4th and 5th axis cnc rotary table brands

At Hosea Precision, quality comes first - at every stage of the production process. We are dedicated to producing 5 axis and 4 axis rotary tables, which are two of our proudest products. With the high-quality and precision feature, our CNC rotary tables have been sold & widely used in the European market and have an enormously high reputation amongst our customers.

In March 2015 Hosea Precision created the independent brand, to make it a household name for high-quality 4 axis rotary tables from Taiwan. We have been following this strategy with great success: more and more manufacturers across Europe cooperate with us and make use of our 5 axis rotary tables and other rotary tables products. Do not hesitate to contact Hosea for more products detail!

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits ...

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater ...

... more compact and versatile 5-axis solution for mid-size mills. The new unit easily fits on one end of a machine’s table, leaving the remainder open for additional fixtures or vises. ...

The new designed rotary swivel unit RT2A is the ideal solution for retrofitting your machine with a 4th and 5th axis. It is based on the proven and robust rotary tables ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

It’s true that less than 10% of machined parts require simultaneous 5-axis movement. Which means that more than 90% of the parts machined in a typical job shop would not benefit from expensive, complicated, full 5-axis contouring; but that doesn’t mean your shop wouldn’t benefit from simple, affordable, 5-axis indexing capability. Work platter: Available in 6.75" diameter, T-sloted platters with drilled and tapped holes to accept Raptor or any brand work-holding, vises, fixtures, chucks, etc. Also available in dual-spindle system for increased efficiencies by cutting the number of tool changes in half.

1. QuindexPneumatic 5th Axis Bolt-on kit:Easily bolts-up to your existing true 4th or semi-4th axis rotary table. Shop air drives the spindle 90 degrees up against hard stops as well as provides 300 lbs. of brake force to allow for heavy cuts. A simple M-code or relay closure triggers indexing. This is the most cost-effective option to start 5-sided machining and is designed to mount to most other brands of rotary tables. (As well as ours of course!)

2. Quindex Semi 4th and Pneumatic 5th Axis Package:This package is everything you need to turn your 3-axis machine into a 5-axis workhorse.This package comes completely assembled and mounted on a subplate for a fast, accurate set-ups.

•Index Designs true 4th axis rotary table with Quindex 5th axis head, outboard support all mounted on a subplate. Call or email for quote on your specific machine. Please provide year, machine and control

brand with model number and if machine is 4th axis ready including amplifier. For example: 2015, XYZ machine with Fanuc OiMF control, not 4th axis ready, no amp.

•Dual Quindex heads on any of the above configurations. Increase your output and cut your tool changes in half by machining two parts in one set-up. Add $4995.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and other dealer installed accessories are not included. All prices are in U.S. dollars.

New Trunnion model TR 100RF has all of the features of the standard wired models while being the perfect application for palletizing VMC An easy to use system with no messy cables

KME CNC can design a trunnion for your application. Custom 5-axis trunnions can be made to specific matching needs including different drive configuration, large or smaller sizes, less

KME CNC’s trunnions have the lowest platter height in the industry, with 7.87” from table to platter, allowing maximum Z height clearance. KME CNC can also manufacture trunnions with 10” platters, depending on their specific needs. No additional drive cards necessary!

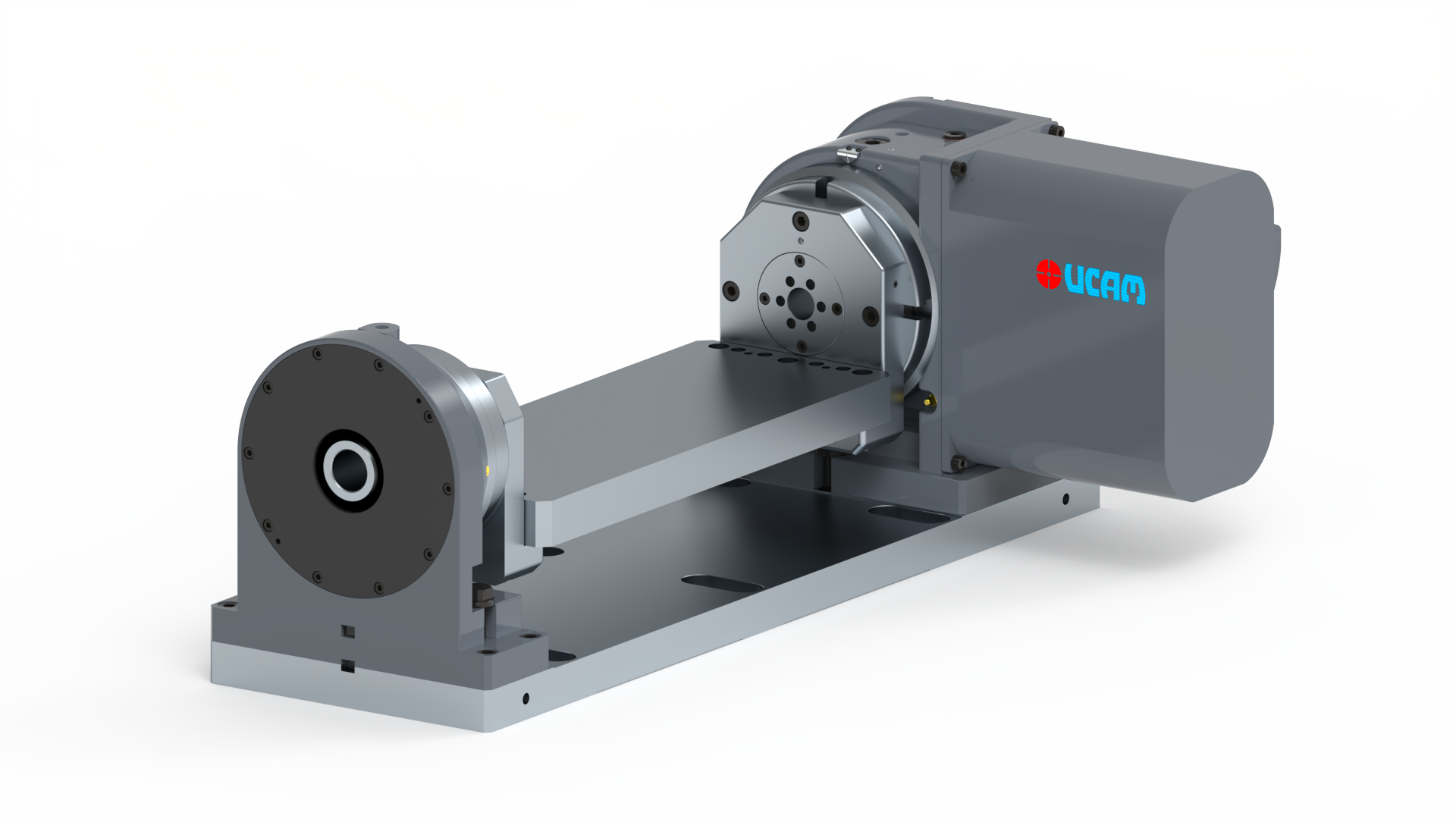

UCAM presents a solution to problems faced with Ball Valve Body Components. This mechanism used in transmission pipelines of gases, oil, and chemicals often faces a challenge in increasing production volume within the given time capacity.

#cncmachining #cncmanufacturing #manufacturing #indianmanufacturing #machinist #metalcutting #5thaxis #5axis #cncmill #cncmachine #5axismill #machineshop #5axiscnc #rotarytable

About UCAM: We offer a wide range of CNC Rotary Tables and custom-built rotary tables which can be used vertically and horizontally based on the application. Our differentiation lies in cutting-edge technology, unceasing product innovation, and proactive customer relationship, making UCAM the most preferred brand in the Indian machine tool industry. UCAM"s product line lays stress on quality, reliability, and performance while machining the needs across industries - Automobile, Aerospace, Medical, Mining, Defence, Power Generation, General Engineering and Others.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new 5 axis rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement 5 axis rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new 5 axis rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

CNC rotary tables are a cost-effective alternative for the shops that cannot afford those high-end multi-axis machining centers. Though less versatile and efficient than a CNC machining center, a typical milling machine that incorporates a rotary table is able to carry out many more intricate tasks. In this article, we will walk you through the basic knowledge of the 4th and 5th axis CNC rotary tables, including how they work and what they can do for the shops.

In essence, it is a mechanical device that offers an additional rotational axis to a machine tool. It is typically designed to work with a milling machine so that the machine has the ability to carry out more complex cuts. Provided with a rotational axis, in a sense it combines a milling machine with a lathe. Besides giving an extra axis, rotary tables are also used for indexing and positioning tasks.

Rotary tables were invented in the early 20th century. The construction has not changed much since the invention except the way they are driven. At first, chains were used. But from 1918 on the shaft-driven mechanisms replaced them. As the technology of powered machines and computer control advanced, NC and CNC models hit the market in the late 20th century. CNC controls facilitated precision positioning and indexing.

The primary benefit is the indexing accuracy. In the past, millimeter-scale accuracy was enough for general-purpose machining applications since the part tolerance requirements were not high. Today, medical equipment, military, and automotive components require higher precision. That is why CNC tables with micrometer precision prevail across industries.

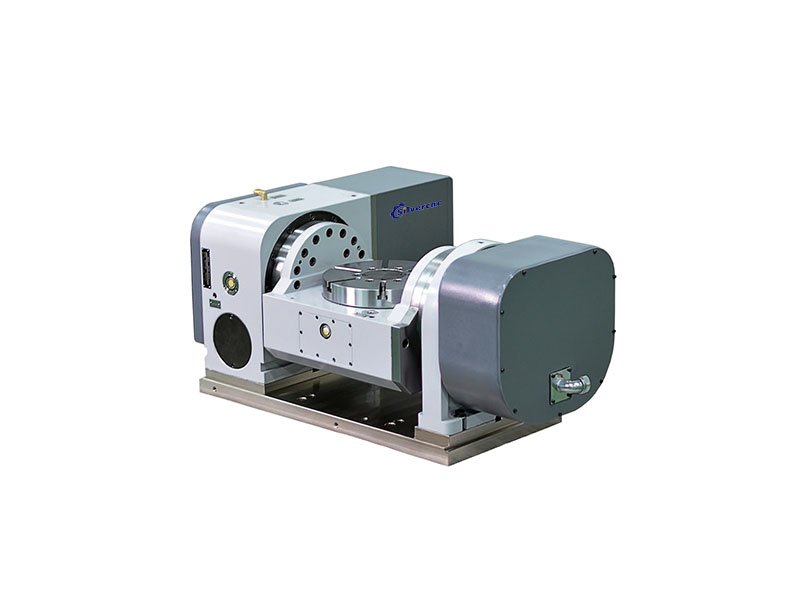

The standard CNC rotary tables are also called the 4th axis or 4-axis rotary tables. The 4th axis refers to the rotational axis, their most important feature. It upgrades an existing machine tool with x, y, z dimensions by adding an additional axis.

As mentioned earlier, the working principle of a 4th axis CNC rotary table is similar to the headstock of a lathe. They are both electrically powered to clamp a workpiece and make turns. The CNC system enables precision positioning so that the milling machine can make cuts on the desired surfaces of a workpiece.

An additional fourth axis is beneficial because it can be adjusted for particular amounts of rotary motion. The degrees the table rotates are pre-programmed and accurately controlled by the computer. The other benefit is that it allows the milling machine to work on cylindrical parts. The milling machine can cut grooves, slots, and planes on the outer diameter of a bar.

The precision indexing ability of the rotary table enables the machine tool to cut equidistant holes in a workpiece around 360 degrees across its surface. Repositioning of the workpiece is not required during such an operation. Similar operations such as arc cuts and curved contours can be performed in a run as well.

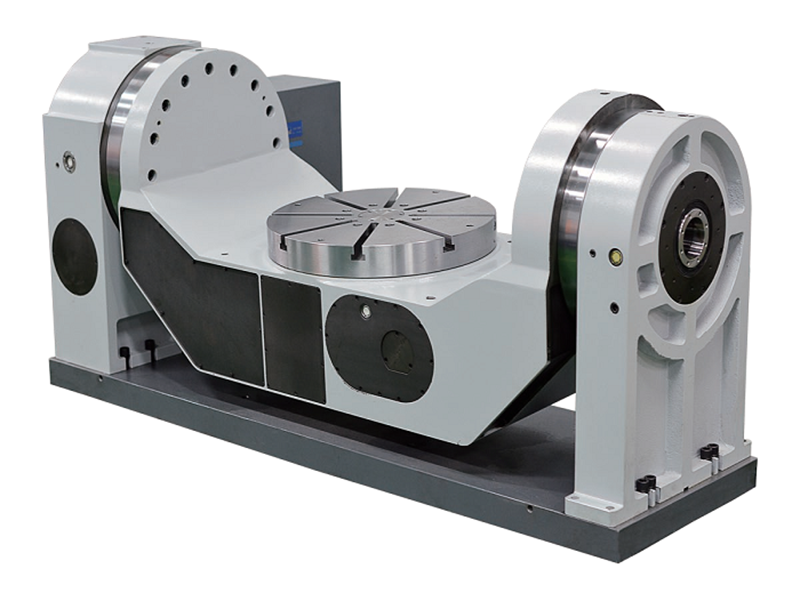

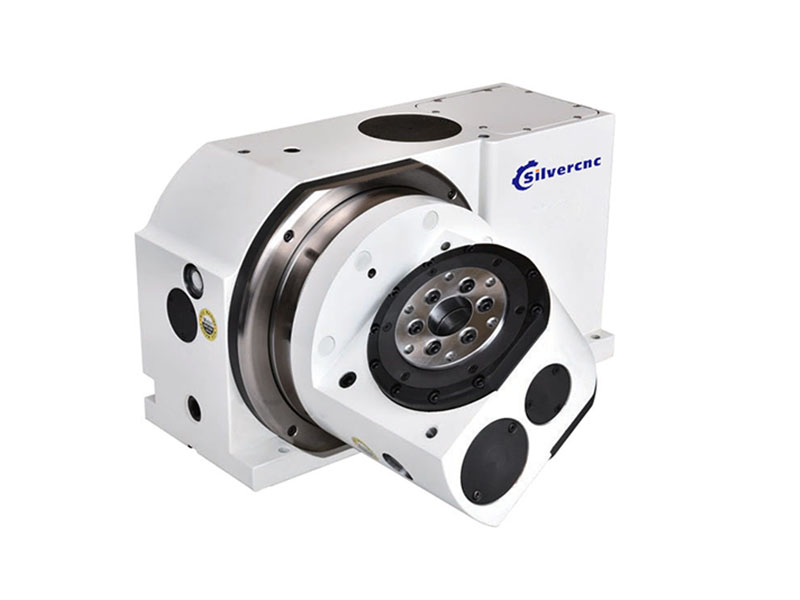

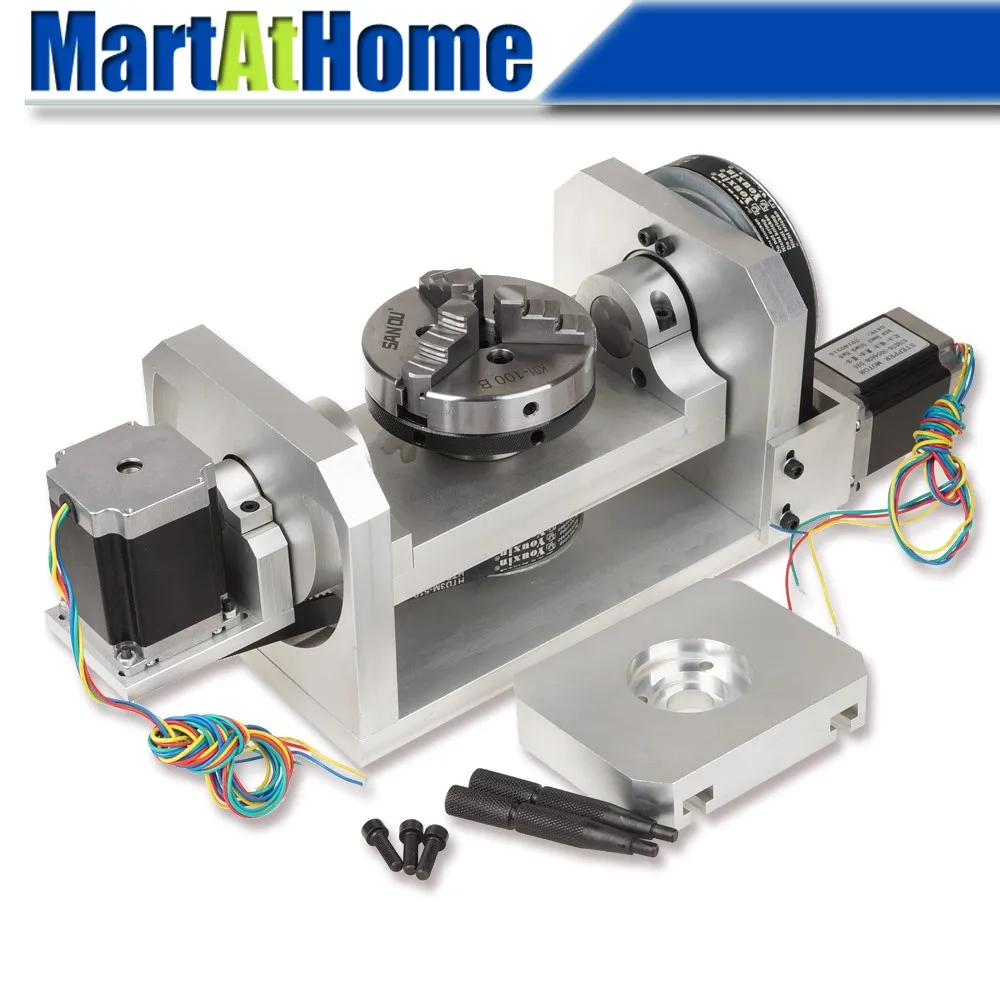

A 5th axis CNC rotary table provides two additional machining axes to a machine tool. Besides the rotational axis, the 5-axis rotaries have another swinging axis. In other words, the table not only turns but also tips. With two more axes, the machine tool is able to perform multi-plane machining.

The working mechanism of a 5-axis CNC rotary table is simple. As you can see in the image above, the rotary is mounted onto a swivel base. In addition to the swivel, other designs such as a swing bed are also available to provide a tilting axis to the table. Here is a video showcasing the moving axes.

A 5th axis CNC rotary table not only features precision positioning but also eliminates multiple setups that are required for complex machining applications. Compared to the standard CNC rotaries, the 5-axis table covers more surfaces on the workpiece. The milling machine can machine a workpiece on any four of the five axes at the same time, which reduces the production lead time significantly.

One of the key applications of 5-axis machining is mold-making. The ability to achieve intricate surface designs on the workpiece allows for the machine to manufacture molds used in industries including aviation/aerospace, automotive, military/defense, and medical.

The 4th and 5th axis CNC rotary tables have their own pros and cons and are suitable for particular applications. The 4th axis rotaries are apt at precision indexing for simpler designs whereas the 5th axis tables excel at complex designs but the rigidity is compromised and chatter or deflection may take place accordingly. The shops should choose a model that meets their actual requirements.

Rotary Tables└ Workholding Supplies└ Workholding & Toolholding└ CNC, Metalworking & Manufacturing└ Business & IndustrialAll CategoriesAntiquesArtBabyBooks & MagazinesBusiness & IndustrialCameras & PhotoCell Phones & AccessoriesClothing, Shoes & AccessoriesCoins & Paper MoneyCollectiblesComputers/Tablets & NetworkingConsumer ElectronicsCraftsDolls & BearsMovies & TVEntertainment MemorabiliaGift Cards & CouponsHealth & BeautyHome & GardenJewelry & WatchesMusicMusical Instruments & GearPet SuppliesPottery & GlassReal EstateSpecialty ServicesSporting GoodsSports Mem, Cards & Fan ShopStampsTickets & ExperiencesToys & HobbiesTravelVideo Games & ConsolesEverything Else

5 axis rotary tables allow you to work with an additional dimension. In addition to the two rotary motions, these indexing tables have an extra swinging axis allowing it to tip as well as turn.

5th Axis CNC Rotary Tables are perfect for larger manufacturers. They offer unmatched levels of versatility, precision and efficiency. Here at 1MTA, we are able to supply a 5 axis indexing table to suit your budget or project size. We also offer a bespoke, custom solution to your project which you can learn more about here.

Because the tilting axis normally needs to bear a heavy load, a robust transmission mechanism for the tilting axis should be employed to improve the wear resistance and precision of the tilting axis. Thus, we can provide roller gear cam, alloy steel worm gear, or Japanese- made worm & worm gear (wear life is 2.6 times longer than aluminum bronze PBC3.) as the transmission mechanism of the tilting axis.

Stop building custom adapters and subplates for every new job that comes into the shop. With the patented RockLock system job changeover becomes simple and repeatable, saving you time and money.

The HRT160-2 has two rotary spindles to allow two workpieces to be loaded. This reduces the number of tool changes and the number of times the machine stops to load parts. Requires a Haas mill with...

This is a high precision rotary table/air bearing spindle made by Professional Instruments Company, Block-Head model 10R-15. It was pulled from a state of the art Moore Tool M18 AG Diamond Tool La...

The new CNC Rotary Table from UCAM has got higher speed and higher clamping torque. Thus making it suitable for machining complex components like turbine blades, when used in synchronous with machine axes.The new CNC rotary table URX Series has got better aesthetics. Further provides higher productivity and are available with Right Hand, Left Hand or Rear Motor mounting arrangement.

UCAM offers wide range of 4th Axis Rotary Table. Depending on the application we can offer precision Standard CNC Rotary Tables, Tilting Table, Large Bore Rotary Tables, Multi-Spindle Rotary Table, Large Size Rotary Table etc. These Rotary Tables can be integrated into 3 Axis machines to form an integrated 4th Axis solution for interpolation as well as positioning applications. The demand for higher speed and higher clamping torque has made us to bring out the latest version of CNC Rotary Tablee, which is beneficial for the customers in increasing productivity of machining operations.

UCAM standard rotary tables are used in various industries as per listed below for machining complex components. The new and improved URX series rotary tables helps in improving productivity.

TANSHING products can be selected depending on different machining conditions. A wide range of models, such as the type of high load, high rigidity, high speed, high precision, long life span, zero backlashes, ultra-high load 10-60 tons large precision rotary table, and hydrostatic table can be customized. In addition, there is a variety of new 5 axis rotary tables, swing head rotary, etc. The complete series is available in our product line.

TANSHING’s R&D team is capable of dealing with a variety of machining requirements, such as speed and load capacity improvement. Any customized accessories can be planned and designed quickly. The same type of rotary table with a direct drive motor has been widely installed at domestic and foreign machine tool manufacturers. Our techniques for the function application of product, assembly, and testing are well-developed. We welcome machine tool manufacturers and machining shops to contact us for any kind of inquiry.

The Stallion Tombstone provides manufacturers with the ultimate time saver. With 4 sides, handling and tool change time decreases substantially. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Tombstone minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary. Our smallest tombstone model, at 4", is perfect for machining small parts at large volume.

8613371530291

8613371530291