4th and 5th axis cnc rotary table pricelist

It’s true that less than 10% of machined parts require simultaneous 5-axis movement. Which means that more than 90% of the parts machined in a typical job shop would not benefit from expensive, complicated, full 5-axis contouring; but that doesn’t mean your shop wouldn’t benefit from simple, affordable, 5-axis indexing capability. Work platter: Available in 6.75" diameter, T-sloted platters with drilled and tapped holes to accept Raptor or any brand work-holding, vises, fixtures, chucks, etc. Also available in dual-spindle system for increased efficiencies by cutting the number of tool changes in half.

1. QuindexPneumatic 5th Axis Bolt-on kit:Easily bolts-up to your existing true 4th or semi-4th axis rotary table. Shop air drives the spindle 90 degrees up against hard stops as well as provides 300 lbs. of brake force to allow for heavy cuts. A simple M-code or relay closure triggers indexing. This is the most cost-effective option to start 5-sided machining and is designed to mount to most other brands of rotary tables. (As well as ours of course!)

2. Quindex Semi 4th and Pneumatic 5th Axis Package:This package is everything you need to turn your 3-axis machine into a 5-axis workhorse.This package comes completely assembled and mounted on a subplate for a fast, accurate set-ups.

•Index Designs true 4th axis rotary table with Quindex 5th axis head, outboard support all mounted on a subplate. Call or email for quote on your specific machine. Please provide year, machine and control

brand with model number and if machine is 4th axis ready including amplifier. For example: 2015, XYZ machine with Fanuc OiMF control, not 4th axis ready, no amp.

•Dual Quindex heads on any of the above configurations. Increase your output and cut your tool changes in half by machining two parts in one set-up. Add $4995.

All prices and specifications subject to change without notice. Freight, rigging, state & local taxes, vendor installation charges, and other dealer installed accessories are not included. All prices are in U.S. dollars.

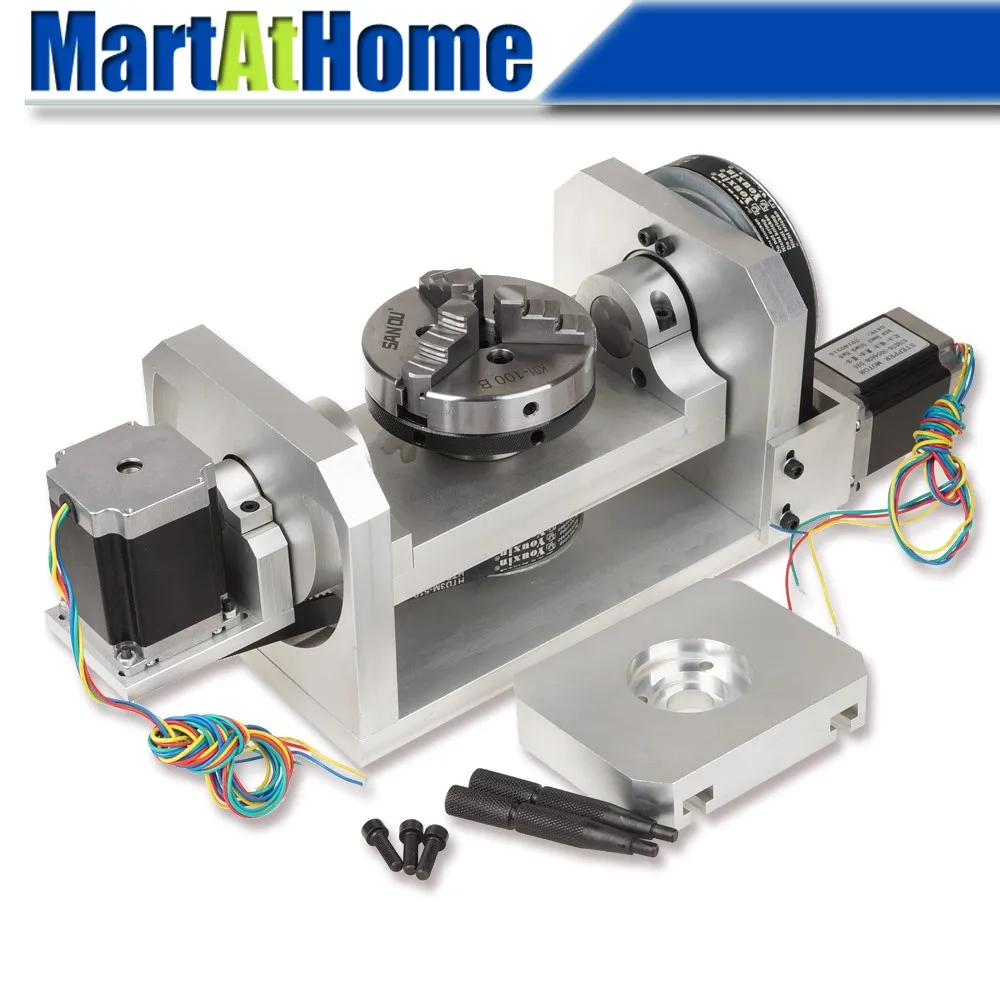

Visit Alibaba.com for your rotary table 5 axis and find a wide range of exemplary products in this category. In this platform, you do not only find these amazing rotary table 5 axis but at the same time, you can get them at extremely low prices.

Filter the Alibaba router listings to find the ideal rotary table 5 axis. You can search for specific wood router models and toggle specifications like weight, power rating, cutting style, throughput rates, table configuration, and many other important features. That way, you can pick a fixed router for heavy processing or the most portable wholesale routers for on-site carpentry. Whether you are cutting dado rails for home construction projects or working on complex sculptures, the wood router selection at Alibaba has what you need.

With a rotary table 5 axis from the Alibaba store, you can shape wood to create the perfect form. Shave the edges to create beveled surfaces, add definition to tables or chairs, and create recessed elements for joints. Whatever your carpentry challenge, a rot table axis can Al Alabaaba"s store features an extruder machine to make life easy. So filter and search until you find the perfect wholesale.aryary 5 5isis you every,, Alibative.com"s wholesale store is the place to head when you need replacement rotary tools. Explore a vast range of testing tools, pick up PPE for hands and face, find basic equipment kits for home users, or equip factories and work sites with heavy duty generation tools. rotary tables 5 axi are to in every demand, and with Alibaba.com you"ll find something for everyone.

The TRT70 is a dual-axis tilting rotary table that offers high-speed, accurate performance for 3+2 and full 5-axis machining of small parts. It fits ...

Our redesigned TRT160 tilting rotary table not only puts 5-axis capabilities well within reach of the average job shop, but its new smaller size also provides greater ...

... more compact and versatile 5-axis solution for mid-size mills. The new unit easily fits on one end of a machine’s table, leaving the remainder open for additional fixtures or vises. ...

The new designed rotary swivel unit RT2A is the ideal solution for retrofitting your machine with a 4th and 5th axis. It is based on the proven and robust rotary tables ...

With DirectIndustry you can: Find the product, subcontractor or service provider you need | Find a nearby distributor or reseller| Contact the manufacturer to get a quote or a price | Examine product characteristics and technical specifications for major brands | View PDF catalogues and other online documentation

A cookie is a small text file that a website saves on your computer or mobile device when you visit the site. It enables the website to remember your actions and preferences (such as login, language, font size and other display preferences) over a period of time, so you don’t have to keep re-entering them whenever you come back to the site or browse from one page to another.

Because the tilting axis normally needs to bear a heavy load, a robust transmission mechanism for the tilting axis should be employed to improve the wear resistance and precision of the tilting axis. Thus, we can provide roller gear cam, alloy steel worm gear, or Japanese- made worm & worm gear (wear life is 2.6 times longer than aluminum bronze PBC3.) as the transmission mechanism of the tilting axis.

Rotary table in market mainly includes 4 kinds of mechanism that is worm gear, roller cam, DD driver and harmonic structure. The following is the introduction:

1. worm gear: it’s one of the most popular structrue in NC rotary table because of its irreversibility and costs.The worm is generally made of bronze, but the wear resistance is poor. In order to improve the service life, some manufacturers use the alloy steel.

2.roller cam: This is the most popular deceleration mode in the Chinese market. Compared with worm gear, it has many advantages, such as wear resistance, high transmission efficiency , good price and basically no maintenance. Chinese consumers like it very much.

3.DD motor: it’s the most efficient rotary table with the highest precision. It has the highest precision because it has no mechanical structure, which is directly driven by motor , no reducer. It has high technical difficulty and high price. It is generally used for five axis machine tools.

4. Harmonic driver: Harmonic reducer is a new transmission structure in gear reducer. It uses flexible gear to produce controllable elastic deformation and cause relative staggered teeth between rigid wheel and flexible wheel to transmit power and motion. This kind of transmission is essentially different from the general gear transmission, and has particularity in meshing theory, set calculation and structural design.

New Trunnion model TR 100RF has all of the features of the standard wired models while being the perfect application for palletizing VMC An easy to use system with no messy cables

KME CNC can design a trunnion for your application. Custom 5-axis trunnions can be made to specific matching needs including different drive configuration, large or smaller sizes, less

KME CNC’s trunnions have the lowest platter height in the industry, with 7.87” from table to platter, allowing maximum Z height clearance. KME CNC can also manufacture trunnions with 10” platters, depending on their specific needs. No additional drive cards necessary!

The Stallion Tombstone provides manufacturers with the ultimate time saver. With 4 sides, handling and tool change time decreases substantially. Every time a part is handled or indicated, there is an increased risk of scrapping it. The Stallion Tombstone minimizes this risk through 4th axis milling. With full 360-degree rotation, machining multiple sides of a part becomes possible, allowing your operators to handle a part as little as necessary. Our smallest tombstone model, at 4", is perfect for machining small parts at large volume.

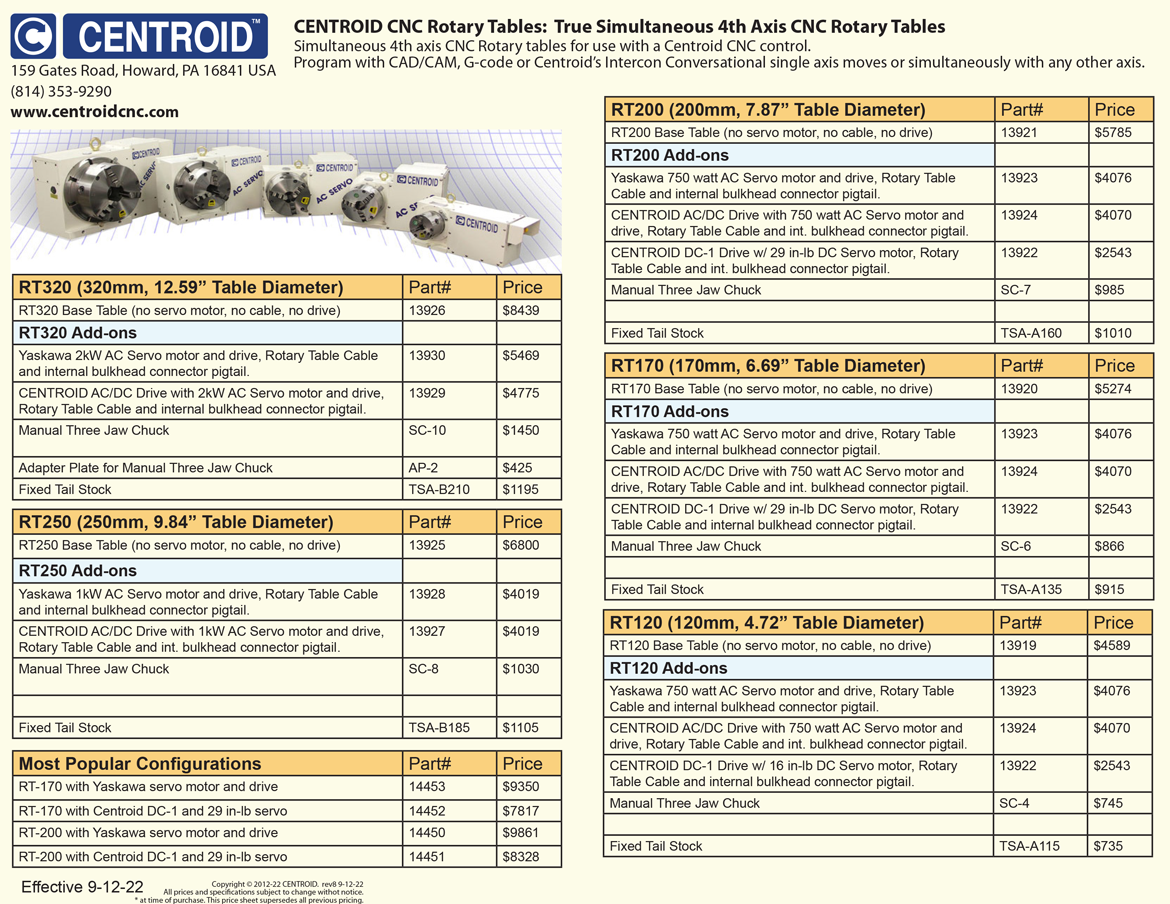

Centroid OEM Machine Tool Manufactures offer a wide variety of Centroid CNC equipped machine tools.. click to to find a Centroid equipped CNC machine tools..

Small Milling Machine CNC Control system: $18,385M400 3 axis with 1Kw AC Brushless Yaskawa servo motors and drivesMedium Milling Machine CNC control system: $22,175M400 3 axis with 2Kw AC Brushless Yaskawa servo motors and drivesLarge Milling Machine CNC Control system: $25,760M400 3 axis with 4.4Kw AC Brushless Yaskawa servo motors and drives

Small Slant Bed Lathe CNC control system: $15,450T400 2 axis with 1Kw AC Brushless Yaskawa servo motors and drivesMedium Slant Bed Lathe CNC control system: $18,795T400 2 axis with 2.2Kw, 2.2kw w/brake AC Brushless Yaskawa servo motors and drivesLarge Slant Bed or VTL CNC control system: $21,597T400 2 axis with 4.4Kw, 4.4 Kw w brake AC Brushless Yaskawa servo motors and drives

Auto part set, Auto tool set, 3D contouring, 4th and 5th axis machining, Available in OEM configurations, Professional Installation with Service & Training and DIY CNC kits for both new machines and retrofit upgrades.

From the May issue of Modern Machine Shop Magazine " A CNC retrofit provides improved reliability and functionality compared to an older machine’s original control, and this is helpful in a number of ways. For example, a more intuitive control interface can help speed setups and minimize the chance for programming and/or setup mistakes, which could possibly damage or scrap a high-value work piece. Similarly, shops are also more confident in quoting work for large, expensive parts knowing the new control won’t hiccup partway through an operation and cause the part to be damaged. Shops also are better-positioned to take in “hot” jobs that require fast turnaround due to the retrofitted machine’s improved"... click here to see the complete article in PDF.

CENTROID Boss series II retrofit customer testimonial"The quality and workmanship of the CENTROID equipment was outstanding and very professional. CENTROID was able to custom tailor the control to allow us to continue to use our rotary milling arrangement as before and even expanded our capability. The short story is that we ended up with a four axis CNC mill for less than half the cost of the three axis Haas. This includes the work that was done by our staff."

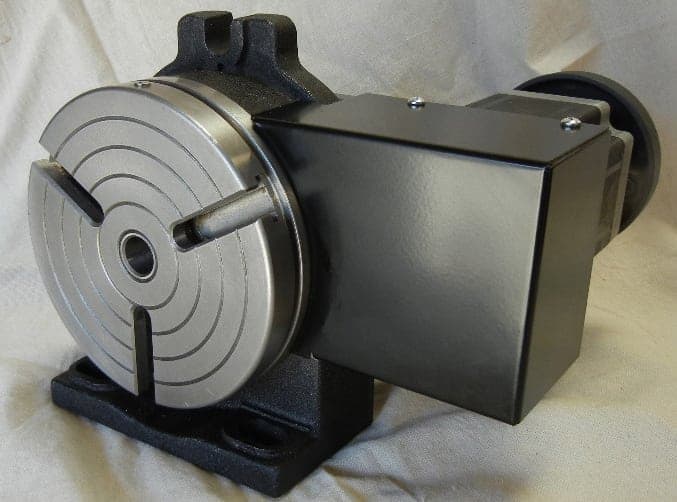

The robust geared rotary tables of the 500 series are extremely flexible to use and, thanks to the combiFLEX® modular system, can be converted or extended at any time to meet new machining tasks. The rotary tables are not only suitable for positioning operation, but can also be used for short simultaneous machining operations. The preloaded gear and the powerful bearings allow high long-term accuracies as well as large spindle loads. The maximum clamping force of up to 7,000 Nm leaves hardly anything to be desired.

Tsudakoma has been providing best-in-class rotary tables for over 100 years, offering multiple models and configurations to ensure seamless integration with your machining centers. Koma Precision has been distributing Tsudakoma’s tables for over 40 of those years and our North American sales team and in-house engineers will work with you to determine which model best suits your machining needs.

Rotary Tables allow machine shops to increase their production and meet their customer’s demand for quicker lead times while manufacturing increasingly complex components.

Production of a machine shop is restricted by the limited floor space the facility has. Due to this issue, Hyfore Workholding has seen an increase in customers looking to invest in 4th axis and 5th axis rotary tables.

Customers approach us from a wide variety of industries, including, but not limited to, automotive, aerospace, medical and packaging sectors. In these industries, high precision parts are increasingly in demand, with small batch orders also being popular.

A typical customer would be a CNC machinist who already has a 3-axis machine but is looking for greater flexibility, without having to spend a considerable amount of money on a 5-axis machine. For example, the software, motors, cables and rotary table could cost between £25k and £30k, compared to a new machine starting from £140K.

UCAM’s CNC Rotary Tables are renowned for their quality, reliability and performance. The tilting capability allows components to manoeuvre 360 degrees, so that the cutting tool can machine on all five sides, reducing secondary and third operations in the process.

CNC Rotary tables arean effectivecomponent for increasing production machine shops. Adding an extra dimension to your capabilities at a relatively low cost.

Index Designs is an all-American company. Their founders were part of the team that helped design, engineer, manufacture and market the very successful line of Fadal Machining Centers – starting in the 1970s. Index Designs entered the rotary table market in 2006 with the goal of creating a line of high-end, rugged and accurate rotary products that we could sell at affordable prices, but still be able to provide reliable delivery and superior customer service and support. Thier products are completely manufactured in our Chatsworth, California facility. Index Designs uses state-of-the-art, HMC’s, VMC’s and CNC gear cutting machines.

The head in which the spindle is housed rotates around a continuous axis controlled by the NC to allow for 5-axis operations. This is an optimal solution for roughing and finishing operations to be carried out on surfaces difficult to reach and on work-pieces with very complex sections.

The tilting head is available both with new generation mechanical spindles to guarantee high torque rates and with electro-spindles to provide higher compactness and rotation speed rates at the same time. Top level accuracy is guaranteed by the backlash recovery systems and the encoder providing a direct measurement of the tiling axis position.

You can find all the details and the technical information about this product inside the " Catalogue Area ". Some examples of this product are shown in our photogallery below. For the videos, link to our YOUTUBE CHANNEL by clicking on the dedicated bar.

8613371530291

8613371530291