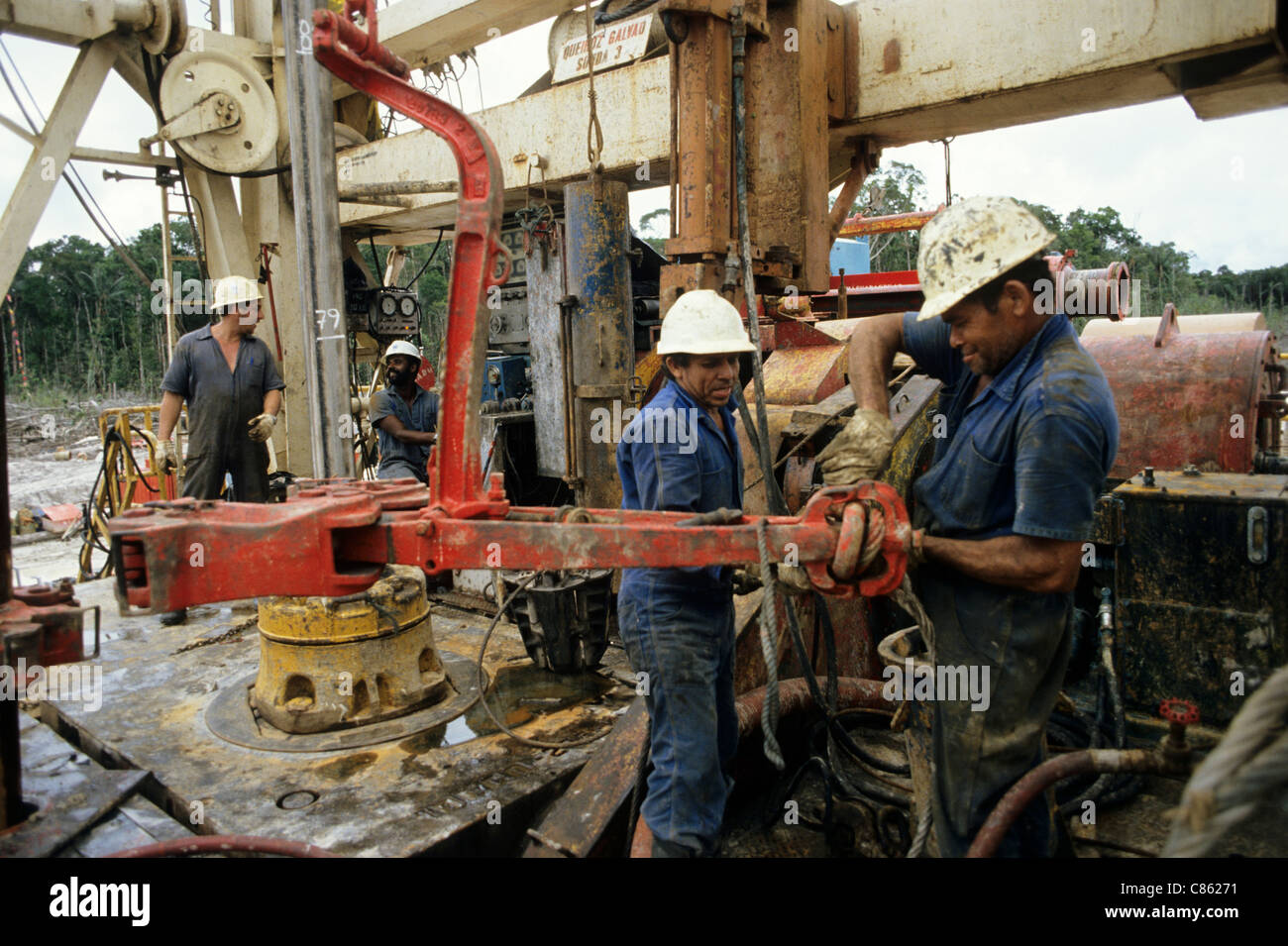

Handle and move casing or tubing tongs by using hands and arms to install, position, and operate tongs. Safely and efficiently operate casing or tubing tongs.

Handle and move casing or tubing tongs by using hands and arms to install, position, and operate tongs. Safely and efficiently operate casing or tubing tongs.

Operate rod wrenches, tongs, elevators and other associated rig tools and equipment. Utilize rig equipment (tongs, slips, elevators, and winch line) to safely…

Assembles parts per manufacturing outlines in specified relationship to each other, using hands, tweezers or tongs. Understanding the sub-assembly process.

Operate rod wrenches, tongs, elevators and other associated rig tools and equipment. Utilize rig equipment (tongs, slips, elevators, and winch line) to safely…

Handle and move casing or tubing tongs by using hands and arms to install, position, and operate tongs. Safely and efficiently operate casing or tubing tongs.

Compact Size and Big Torque! If this is what you are looking for in a power tong, look no further. Our 5½ Hydra-Shift® is sized smaller in width than our 5½ Standard model. Like all of our newly developed tongs, the 5½ incorporates the Hydra-Shift® technology, allowing the operator to shift from high speed to low speed without having to shift the tong manually. You will see many years of trouble-free operation, not to mention the smoother hydraulic shifting. With two models to choose from, Eckel has the right 5½ Hydra-Shift® for your needs. The 5½ Hydra-Shift® (VS) with a two-speed motor and a two-speed gear train offers the operator a more flexible choice of torque/RPM"s to work with during make-up or break-out. At the beginning of the job, the operator will choose which tong gear ratio is most appropriate for the current tubular connections and adjust the mechanical shifting lever. During make-up or break-out, further adjustments are actuated through the two-speed motor. Slide heads with rig dies are available for handling drill pipe tool joints.

The Model 300 Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong.

The Model 300M Sucker Rod Tongs made to make getting on and off the rods easier and to reduce weariness and mishaps. The Model 300 accelerates tripping the pipe, protects rods, and all while simply using the same power unit as a tubing tong. The Model 300 comes with a modifiable relief valve to set the torque; 95 RPM and 850ft/lbs. of torque at high range. Situated by a firm torque arm, this tong can engage automatically and release automatically by a reversing tong. A feature unique to this model is the ability to breakout and make-up 1-1/8” rods without over torqueing.

The Model 500 Power Tubing Tong has a size range of 1-5/16” to 7”, joint make-up in 5 seconds, and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated. The Model 500 also features an adjustable clutch and air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power.

The Model 600 Power Tubing Tongs feature an adjustable clutch and is available in either air or hydraulic assist for the back-up tool. Also fitted with a “Power Shift” Transmission, the operator is able to adjust gears during operation while the Improved Drive Alignment minimizes wasted power. The Model 600 permits joint make-up in 5 seconds and joint break-out in 7 seconds. With a split glide ring, both safer and more convenient access to jaws and final drive gear components is attainable, while pressurized oil baths ensure that the Model 500 is properly lubricated.

The Model RSHD Power Tubing Tongs are truly a heavy duty piece of equipment that is for the tough jobs. The Model RSHD has more steel weight and gussets added to the bottom in order to diminish chance of case spreading. This model features a customary chain-driven design, integral sprocket, and outer ring. Lastly, the Model RSHD utilizes a familiar jaw-and-bushing biting system.

The Model 700 features the highest torque of all the Power Tubing/Casing Tongs at 20,000 ft./lbs. at 2000 PSI. This model consists of a light drill pipe, tubing, and casing.

World Petroleum Supply, Inc stocks a wide selection of West International Consulting, Inc. Power Tongs & Hydraulic Power Units to suit every application. All power tongs products of which are API Certified.

K&S Power Tongs committs to providing quality casing services in a safe, reliable, cost efficient and timely manner. Safety is everyone’s full time job and we are committed to the prevention and elimination of all safety nad health hazards. All operators are specially trained and industry safety certified. Safety is never compromised. Unsafe acts are never tolerated and our employees are held accountable to work safe.

K&S Power Tongs offers coventional and integral power tong services, volant casing running tools, computer torque-turn systems, power thread washing, thread inspection, handling equipment rentals and light oilfield hauling.

Carter Tool Company was established in 1972 as a power rod and tubing tong rental and repair service business. The company manufactures parts and equipment for the well servicing industry. It offers rental services for various tongs with jaw assemblies. Its power tong features operator-controlled torque adjustments at the tool, a direct-reading torque gauge, tandem control locations and a gear-type hydraulic drive. The company s more than 4,000-square-feet machine shop facility features up-to-date equipment, including computerized numerical control machining and turning centers. Its gear hob handles spur and helical gears with diameters up to 30-inch, and the gear shaper can cut internal and external gear teeth and splines. The company also offers new and remanufactured tubing and rod tongs and their accessories. Carter Tool Company is based in Odessa, Texas.

Caltex Oil Tools is a service company that has been in business since 2000. We provide specialty solutions for oil & gas operators and contractors. The company provides consultancy services and develops customized oil tools to solve complex down-hole problems on land and subsea.

8613371530291

8613371530291