velmex rotary table in stock

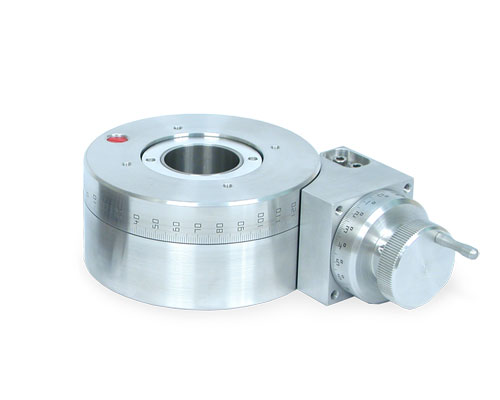

Velmex offers two series of Rotating Tables – the A4800 in three different gear ratios (18:1, 36:1 and 72:1) and the A5990 with a 90:1 gear ratio. The A4800 Series of Rotary Tables has a load capacity up to 200 lbs. (90.7 kg.) horizontally and 25 lbs. (11.3 kg.) vertically. The A5900 can handle 50 lbs. (22.6 kg.) horizontally and 5 lbs. (2.3 kg.) vertically. They easily integrate with Velmex UniSlides®, BiSlides® and XSlides™ in a array of configurations.

Since 1967, Velmex, Inc. has manufactured linear and rotary motion-control positioning systems for scientific, research, machining, instrumentation and industrial applications. Velmex produces UniSlide®, BiSlide® and XSlide™ manual and motor-driven stages; manual and motor-driven XY tables, rotary tables, elevating tables and turntables; as well as, VXM™ motor controls and VRO™ encoder readouts - all, American-made. All providing a variety of precise, yet simple, modular configurations to satisfy a broad range of positioning applications where high precision and value are essential. Common applications include manufacturing, research, automation and prototyping. Services provided include custom machining and controller integration.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

Normally, the worm/worm gear drive of Velmex rotary tables do not need any servicing. However, under severe conditions replenishing the lubricant will prolong the life of the gears. A small amount of Lubriplate can be placed in the access hole. See the user guide that came with your Rotary Table for instructions.

Yes, both models of Rotary Tables have a hollow spindle or open aperture in the center for optical applications. The manually-operated Velmex Turntable does not.

Yes, Rotary Tables can be and are frequently combined with other slides to achieve a particular motion or positioning. Which stage used in conjunction with the Rotary Table will determine which adapter plate or bracket might be required.

EMIX23 Magnetic Encoder for Velmex Linear Assemblies (Part # ENCMAGL1-xx) Magnetic linear encoder Connections Unterminated Cable Bendix PTO 6A-10-6P (For Metronics DROs) Standard With periodic index pulse Differential 5 V-TTL line driver outputs Resolution 0.001 mm (using 4 times edge multiplier) Repeating accuracy +/- 0.001 mm Small sensor with integrated translator Function 0V (GND) 5VDC VDC in Channel A Channel B Channel Z Channel A’ Channel B’ Channel Z’ Shield Technical Specifications 5V TTL output version Color White Brown Green Yellow Black Violet Orange Gray PE SENSOR electrical data Measuring principle Signal output Resolution at 4 edge triggering Repeat accuracy Accuracy of the system in µm at 20 ° C Max. permitted distance to the tape Power supply Tolerance of power supply Incremental Speed proportional 0.001 mm +/- 0.001 mm +/- 25 + 20 x L (L = measuring length in meters) 0.8 mm 5 VDC 5 VDC: +/- 2.5 %, remaining ripple < 50 mV Translator circuit intern/extern Output levels Output channels Output characteristics Max. output frequency per channel intern 5 VDC - TTL Line Driver A, A’, B, B’, Z, Z’ Push/pull, durable short circuit proof TTL: 100 KHz at 0.4 m/s resp. 500 KHz at 2.0 m/s Output current per channel Max. operating speed Index pulses Cable length 20 mA 2.0 m/s Periodic output of channels Z and Z’ NOTE: A’, B’, Z’ are for differential encoder interfaces. For single ended interfacing leave A’, B’, Z’ unconnected. A/B Quadrature Pulse diagram A Min. bend radius of sensor cable Operation temperature Stock temperature Humidity The channels A and B are 90 ° phase shifted The output of the index pulse is periodically after 2 mm’s

In addition, since rotary motion is often performed for the purpose of processing, measurement, or some other subsequent operation, the use of rotary tables by themselves is rare.

Rotation mechanisms used in chairs and other equipment are also classified as rotary stages in the broad sense of the term, so they are used not only in manufacturing but also in home applications.

A crossed roller bearing is a bearing structure in which rollers are arranged between the inner and outer rings. The rollers are arranged in a straight row with a 45° contact angle, enabling the back bearing structure of a ball bearing to be realized with a single row, and the structure is capable of receiving loads from multiple directions simultaneously. The rotary table and cross roller bearings can be directly connected, which reduces the number of structural parts.

Since the rotational accuracy of the rotary table is directly related to the accuracy of the rollers, high rotational accuracy can be obtained depending on the accuracy grade of the rollers. In addition, since cross roller bearings have low frictional force and can be operated with light force, micrometer heads can be used in the fine-tuning rotation mechanism to obtain high positioning accuracy.

Velmex, Inc. was one of the first manufacturers of precision positioning equipment and is still a leader in the industry today. Founded in 1967, Velmex, Inc. is a premier manufacturer of stock and custom linear and rotary motion control positioning equipment for scientific, research, machining, instrumentation and industrial applications. We produce UniSlide®, BiSlide® and XSlide™ manual and motor-driven assemblies; manual and motor-driven XY tables, rotary tables, elevating tables and turntables; as well as, VXM™ motor controls and VRO™ encoder readouts. Hundreds of thousands of UniSlides®, BiSlides® and XSlides™ are in use around the world providing simple, rugged, reliable motion. We take great pride in building every part to your exact custom specifications, so you receive precisely what you want and need. UniSlides® are available in nearly 1,000 standard models, including Free Sliding, Screw Drive, Graduated Knob and Scale with Vernier. Parts we can produce are limited only by your imagination. If you need precise, versatile movement in one, two or three dimensions, do it more efficiently and less expensively with a Velmex Inc. Our services also include custom design and machining and motor controller integration. Jack Evans founded the company 50 years ago, in Bloomfield, in upstate New York. His original patented UniSlide® design continues to be produced today. We cut, machine, assemble and test all our products starting with the raw extrusions. Our administrative, manufacturing and research and development facilities are all in one location, to provide extraordinary customer service to you. Rapid/fine motion, thumb screw locks, way covers, special finishes, revolution counters, position encoders or some other feature? We can do it!

Manufacturer of standard and custom 360 degree linear rotary tables for scanning, assembly, testing and production applications. Features vary depending upon model, including worm and gear drive design with central rotating ball bearings, manual and motorized operation, hollow spindles, four mounting holes, accessible adjustment clamps and graduated knobs. Accessories such as rotating table adapter plates, brackets, platform shelves, thumbscrew locks, alternative knobs, limit switches provided. Manually operated rotary motion turntables also available. Suitable for mounting and rotation of test specimens, cameras, transducers, sensors, mirrors and other components. Stock items and repair services are offered. One year warranty. Made in the USA.

8613371530291

8613371530291