4th and 5th axis cnc rotary table free sample

The Computer-Aided Design ("CAD") files and all associated content posted to this website are created, uploaded, managed and owned by third-party users. Each CAD and any associated text, image or data is in no way sponsored by or affiliated with any company, organization or real-world item, product, or good it may purport to portray.

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

Whether you use mills, presses or lathes, machine tools are often only as useful as the accessories that come with them. Take care of repair tasks and add extra functionality with the machine tools accessories at Alibaba.com. If you need new 5 axis rotary table or are seeking to replenish your component stocks, our wholesale store is the ideal place to look. We stock accessories for every type of machine tool, with multiple options in most cases. So add resilience to your operations and be ready for any production challenge with the machine tools accessories in our store.

Machine tools come in all shapes and sizes, and so do the accessories that make them tick. For instance, CNC and manual lathes can be customized with jaw chucks, shanks, woodworking knives, drill chucks, rotary chucks, clamps, and turning tools. Add brushes and sanding discs, and turn your machine tool into a multi-purpose machining center. Add a range of cutting tools to milling machines, pick the right drum sanders for your drills, or add a lathe dog to make turning much easier. There are accessories for hydraulic presses, add-ons like drag chains, and many other machine tools accessories. And if you need replacement 5 axis rotary table, Alibaba has everything you need.

Our machine tools catalog is packed with accessories. Search the listings for your preferred tool and zero in on accessories that can enhance its functionality. From control handles to tool holders, thread holders and saw blades, the whole panorama of machine tools accessories is here and ready to order. There"s no better way to add extra stocks and renovate machinery when the time comes. When new 5 axis rotary table are required, head to the Alibaba wholesale store and give your machinery a new lease of life.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

It’s true that less than 10% of machined parts require simultaneous 5-axis movement. Which means that more than 90% of the parts machined in a typical job shop would not benefit from expensive, complicated, full 5-axis contouring; but that doesn’t mean your shop wouldn’t benefit from simple, affordable, 5-axis indexing capability. Work platter: Available in 6.75" diameter, T-sloted platters with drilled and tapped holes to accept Raptor or any brand work-holding, vises, fixtures, chucks, etc. Also available in dual-spindle system for increased efficiencies by cutting the number of tool changes in half.

1. QuindexPneumatic 5th Axis Bolt-on kit:Easily bolts-up to your existing true 4th or semi-4th axis rotary table. Shop air drives the spindle 90 degrees up against hard stops as well as provides 300 lbs. of brake force to allow for heavy cuts. A simple M-code or relay closure triggers indexing. This is the most cost-effective option to start 5-sided machining and is designed to mount to most other brands of rotary tables. (As well as ours of course!)

2. Quindex Semi 4th and Pneumatic 5th Axis Package:This package is everything you need to turn your 3-axis machine into a 5-axis workhorse.This package comes completely assembled and mounted on a subplate for a fast, accurate set-ups.

•Index Designs true 4th axis rotary table with Quindex 5th axis head, outboard support all mounted on a subplate. Call or email for quote on your specific machine. Please provide year, machine and control

brand with model number and if machine is 4th axis ready including amplifier. For example: 2015, XYZ machine with Fanuc OiMF control, not 4th axis ready, no amp.

•Dual Quindex heads on any of the above configurations. Increase your output and cut your tool changes in half by machining two parts in one set-up. Add $4995.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and other dealer installed accessories are not included. All prices are in U.S. dollars.

In the latter half of the 20th century, forces have conspired to make the human community, at last, global. The easing of tensions between major nations, the expansion of trade to worldwide markets, widespread travel and cultural exchange, pervasive high-speed communications and automation, the explosion of knowledge, the streamlining of business, and the adoption of flexible methods have changed the face of manufacturing itself, and of research and education in manufacturing. The acceptance of the continuous improvement process as a means for organizations to respond quickly and effectively to swings in the global market has led to the demand for individuals educated in a broad range of cultural, organizational, and technical fields and capable of absorbing and adapting required knowledge and training throughout their careers. No longer will manufacturing research and education focus on an industrial sector or follow a national trend, but rather will aim at enabling international teams of companies to cooperate in rapidly designing, prototyping, and manufacturing products. The successful enterprise of the 21st century will be characterized by an organizational structure that efficiently responds to customer demands and changing global circumstances, a corporate culture that empowers employees at all levels and encourages constant communication among related groups, and a technological infrastructure that fully supports process improvement and integration. In changing itself to keep abreast of the broader transformation in manufacturing, the enterprise must look first at its organization and culture, and thereafter at supporting technologies.

Machining Overview5-sided vs. Simultaneous 5-axis There are pros and cons to both 5-sided machining and 5-axis machining. 5-sided (3+2) Simultaneous 5-axis (full 5-axis) Simple to program Cuts faster Fewer concerns about tool interference Excellent roughing strategy Better surface finish Longer tool life Allows tool to reach difficult places smoothly Impressive but slow – avoid if possible Basics of axis configuration http://www.youtube.com/watch?v=NAjuZnNKEnM To understand machine configurations, it’s important to understand the basic terminology of 5-axis machining centers. If you think in terms of a 3-axis machining center, it has an X-axis, Y-axis, and Z-axis. With a 5-axis machining center, the additional rotary axes will rotate about two of those three primary axes. The axis that rotates about the X-axis is called the A-axis. The axis that rotates about the Y-axis is called the B-axis. The axis that rotates about or under the Z-axis is called the C-axis.

Machine ConfigurationsDedicated 5-axis machining centers There are three types of machine configurations for 5-axis machining. Integrated trunnion table Swivel head with rotary table Traveling column Why / a swivel head with rotary table 5-axis machining center BC rotation axes configuration Heavier Parts: Because the table is stationary, the swivel head/rotary table machines are used with heavier parts. Versatility. You can add a vise for greater versatility because of the large table size. Use the extra space to finish the sixth side of the part or do 3-axis work. Minimizes tool interference Because the swivel head tilts the tool, you don’t need to worry about tool interference with the machine’s spindle head. Better chip control With the swivel head/rotary table configuration, you can run the machine horizontally and gain better chip control. Geographical preference The swivel head/tilting rotary table configuration continues to be more popular Germany and throughout Europe than the United States and Canada. Why / integrated trunnion table 5-axis machining center AC rotation axes configuration Better undercut capability The trunnion rotates +/-110 degrees versus the +/-92 degree rotation on a swivel head/rotary table design. Larger work volume compared to swivel head rotary table 5-axis machine because you don’t have to…

Tilt Rotary TablesTilt-Rotary Tables For some shops, adding a tilting rotary table to their 3-axis machining center is an economical solution to achieve 5-axis capabilities. There are some limitations to consider. Because the tilting-rotary tables are quite large, they monopolize most of the 3-axis machining center’s work envelope. The relatively small work surface means it should only be used for small parts (12 inches or less) and should not be used for heavy cutting operations. Additionally, you need to make sure the control of your 3-axis VMC is 5-axis capable.

-Select-AfghanistanAlbaniaAlgeriaAmerican SamoaAndorraAngolaAnguillaAntigua and BarbudaArgentinaArmeniaArubaAustraliaAustriaAzerbaijan RepublicBahamasBahrainBangladeshBarbadosBelarusBelgiumBelizeBeninBermudaBhutanBoliviaBosnia and HerzegovinaBotswanaBrazilBritish Virgin IslandsBrunei DarussalamBulgariaBurkina FasoBurundiCambodiaCameroonCanadaCape Verde IslandsCayman IslandsCentral African RepublicChadChileChinaColombiaComorosCook IslandsCosta RicaCyprusCzech RepublicCôte d"Ivoire (Ivory Coast)Democratic Republic of the CongoDenmarkDjiboutiDominicaDominican RepublicEcuadorEgyptEl SalvadorEquatorial GuineaEritreaEstoniaEthiopiaFalkland Islands (Islas Malvinas)FijiFinlandFranceFrench GuianaFrench PolynesiaGabon RepublicGambiaGeorgiaGermanyGhanaGibraltarGreeceGreenlandGrenadaGuadeloupeGuamGuatemalaGuernseyGuineaGuinea-BissauGuyanaHaitiHondurasHong KongHungaryIcelandIndiaIndonesiaIraqIrelandIsraelItalyJamaicaJapanJerseyJordanKazakhstanKenyaKiribatiKuwaitKyrgyzstanLaosLatviaLebanonLesothoLiberiaLibyaLiechtensteinLithuaniaLuxembourgMacauMacedoniaMadagascarMalawiMalaysiaMaldivesMaliMaltaMarshall IslandsMartiniqueMauritaniaMauritiusMayotteMexicoMicronesiaMoldovaMonacoMongoliaMontenegroMontserratMoroccoMozambiqueNamibiaNauruNepalNetherlandsNetherlands AntillesNew CaledoniaNew ZealandNicaraguaNigerNigeriaNiueNorwayOmanPakistanPalauPanamaPapua New GuineaParaguayPeruPhilippinesPolandPortugalPuerto RicoQatarRepublic of CroatiaRepublic of the CongoReunionRomaniaRwandaSaint HelenaSaint Kitts-NevisSaint LuciaSaint Pierre and MiquelonSaint Vincent and the GrenadinesSan MarinoSaudi ArabiaSenegalSerbiaSeychellesSierra LeoneSingaporeSlovakiaSloveniaSolomon IslandsSomaliaSouth AfricaSouth KoreaSpainSri LankaSurinameSwazilandSwedenSwitzerlandTaiwanTajikistanTanzaniaThailandTogoTongaTrinidad and TobagoTunisiaTurkeyTurkmenistanTurks and Caicos IslandsTuvaluUgandaUnited Arab EmiratesUnited KingdomUnited StatesUruguayUzbekistanVanuatuVatican City StateVenezuelaVietnamVirgin Islands (U.S.)Wallis and FutunaWestern SaharaWestern SamoaYemenZambiaZimbabwe

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Regardless of a particular OEM machine tool builder, there are several common machine configurations for 5-axis CNC machines that are available - and each one has its own set of strengths that make it stand out among the choices. The most common types are: Table-Table, Head-Table, and Head-Head configurations.

But first things first…when talking about 5-axis machining center configurations, I always begin by clarifying the correct definition of each of the rotary axes. Often times, when discussing a particular machine type, people will refer to the rotary axes incorrectly…so I like to use this as an opportunity to teach! If you think about the linear axes of the machine in alphabetical order (XYZ), you can also think about the rotary axes in the same manner (ABC). The A-axis always rotates around the X-axis, the B-axis always rotates around the Y-axis, and the C-axis always rotates around the Z-axis. This is true, regardless of the machine configuration or machine tool builder.

One of the most common configurations – or at least the one most people identify with the most when they hear the term “5-axis CNC machine” – is the trunnion table machine. The trunnion configuration can also be referred to as a Table-Table configuration…because both rotary axes are contained in the trunnion table itself, and the head is always stationary.

Most operators and programmers can easily identify with this setup, because it is a simple process progression from standard 3-axis CNC machining. Because the two rotary axes are often used to simply locate the workpiece into a desired orientation, it is easy to visualize how the machine will position and behave during machining.

Often times the trunnion CNC machine will offer better undercut capabilities than other machine configurations, because the table can tilt farther (at least in one direction) than the swivel head designs…110 degrees in the example machine above…providing more access to the underside of a part. The trunnion configuration can also give the operator a larger overall usable work volume – because the table simply tilts and locks into position, providing the XYZ axes their full range of travel. In a swivel head machine design, some of the overall work envelope must be utilized to accommodate the length of the tool as the head tilts back and forth. This scenario can be magnified when machining with longer tools, which can impact the overall work envelope tremendously.

The trunnion style of CNC machine can also be a better choice for heavy metal removal. Due to the fact the head doesn’t articulate, therefore allowing the use of geared or belt driven spindles, this machine type will usually offer more torque at lower RPM’s. This stationary head design will also eliminate the possibility of pushing the head out of position while machining…that can sometimes happen on swivel head machines during heavy cuts.

The next machine configuration we should discuss is the swivel, or articulating head machine. This type of machine can be either a head-head configuration, where all rotations are completed by the head, and the table is stationary; or the head-table configuration that consists of a tilting head and a rotating table. Below is a Hurco VMX42SRTi machine, which is a head-table design.

This head-head, or head-table design will often allow you to machine much heavier parts than the trunnion design. Because the table doesn’t tilt, the entire weight of the part is transferred directly down though the base of the CNC machine and onto the floor…making this a very rigid setup for larger parts. Also, the design of the table itself – in contrast to the trunnion style machine – allows for larger parts in general as well, regardless of weight. The trunnion is limited by the size of the part that can be placed between the table risers.

Furthermore, the rotating head allows for the use of shorter or more standard length tooling when machining, because all rotations of the tool happen above the part. On a trunnion style machine, the spindle has to reach out over the tilting table…and the closer the table tilts toward 90 degrees, the more the spindle has to reach. This will often cause the operator to use longer than desired tooling, to accommodate for this scenario. This also means that when purchasing a trunnion style machine, you really need to think about the size of the work you will be running on the machine, and size it accordingly…the smaller the work, the smaller the machine.

As you can see by the picture above, the head-table design can be more versatile than a trunnion or head-head type of configuration. In addition to 5-axis work, the whole table can be utilized for multiple vise setups, for plate work, or for machining the 6th side of the part (in preparation for a 5-axis setup) when machining in 3-axis mode. A tombstone can even be utilized on the C-axis table to simulate a horizontal machine setup, for better chip control, or to allow for more parts to be machined in one setup.

In addition to the dedicated 5-axis CNC machine configurations discussed above, there are also a large number of “add-on” 5-axis tables available that can be added to existing 3-axis CNC machines for increased productivity. Although somewhat limited in the size of work that can be run, these add-on’s can be a fantastic way to improve efficiency. Most controls, like the Hurco WinMax control, can be adapted very easily to accept these add-on’s - but when being added to an existing machine, you definitely have to consider the age of the control technology on the machine, and whether it is worth the substantial investment that usually accompanies these tables.

The robust geared rotary tables of the 500 series are extremely flexible to use and, thanks to the combiFLEX® modular system, can be converted or extended at any time to meet new machining tasks. The rotary tables are not only suitable for positioning operation, but can also be used for short simultaneous machining operations. The preloaded gear and the powerful bearings allow high long-term accuracies as well as large spindle loads. The maximum clamping force of up to 7,000 Nm leaves hardly anything to be desired.

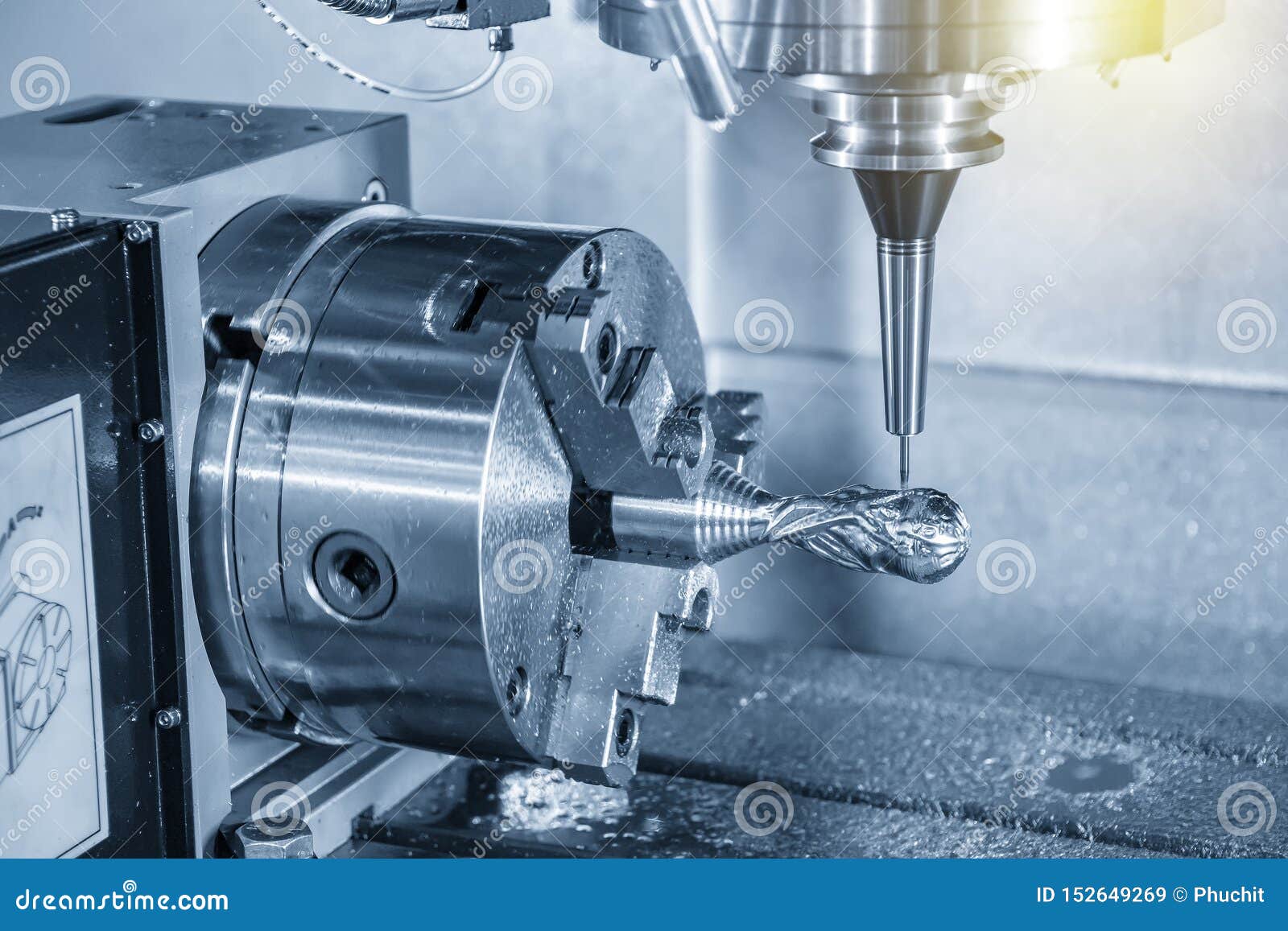

The 4-axis CNC milling machine cutting the sample parts with ball endmill tools. The 3-axis machining center attach the rotary table for cutting the sample parts.

Some products are machined using old-fashioned methods — often at a slow pace. With the help of techniques like computer numerical control (CNC) machining, mass-producing products quickly is easier than ever before.

Machinists use CNC machining paired with computer-aided design (CAD) and computer-aided manufacturing (CAM) software like Autodesk Fusion 360 to create anything from a keychain to useful soft jaws for CNC vises. Milling mechanisms are vital to CNC machining and provide applications for aerospace, automotive, and medical industries. That said, conventional machining is limited to three dimensions: the X-axis, Y-axis, and Z-axis. However, machinists have revitalized the machining process by adding more milling axes to CNC machines, creating 4-axis, 3+2 axis, and 5-axis machining.

4-axis machining involves the original three axes (X, Y, and Z) plus the A-axis, which is the rotational axis around X. 4-axis machining is practical for when you need a hole or cut-out around a cylinder.

The A, B, and C axes are labeled alphabetically in correlation to X, Y, and Z. Hence, the A-axis is the rotation around the X-axis; the B-axis is the rotation around the Y-axis, and the C-axis is the rotation around the Z-axis.

A Wrap Toolpath can analyze the selected chain and create a 4th axis rotary contouring toolpath. This option is only available in the 2D Adaptive, 2D Pocket, and 2D Contour toolpaths. It is important to always select the geometry from a 3D model, so the toolpaths maintain associativity. The concept is relatively simple: select the edges to machine and then select the face representing the cylindrical part’s radius. As a result, Fusion 360 will calculate an unwrapped geometry, create a toolpath, and re-wrap the toolpath around the specified radius.

You can find the Wrap Toolpath functionality on the Geometry Tab in the 2D Adaptive, 2D Pocket, and 2D Contour Toolpaths. Select this option before attempting to select the geometry. Fusion 360 will change the geometry selection capabilities if it recognizes the creation of a 4th axis wrapped toolpath.

8613371530291

8613371530291