velmex rotary table free sample

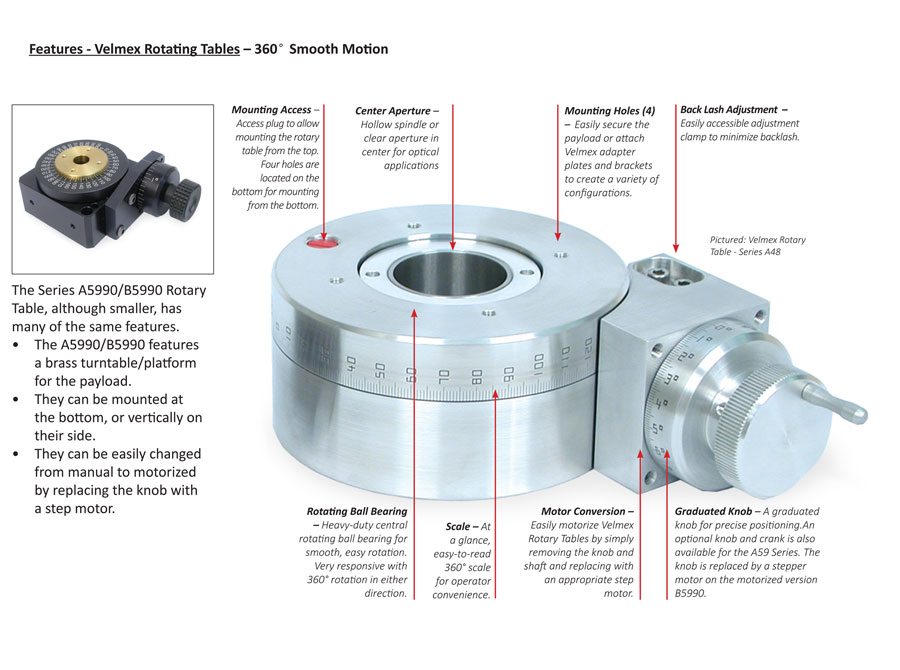

Velmex offers two series of Rotating Tables – the A4800 in three different gear ratios (18:1, 36:1 and 72:1) and the A5990 with a 90:1 gear ratio. The A4800 Series of Rotary Tables has a load capacity up to 200 lbs. (90.7 kg.) horizontally and 25 lbs. (11.3 kg.) vertically. The A5900 can handle 50 lbs. (22.6 kg.) horizontally and 5 lbs. (2.3 kg.) vertically. They easily integrate with Velmex UniSlides®, BiSlides® and XSlides™ in a array of configurations.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

These are examples of Velmex products. If you wish a similar product, please contact us with your specific application specifications (travel distance, payload, hours per day in use, resolution, speed range, etc.). You can use the Request Assistance form.

You would use an elevating table when you require free standing vertical travel with a platform shelf. The Velmex Elevating Tables are more rigid then turning a linear stage into a vertical axis, making them more stable. However, if you do want longer travel distance or a narrower or wider frame, almost all Velmex linear stages can be converted to an elevating table with the addition of a base plate and a platform shelf. They can be engineered to provide added rigidity, support and stability.

Velmex Elevating Tables are made of Velmex world renown UniSlide assemblies. They use a deeper base under the dovetail ways for added support and feature an oversize base for added stability in the vertical position. A right angle platform is mounted to the carriage that can be mounted in the inverse to add versatility to the travel envelope.

Lubrication is important for motion systems or wherever you want maximum life and the lowest friction. UniSlide Assemblies can be lubricated with Velmex Lubriplate Aero®. Only a few drops are required to keep your slide running smoothly. The load and hours of use effect the amount and frequency of lubrication. See the user guide that came with your UniSlide for recommendations.

Yes, UniSlides can be mounted together in XY, XZ, XYZ configurations. Mounting UniSlide assemblies in multi-axis systems requires the use of adapter plates and brackets. They also can be combined with Velmex Rotary Tables and our other linear stages to make custom systems to meet a wide range of applications. See UniSlide Options and Accessories for more information on the plates and adapters. Also see our examples pages for images featuring Elevating Tables combined with other Velmex products.

Velmex slides, stages and tables are available in manual or motor-driven configurations. Standard “off-the-shelf” sizes are built-to-order to the customer"s required configuration specifications. Custom sizes and configurations are also available. No minimum or maximum quantity requirements.

Cross Sections – The cross sections of the Velmex linear stages are a key differentiation. While the three Velmex linear stages all have bases with dovetail ways, they each have a different cross-section profile. (images above) The sliders (carriages) each ride on the ways differently.

Velmex UniSlide® Assemblies are available in a variety of configurations, models and sizes including Linear Slide Assemblies, Elevating Tables and XY Tables. All available as manually-operated or motor-driven stages. Linear UniSlides have a load capacity up to 400 lbs horizontally and 100 lbs vertically with travel distances to 42". UniSlide Elevating Tables and XY Tables can lift up to 100 lbs.

Velmex BiSlide® Assembly"s modular design makes it highly configurable for a multitude of different motion-control applications. A several models including free motion and lead-screw available both manually-operated and motor-driven. BiSlide Assemblies have a load capacity of 300 lbs. horizontally. BiSlide configurations come in travel lengths up to 80". The Belt-Drive BiSlide can travel 228".

Velmex offers several pre-configured specialized BiSlide systems including the Side Knob BiSlide, Parallel-coupled BiSlides and Belt-Driven BiSlides.

XSlide™ is a compact positioning stage for smaller loads and ideal for limited space applications, highly suitable for either high performance incrementing or scanning functions.

Robust, fast and smooth turning performance from Velmex Rotary Tables and Turntables. Two sizes of rotary tables with varying gear ratios are available both manually-operated and motor-driven. The largest Rotary Table has a load capacity up to 200 lbs.

Velmex offers a number of it"s stages already pre-configured for specific applications. These include UniSlide XY and Elevating Tables with large bases and payload plates. Also available is our globally-recognized Tree Ring Measuring system using Velmex UniSlide® linear stages and our concrete void analyzing (Petrography) system using either UniSlide® or BiSlide® Assemblies.

Velmex Controls include VXM™ Controllers for easy control of single or multi-axis systems and VRO™ Readouts for ultra-precise position information. AC and DC motors; and linear, magentic and rotary encoders are also available.

Details on accessories, options and other components that are combined with Velmex devices to construct positioning systems that address your specific requirements.

• A means to control the position of the carriage. This can be a crank and knob, a graduated knob, a micrometer head or a motor. On a Velmex Free Slide, position is controlled by the operator pushing the carriage into position.

An XY Table can also be comprised of 2 linear slides traveling in tandem on the X axis and 2 traveling in tandem on the Y axis. In this configuration the tandem slides affixed at the outside perimeter of the base plate and platform plate. Frequently this type of XY table will have an aperture in the center because the slides are attached at the perimeters of the base and platform plate.

Another form of elevating table uses a linear slide mounted on the Z axis to a base plate. The payload can be mounted directly to the carriage or it can be mounted on a L-shaped platform bracket which is in turn mounted to the carriage.

Rotary tables can be manually- or motor-driven. Large scale rotary tables are frequently found in CNC machining operations. They are also used in indexing or pan and tilt operations.

Lubrication is important for motor-driven systems or wherever you want maximum life and the lowest friction. BiSlide Assemblies should be lubricated with Velmex BL-1 oil. Only a few drops are required to keep your slide running smoothly. The load and hours of use effect the amount and frequency of lubrication. Manual BiSlide assemblies require less frequent lubrication. See the user guide that came with your BiSlide for recommendations.

Yes, BiSlides can be mounted together in XY, XZ, XYZ configurations. Mounting BiSlide assemblies in multi-axis systems is easy using cleats. T-slot bases and frames can be added for more structure and to create application specific systems. They also can be combined with Velmex Rotary Tables and our other linear stages to make custom systems for a wide range of requirements. See BiSlide Options and Accessories for more information on the cleats and T-slot structuring.

Adjustments the carriage on a BiSlide may be necessary after break in period and less frequently thereafter. The Lead Screw Nut (StabilNut) has an adjustable mesh to minimize backlash. Carriage fit can be adjusted by tightening the bolts on the carriage surface. See the BiSlide Owners Manual for how and when to adjust

When used with a Velmex VXM™ controller you can lift up to 20 lbs. with the Belt Drive model. However, when using a BiSlide® Belt driven slide mounted vertically it should be used in conjunction with a "Fail-Safe-Brake" option to prevent rapid dropping. A VXM™ with braking option is offered. A servo system with similar braking option can lift up to 40 lbs vertically on the Belt Drive.

Lubrication is important for motor-driven systems or wherever you want maximum life and the lowest friction. UniSlide Assemblies can be lubricated with Velmex Lubriplate Aero®. Only a few drops are required to keep your slide running smoothly. The load and hours of use effect the amount and frequency of lubrication. See the user guide that came with your UniSlide for recommendations.

Yes, UniSlides can be mounted together in XY, XZ, XYZ configurations. Mounting UniSlide assemblies in multi-axis systems requires the use of adapter plates and brackets. They also can be combined with Velmex Rotary Tables and our other linear stages to make custom systems to meet a wide range of applications. See UniSlide Options and Accessories for more information on the plates and adapters.

An adjustable expansion gib controls the fit of the UniSlide carriage. Adjust by tightening the Allen head screws located at the end of the slider. See the UniSlide Owners Manual for how and when to adjust.

UniSlide Stages cannot be converted, except at the factory. You should purchase the version you require at the onset. It is possible, however, to buy Velmex UniSlide Stages pre-configured for both manual and motorized operation with a double shaft stepper motor.

Options and accessories like revolution counters can be added to Velmex assemblies after the fact. However, because of special adjustments, possible cutting or turning and additional hardware that may be required, the assembly needs to be returned to the factory to properly fit the additional component. There is a nominal charge for reconfiguring assemblies.

Cross Sections – The cross sections of the Velmex linear stages are a key differentiation. While the three Velmex linear stages all have bases with dovetail ways, they each have a different cross-section profile. (images above) The sliders (carriages) each ride on the ways differently.

Most Velmex linear stages can be mounted on their ends and used as a stand alone Z axis. The load in this case is often considered a cantilever load. When mounted in combination with multiple stages in X or XY axis other factors need to be considered to calculate load including the weight of all the components. Which assembly and the dovetail profile of the carriage can also make a difference in the load the slide can carry. (See the load questions below.)

Yes, all Velmex stages can be used in either the vertical (Z) or inverted X or Y position. However, inverting the stage puts restrictions on the load it can carriage. See the FAQ that follows on loads and how to calculated the permissible load.

Most Velmex linear stages can be mounted to other stages in the same product line in XY, XZ, XYZ configurations. They also can be combined with Velmex Rotary Tables and our other linear stages to make custom systems to meet a wide range of requirements and applications.

Velmex has several thousand standard configurations of linear slides when you include the options, accessories and the multitude of sizes. However, our standard offering does not always meet every requirement. Our sales application engineers can design a custom solution to the meet a customer"s specification. Custom systems could include design, mounting and testing charges; and contain custom, externally-fabricated components.

All of the above assume a single axis stage. You also need to consider the number of axes in the system. If it entails more than one axis, the weight and orientation of each subsequent stage and any required adapter plates or gussets need to be considered. Combining slides or rotary tables in XY or XYZ configurations can create a cantilever load. In these configurations the X axis carries the weight of the Y axis and/or Z axis (and/or theta axis), any components and the attached payload.

Additional design factors can be incorporated to accommodate larger payloads such as going up in stage size, adding additional carriages to the slide, or looking at tandem or parallel Velmex slides.

Load calculations for Maximum and Normal (in Horizontal Center and Vertical Center), along with Load Thrust and Cantilevered Loads are found under the specifications for each brand of Velmex stages.

Cantilever loads and the load on the stage when mounted inverted or on the stage"s side are also affected by gravitational forces that pull the payload and the carriage down. The rating for a Cantilever type load is always going to be less than that of a normal load. How to calculate the allowable load and illustrations of each follow. The profile of the carriage and the dovetail way the carriage is nested in also affects the tensile strength the stage has to support the weight of the payload when placed in a cantilever, suspended (gantry) or inverted position. Depicted below is the load calculation for Velmex UniSlide Linear Assemblies.

Velmex products are primarily manufactured from hard-alloy aluminum. Lead screws are either 303 stainless steel or nickel-plated steel depending on the pitch. The BiSlide and XSlide assemblies have black anodized bases. Black anodizing is an option for UniSlides. They also can be hard coat anodized or nickel-plated for an additional charge.

BiSlide assemblies can easily be converted from a manually-operated slide to a motorized version. See the BiSlide Owners Manual for the instructions on converting the stage. UniSlides, XSlides and Velmex Rotary Tables cannot be converted. You should purchase the version you require at the onset. It is possible, however, to buy Velmex stages pre-configured for both manual and motorized operation with a double shaft stepper motor.

Options and accessories like revolution counters can be added to Velmex assemblies after the fact. However, because of special adjustments, possible cutting or turning and additional hardware that may be required, the assembly needs to be returned to the factory to properly fit the additional component. There is a nominal charge for reconfiguring assemblies.

Below is a chart showing the available lead screws and pitches. Followed by the lead screw code for each Velmex brand. The code can be found after the base lengthin the model number. See the Model Number explanation that follows.

Velmex products are used in many industries for a variety of applications. Both manual and motorized versions are used in single and multiple axes configurations. A few examples:

• Velmex stages have successfully been used in environments including: clean rooms; outdoors; underwater; in a vacuum; attached to aircraft; on naval ships; and in outer space.

Yes, Velmex products can be used in vacuum or specialty environments with modifications or material substitutions. What is required depends on the environment. For more information on material substitutions, outgassing and other environmental considerations, please check theVacuum Environments page.

Lubrication is important for motor-driven systems or wherever you want maximum life and the lowest friction. Only a few drops are required to keep your device running smoothly. The load and hours of use effect the amount and frequency of lubrication. See the user guide that came with your Velmex device for recommendations.

• Normally, the worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole.

• An adjustable expansion gib controls the fit of the UniSlide carriage. Adjust by tightening the Allen head screws located at the end of the slider.

• Adjustments on the carriage on a BiSlide may be necessary after break in period and less frequently thereafter. The Lead Screw Nut (StabilNut™) has an adjustable mesh to minimize backlash. Carriage fit can be adjusted by tightening the bolts on the carriage surface.

Yes, the drive nut tension can be adjusted all Velmex linear slides. An adjustable mesh minimize backlash on each of the drive nuts. Refer to the product Owner"s Manual for instructions and frequency.

• UniSlides and XSlides use a tension adjustable drive nut made of Delrin AF®. The UniSlide has one adjustment location the top of the drive nut. The XSlide adjustment in located from the side of the slider.

Step motors are very common in linear positioning because of their ability to operate within very precisely defined increments. They work efficiently when there is frictional load to dampen them. Velmex assemblies have friction, and a polymer lead screw drive nut which absorbs step vibration. Velmex lead screws have low inertia relative to the motor inertia, making very fast accelerations and decelerations possible. Step motors reach full torque in just one step.

Step motors, when controlled with Velmex Controllers, do not miss or lose steps. Step motors run synchronously to their phase switching speed. When an external motor load exceeds the running torque of the motor, the motor may stall and lose a position greater than one step.

Velmex step motor controllers remove the problems of low speed motor resonance by utilizing half-stepping and controlling the current. The VXM switches the motor drive amplifiers directly, eliminating the sensitive pulse to motor translator link.

Proper motor sizing and operating the motor in a range that provides a torque reserve will ensure reliable operation. Review the motor speed/torque curves to determine the maximum reliable operating speed. Our Sales Application Engineers can help you determine the right motor size to operate the Velmex slide efficiently and effectively.

In order to program the VXM Controller for your specific application, it should be connected to a PC, Laptop, Tablet or PLC. However, the VXM-1J Control has a simple jog and auto-reverse functioning and does not require a computer to program.

Yes, if you have your own motors and controllers, you can use them with Velmex motor-ready products. The VXM Controller, however, has been specifically designed to optimize stepper motor control. Its a very dependable and low cost solution for high precision positioning requirements.

The Velmex VXM for step and direction has been designed to work with other motors, specifically motors with built-in controllers, if the motor can take step pulses. With this VXM version, you gain "smart control" of the motor. .

Velmex motorized stages, motors and the VXM Motor Controller come as a complete system, ready to plug in. See the Controllers Page for more details and specifications.

Yes, encoders can be used to determine payload positions on Velmex slides and tables. We offer inductive and magnetic encoders for UniSlide and BiSlide linear stages and rotary encoders for the Rotary Tables and the compact XSlide. You would also need a readout like the VRO™ to interpret the data being transmitted by the Encoder.

Because the carriage rides on the outside of the ways as opposed to the inside it"s difficult to tell where the carriage is positioned in relation to the travel distance. A rotary encoder fixed to the lead screw at the end of the XSlide is a better solution.

Yes, Velmex offers an number of options in addition to the linear and rotary encoders to measure travel. In most cases, these options would be used with manually-operated stages. They include:

The VRO can provide a readout from linear and rotary encoders for one or two axes. The axes can be configured in X, XY and XZ. An XYZ or other multi-axis configuration would require additional VRO Readouts.

The VRO can report position in either Imperial English or metric. It can count revolutions. It also can report in degrees when connected to a rotary encoder.

Velmex has over 4,000 possible sizes and configurations of linear and rotary stages. Please contact one of our Application Sales Engineers about your needs and your product specification requirements. They can aid you in selecting the proper stage and configuration at the lowest cost.

We build every Velmex product to order. A typical lead time is 2 to 3 weeks after receipt of the order for standard products. Custom configurations will usually take longer. Please contact us for a precise lead time.

We manufacture all Velmex products in our facilities in upstate New York. You can buy direct through us or through one of our international distributors. We ship worldwide.

These are examples of Velmex products. If you wish a similar product, please contact us with your specific application specifications (travel distance, payload, hours per day in use, resolution, speed range, etc.). You can use the Request Assistance form.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

Manual Linear UniSlide® Assemblies For Nearly Four Decades Velmex... positioning equipment has been used to produce linear and rotational motion in scientific, research, machine, instrument and industrial applications. Hundreds of thousands of UniSlides and BiSlides are in use providing simple, rugged, reliable motion. Velmex applications are limited only by your imagination. For example: measurement, alignment, inspection and QA/QC, optical focusing, antenna alignment, film and animation work, medical and biological analysis, for moving probes, sensors, components, and thousands of other uses. If you need precise, versatile movement in one, two or three dimensions, do it more efficiently and less expensively with a Velmex UniSlide®, BiSlide® or XSlide™. UniSlides are available in nearly 1000 standard models, including Free Sliding, Screw Drive, Graduated Knob and Scale with Vernier. Read position from 0.025” to 1 micron using mechanical or optical mechanisms. Finally, our Rapid Advance models save time. That is an impressive array of products, but the real versatility of UniSlides is their amazing flexibility. Every UniSlide is built to order. Customers are not limited to off the shelf products — you can customize your UniSlide to meet your exact requirements. Rapid/fine motion, thumb screw locks, special finishes, way covers, revolution counters, position encoders or some other feature? We can do it. BiSlide, XSlide and UniSlides Assemblies from Velmex, we’ve put quality into motion. Manual Introduct

UniSlide Features BiSlide Features • Rugged I-beam design • Integrated T-slot system for mounting and configuring XYZ systems • Manual and motorized versions • Corrosion resistant anodized finish • In stock Widths from 1.5” to 9” Lengths from 3” to 93” Weight capacities to 400 pounds Resolutions to 0.00005” Manual and motorized versions More compact than ball screw-driven stages Lighter weight-high strength aluminum alloys Low friction adjustable Rulon® sliding element eliminates lubrication, greatly decreases wear Resistant to impact loads Corrosion resistant Fewer parts Lower cost...

www.velmex.com Table of Contents Manual UniSlide® Contents Examples and Application Photos 1.4 Actual Size Cross-Sections 1.6 Selecting the Right UniSlide 1.8 TA Rapid Advance UniSlide with Linear Encoder 1.52 B Series Dovetail Base 1.54

Examples and Application Photos Here are examples of UniSlide® stock and custom positioning equipment. Many more examples are shown on our website. For help, please call our engineering staff, fill out the RFQ/RFA form on our website or the Fax-a-Quote form on page 1.58. Example 1: A manual rotary table that rotates a small, motorized slide. Example 2: A three axis system including an elevating table, all with a black anodized finish. Example 3: A four axis system to measure travel distance for medium-sized payloads. Manual UniSlide

www.velmex.comChoose a Size or SeriesActual size cross sections of the 5 different UniSlide Assembly Series. Drive nut diameter will vary. A15 Series See page 1.9 for details. Travel Distances and Load Capacities of Manual UniSlides Width Series Travel Horizontal Cantilevered Vertical Range Central Load Central * A25 Vertical Central Load Capacity with a 10 pitch (W1 and P10) screw is 30 lbs/15.5 kg. to due to a stronger thrust bearing design. Also, for greater base stiffness, Series A25, A40 and A60 are available in deeper cross sections. See the B Series Bases on page 1.54 for...

www.velmex.com Introduction All Series A15 UniSlides are 1.5” wide. Lengths vary by Type. There are 9 types. Each Type offers you specific features and benefits to satisfy your requirements. The UniSlide Model Number specifies the Type and other char-acteristics. Series A15 Series A15 Common Dimensions and Load Capacity 1.187" 0.62" T LEAD SCREW EXTENSION END BEARING BLOCK ASSEMBLY LEAD SCREW EXTENSION DIA. 0.218" FOR B & P20 0.231" FOR C & P40 0.250" FOR K1 & Q1 0.250" FOR K2 & Q2 S is the slider length. The standard length is 1 1/2.” Optional longer 2” and 3” length sliders are...

The KP1-V single-axis turntable with vertical rotational axis is used for direct workpiece positioning or as a modular base. It is available with a payload capacity of 500 ...

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits into the CM-1 or larger machines. It is ideal for smaller ...

100 mm (3.9") High-Speed Tilting 2-Axis Rotary Table, with indexing up to 1000 deg/sec. Requires a Haas mill with 4th- and 5th-axis drives for true 4th- and 5th-axis operation. Requires software version ...

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater mounting flexibility than its predecessor. ...

The rotary table TP 004 is a simply designed turning unit of high-quality gear and drive motor as a main component. It is equipped with an inductive reference ...

The base and circular positioning tables are made out of anodized aluminium alloy. The self-locking spindle is made from steel and its slide bearing is maintenance-free. The table has ...

... accumulation turntables are made from the highest quality stainless steel and can be supplied in numerous sizes. They are utilized for the collection of filled bags, bottles and packages and can be added to an existing ...

... turning table is equipped with motorized roller conveyors. It is used in conveying systems for changing the direction of the package units, without difference in the forward front. In addition, it is ...

Microplan"s TR rotating tables are designed and manufactured out of 2 granite disks each, moving on pressure/vacuum air bearings in ways to obtain highest possible stability. These apparatuses ...

Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

Compact package and Superior design of the Planar ServoRing rotary stages was optimized to minimize stage height. The low profile of the stage reduces total system ...

The Compact Clean room rotary table PSX Series is manufactured by ITALPLANT. The product is made of plastic, making it very light. It is suitable for corrosive and explosive environmental conditions. ...

Our FÖRSTER swivel welding tables offer maximum working comfort for all-round welding of complex assemblies. Ideal for all tasks due to a variable arrangement of our patented T-slot system.

Velmex Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating ...

Velmex Rotating Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning or rotating ...

... positioning accuracy, bi-directional repeatability, motion stability and low friction. Rotary stages 8MRL80 have clear aperture of 5mm while 8MRLP80 have dedicated pneumatic collet holder ...

The turntable roller conveyor is used for rotating a pallet to any desired angle. The transport direction of the pallet remains the same. Its modular structure consisting ...

Velmex manufactures linear and rotary motion-control positioning equipment for scientific, research, machining and industrial applications; including UniSlide®, BiSlide® and XSlide™ manual and motor-driven assemblies; Rotary Tables, XY Tables, Elevating Tables; VXM™ and VRO™ controls.

8613371530291

8613371530291