machinist rotary table quotation

Penn Tool Co. has a variety of precision rotary tables for sale. Simplify your production work with a rotary table that can be used for many different machining applications. In production, it is essential that jobs are done quickly, efficiently, and precisely. In the industry of intricate metalworking, precision matters and can make all the difference. All of the parts should look identical in the end, and our tools can help you do just that. To ensure quality and durability, we only carry top-rated, premium brands you can trust including Vertex, Harig and Phase II. With an easy-to-operate precision rotary tablefrom Penn Tool Co., get the accuracy you need and a timely, beautiful end result. Browse our collection, and order today!

The TR160 5 Axis Rotary Tables, manufactured by Haas, consist of dual axis Trunnion rotary table that is capable of tilting up to 160 mm. It also has a scale assessment ...

The TR210 is HAAS"S rotary table developed and configured to be integrated with HAAS"S mills 4th and 5th axis drivers to provide complete and optimum operation. It has a diameter of 210 mm made from trunnion ...

... space with high load capacity. The individual rotary tables are equipped with Harmonic Drive units, which ensure high moment load capacities and high concentricity and axial runout accuracies.

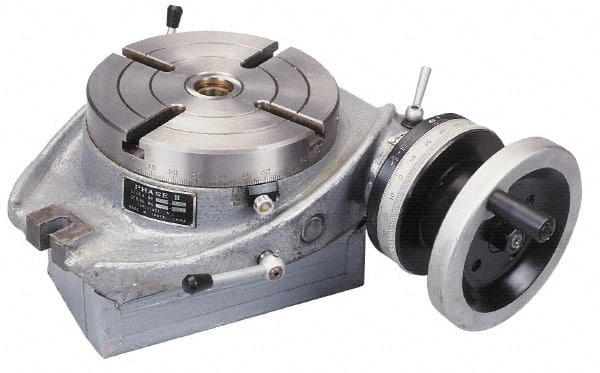

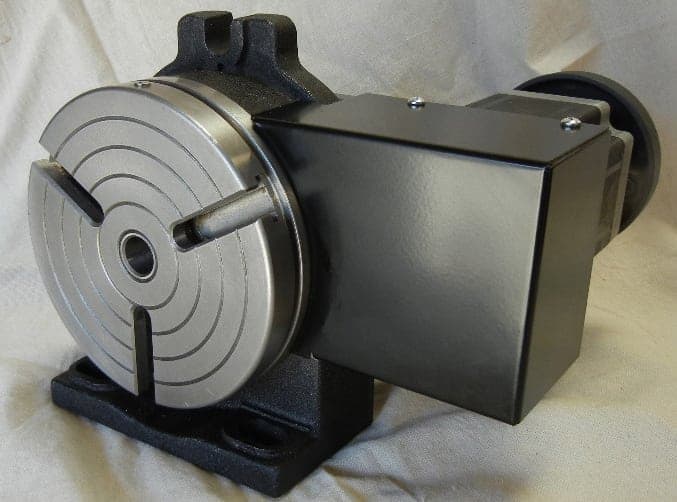

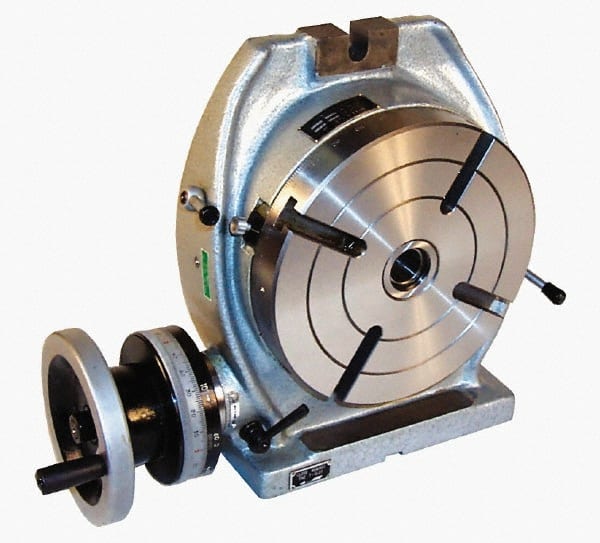

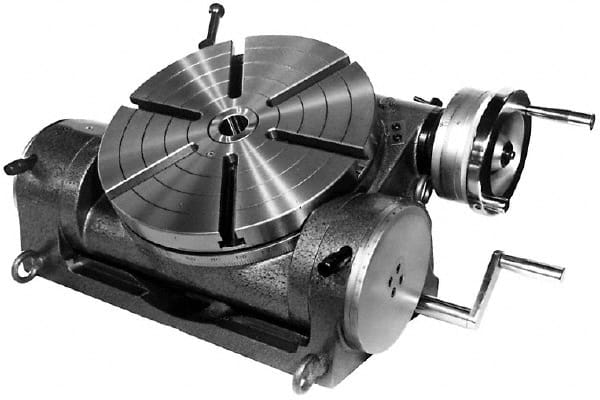

The work table is graduated 360 degrees around its circumference and is driven by a precision Worm and Gear providing a 90:1 reduction ratio. One turn of the Handle moves the Table through 4 degrees. ...

... Tilt-Yaw (A/B) two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

... ) MDR two-axis rotary assembly provides high-speed machining capabilities for complex 3D part geometries. The precision-aligned system allows accurate positioning on a hemispherical surface. Uses cost-effective ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

The hydrostatic rotary tables from ZOLLERN impress with their durability and a high concentricity and axial runout accuracy. Thanks to the ZOLLERN bearing clearance compensator, the optimal pocket pressure ...

... the table is the rotation, the user may require the rotary table for drilling operations and milling. Using the servo drives in conjunction with the machine CNC control ...

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

ATS Systems is a national leading machine tool accessories and automation supplier delivering reliable solutions with unwavering support that increases manufacturing productivity and throughput leading to profitable results for its customers. For over 20 years, ATS has installed over 135K machine tool accessories and automation systems allowing customers to achieve productivity gains of over 50% and increasing profitability.

Technitron has been integrating rotary tables and accessories on machine tools since 1992. Over the past 30 years Technitron has pioneered new technology and techniques to allow us to set the industry standard for rotary table and accessory integrations. By utilizing our vast experience, we have been able to meet and exceed our customers’ expectations. No other company has our experience on a variety of machines and controls.

Technitron is dedicated to supplying high quality Integration Services to the Machine Tool Industry. Our Turn-Key Integration Services are designed to enhance the productivity from both new and existing machine tools. We have installed more than 3500 rotary tables to date.

Lagun’s BM RT is a bed type mill with C-Axis rotation and equipped with a rotary table. With a compact and robust design, this milling machine is ideal for machining bulky workpieces on all 5 sides.

Additionally the sturdy, oversized mill bed comes with reinforced ribbing, fortifying its stability during heavy milling. The hardy table, measuring at 63” x 47” (1600mm x 1200mm), column, slide and ram systems have been studied and as a result designed with roller/shoes that exceed the manufacturing requirements. Designed to be as close to the column as possible, the mills ram placement ensures a sturdy column-slide-ram assembly. This results in a rigid and light slide for vertical movement. To correct any ram deflection during cross movement they come equipped with special wedges.

Lagun’s BM-C Bed Mill is a bed type mill with an integrated rotary table. With a compact and robust design, this milling machine offers application-oriented technological solutions while offering high profitability.

Additionally the sturdy, oversized mill bed comes with reinforced ribbing, fortifying its stability during heavy milling. The table, column, slide and ram systems have been studied and as a result designed with roller/shoes that exceed the manufacturing requirements. Designed to be as close to the column as possible, the mills ram placement ensures a sturdy column-slide-ram assembly. This results in a rigid and light slide for vertical movement. To correct any ram deflection during cross movement they come equipped with special wedges. With a load capacity of 6 ton (12,000 lbs), the mills hefty table is suited for heavy-duty and specific jobs.

A couple of things to look for. First, the worm adjustment may not be locked down. Or if it is, it may be too tight in places on the worm gear. It"s not the cleanest or best arrangement for a rotary table. Next, make sure the hold down or table locks are loose and not snug or tight. They will bind on you occasionally if your not careful. Also, if they are missing, the pieces under the top on the RT may still be there. And last, yeah, just like everyone else is saying the method of securing your part to the table is flexing the table top. The table top is so thin, it wouldn"t take much to cause it to flex. It"s expected from something from Palgrim.

My suggestion is get you a piece of aluminum plate about 7-8" square or diameter by about 3/4-1" thick. Machine it flat, unless it is tooling plate that has been ground flat, and mount at the outer edges with hold down bolts. Next drill and tap a field of holes on 1" x 1" grid on the plate. This will allow you bolt down just about anything with out worrying about the table top flexing. Plus, if you bugger up the surface of the sub table, you can re surface it or replace with a fresh top. Ken

I"ll also endorse the 8" Phase II rotary table. At one point in time I had, and used my 8" table on an RF-31. As McGyver says, you should allow room for clamping your stock and the 8" provides that for a hobbyist. Definitely go for the dividing hardware and tailstock............

Also, please note, in the main catalog Enco offers some additional accessories for the Phase II rotary tables to make them into "Superspacers", which consists of a three jaw chuck and an adapter plate (sold separately), complete with mounting hardware to fit the table as well as an alignment plug to set everything in the proper alignment. After the chuck and plate are bolted to the table, the alignment plug can be removed through the open chuck jaws, leaving a through hole.

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

ABTech’s standard line of high precision, air-bearing rotary tables (AT Series) and heavy-duty rotary tables (HDRT Series) are ideal for low-speed TIR measurements, optical inspection, precision assembly, or light machining and grinding where radial and axial accuracies down to 2.0 µ” are required. These are available with tilt and center worktables, precision fixtures, 3-jaw chucks, vacuum feed through the center, and motor drives. They are manufactured with 440CSS and hardened to 58 – 60 RC, making these rotary tables the most robust available.

8613371530291

8613371530291