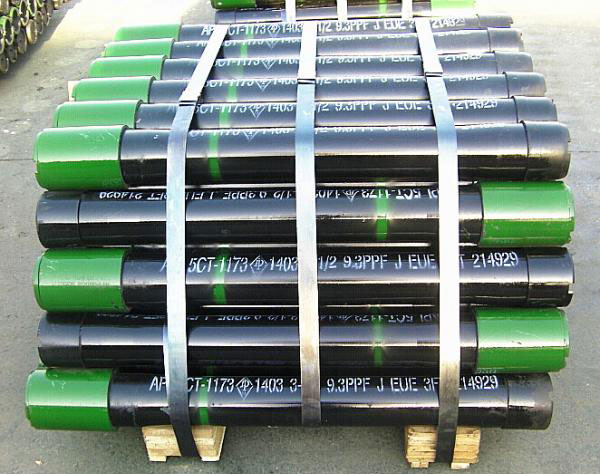

flag pup joint factory

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

A joint of tubing or casing included in the string at a known position to provide a reference point for further operations. A short pup joint that registers clearly in a collar locator log is a common flag joint.

Transparency Market Research delivers key insights on the global pup joint market. In terms of revenue, the global 7%during the forecast period, owing to numerous factors regarding which TMR offers thorough insights and forecasts in the global pup joint market report.

In the report, TMR predicts that the global pup joint market would be largely driven by factors such as increase in demand for oil & gas and increase in number of explorations. Rise in demand for high-grade pup joints, use of advanced drilling technology, and penetration in developing nations are set to drive the global pup joint market during the forecast period.

According to the pup joint market report, the product type segment includes crossover pup joint, drill pipe pup joint, and tubing pup joint; the technology segment includes hot rolled and cold rolled; the end use segment includes oil & gas, chemical industry, mining, construction, and others. Based on product type, drill pipe pup joint accounts for major share. Increase in drilling activities in various countries contributes maximum to this segment. The segment is projected to expand at a significant rate in the near future.

The oil & gas segment holds maximum share in the global pup joint market. Economic growth and high demand for electricity has increased the demand for offshore exploration and production activities worldwide.

Volatility in raw material prices has an obvious impact on pup joint manufacturers. Fluctuating prices of raw materials have impact on the production of pup joints.

Rising demand for oil & gas is set to increase drilling activities. New drilling technologies such as horizontal drilling and hydraulic fracturing is expected to have a positive impact on the oil & gas market. These factors are expected to drive the demand for pup joints during the forecast period.

Middle East & Africa holds a major share of the global pup Joint market followed by Europe. Key players largely depend on geographical expansion, promotions, and technological advancements to cater to customer demand and gain a competitive edge in the global pup joint market.

Middle East & Africa accounted for approximately 30% share of the global pup joint market in 2018, followed by North America and Europe. It is anticipated to maintain its dominance in the market during the forecast period. Domestic production capacity is increasing in several countries; exploring undeveloped sites and exploring new sites for drilling is projected to generate more options for business growth.

Key players operating in the global pup joint market include Anvil International, AZZ Inc., Dmh United Steel Industry Co., Ltd, Forum Energy Technologies, Inc., National Oilwell Varco, Oil Country Tubular Limited, Sledgehammer Oil Tools Pvt. Ltd, Stewart Tubular Products, Texas Pipe Works Inc., and TPS-Technitube Röhrenwerke GmbH.

We are the largest manufacturer of API pup joints in North America. All of our pup joints are manufactured from the highest quality API seamless tubing, and per API 5CT requirements. We have dedicated heat treat, NDT, and automated threading lines to provide you with best quality pup joints with quicker turnaround times.

The word etymology is derived from the Greek word ἐτυμολογία, etymologia, itself from ἔτυμον, etymon, meaning "true sense" and the suffix -logia, denoting "the study of".[1][2] RE: Pup joint etymology?

Fox Valley Forge is a World-Wide Leading Suppler and the Industry Authority in manufacturing Pup Joints for Fracking Operations. Our Fanatical Quality Control Department ensures a Zero Defect Rate which allows us to produce a steady supply of High Quality Pup Joints with Unrivaled Reliability at an Unmatched Value.

The booming oil and gas and mining sectors are directly dependent on a large number of industry sectors for end-to-end operations. The extensive array of activities for oil and gas exploration requires a wide range of industrial, mechanical, and technical equipment of varying sizes, of which, albeit its simple and intermediate use, pup joint is one.

With the first recorded use of pup joint as early as in 1930, a pup joint is aptly an important component of equipment for almost any well in the oil and gas sector. Pup joints of varying lengths of tubing and casing are used to adjust the length of the production string as much as possible to the required value. Precisely, pup joints are used to bridge the distance gap between tubing and casing components. They are also used to adjust the bottom of downhole tools.

In fact, pup joints are mostly easy to handle and use thanks to their friendly design, and provide the same performance as tubing/casing drill pipes. With drill pipes being an integral component of oil drilling of the high value oil and gas sector, the seemingly trivial pup joint has emerged as a distinct industry sector. So much so, the pup joint industry sector directly witness gains with the demand for petroleum products mostly soaring world over for last few decades. In such a scenario, the pup joint market exhibits steadfast growth, which in the near future from 2019- 2027 is projected to expand at a healthy ~7% CAGR.

With established use in the oil and gas sector, the demand for pup joints to optimize wireline activities remains consistent. Besides this, savvy players in the pup joints market are increasingly focusing on to offer customized products for downhole applications. Efforts to improve the quality of products, and to ensure they can withstand high-pressure environments and corrosion are also some pursuits keen players in the pup joints market are engaged in.

Explore 132 pages of superlative research, current market scenario, and extensive geographical projections. Gain insights into the Pup Joint Market (Product Type: Crossover Pup Joint, Drill Pipe Pup Joint, and Tubing Pup Joint; Technology: Hot Rolled and Cold Rolled; and End Use: Oil & Gas, Chemical Industry, Mining, Construction, and Others) - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2019 - 2027 at https://www.transparencymarketresearch.com/pup-joint-market.html

The ever-increasing demand for petroleum products has necessitated exploration of new oil and gas reserves. Several governments either independently or in collaboration with large oil companies are undertaking initiatives to tap unexplored oil reserves. This indirectly favors growth in the pup joint market.

In several parts of the world, extensive programs undertaken by governments and environmental agencies to promote the use of renewable and alternate sources of energy have directly hit the oil and gas sector. This, in turn, has negatively impacted revenues in several industry sectors that are closely associated with oil and gas exploration activities, including pup joints.

Analyze global pup joint market growth in 30+ countries including US, Canada, Germany, United Kingdom, France, Italy, Russia, Poland, Benelux, Nordic, China, Japan, India, and South Korea. Request a sample of the study

Stewart Tubular Products will manufacture Pup Joints to any length – inch or metric. Typical lengths are 2’, 4’, 6’, 8’ and 10’. Either API or proprietary threaded connections may be provided. Pup Joints manufactured by Stewart Tubular Products are available in all API and proprietary grades of steel, stainless steel and CRA steel.

8613371530291

8613371530291