pup joint yield strength api brands

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Crossover pup joints are manufactured from seamless mechanical tube. As with all Crossover products, each piece is marked with a distinctive job number and heat number that is fully traceable. A complete range of sizes (1" to 4.5"), weights (standard or heavy wall), and grades (J-55, N-80, L-80, and P-110) are commonly available from stock in 2", 3", 4", 6", 10", and 12" lengths. Lengths up to 20" are available upon request.

Manufactured according to API Spec 5CT using prime API monogrammed, seamless oil country tubing. Optional diameters, lengths, weights, and grades are available upon request.

Seamless pup joints with premium connections are available in API and exotic alloy grades. Premium ends are threaded by the manufacturer or authorized licensee.

Available with standard or special perforation spacings. Each joint has four rows of ⅜ inch holes drilled longitudinally along the tube. Optional patterns, hole size, and lengths furnished upon request.

Crossover, Inc. handles many types of API Couplings. As a rule, we stock enough of your common couplings which enable us to ship the same day if needed. We carry in stock J-55, L-80, N-80, and P-110. As for sizes, we carry 2 3/8”, 2 7/8” 3 ½”, 4 ½” tubing and some of the casing sizes up to 13 3/8”. Stock connections are EU 8 Rd., Nu 10 Rd., LTC, STC, and BTC. Our couplings are primarily of USA manufacture. If origin is not important, we can source other origins and sometimes beat the USA manufactured cost.

We manufacture a wide range of Crossover Couplings. Couplings are used to connect two sizes of pipes, or two different dissimilar threaded parts together. We offer special clearance couplings, special clearance couplings with bevels on both ends, and couplings with the API Seal Ring Modification.

Crossover swages are made from API grades of pipe and mechanical tubing. Rigid quality standards are maintained throughout the manufacturing process by frequent inspection and testing. Raw material quality is assured by our quality assurance program.

A blast joint is shorter in length than standard tubular joint. Built with a heavy wall pipe it is incorporated in the production string to facilitate production across any perforated interval and zone. Blast Joints are manufactured to the following specs connections, lengths, weights and material grade.

Crossover Blast Joints are heavy wall pin by box connectors used in tubing strings and are designed to minimize the effect of external erosive action caused by production fluids. Blast joints are located opposite the location of perforations in the production casing or just below the tubing hanger in sand frac designs. Crossover blast joints are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 10" and 20". Both API and Premium threads are available.

Crossover Flow Couplings are heavy wall box by box connectors used in tubing strings and are designed to minimize the effect of internal erosive action caused by production fluids. Flow couplings are located just above or below Landing Nipples, Safety Valves or Control Devices where turbulent flow problems are likely to occur. Crossover flow couplings are manufactured from seamless mechanical tube in sizes ranging from 2 3/8” to 4 1/2” OD. Any length, grade of material, and threading is available at the customers request. Typical lengths are 3" and 6". Both API and Premium threads are available.

Crossover Coarse Thread Tubing Safety Joint provides for emergency recovery of the major portion of the tubing string should it become necessary to abandon the equipment below. Precision left-hand threads facilitate the release of the joint by right-hand tubing rotation. Equipment requiring right-hand rotation should not be used below the Safety joint.

Crossover Straight-Pull/Shear-Out Safety Joint is used between packers in dual and triple completions and in selective completions using Hydrostatic Single-String Packers. It is also used when rotational releasing is not desired. When ran above the upper packer in a single-string completion, however, the shear value should be adjusted to compensate for any hydraulic conditions that exist when the string is landed, or that are created by well treating operations. They are available in keyed and non-keyed configurations.

Crossover can build these in any of the regular API Grades such as J-55, L-80, or P-110. These are usually only made going up or down one size in either direction such as ¾” to 1” or 1 ½” to 2”.

A saver sub falls under the drill string accessory tool category and a short pipe that is replaceable and expendable without a major investment. This accessory protects the Kelly or topdrive component threads and those components represent a significant capital cost and considerable downtime when replaced. Saver sub are manufactured to the following specs connections, lengths, weights and material grade.

Crossover rotary shoes are manufactured from specially tempered steel to provide the ultimate in toughness and durability. They are used to cut a clearance between the fish and the wall of the well bore. Each shoe is tailored to fit a particular downhole need and normally is run on the bottom of one or more joints of washover pipe. Shoe design is dictated by whether it cuts on the bottom, on the OD, on the ID, or any combination of these. When hole sizes permit, additional clearances can be cut using side ribs, thus providing greater circulation.

Pup joints are manufactured from AISI 4145H or 4140H-modified alloy, heat-treated to a Brinell Hardness range of 285-341 with a Charpy “V” notch minimum impact strength of 40 ft/lb at 70° F and one inch below the surface. Pup joints are heat-treated to 110,000 psi minimum yield. All connections are phos-coated to impede galling during initial make-up. They are available in standard lengths of 5′, 10′, 15′ and 20′ with other configurations upon request.

Pup joints are commonly used to adjust the length of the drill string to the elevation of rotary table for easy surface handling and drilling practices. They undergo the same stresses as drill pipe and their performance depends primarily on their superior mechanical properties.

We manufacture pup joints in all sizes, grades, and thread profiles to meet any requirement. Our tubing pup joints are manufactured out of seamless tubing and machined or upset to final dimensions. All API casing and tubing pup joints are manufactured according to API Spec 5CT. Special requirements are available on request.

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Integral Pup Joints dedicated to Sour Service applications are available. PJ -110 PUP S are Sour Service Pup Joint using ASCOWELL C material providing improved resistance to Sulfide Stress Cracking with high yield strength.

The API 5L product grades include API 5L X65 pipe and heavy wall linepipe covering welded and seamless carbon and galvanized steel pipes. These product categories are for conveyance or transport of gas, oil and water by the natural gas and petroleum drilling, production and transport industries.Reliable Pipes & Tubes Ltd. provides standard and heavy wall tubing, pipes and high yield (pressure) linepipes and accessories.

Flanges and flange protectors –weldnecks, blind flanges, lap joints, slip-ons, threaded flanges, socket-weld flanges, reducing and orifice flanges; and category number grades including numbers 150#, 300#, 600#, 900#. 500# and 2500#

Whether you need standard length and diameter pipes and tubing or you need high strength, high tensile, heavy wall linepipe requirements for deep sour wells, drilling, offshore drilling and production, arctic exploration and production, or you need standard linepipes for natural gas, oil or water transport,Reliable Pipes & Tubes can meet the demands of your company. All products are industry standard conforming to or exceeding API, ASTM, ASME, ANSI and other national and international standards.

Seamless & Welded Standards API Specification 5CT latest edition at time of manufacture (PSL-1, PSL-2, PSL, 3)-ISO 11960:2004 – Petroleum and Natural Gas industries – Steel pipe for use as casing or tubing for wells Sizes: Outside Diameter: 1.660- – 30- Grades: H40, J55, K55, N80,N80Q, L80, C90, C95, T95, P110, Q125, SS95, SS110, 9%CR, 13%CR Connections

M65, and R95 are newer grades, each with their own field of application. These casing grades mainly differ in their yield strength and tensile strength.

Both N80-1 and N80-Q have the same yield strength and tensile strength, but N80-Q, which is quenched and tempered, shows a higher resistance to internal pressure and collapsing.

M65, and R95 are newer grades, each with their own field of application. These casing grades mainly differ in their yield strength and tensile strength.

Same yield strength range and tensile strength as grade T95, but without the requirement for SSC or hardness tests. Steel grade R95 therefore is a better-priced alternative to T95 in wells without the risk of sulfide stress cracking.

Manufactured to API specification 5CT. This is a controlled yield strength material with a hardness testing requirement. L80 is usually used in wells with sour (hydrogen sulfide) environments.

We are having our sub dealers of above brands with adequate stock of API 5L line pipe, Tube & Tubular in UAE, Kuwait, Saudi Arabia, Australia, Indonesia, Malaysia, Bahrain, Singapore, Thailand, UK, Canada, Brazil, Venezuela, Kazakhstan, Sudan, South Africa, Mozambique, Nigeria, Kenya, Tanzania for quick delivery of API Line Pipe, Carbon Steel Seamless Pipe & Tubular with mill certificate & all required documents.

We provide a variety seamless and welded petroleum industry casing, tubing, sucker rods and drill pipes with various end connections. All of our OCTG (Oil Country Tubular Goods) products are manufactured to the API specifications. Reliable Pipes & Tubes Ltd. is full serviceorganization in OCTG distribution as well as pressure pipe and gas lines. Our team having the experience of 40 years & full of dedication to meeting your requirements.

We stock variety of OCTG products such as Casings, Tubings, Line Pipes, Coupling Stock, Finished Coupling (API) and specialized tubes for mechanical applications such as the manufacture of perforator guns, fishing tools, etc; These items can be customized to the requirements of individual customers in terms of heat-treatment and end finishes.

We stock The American Petroleum Institute certified products (API License No.5CT-0395, 5CT-0123, 5L-0102, 5L-0296, 5-D0018) and the API monogram for specification API 5L, 5CT and 5D – plain ended pipes.

API 5CT Pipe, Seamless pipe, Seamless tube, Boiler Pipe, Gas Cylinder Pipe, Mechanical Pipe, Line Pipe, Offshore line Pipe, Nuclear Pipe, Casing and Tubing distributor, stockholder and supplier in Iran, Singapore & Saudi Arabia

A pup joint is Casing, Pipe or Tubing shorter in length than a standard tubular string. This allows for the adjustment and installation of tools and various tubular components when placement downhole is critical for a specific project. A Spacer Pipe is another reference used to identify pup joints. Pup joint features consist of connections, lengths, weights and material grade.

Tubing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of tubings, and tubing pup joints are made of seamless steel tubings. Material grade of tubing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of tubing pup joint range from 2⅜¡± to 4½¡±, thread of pup joint can be 8RD, 10RD or BTC, and end connection types can be NUE and EUE. length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Tubing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of tubing pup joint is the same as tubing. Tubing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished tubing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

Casing pup joints are desiged and manufactured as per API 5CT to be used be adjust height of casings, and casing pup joints are made of seamless steel casings. Material grade of casing pup joint can be avalialbe in J55, K55, N80, L80 or P110, sizes of casing pup joint range from 4½¡± to 13⅜¡±, thread of pup joint can be 8RD, 10RD or BTC, length of tubing pup joint are often offered in 2ft, 3ft, 4ft, 6ft, 8ft, 10ft and 12ft, length of pup joint for special purpose can be available as per order. Casing pup joints are machined with interchangeable Pin & Box thread on two ends or other configuration, one end is equipped with coupling, and another end is protected with closed end thread protector. Nominal weight of casing pup joint is the same as casing. Casing pup joints are internally and externally hydrostatic tested with tension and compression loads, and torque tested, electromagnetically inspected, pup joint is full-body drift and straightness visual inspected, and phosphated and dye-penetrant inspected. and finally painted by machine to ensure excellenct appearance. Finished casing pup joints are often packed by steel belts in bundles, and then fixed in steel rack for easy transportation.

API Coupling refers to the steel couplings that used in connecting casing pipe and tubing. Also known by OCTG coupling, it is usually manufactured in seamless type, material grade same with the pipe body (API 5CT K55/J55, N80, L80, P110 etc), same PSL or providing higher grades than requested. Same heat treatment also applicable, except there is an special requirements.

With this purpose, API 5CT standard coupling plays an important feature in connecting casing and tubing line pipes. On the contrary, the biggest different with general steel pipe coupling is: API coupling manufacturing processes is more rigorous, requires a precisely control in the different processes as blew listed.

As we told, one of the important figure of API coupling, that it shall be made of seamless, another is the same grade as the casing or tubing pipe body, and these materials are used for manufacturing the blank coupling.

Coupling should be processed from coupling blanks or from coupling stock, including manufactured in hot forging. (Except Grade C110 and Q125 couplings shall not be in hot forging. These two grades material are typically different from other grades, so if you are purchasing couplings in this grades, should pay more attention to read regulations in API 5CT spec.)

There are several types covered in API 5CT standard for coupling specifications, classified in regular couplings, special clearance couplings, combination couplings, reducing couplings, seal ring couplings, and special bevel tubing regular couplings.

Regular couplings diameters complied with API 5CT Tables C.32 to C.35 or Tables E.32 to E.35. Coupling bearing contact face inside and outside edges shall be rounded or broken, but shall not significantly reduce the width of the bearing face (dimension b), since less thickness will not be safe to support the pipe weight. The ends of couplings shall be faced exactly at right angles to the axis.

The oil casing coupling is a necessary piece used to connect the two casing. The coupling manufacturing method is the same as seamless pipe. The steel pipe ends with internal thread to connect with the upper and lower casing. In order to ensure the joint tightness, the precision of screw thread is strictly required.

API Threads is for the threads manufactured and inspected under API 5B. Couplings shall not be expanded to provide required threads taper under API specifications.

(NOTE Couplings with API threads may not have a leak resistance as high as the internal yield pressure of the pipe body, due to inadequate bearing pressure between the coupling and pin.)

API 5B covers dimensions, tolerances, and marking for API threads and the gauges that control the acceptance criteria for the threads. It includes thread element gauges, instruments, and requirements for the inspection of threads for line pipe, casing and tubing (round threads), and buttress casing connections. Thread dimensions shown without specifications (or shown as NA) are not subject to inspection of diameter, ovality, and addendum. Thread dimensions shown without tolerances are related to the basis for connection design and are not subject to measurement to determine acceptance of product.

The inspection requirements include measurements of standoff, diameter, ovality, addendum, taper, lead, height, and thread angel. It shall be noted that these specification are only applicable to threads quantity less or equal to 11 1/2 per inch (which 0.45 or less turns per mm). Ring and plug gauges are designed to measure the functional size of an internal or external thread. Individual thread elements listed in API 5B are measured with one or more specific instruments.

Premium connection is a higher class connection type for used to connect casing or tubing pipelines. The reason to use premium connection is due to it’s high seal performances, high strength, and longer durability.

API casing and tubing coupling dimension ranges from OD 1.05 inch to 20 inch (26.7 mm to 508 mm), wall thickness normally ranges from 0.16 inch to 1 inch (4.2 mm to 22 mm).

For Group 1, 2 and 3, Unless specified in the purchase agreement, coupling dimensions and tolerances shall be complied to API 5CT table C.32 to C.35 or tables E.32 to E.35.

For Group 4: Not only internal machining could be done to Coupling, external machining also could be done to. Except API couplings and threads shall comply to C.32 and C.33, or E.32 and E.33, in case other connections couplings or threads (Premium connection), couplings sizes shall be specified in the agreement.

According to API 5CT specification, the internal and external surface of coupling shall not have folding, cracks, separation, scaling and other defects.

Octal supplies API couplings for casing and tubing connections, feel free to contact us for any of the request refer to the API or premium connections.

8. Our tubing pup joint conform to API 5 CT standards, Length: 2FT/3FT/4FT/5FT/6FT/8FT/10FT/12FT and we can make different lengths and sizes according to the customer"s requests.

KINGWELL have experienced team, stronger enough to meet any challenge, we do believe honest is the base of business and cooperation, our aim is to build solid relationship with any part of honest. kingwell can provide highly efficient services to its clients resulting in accurate and timely deliveries at the best prices.is a professional supplier for oilfield products according to the API standard. We exporting ALL KINDS OF OILFIELD MACHINERY AND TOOLS with super Quality and Competitive Price in CHINA.

Now, Our Pup Joints have exported to USA, Egypt, India and UEA , etc with high quality and short supply and good service. Our Pup Joint has got good reputation home and abroad Here we got some prise as follows.

A well-established Quality System from Materials receipt to Products delivery ensures consistent quality at all levels of the activity. QMS Procedures & Measurements are tailored to establish high standards of Quality Assurance in the Operations. The Company maintains the 100% Traceability records as per API requirements&NACE MR 0175-2002 Standards and complies with all the legal, statutory and regulatory requirements.

Our TUBING PUP JOINT cover all API Standard scope from 2-3/8" - 4-1/2" with strickly inspection, which all the goods should be checked one by one before packing. Euipped withthe world-class facilities and professional laboratory technicians, we pay more attention the quality of every products.

ll pump joints are made from modified alloy steel heat-treated to a Brinell Hardness range of 285–341 with a Charpy V-Notch minimum impact strength of 40 ft-lbs at 70°F guaranteed to one inch below the surface Connections can be cold rolled after machining, if requested All connections are phos-coated to prevent galling during initial make-up

API Spec 5CT – This Standard specifies the technical delivery conditions for steel pipes (casing, tubing and pup joints), coupling stock, coupling material and accessory material and establishes requirements for three Product Specification Levels (PSL-1, PSL-2, PSL-3). The requirements for PSL-1 are the basis of this Standard. The requirements that define different levels of standard technical requirements for PSL-2 and PSL-3, for all Grades except H-40, L-80 9Cr and C110, are contained in Annex H.

All kinds of Casing and Tubing Jfe Nsct Pup Joint for OCTG produced by our company have reached the national standards. We keep on with our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We hope to gain the trust and support of our customers, employees, communities and other stakeholders, and work together to make our company stronger, better and bigger.

The upset (thread-end finish) refers to the wall of the tool joint at the threaded connection. Drill pipe is offered with an internal upset (IU), an external upset (EU), or an internal-external upset (IEU).

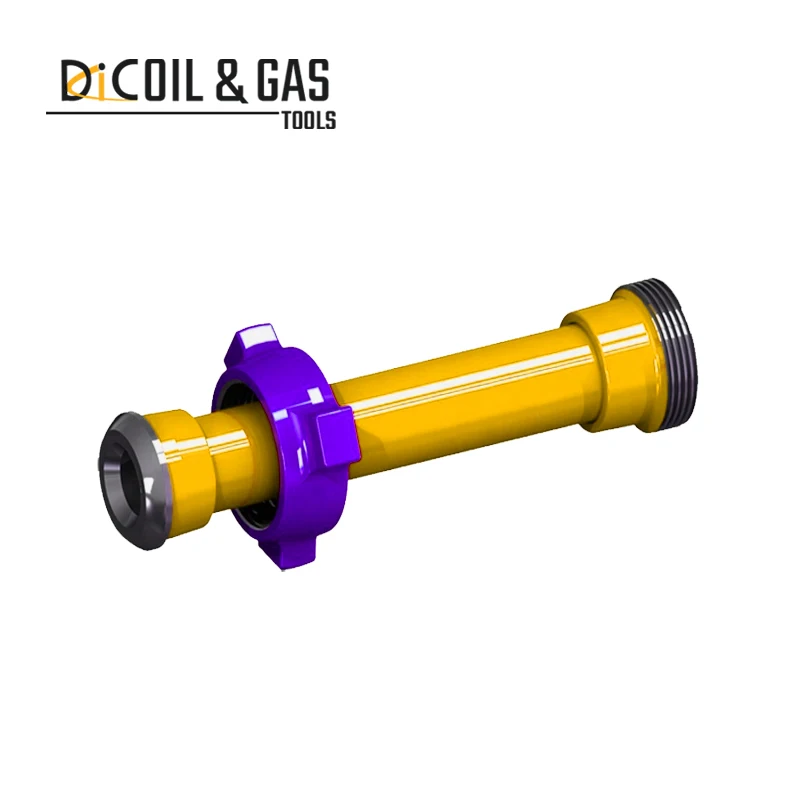

DIC OIL TOOLS is a well-reputed manufacturer and exporter Oil and Gas Equipment. Our products are manufactured by using the best material and modern techniques, which make them extremely up to the standard in this challenging domain. The offered products are highly appreciated among customers due to their corrosion resistance, robust design, optimum finish, and high tensile strength. Also, these are available in various sizes, dimensions, and patterns in order to meet the requirements of customers.DIC OIL TOOLS considers quality as an integral aspect of our process as it"s not only to satisfy customers but also imparts us with a feeling of contentment. Quality is our mission. We maintain a strict quality management policy, which is religiously practiced within the organization.

Pup Joints are a mandatory part of equipment in almost any well. Due to their shorter length, they are typically easier to handle and to use. At the same time, they provide the same performance as the tubing/casing/drill pipe that they are attached to.

8613371530291

8613371530291