pup joint yield strength brands

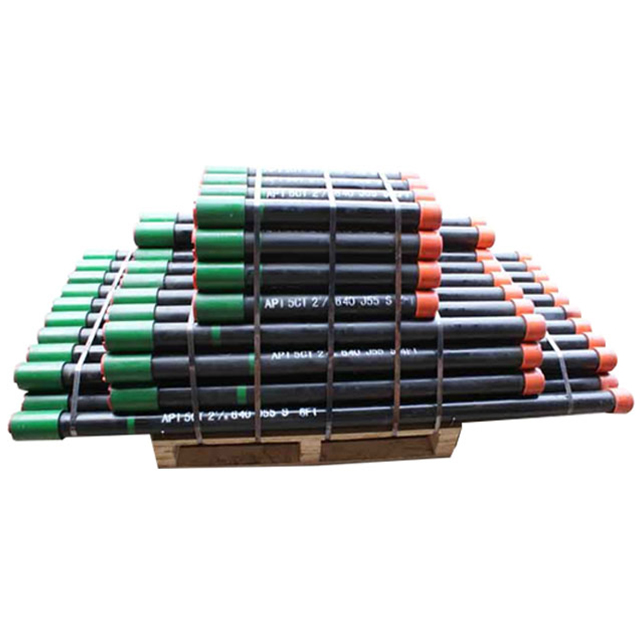

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

Pup Joints are a mandatory part of equipment in almost any well. Due to their shorter length, they are typically easier to handle and to use. At the same time, they provide the same performance as the tubing/casing/drill pipe that they are attached to.

The upset (thread-end finish) refers to the wall of the tool joint at the threaded connection. Drill pipe is offered with an internal upset (IU), an external upset (EU), or an internal-external upset (IEU).

A pup joint is a casing or tubing of length shorter than Range 1 with the same thread connection, used to adjust the length of tubular strings to its exact requirement.

Pup Joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup Joints are heat-treated to 110,000 PSI minimum yield. All connections are phosphate coated to impede galling during initial make-up.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

Thanks to advances in veterinary medicine, dogs are living longer than ever. However, longevity also increases the odds they’ll suffer from arthritis pain. Instead of running, your dog may limp or walk stiffly, and jumping into their favorite chair becomes near impossible. No longer the playful pup you remember, your dog may now prefer resting and might even have a shift in personality. PupGrade works to strengthen your pup’s joints to ease pain and increase overall wellness.

The oil casing coupling is a necessary piece used to connect the two casing. The coupling manufacturing method is the same as seamless pipe. The steel pipe ends with internal thread to connect with the upper and lower casing. In order to ensure the joint tightness, the precision of screw thread is strictly required.

(NOTE Couplings with API threads may not have a leak resistance as high as the internal yield pressure of the pipe body, due to inadequate bearing pressure between the coupling and pin.)

Premium connection is a higher class connection type for used to connect casing or tubing pipelines. The reason to use premium connection is due to it’s high seal performances, high strength, and longer durability.

Ultra high-strength casing is often used as oil casing widely applicable in deep and ultra deep wells and HP-HT wells (high pressure and high temperature wells). The super high-strength pipe is also used for well exploration in other complex geological conditions. It has high strength, super toughness, good wear resistance and corrosion resistance, and strong anti-collapse, anti-dislocation deformation, anti-perforation deformation abilities. In order to explore petroleum and gas in the deep and ultra deep wells, JST ultra high-strength casing or super high-strength pipe is quite necessary (160ksi), because they have good impact toughness and they will not be in brittle fracture when using.

1. Based onconventional CrMoV quenched and tempered steel, alloy design of JST ultra high-strength casing or super high-strength pipe adopts proper steel grades like low C, low Si, high-Cr, mid-Mo and micro-V. Under the premise of ensuring hardenability of steel, this design minimizes the carbon content so as to avoid damaging the steel toughness.

2. The joint and pipe body has same strength to ensure the resistance to internal pressure, external squeeze and the overall link performance of ultra high-strength casing.

3. To meet the casing load requirements for operations in ultra deep wells, the yield strength of super high-strength pipe (Rt) should be equal or over 1000 Mpa, even reaching 1034 to 1172 Mpa. The tensile strength (RRm) should be equal or over 1120 Mpa. According to ultra-deep operating environment, there are corresponding collapse resistance requirements for casing.

4. Our ultra high-strength casings are manufactured according to API grades, allowing us to offer the best solutions for each customer’s particular well conditions.

5. All of super high-strength pipes are manufactured to the most exacting quality standards. We hold a global ISO 9001 registration for our operations, which follow a uniform quality policy and apply a rigorous quality management system.

7. Through the JST global network of manufacturing facilities and threading shops, we are able to ensure flexible delivery for our super high-strength pipes.

10. JST super high-strength pipe adopts the most advanced imported high-precision CNC dedicated screw thread machine tool to process threads. This ensures the processing precision of screw threads. Combined with unique threaded surface treatment technology, it greatly improves anti-adhesion and other properties of casing joint.

The mechanical properties of super high-strength pipe are most sensitive to C, Si and Cr fluctuations. C significantly reduces the body ductility. Si easily reduces the low temperature toughness of steel and Cr is easy to form M23C6 carbide to reduced toughness. It is generally believed that S or P and other impurities will validate steel impact toughness. But its content is strictly controlled at a low level and the fluctuation range is very small, so its influence is not significant. Take JST Q125 steel for example, chemical composition control coefficient is as follows:

Founded in 1984, Jiangyin Changjiang Steel Tube Making Factory is a professional manufacturer of seamless steel tubes and various special pipes. Our products mainly cover tubing, line pipe, drill pipe, high strength casing, high pressure boiler pipe, marine pipe, cylinder tube, hydraulic prop tube, fluid pipe, structure pipe, etc. They have passed API 5CT, API 5L, API 5DP, CCS, LR, DNV, ABS, NK, BV, GL, PED, SGS, ISO9001:2000 and ISO14001:2004 certifications. Our ultra strength high-casings/super high-strength pipes have won widespread praise and recognition by customers.

or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order.

Pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of tubing pup joint is the same as tubing, and casing pup joint is the same as casing.

and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished tubing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Casing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of casing pup joint is the same as casing. Casing pup joints are

8613371530291

8613371530291